A method and application of ionic liquid-assisted preparation of vanadium phosphorus oxygen catalyst

An ionic liquid, vanadium phosphorus oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve the effects of increasing active sites, increasing specific surface area, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

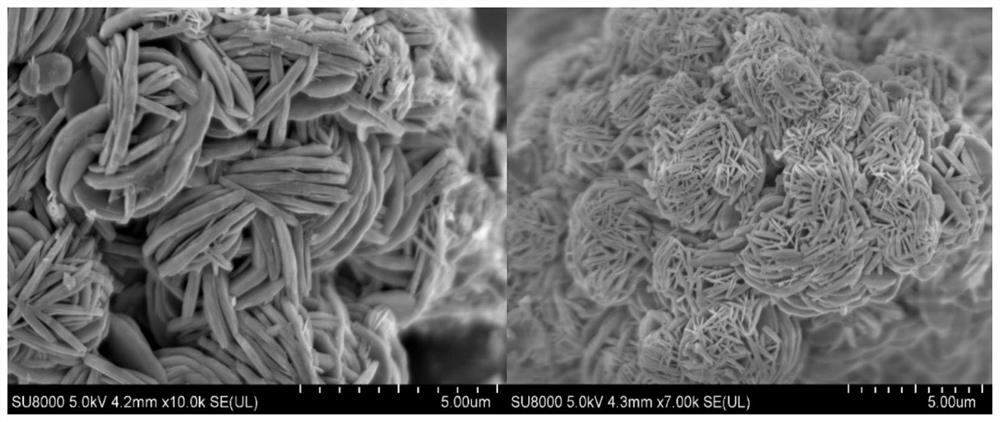

Embodiment 1

[0031] Weigh V 2 o 5 Put 20g in a 500ml container, add a mixture of isobutanol and benzyl alcohol (160ml / 40ml), then add 2ml of 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid, stir and mix evenly, at 135°C After reflux for 3 hours under the same conditions, the temperature was lowered to 60 °C, and then slowly added dropwise H2O with a mass fraction of 85%. 3 PO 4 15.5ml, and the temperature was raised to 135°C and the reflux was continued for 16 hours. Filter and wash to obtain a blue precipitate, and dry it in air at 120° C. for 12 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder was pressed into tablets under a pressure of 15 MPa, crushed, and 20-40 mesh catalyst particles were sieved. The catalyst particles were then placed in a reaction atmosphere (C4H 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 400°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxyge...

Embodiment 2

[0034] Weigh V 2 o 5 20g is placed in a 500ml container, add the mixed solution of isobutanol and benzyl alcohol (160ml / 40ml), then add 1.5ml 1-butyl-3-methylimidazolium tetrachloride ionic liquid, mechanically stir and mix evenly, 135 After reflux for 3 hours under the condition of ℃, cool down to 60 ℃, then slowly dropwise add H 3 PO 4 15.5ml, and the temperature was raised to 135°C and the reflux was continued for 16 hours. The gray-green precipitate was obtained by filtering and washing, and dried in air at 120° C. for 12 hours to obtain catalyst precursor powder. The obtained catalyst precursor powder was pressed into tablets under a pressure of 15 MPa, crushed, and 20-40 mesh catalyst particles were sieved. Afterwards, the catalyst particles were placed in the reaction atmosphere (C 4 h 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 400°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxygen catalyst. ...

Embodiment 3

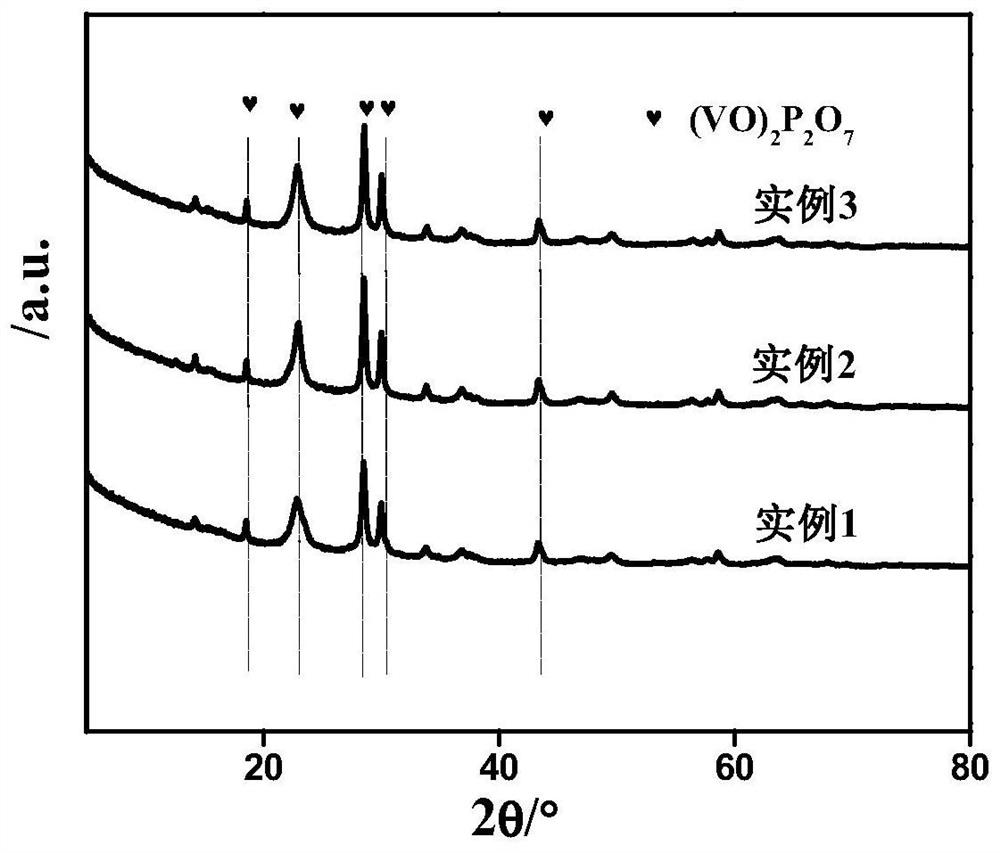

[0037] Weigh V 2 o 5 Put 20g in a 500ml high-pressure glass reactor, add a mixture of isobutanol and benzyl alcohol (160ml / 40ml), then add 1ml of 1-sulfobutyl-3-methylimidazolium bisulfate ionic liquid, stir and mix evenly , reflux at 135°C for 3 hours and then cool down to 60°C, then slowly dropwise add 85% H 3 PO 4 16.7ml, and the temperature was raised to 135°C for reflux for 16 hours. Filter and wash to obtain a light green precipitate, and dry it in air at 120° C. for 12 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder was pressed into tablets under a pressure of 15 MPa, crushed, and 20-40 mesh catalyst particles were sieved. The catalyst particles were then placed in a reaction atmosphere (C4H 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 400°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxygen catalyst. The catalyst is mainly composed of vanadyl pyrophosphate phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com