Preparation method of inorganic bentonite for drilling fluid

A technology of inorganic bentonite and drilling fluid, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of less research and achieve the effects of improving the performance of bentonite, reducing production costs, and optimizing processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

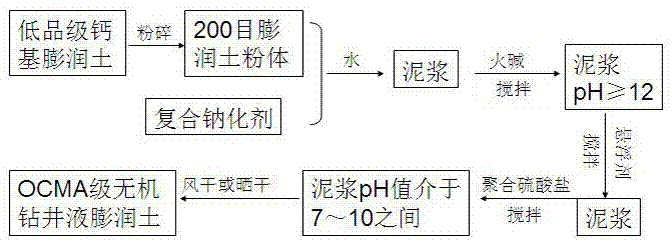

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of inorganic bentonite for drilling fluid, specifically comprising the following steps:

[0027] (1), take Na 2 CO 3 Mix well with complexing agent to make composite sodiumizing agent (Na 2 CO 3 The mass ratio to the complexing agent is 20:1, and the complexing agent is sodium nitrilotriacetate), the low-grade calcium-based bentonite (the content of montmorillonite is 60%) is crushed and passed through a 200-mesh sieve, and the compound sodiumizing agent is added (The weight ratio of low-grade calcium-based bentonite and composite sodium agent is 25:1), stir evenly to obtain a mixture, then dissolve the mixture in water (the weight ratio of mixture to water is 1:5), and adjust with caustic soda pH to 12, stir evenly, get mud, set aside;

[0028] (2), add inorganic composite suspending agent to the mud prepared in step (1) (the addition of inorganic composite suspending agent is 1 / 25 of the weight of the mixture in step (1), and the inorganic com...

Embodiment 2

[0030] A preparation method of inorganic bentonite for drilling fluid, specifically comprising the following steps:

[0031] (1), take Na 2 CO 3 Mix well with complexing agent to make composite sodiumizing agent (Na 2 CO 3 The mass ratio to the complexing agent is 15:1, and the complexing agent is ethylenediaminetetraacetic acid salt), and the low-grade calcium-based bentonite (the content of montmorillonite is 68%) is crushed and passed through a 200-mesh sieve, and added to the compound Sodiumizing agent (the weight ratio of low-grade calcium-based bentonite and composite sodiumizing agent is 25:1), stir evenly to obtain a mixture, then dissolve the mixture in water (the weight ratio of mixture and water is 1:9), and use Adjust the pH to 13 with caustic soda, stir evenly to obtain mud, and set aside;

[0032] (2), add inorganic composite suspending agent to the mud prepared in step (1) (the addition of inorganic composite suspending agent is 1 / 25 of the weight of the mix...

Embodiment 3

[0034] A preparation method of inorganic bentonite for drilling fluid, specifically comprising the following steps:

[0035] (1), take Na 2 CO 3 Mix well with complexing agent to make composite sodiumizing agent (Na 2 CO 3 The mass ratio to the complexing agent is 12:1, and the complexing agent is sodium ethylenediamine tetramethylene phosphate), and the low-grade calcium-based bentonite (the content of montmorillonite is 75%) is crushed and passed through a 200-mesh sieve, and added Composite sodium agent (the weight ratio of low-grade calcium-based bentonite and composite sodium agent is 25:1), stir evenly to obtain a mixture, and then dissolve the mixture in water (the weight ratio of mixture to water is 1:12), And use caustic soda to adjust the pH to 12, stir evenly to obtain mud, and set aside;

[0036] (2), add inorganic composite suspending agent to the mud prepared in step (1) (the addition of inorganic composite suspending agent is 1 / 25 of the weight of the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com