A kind of preparation method and application of vanadium phosphorus oxygen catalyst

A technology of vanadium phosphorus oxide and catalyst, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of low conversion rate, easy over-oxidation, difficult conversion control, etc. Large specific surface area and the effect of increasing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

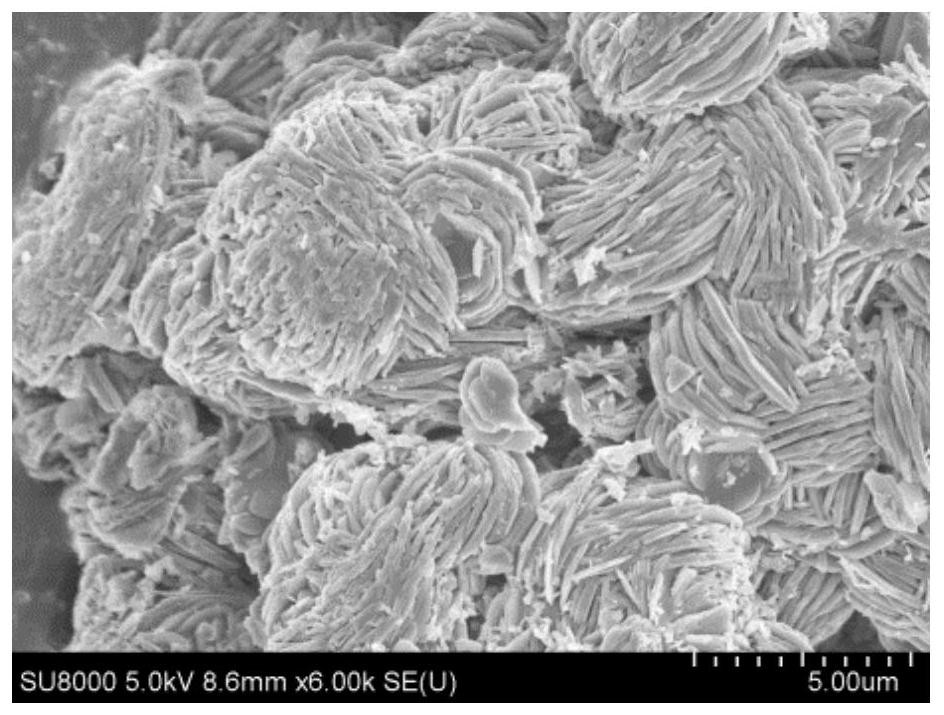

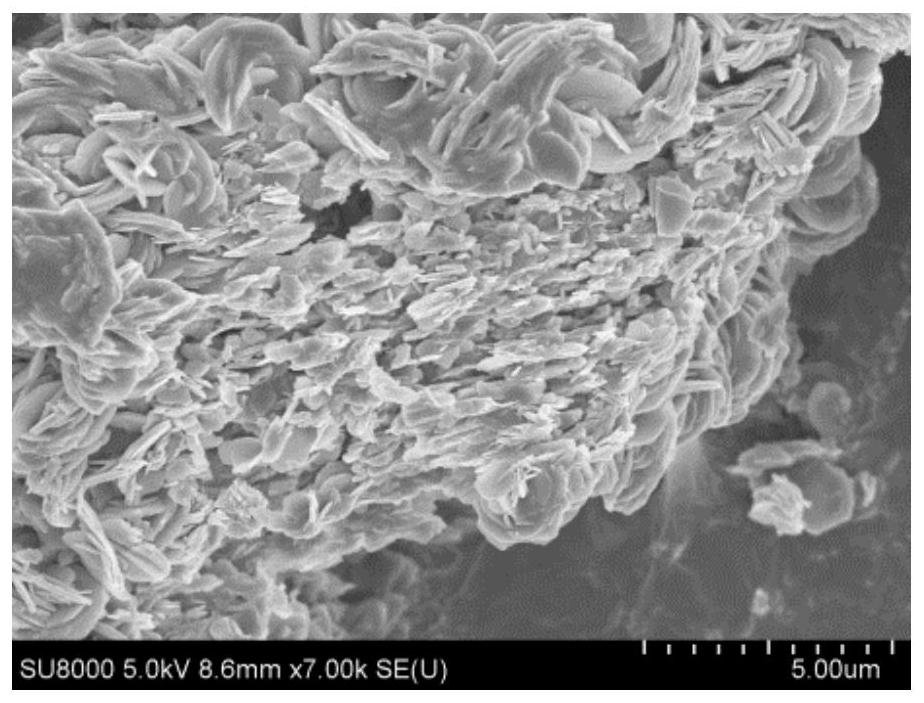

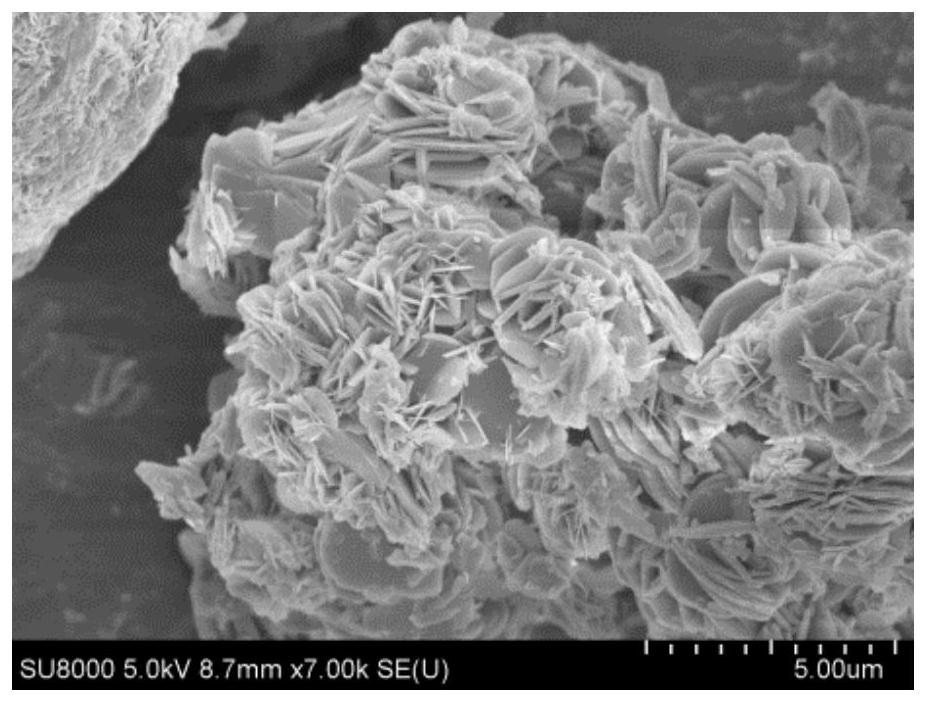

Image

Examples

preparation example Construction

[0018] The embodiment of the present invention provides a method for preparing a vanadium phosphorus oxygen catalyst, which includes the following steps:

[0019] S01: Put the vanadium source in a container, add a mixture of isobutanol and benzyl alcohol with a volume ratio of 2-6:1, heat up to 100-180°C for 2-8 hours, then cool to 30-80°C, add glucose , then add a phosphorus source into the container, heat up to 100-200°C and continue the reaction for 10-24 hours, the product is filtered, washed, and dried to obtain a vanadium-phosphorus-oxygen precursor, wherein the phosphorus in the phosphorus source and the vanadium source The molar ratio of vanadium is 0.8-1.5:1, the concentration of the vanadium pentoxide in the mixture of isobutanol and benzyl alcohol is 0.02g / mL-0.12g / mL, and the mass ratio of the vanadium source to glucose is 3 ~15:1;

[0020] S02: Calcining the vanadium phosphorus oxide precursor at a temperature of 350˜550° C. for 10˜24 hours, and cooling to obtain...

Embodiment 1

