Betonite for non-excavation drilling fluid

A technology of bentonite and drilling fluid, which is applied in the field of trenchless horizontal directional drilling and bentonite in water-sensitive strata, can solve the problems of hole wall stability, improper use of drilling fluid, poor quality of bentonite, etc., to meet the requirements of hole wall stability , cost-effective, high pulping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

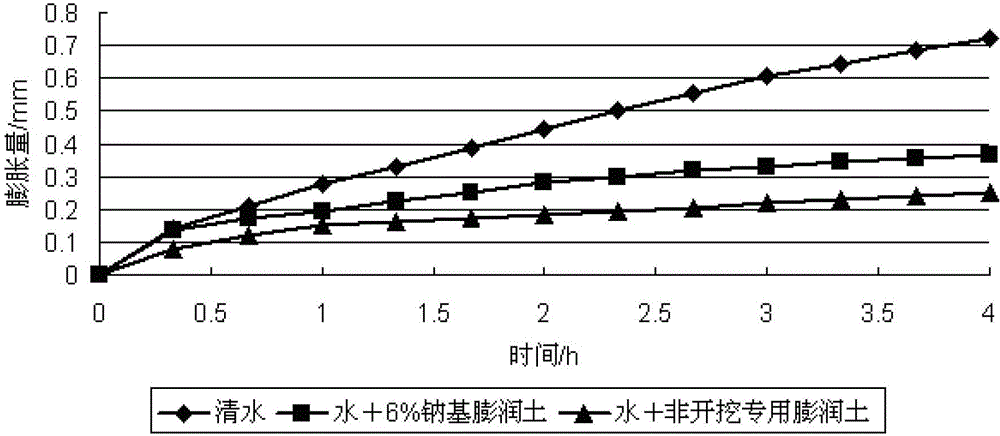

Image

Examples

Embodiment 1

[0018] The bentonite for non-excavation drilling fluid provided in this embodiment is mixed by the dry powder of sodium bentonite, polymer and shale inhibitor, and the mass ratio between sodium bentonite, polymer and shale inhibitor is 15:1.75:2.75, wherein the sodium bentonite sodium bentonite is sodium bentonite produced in Weifang, Shandong, the polymer is konjac, and the shale inhibitor is polyethylene glycol PEG-10000.

[0019] The method for adopting the bentonite configuration drilling fluid provided in the present embodiment may further comprise the steps:

[0020] According to the People's Republic of China Petroleum and Natural Gas Industry Standard "Bentonite for Drilling Fluid Test" (SY5490-93) to prepare drilling fluid: add water to the container (mud cup), then add bentonite for trenchless drilling fluid, and add bentonite per 100mL of water The amount is 3g, stir at high speed for 5 minutes, pause to scrape the cup wall, continue to stir for 15 minutes, cover an...

