Method of regenerating waste thermal transfer color bars and device thereof

A technology for heat transfer ribbons and regeneration equipment, applied in printing, ink ribbons, inking devices, etc., can solve problems such as air pollution, water source and soil pollution, and does not propose a method for reusing base film and ink, and achieves environmental protection The effects of resource protection, easy promotion, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

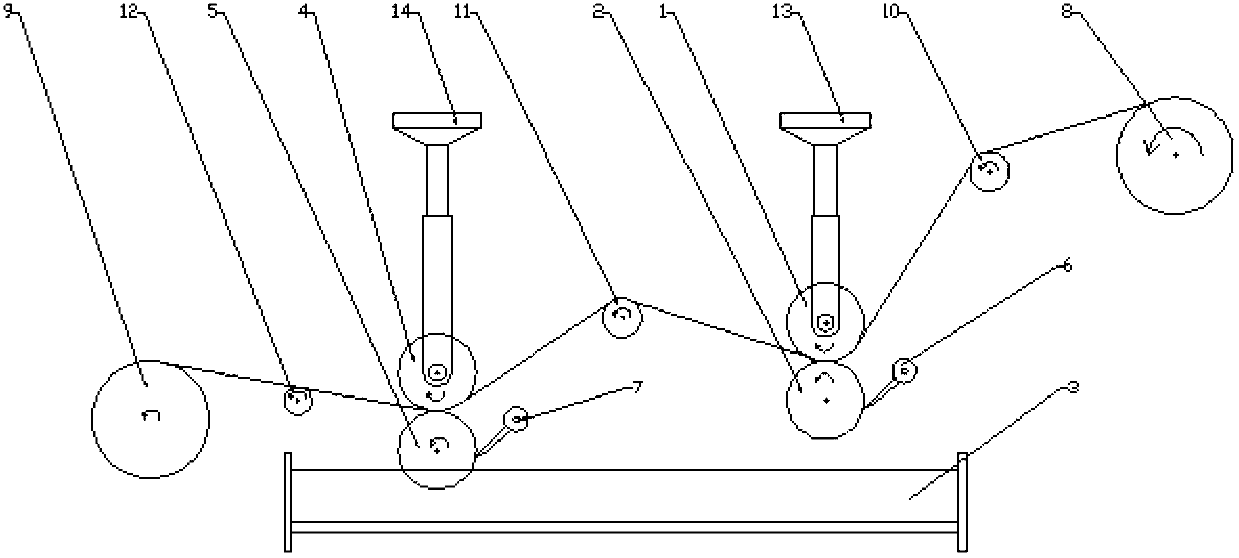

[0030] Embodiment 1 equipment of the present invention (start basement film ink separation device and ink coating device simultaneously)

[0031] Ribbon: STB101 ribbon

[0032] Such as figure 1 As shown, place the selected color ramp in accordance with the figure 1 The way shown is installed on the equipment, passing between the hot pressing body 1 and the receiving body 2, and pressing, the pressure is 10N / m 2 , the temperature of hot pressing body 1 is 180 degrees, the temperature of receiver 2 is 130 degrees, the temperature of ink collector 3 is 180 degrees, the temperature of anilox roller 5 is 200 degrees, the pressure of silicone rubber roller 4 and anilox roller 5 is 3N / m 2 , Transmission speed 50 m / min. Squeegee 6, 7 is pressed tightly, and the separation rate of base film and ink is 95%. Coating ribbon index conforms to STB101 technical index.

