Cellutloid sheet material for producing ping-pong ball

A technology of celluloid sheets and table tennis balls, which is applied in the field of making celluloid sheets for table tennis, and can solve problems such as unstable center of gravity, poor toughness, and low strength of table tennis balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

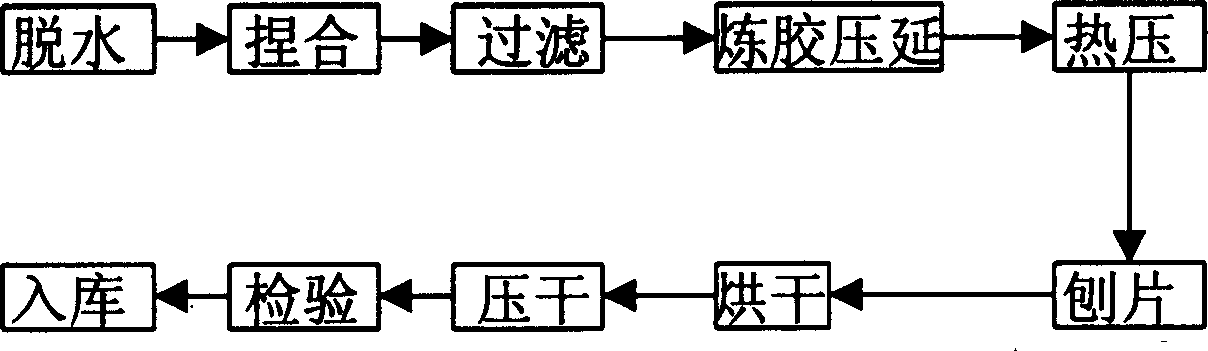

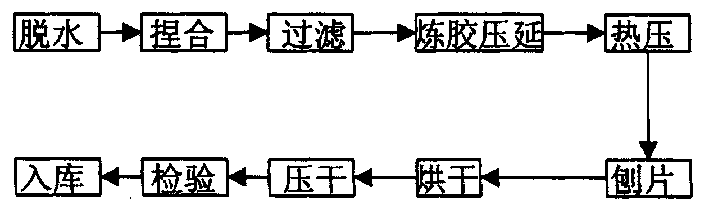

Method used

Image

Examples

Embodiment 1

[0011] Get nitrocellulose 550kg, alcohol 120kg and acetone 67.5kg, zinc oxide powder 10kg, camphor powder 250kg, ethyl acetate 2kg and pigment 0.5kg, its production process is as follows:

[0012] 1. Add a certain amount of grain industrial grade ethanol to nitrocellulose and stir evenly before dehydrating;

[0013] 2. Add synthetic acetone, ethanol, synthetic camphor powder, ethyl acetate, pigment, zinc oxide powder filler and color fixing agent in a quantitative ratio, put it into a 500L kneader, heat and knead for 90 minutes, and then discharge;

[0014] 3. The discharge temperature is controlled at 68±2°C, and the discharge is filtered with silk cloth and stainless steel mesh;

[0015] 4. After filtering, put it into the rubber mixer, heat and calender for 2.5 hours, control the temperature of the block material at 68±2°C, and control the alcohol content at 15-16%;

[0016] 5. Use a 200-ton press to press 200kg for 5 hours, and block the material for 72 hours;

[0017] 6...

Embodiment 2

[0020] Get nitrocellulose 700kg, alcohol 70kg and acetone 23kg, zinc oxide powder 50kg, camphor powder 150kg, ethyl acetate 5kg and pigment 2kg, its production process is as follows:

[0021] 1. Add a certain amount of grain industrial grade ethanol to nitrocellulose and stir evenly before dehydrating;

[0022] 2. Add synthetic acetone, ethanol, synthetic camphor powder, ethyl acetate, pigment, zinc oxide powder filler and color fixing agent in a quantitative ratio, put it into a 500L kneader, heat and knead for 60 minutes, and then discharge;

[0023] 3. The discharge temperature is controlled at 68±2°C, and the discharge is filtered with silk cloth and stainless steel mesh;

[0024] 4. After filtering, put it into the rubber mixer, heat and calender for 2.5 hours, control the temperature of the block material at 68±2°C, and control the alcohol content at 15-16%;

[0025] 5. Use a 200-ton press to press 150kg for 6 hours, and block the material for 96 hours;

[0026] 6. The...

Embodiment 3

[0029] Get nitrocellulose 600kg, alcohol 110kg and acetone 61kg, zinc oxide powder 25kg, camphor powder 200kg, ethyl acetate 3kg and pigment 1kg, its production process is as follows:

[0030] 1. Add a certain amount of grain industrial grade ethanol to nitrocellulose and stir evenly before dehydrating;

[0031] 2. Add synthetic acetone, ethanol, synthetic camphor powder, ethyl acetate, pigment, zinc oxide powder filler and color fixing agent in a quantitative ratio, put it into a 500L kneader, heat and knead for 120 minutes, and then discharge;

[0032] 3. The discharge temperature is controlled at 68±2°C, and the discharge is filtered with silk cloth and stainless steel mesh;

[0033] 4. Put it into the rubber mixing machine after filtering, heat and calender for 2 hours, control the cutting temperature of the block at 68±2°C, and control the alcohol content at 15-16%;

[0034] 5. Use a 200-ton press to press 250kg for 4 hours, and block the material for 48 hours;

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com