Method for treating waste alkaline liquor produced in butanol and octanol production device

A production device and treatment method technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult treatment, low removal efficiency, and complicated treatment process. To achieve the effect of highlighting substantive features, low heat source taste requirements, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

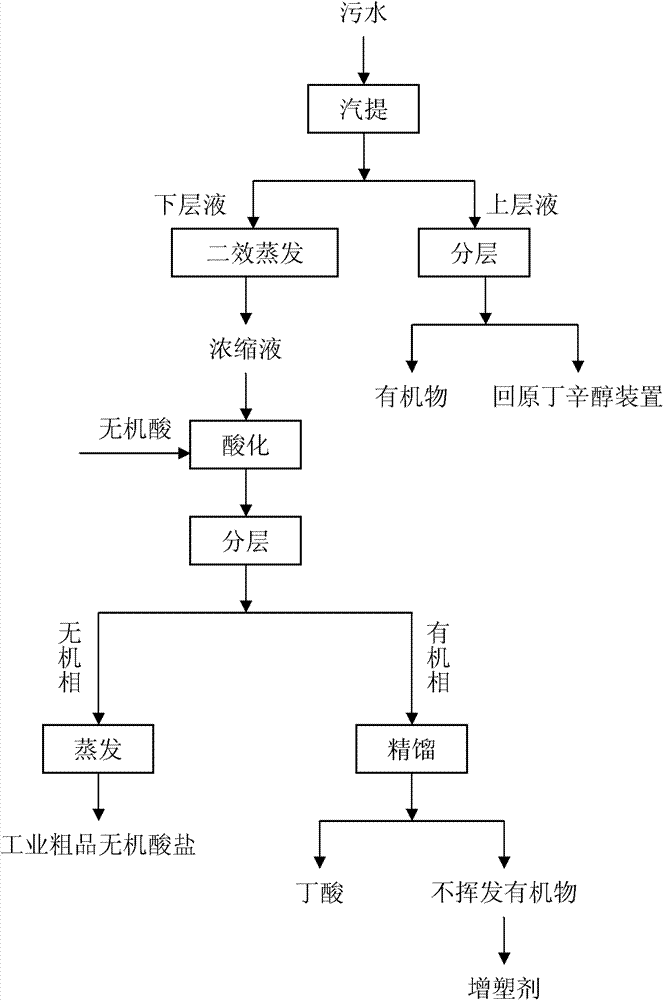

[0060] The processing method of the spent lye produced in the butyl octanol production unit of the present invention, comprises the technological operation step that following order is carried out:

[0061] a. Atmospheric pressure stripping

[0062]In the stripping tower, the volatile organic compounds are extracted from the top of the tower together with water vapor to separate the volatile organic compounds in the waste water; the process parameters are as follows:

[0063] Output at the top of the tower: feed rate = 2% to 10%

[0064] Reflux ratio 0.5~5

[0065] The number of trays at the feeding position: the total number of theoretical trays with the tower = 0.1 to 1;

[0066] b. Low pressure evaporation and concentration

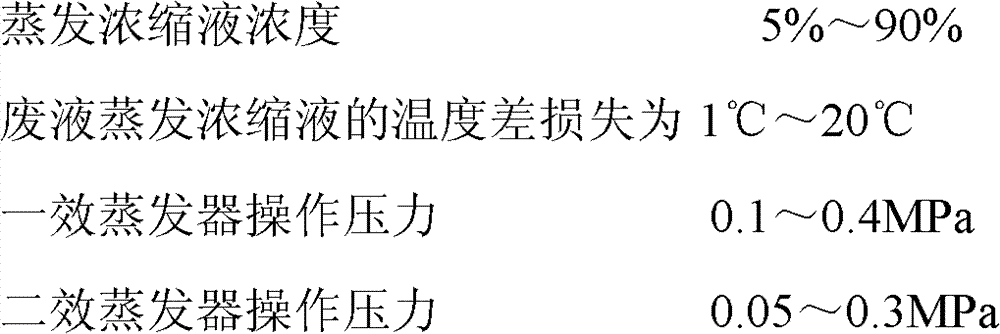

[0067] .The waste liquid after the stripping in step a is carried out with the low-pressure secondary steam as the heat source, and performs two-stage evaporation and concentration in the first effect and the second effect;

[0068] The process par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com