Embodiment 2

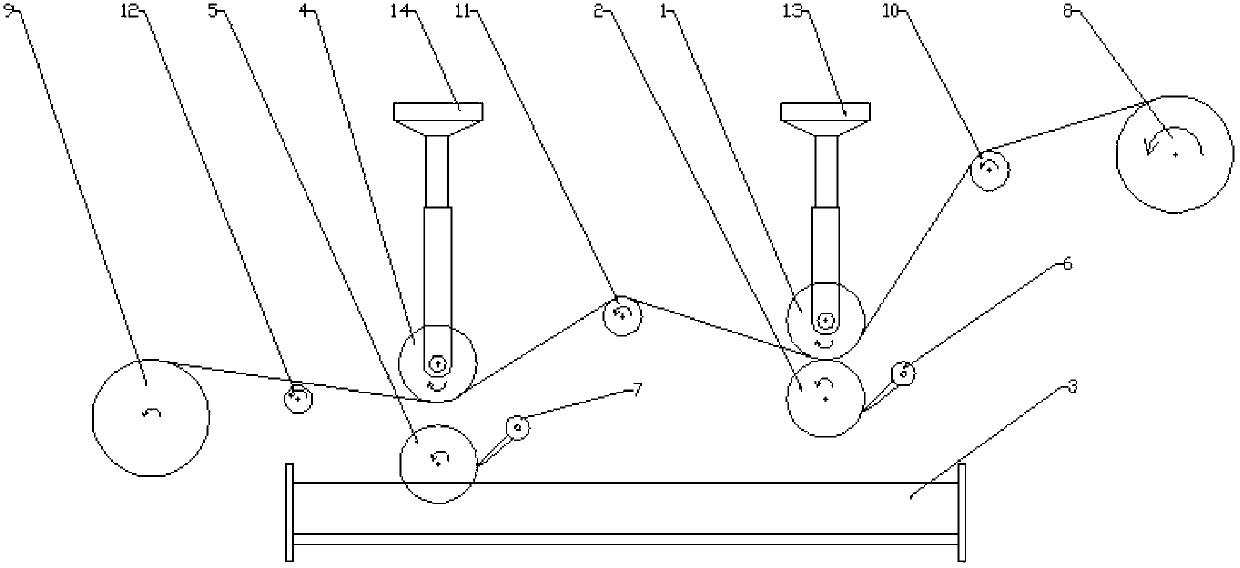

[0033] Embodiment 2 equipment of the present invention (only start basement membrane ink separation device)

[0034] Such as figure 2 As shown, place the selected color ramp in accordance with the figure 2 The way shown is installed on the equipment, passing between the hot pressing body 1 and the receiving body 2, and pressing, the pressure is 10N / m 2 , the temperature of hot pressing body 1 is 180 degrees, the temperature of receiver 2 is 130 degrees, the temperature of ink collector 3 is normal temperature, the temperature of anilox roller 5 is normal temperature, the silicone rubber roller 4 is separated from the anilox roller 5, the separation gap is 1 cm, and the transmission speed is 50 m / min . The scraper 6 is pressed tightly, and the separation rate of the base film and the ink is 95%.

Embodiment 3

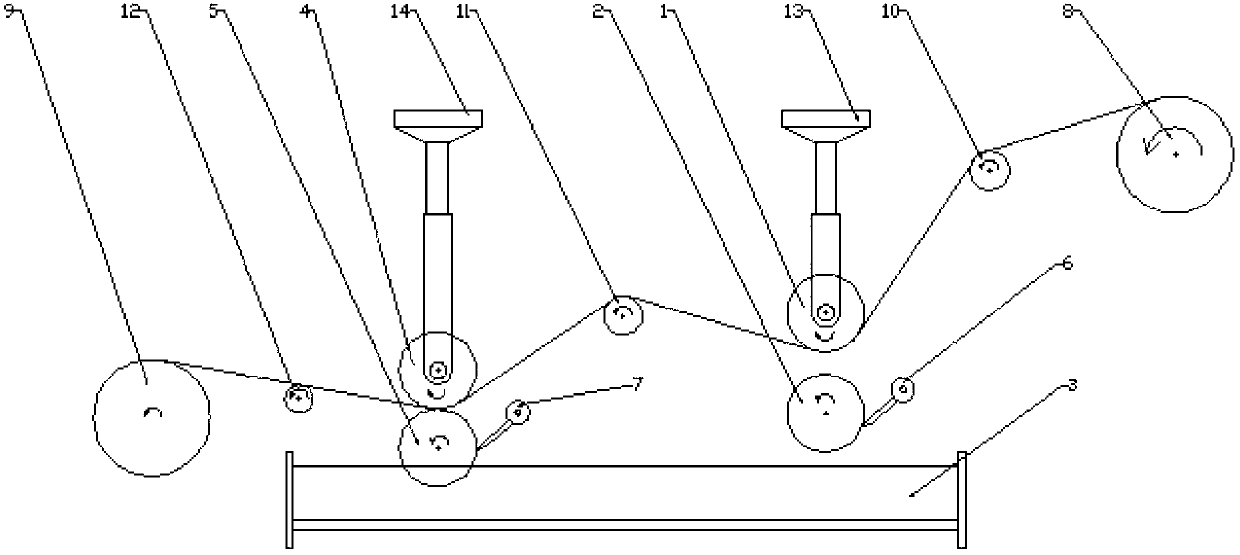

[0035] Embodiment 3 equipment of the present invention (only start ink coating device)

[0036] Such as image 3 As shown, place the selected color ramp in accordance with the image 3 The method shown is installed on the equipment, passing between the hot pressing body 1 and the receiving body 2, the hot pressing body 1 and the receiving body 2 are separated in temperature, the separation gap is 1cm, the temperature of the ink collector 3 is 180 degrees, and the temperature of the anilox roller 5 is 200 degrees, silicone rubber roller 4 and anilox roller 5 pressure 3N / m 2 , Transmission speed 50 m / min. The scraper 7 is pressed tightly, and the index of the coating ribbon complies with the technical index of STB101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com