Method for preparing oligogalactomannose enzymatic hydrolysis solution from guar gum solution

A mannose enzymatic hydrolysis solution and mannanase technology are applied in the field of guar gum solution to prepare galactomannose oligosaccharide enzymatic hydrolysis solution, and can solve the problems of long time, low enzymatic hydrolysis efficiency, low oligosaccharide and the like, Achieve the effect of saving production time and cost, fast enzymatic hydrolysis and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 12g of guar gum powder, dilute to 100mL with 0.2mol / mL citric acid-sodium citrate buffer solution, adjust the pH value to 6.0; then heat and swell at 92°C for 50min; after cooling to 25°C, At the same time, add β-mannanase 840U, xylanase 12000U, endoglucanase 24000U, mix well;

[0025] After adding the three enzymes, the temperature gradient enzymatic hydrolysis method is adopted, specifically:

[0026] (1) Raise the temperature from the cooled temperature to 35°C, and perform enzymatic hydrolysis for 1.5h;

[0027] (2) Raise the temperature to 48°C and perform enzymatic hydrolysis for 3 hours; increase the temperature by 1°C every 3 minutes during the heating process, and keep it for 10 minutes for every 1°C increase;

[0028] (3) Raise the temperature to 55° C. and perform enzymatic hydrolysis for 2 hours.

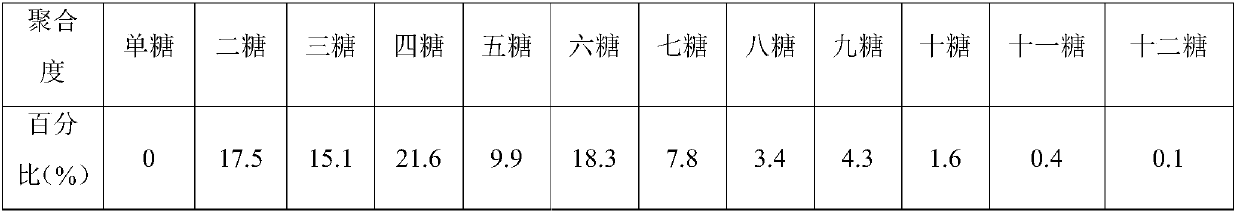

[0029] After the enzymatic hydrolysis, the oligogalactomannose enzymatic hydrolysis solution is obtained. The mass percentages of galactomannose oligosacc...

Embodiment 2

[0033] Take 13g of guar gum powder, dilute to 100mL with 0.2mol / mL citric acid-sodium citrate buffer solution, adjust the pH value to 6.3; then heat and swell at 93.5°C for 55min; after cooling to 28°C, At the same time, 1040 U of β-mannanase, 19500 U of xylanase and 32500 U of endoglucanase were added and mixed thoroughly.

[0034] After adding the three enzymes, the temperature gradient enzymatic hydrolysis method is adopted, specifically:

[0035] (1) Raise the temperature from the cooled temperature to 37°C, and perform enzymatic hydrolysis for 2 hours;

[0036] (2) Raise the temperature to 50°C and perform enzymatic hydrolysis for 3.5 hours; increase the temperature by 1.5°C every 4 minutes during the heating process, and keep it for 10 minutes for every 1.5°C increase;

[0037] (3) Raise the temperature to 55° C. and perform enzymatic hydrolysis for 2.5 hours.

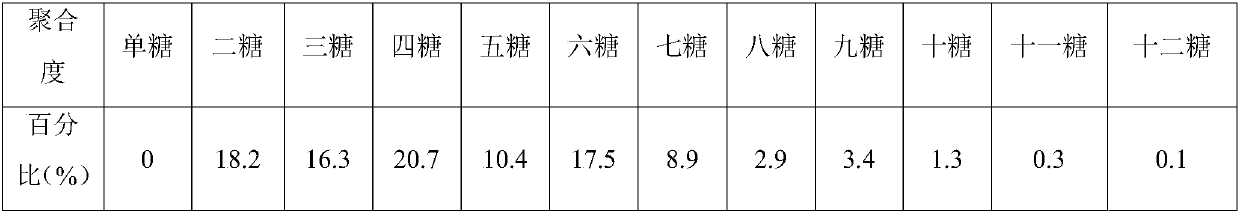

[0038] After the enzymatic hydrolysis, the oligogalactomannose enzymatic hydrolysis solution is obtained. T...

Embodiment 3

[0042] Take 15g of guar gum powder, dilute to 100mL with 0.2mol / mL citric acid-sodium citrate buffer solution, adjust the pH value to 6.6; then heat and swell at 95°C for 60min; after cooling to 30°C, At the same time, 1350 U of β-mannanase, 30000 U of xylanase and 45000 U of endoglucanase were added and mixed thoroughly.

[0043] After adding the three enzymes, the temperature gradient enzymatic hydrolysis method is adopted, specifically:

[0044] (1) Raise the temperature from the cooled temperature to 40°C, and perform enzymatic hydrolysis for 2.5 hours;

[0045] (2) Raise the temperature to 53°C and perform enzymatic hydrolysis for 4 hours; during the heating process, increase the temperature by 2°C every 5 minutes, and keep it for 10 minutes for every 2°C increase;

[0046] (3) Raise the temperature to 55° C., and perform enzymatic hydrolysis for 3 hours.

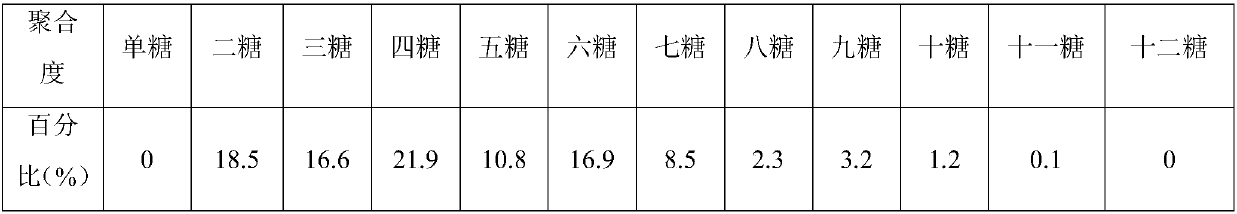

[0047] After the enzymatic hydrolysis, the oligogalactomannose enzymatic hydrolysis solution is obtained. The mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com