Full-sealed water, fire and explosion prevention cable joint safety box

A technology of cable joints and safety boxes, which is applied in the field of fully sealed cable joint waterproof, fireproof and explosion-proof safety boxes, which can solve the problems of cable explosion damage, cable head breakdown, spontaneous combustion, etc., and achieve good fire prevention, long aging resistance, Colloidal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

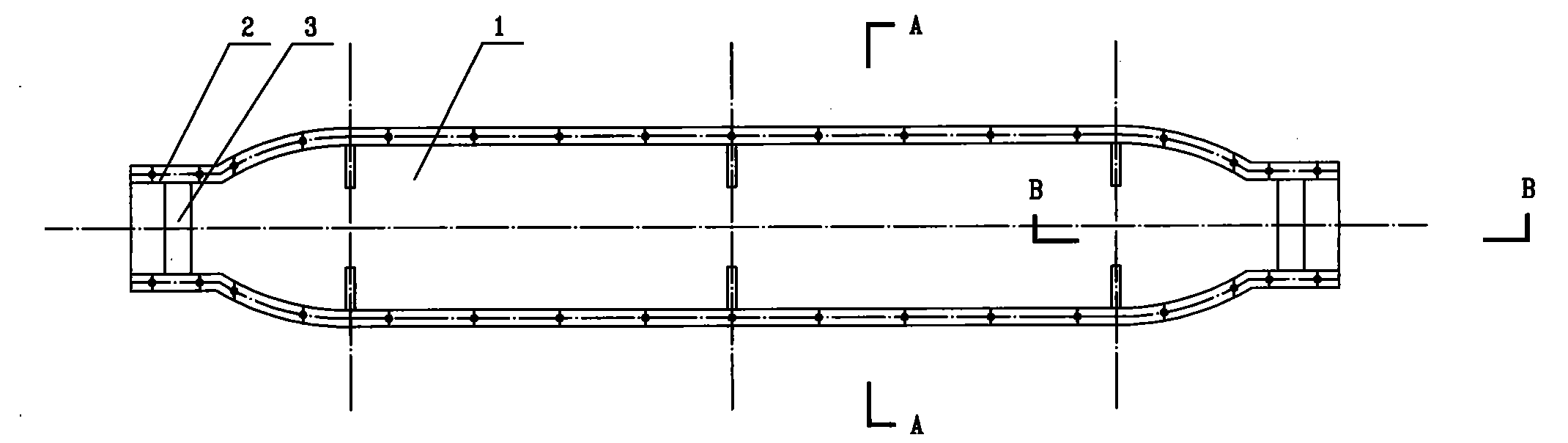

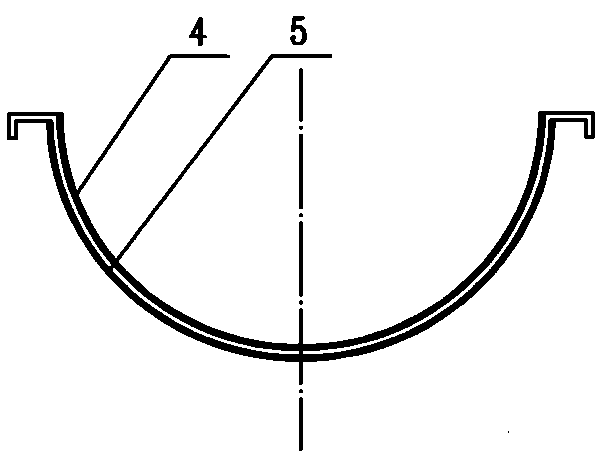

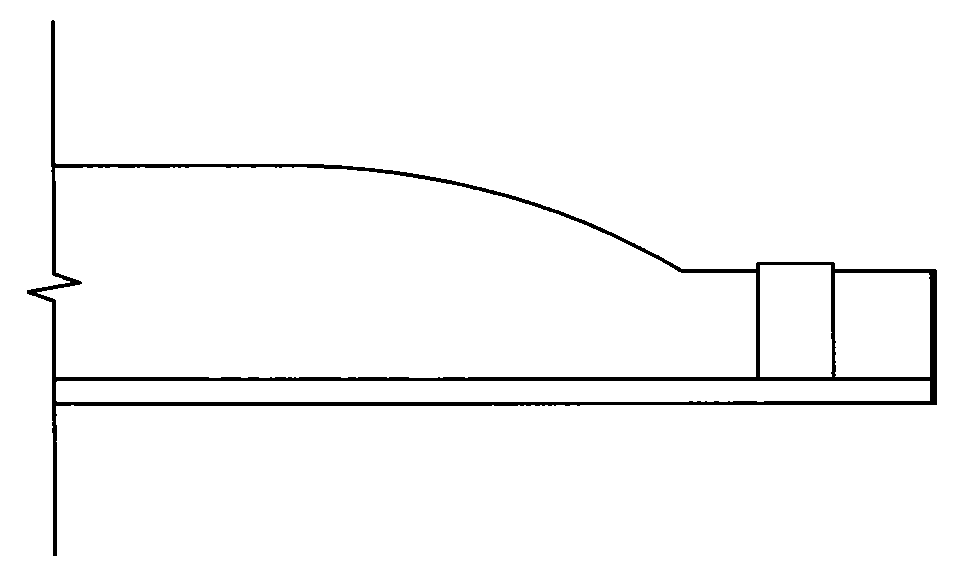

[0013] Such as Figure 1-3 As shown, the fully sealed cable joint waterproof, fireproof and explosion-proof safety box includes a shell 1 made of weak magnet plate composite material. The shell 1 is a cylindrical shape formed by two semi-cylindrical shells at one time without welding. The two semi-cylindrical shells of 1 are connected by explosion-proof hexagonal socket set screws. The diameters of the two ends of the shell become smaller to form a tightening port 2, and a small-sized cylindrical shape is formed at the tightening port 2. The inner part of the tightening port 2 is installed There is a waterproof sealing attachment 3, which is made of high-quality silicone rubber material. The inner wall of the housing 1 is attached with a fire-resistant, flame-retardant and heat-insulating layer 4, and the outer surface of the housing 1 is sprayed with anti-corrosion and anti-ultraviolet powder 5.

[0014] The beneficial effects of the invention are: the whole shell is formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com