Surfactant flooding system and application thereof

A technique of surfactant flooding and surfactant, which is applied in the field of surfactant systems for tertiary oil recovery, can solve problems such as water sensitivity enhancement, formation damage, and impact on sustainable development of oil, and achieve good emulsification performance and low-cost finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Product preparation:

[0016] Under normal temperature and pressure, add 1% anionic surfactant sodium petroleum sulfonate (Panjin Wuyuan Technology Industry and Trade Co., Ltd.) into a reaction kettle with a capacity of 5 L, add 1% isopropanol, stir thoroughly for 30 minutes to dissolve completely, and then Add 1% nonionic surfactant isomerized decanol polyoxyethylene ether (LT-601, Shanghai Boyihe Chemical Co., Ltd.), 1% anionic sulfonate gemini surfactant N, N'-dilauric Sodium acyl ethylenediamine diethylsulfonate (Gemini, Xi'an Chulongda Chemical Co., Ltd.), stirred well, and finally added water and stirred for 1 hour to obtain the oil displacement product.

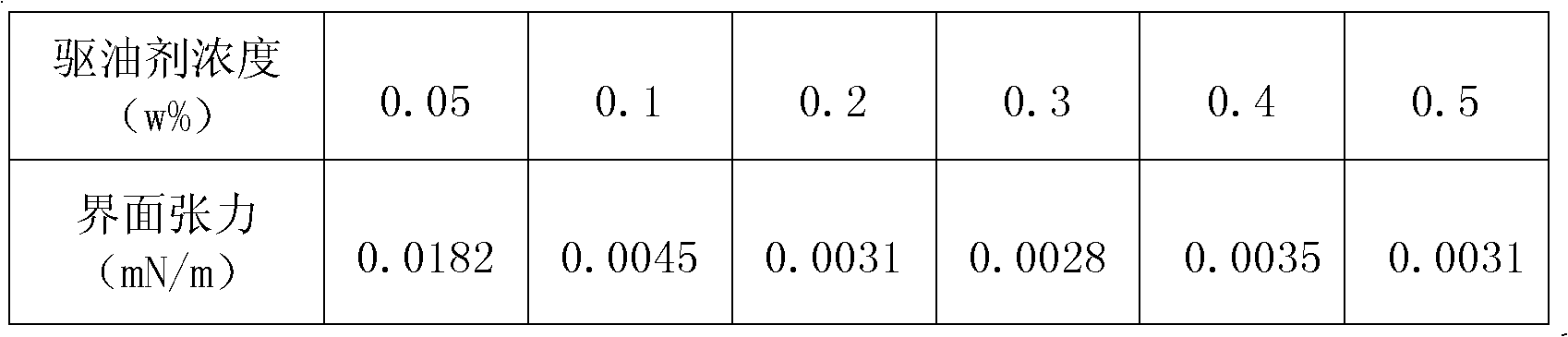

[0017] Interfacial tension test:

[0018] 1. Test instrument: TX500TM automatic rotating drop interfacial tensiometer

[0019] 2. Temperature: 60°C

[0020] 3. Crude oil: long 6 layers of crude oil

[0021] 4. Water: inject water

[0022] 5. Oil displacement agent composition: anionic-nonionic surfactant sy...

Embodiment 2

[0030] Product preparation:

[0031] Under normal temperature and pressure, add 2% anionic surfactant sodium petroleum sulfonate (Panjin Wuyuan Technology Industry and Trade Co., Ltd.) into a reaction kettle with a capacity of 5 L, add 2% isopropanol, stir thoroughly for 30 minutes to dissolve completely, and then Add 1% nonionic surfactant isomerized decanol polyoxyethylene ether (LT-601, Shanghai Boyihe Chemical Co., Ltd.), 1% anionic sulfonate gemini surfactant N, N'-dilauric Sodium acyl ethylenediamine diethylsulfonate (Gemini, Xi'an Chulongda Chemical Co., Ltd.), stirred well, and finally added water and stirred for 1 hour to obtain the oil displacement product.

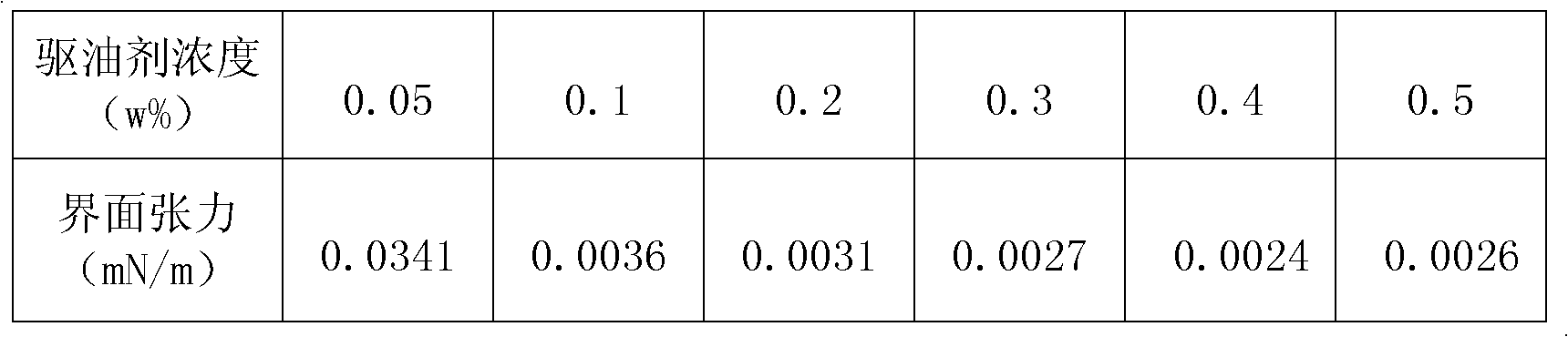

[0032] Interfacial tension test:

[0033] 1. Test instrument: TX500TM automatic rotating drop interfacial tensiometer

[0034] 2. Temperature: 60°C

[0035] 3. Crude oil: long 6 layers of crude oil

[0036] 4. Water: inject water

[0037] 5. Oil displacement agent composition: anionic-nonionic surfactant sy...

Embodiment 3

[0045] Product preparation:

[0046] Under normal temperature and pressure, add 3% anionic surfactant sodium petroleum sulfonate (Panjin Wuyuan Technology Industry and Trade Co., Ltd.) into a reaction kettle with a capacity of 5 L, add 3% isopropanol, stir thoroughly for 30 minutes to dissolve completely, and then Add successively 0.5% of 1% nonionic surfactant isomeric decanol polyoxyethylene ether (LT-601, Shanghai Boyihe Chemical Co., Ltd.), 0.5% of anionic sulfonate gemini surfactant N, N' -Sodium bislauroyl ethylenediamine diethanesulfonate (Gemini, Xi'an Chulongda Chemical Co., Ltd.), stir well, and finally add water and stir for 1 hour to obtain the oil displacement product.

[0047] Interfacial tension test:

[0048] 1. Test instrument: TX500TM automatic rotating drop interfacial tensiometer

[0049] 2. Temperature: 60°C

[0050] 3. Crude oil: long 6 layers of crude oil

[0051] 4. Water: inject water

[0052] 5. Oil displacement agent composition: anionic-nonioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com