[0029] Weigh 20g V 2 o 5 Place in a 500mL three-neck flask, add a mixture of 160mL isobutanol and 40mL benzyl alcohol, stir and mix evenly, reflux at 135°C for 4 hours, then cool down to 60°C, then add 2.0g of glucose, and then slowly drop 15.2mL 85% H 3 PO 4 , and continued to reflux for 16 hours at a temperature of 135° C. Filter and wash with absolute ethanol to obtain a blue precipitate, and dry it in air at 120°C for 24 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder is compressed under a pressure of 15MPa, crushed, and 20-40 mesh catalyst particles are sieved. Afterwards, the catalyst particles were activated in situ from room temperature to 380°C at a rate of 5°C / min under a nitrogen atmosphere for 12 hours to obtain a vanadium-phosphorus-oxygen catalyst.

[0030] Weigh 4.5g of vanadium-phosphorus-oxygen catalyst and place it in a fixed-bed reactor with an inner diameter of 14mm for catalyst performance evaluation. 4 h 10 / O 2...

Embodiment 2

[0032] Weigh 20g V 2 o 5 Place in a 500mL three-neck flask, add a mixture of 160mL isobutanol and 40mL benzyl alcohol, stir and mix evenly, reflux at 135°C for 4 hours, then cool down to 60°C, then add 2.8g of glucose, and then slowly drop 15.2mL 85% H 3 PO 4 , and continued to reflux for 16 hours at a temperature of 135° C. Filter and wash with absolute ethanol to obtain a blue precipitate, and dry it in air at 120°C for 24 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder is compressed under a pressure of 15MPa, crushed, and 20-40 mesh catalyst particles are sieved. Afterwards, the catalyst particles were activated in situ from room temperature to 380°C at a rate of 5°C / min under a nitrogen atmosphere for 12 hours to obtain a vanadium-phosphorus-oxygen catalyst.

[0033] Weigh 4.5g of vanadium-phosphorus-oxygen catalyst and place it in a fixed-bed reactor with an inner diameter of 14mm for catalyst performance evaluation. 4 h 10 / O 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com