Low-temperature pretreatment auxiliary with easiness in biodegradation and for cotton fabric

A biodegradable cotton fabric technology, applied in fiber treatment, plant fiber, textiles and papermaking, etc., to achieve enhanced washing effect, improved treatment effect, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The formula of the cotton fabric low-temperature pretreatment aid provided in this embodiment is composed as follows in weight percentage:

[0022] N,N′-Dipalmitoyl ethylenediamine sodium diethylsulfonate 10%

[0023] N,N′-bislauroyl ethylenediamine sodium diethylsulfonate 8%

[0025] Sodium polyacrylate with a molecular weight of 800 6%

[0026] Industrial salt 4%

[0027] Water 60%.

Embodiment 2

[0029] The formula of the low-temperature pretreatment auxiliary agent for cotton fabric provided in this embodiment is composed as follows in weight percentage:

[0030] N,N′-bismyristoyl ethylenediamine sodium diethylsulfonate 10%

[0031] N,N′-bislauroyl ethylenediamine sodium diethyl sulfonate 15%

[0033] Sodium polyacrylate with a molecular weight of 1500 7%

[0034] Yuanming powder 2%

[0035] Water 59%.

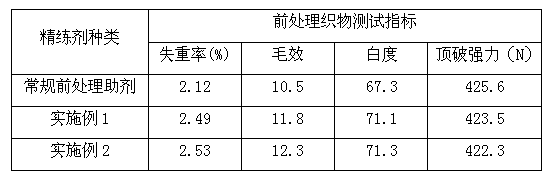

[0036] The low-temperature pre-treatment aids provided in Examples 1 and 2 of the present invention are used in the low-temperature pre-treatment processing of cotton knitted fabrics, and compared with conventional pre-treatment aids.

[0037] The treatment process is as follows:

[0038] Into the cloth-add water to moisten-add low-temperature pretreatment aid-heat to 60 ℃-run for 10 minutes-add hydrogen peroxide and caustic soda-cycle operation for 10 minutes-add low-temperature bleach activator-warm up to Cycle operation at 70°C for 45 minutes-cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com