Pitted-surface metal and rubber composite conductive particle

A technology of conductive particles and metals, applied in circuits, electric switches, electrical components, etc., can solve the problems of inability to balance conductivity and strength, and achieve the effects of easy industrial production and batch application, controllable cost and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

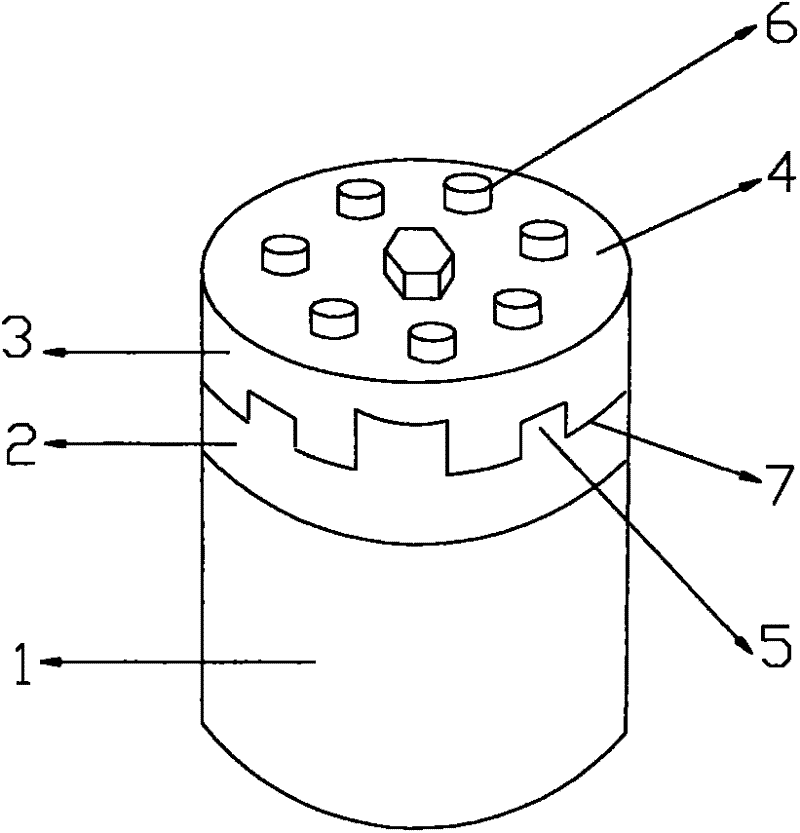

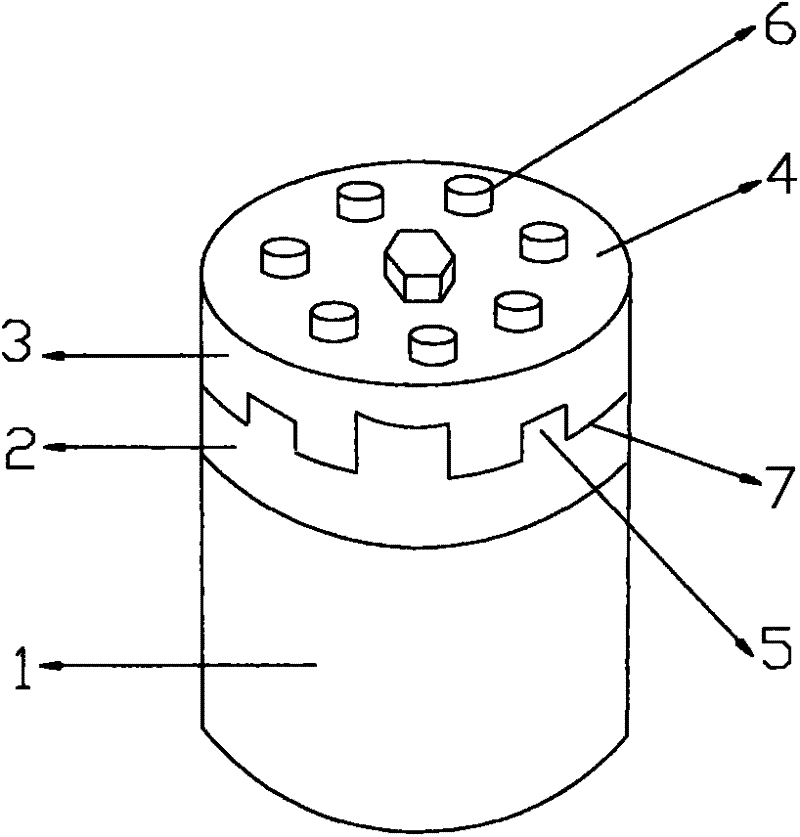

[0025] As shown in the drawings, the depth of the pits 5 is less than the thickness of the metal surface layer 1 , and the height of the bumps 6 is less than twice the thickness of the metal surface layer 1 . The maximum area of the pits 5 and bumps 6 is 0.1mm 2 -1mm 2 ; The distance between the adjacent pits 5, between the bumps 6 or between the adjacent pits 5 and the bumps 6 is 0.05mm-0.5mm.

[0026] The distribution of the pits 5 or bumps 6 on the metal surface layer 1 is uniform. The metal surface layer 1 is circular, and the planar shape of the pits 5 or bumps 6 is circular. The metal surface layer 1 is made of 0.1 mm thick metal copper, and the outer surface 4 of the metal surface layer is also plated with 4 micron thick nickel, and then a layer of 1.5 micron hard gold is plated on the nickel. As an intermediate layer, the nickel plating acts as a barrier between gold and copper. It can prevent the mutual diffusion between gold and copper and prevent copper from pe...

Embodiment 2

[0029] As shown in the drawings, the depth of the pits 5 is smaller than the thickness of the metal surface layer 1 , and the height of the bumps 6 is smaller than the thickness of the metal surface layer 1 . The maximum area of the pits 5 and bumps 6 is 0.5mm 2 -2mm 2 ; The distance between adjacent pits 5, adjacent bumps 6 or between adjacent pits 5 and bumps 6 is 0.5mm-1mm, ensuring reliable contact with the integrated circuit.

[0030] The distribution of the pits 5 or bumps 6 on the metal surface layer 1 is random, the metal surface layer 1 is heart-shaped, and the plane shape of the pits 5 or bumps 6 is ellipse.

[0031] The metal surface layer 1 is made of aluminum alloy, and the outer surface 4 of the metal surface layer is also plated with silver to increase electrical conductivity and corrosion resistance. The adhesive layer 2 is vulcanized rubber adhesive, the rubber matrix 3 is silicone rubber, and the adhesive layer 2 is embedded in the pit 5 of the metal surf...

Embodiment 3

[0033] As shown in the drawings, the height of the bumps 6 is less than twice the thickness of the metal surface layer 1 . The maximum area of the planes of the pits 5 and bumps 6 is 1mm 2 -5mm 2 ; Between the adjacent pits 5 and between the adjacent bumps 6 are 1mm-2mm.

[0034] The distribution of the pits 5 or bumps 6 on the metal surface layer is regular. The metal surface layer 1 is a regular polygon, the planar shape of the pits 5 is irregular, and the planar shape of the bumps 6 is circular. The metal surface layer 1 is made of iron-nickel bimetallic composite material, the adhesive layer 2 is a thermally vulcanized rubber adhesive layer, and the rubber matrix 3 is silicone rubber.

[0035] Before the metal surface layer 1 is bonded to the rubber substrate 3, the inner surface 7 of the metal surface layer is degreased by an organic solvent, and the bonding surface of the rubber substrate 3 is decontaminated by a synthetic washing liquid; the degreasing and decontamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com