Iron oxide pigment and its production method

A technology of iron oxide pigment and production method, applied in the field of chemistry, can solve the problem of high quality requirements of iron sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

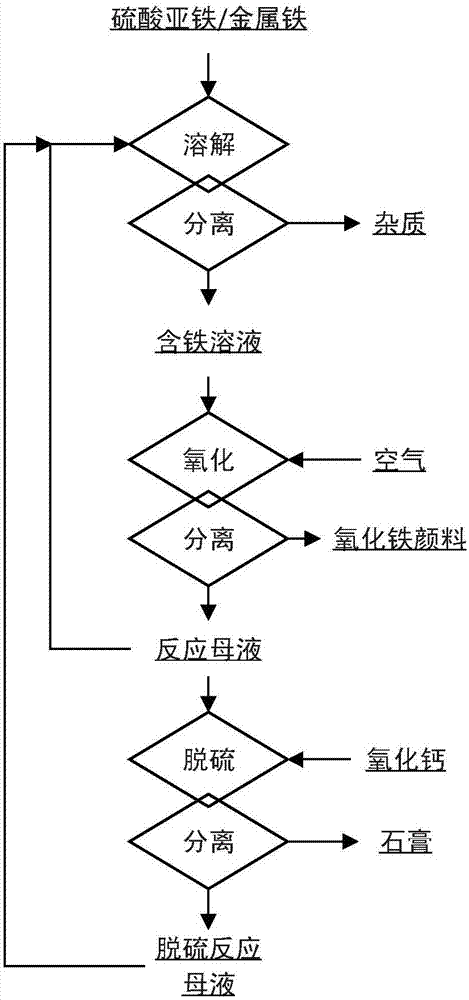

Method used

Image

Examples

Embodiment 1

[0078] 1) Prepare 50L of reaction liquid containing 1.0mol / L ethylenediamine, 1.5mol / L ethanolamine, 1.5mol / L sodium sulfate, 1g / L sodium lauryl sulfate, add feed grade heptahydrate sulfurous acid at 60°C 14kg of iron, use sulfuric acid to maintain the pH value of the solution between 9.0-9.5, react for 0.5 hour, and filter to obtain an iron-containing solution.

[0079] 2) Air is passed into the iron-containing solution obtained in step 1), the air temperature is controlled to be not lower than 50°C, the humidity is not lower than 50%, the ventilation rate is 50L / min, and the reaction temperature is controlled between 95-100°C. Using sulfuric acid to maintain the pH value of the solution between 9.0-9.5, the reaction time is 8 hours, filtering and washing to obtain the product iron oxide red and the reaction mother liquor.

[0080] 3) Take 20L of reaction mother liquor and add 3kg of calcium oxide, control the reaction temperature between 60-65°C, and react for 2 hours, filte...

Embodiment 2

[0083] 1) Prepare 5L of reaction solution containing 0.5mol / L alanine, 1.0mol / L histidine, 0.01mol / L cobalt sulfate catalyst, 0.01mol / L potassium chlorate oxidant, and 0.5mol / L potassium sulfate, at 90°C Add 70g of scrap iron, use potassium hydroxide to maintain the pH value of the solution between 8.0-8.5, react for 10 hours, and filter to obtain an iron-containing solution.

[0084] 2) Add 10 g of aluminum sulfate as a seed crystal additive to the iron-containing solution obtained in step 1), and pass air into it, control the air temperature not lower than 80°C, humidity not lower than 90%, ventilation rate 0.5L / min , the reaction temperature is controlled between 90-95 ° C, during which potassium hydroxide is used to maintain the pH value of the solution between 8.0-8.5, the reaction time is 6 hours, filtered and washed, and the product iron oxide yellow and the reaction mother liquor are obtained.

[0085] 3) Return the reaction mother liquor obtained in step 2) to step 1)...

Embodiment 3

[0087] 1) Prepare 500L reaction solution containing 2.0mol / L phenylalanine, 0.5mol / L ethanolamine, 1.0mol / L sodium sulfate, 0.1g / L sodium oleate, add industrial grade sulfuric acid heptahydrate at 80-85℃ 100kg of ferrous iron, use sodium hydroxide to maintain the pH value of the solution between 10.0-10.5, react for 1.0 hour, and filter to obtain an iron-containing solution.

[0088] 2) Introduce air into the iron-containing solution obtained in step 1), control the air temperature not lower than 60°C, humidity not lower than 70%, ventilation rate 800L / min, control the reaction temperature between 80-85°C, during use Sodium hydroxide maintains the pH value of the solution between 10.0-10.5, and the reaction time is 6 hours. After filtration and washing, the product iron oxide black and reaction mother liquor are obtained.

[0089] 3) Take 100L of the reaction mother liquor, add 12kg of calcium oxide with an effective content of 70% to it, control the reaction temperature betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com