High-toughness high-welding speed sintered flux suitable for submerged-arc welding of X90/X100 ultrahigh-strength pipeline steel pipe

An ultra-high-strength, sintered flux technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that cannot meet the weld performance and process requirements, and achieve high toughness, smooth weld surface, good transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Flux composition (wt%): MgO 21.5, CaF 2 20.1, Al 2 o 3 20.8, CaO6.2, rare earth 5.3, MnO6.5, SiO 2 26.5, S0.014, P0.029, add deoxidizer Si-Fe1~2, Mn-Fe3~4;

[0026] 2) Dry mix the raw materials containing certain ingredients according to a certain ratio, and after stirring evenly, add an appropriate amount of adhesive (potassium sodium water glass) according to a certain percentage of the total mass of the mixture for wet mixing, and then use a dustpan or make According to GB / T 12470-2003 "Welding wire and flux for low alloy steel for submerged arc welding", the particle size of the flux is controlled between 10-60 mesh, and then dried at 200-250°C at low temperature , and then sintered at a high temperature of 800-900 ° C, and then packed in a moisture-proof packaging bag after being screened with 10-60 mesh.

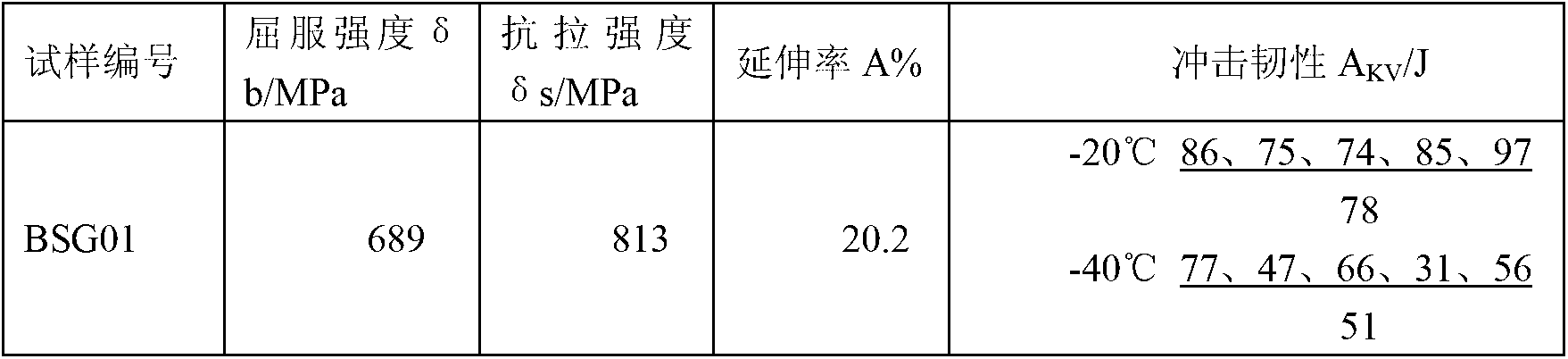

[0027] 3) Mechanical properties of weld deposited metal test

[0028]

[0029] 4) Welding test and performance test (with high steel grade welding wire...

example 2

[0032] 1) Flux composition (wt%): MgO24.8, CaF 2 21.5, Al 2 o 3 21.5, CaO6.5, Y 2 o 3 5.3, MnO6.8, SiO 2 24.5, S0.012, P0.021, add deoxidizer Si-Fe2~3;

[0033] 2) Same manufacturing process as Example 1

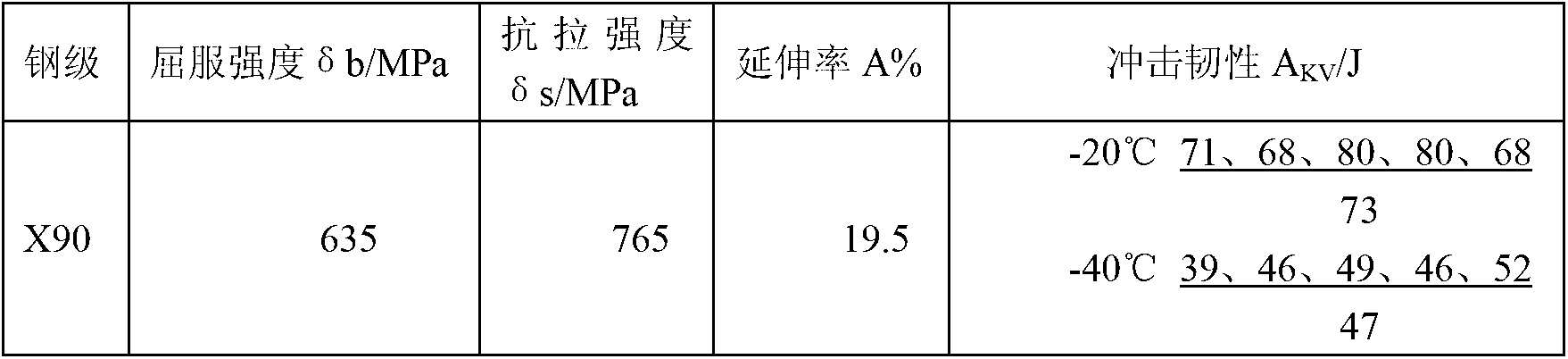

[0034] 3) Mechanical properties of weld deposited metal test

[0035]

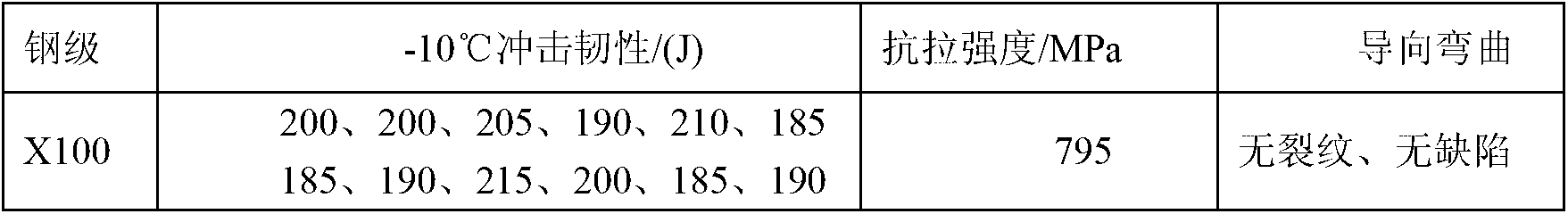

[0036] 4) Welding test and performance test (with high steel grade welding wire BG-H06H2-2 and corresponding pipeline steel raw materials)

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com