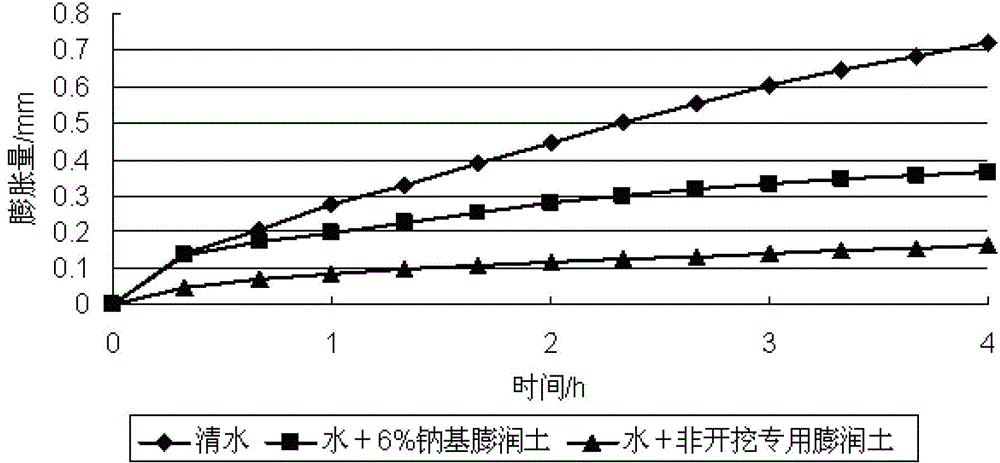

Embodiment 2

[0044] The bentonite for non-excavation drilling fluid provided in this embodiment is mixed by the dry powder of sodium bentonite, polymer and shale inhibitor, and the mass ratio between sodium bentonite, polymer and shale inhibitor is 16:2:3, wherein the sodium bentonite sodium bentonite is sodium bentonite produced in Xiazijie, Xinjiang, the polymer is konjac, and the shale inhibitor is polyalcohol JLX.

[0045] The method for adopting the bentonite configuration drilling fluid provided in the present embodiment may further comprise the steps:

[0046] According to the People's Republic of China Petroleum and Natural Gas Industry Standard "Bentonite for Drilling Fluid Test" (SY5490-93) to prepare drilling fluid: add water to the container (mud cup), then add bentonite for trenchless drilling fluid, and add bentonite per 100mL of water The amount is 3g, stir at high speed for 5 minutes, pause to scrape the cup wall, continue to stir for 15 minutes, cover and let stand for 16 ...

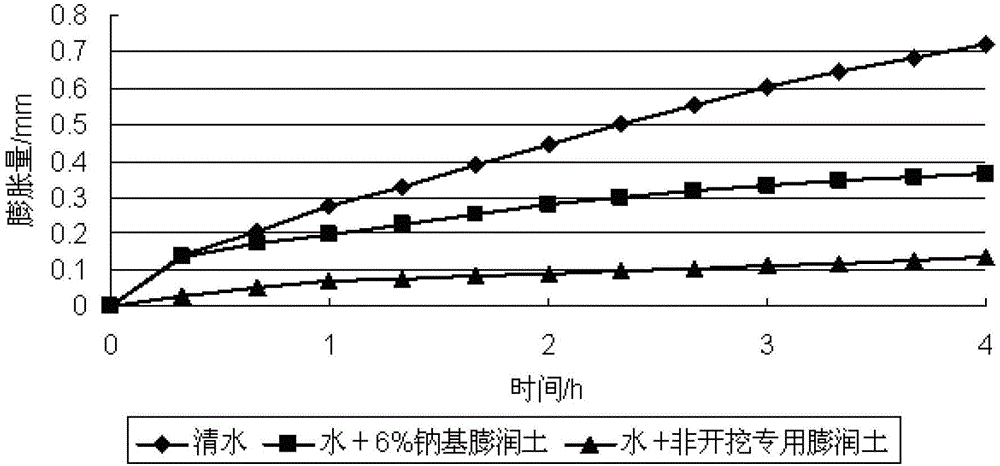

Embodiment 3

[0061] The bentonite for non-excavation drilling fluid provided in this embodiment is mixed by the dry powder of sodium bentonite, polymer and shale inhibitor, and the mass ratio between sodium bentonite, polymer and shale inhibitor is 17:2.25:3.25, wherein the sodium bentonite sodium bentonite is sodium bentonite produced in Xiazijie, Xinjiang, the polymer is konjac, and the shale inhibitor is polyethylene glycol PEG-10000.

[0062] The method for adopting the bentonite configuration drilling fluid provided in the present embodiment may further comprise the steps:

[0063] According to the People's Republic of China Petroleum and Natural Gas Industry Standard "Bentonite for Drilling Fluid Test" (SY5490-93) to prepare drilling fluid: add water to the container (mud cup), then add bentonite for trenchless drilling fluid, and add bentonite per 100mL of water The amount is 3g, stir at high speed for 5 minutes, pause to scrape the cup wall, continue to stir for 15 minutes, cover a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com