Method for processing roadbed by means of matching of waste tire piece bodies and reinforced soil

A technology for waste tires and sheets, which is applied in the directions of roads, roads, buildings, etc., to achieve the effects of low maintenance cost, reduced soil weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

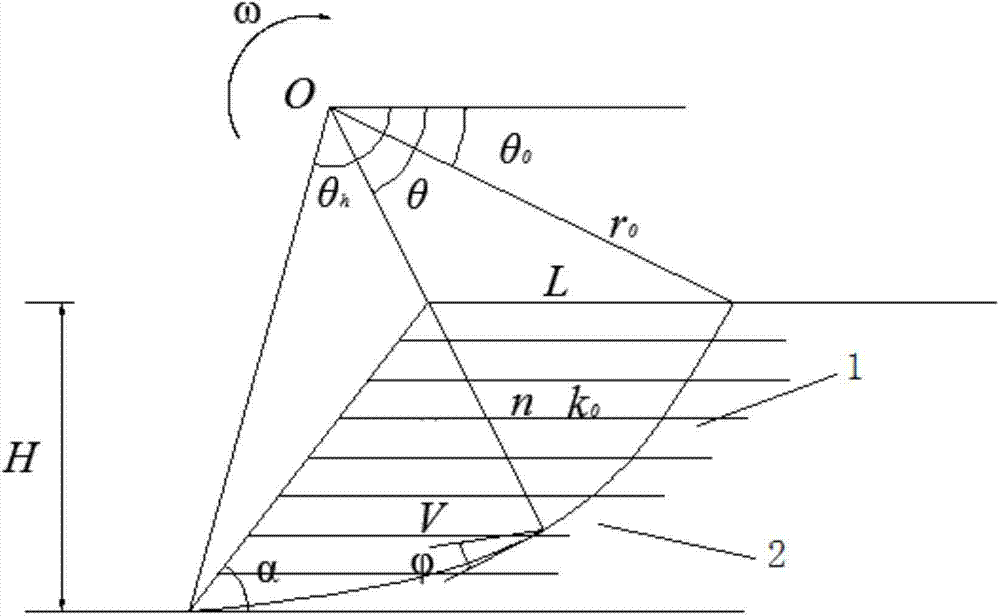

Embodiment 1

[0063] The backfill soil behind a gravity retaining wall is made of waste tire sheet reinforced composite material, the filling height is 5m, the waste tire sheet accounts for about 50% of the total volume of the material, and the ratio of the average weight of natural rubber to the original soil is about 1 :17, the subgrade soil weight is reduced by about 45%. Affected by the decrease of the soil's own weight and the increase of the internal friction angle, the active earth pressure of the gravity retaining wall according to Rankine's earth pressure theory is reduced by about 58% under the condition of no external load. The fill is compacted in layers, the layer thickness is 30cm, the compaction degree is greater than 95%, and the measured CBR value reaches 60%. The average permeability coefficient is 2mm / s, with high permeability. The geogrids are distributed evenly along the vertical direction, and the width of the overlap is 20cm, and the layers are staggered. The averag...

Embodiment 2

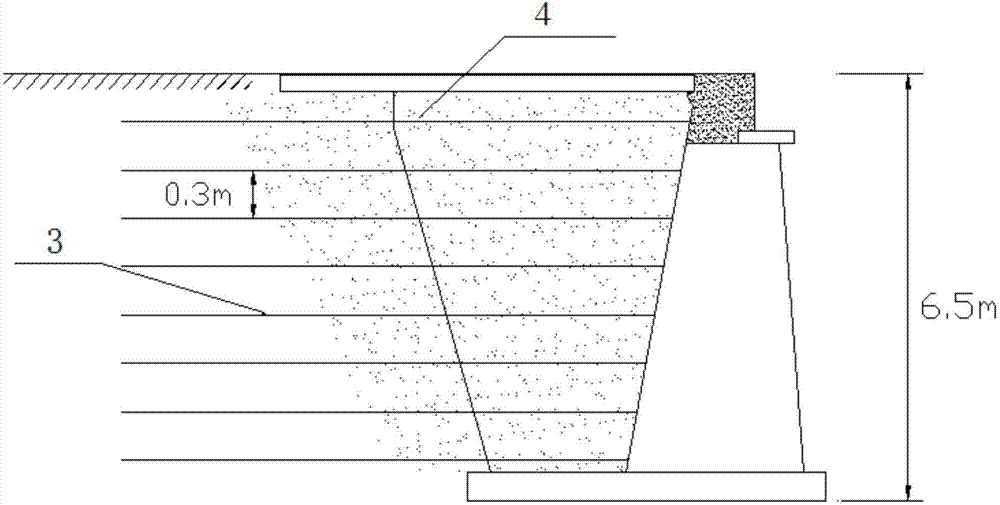

[0065] The backfill of the gravity abutment of a four-span concrete girder bridge is made of waste tire sheet reinforced composite material, and its structure is as follows figure 2 shown. Among them, the uniformly distributed geogrid 3 and the composite filling 4 composed of waste tire pieces and soil.

[0066] The proportion of waste tire pieces to the total volume of the material is about 40%, the average weight ratio of natural rubber to original soil is about 1:17, and the weight of roadbed soil is reduced by about 35%. The fill is compacted in layers, with a layer thickness of 30cm, a degree of compaction greater than 95%, and an average permeability coefficient of 1.5mm / s, with high permeability. The natural foundation is silty clay with a plasticity index of 12. Excluding the additional stress of the abutment base, the foundation settlement caused by the composite fill 4 is about 2.5cm, which is less than the total settlement theory of ordinary fill foundation estima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com