Railway vehicle outside-sleeper structure

A technology of rail vehicle and outer structure, which is applied in the directions of railway car body parts, chassis, transportation and packaging, etc., can solve the extrusion distance, the bearing capacity of the outer structure of the pillow, the chassis and the coupler interface arranging the car body and the bogie to avoid difficulties and other problems, to achieve the effect of small curve radius, meeting avoidance range and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

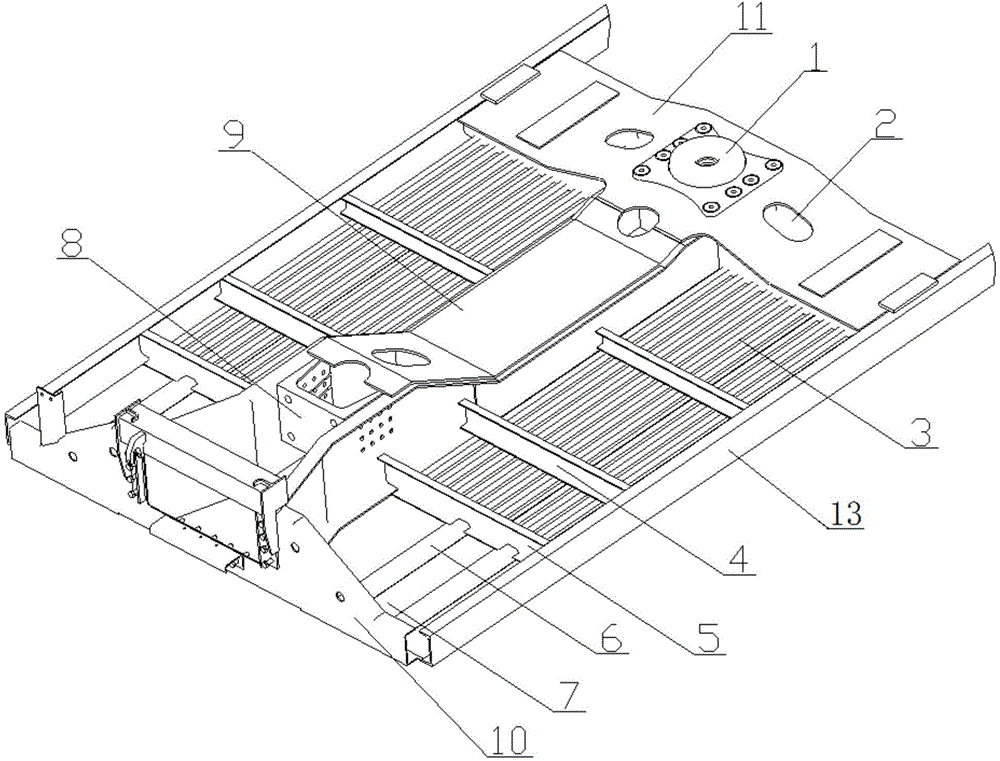

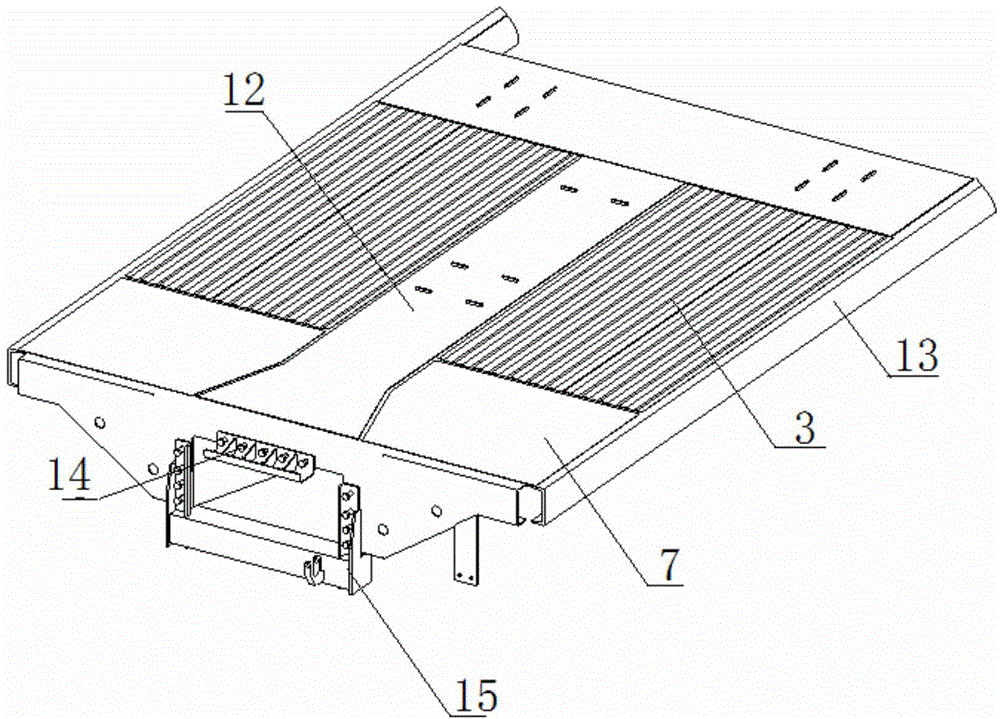

[0021] Such as figure 1 , figure 2 As shown, the rail vehicle sleeper structure of the embodiment of the present invention includes side beams 13, end beams 10, traction beams 9, and corbels 11, and the end beams 10, traction beams 9, and corbels 11 form an end-leading pillow structure successively, and The two ends of the end beam 10 and the draw beam 9 are welded and fixed between the two underframe side beams 13, the draw beam 9 is equipped with a coupler mounting seat 8, and the lower cover plate of the corbel 11 is fixed with the center disc seat 1 by bolts, and the traction The rear end of the beam 9 is welded to the corbel 11, the interface of the bogie is placed between the two webs of the corbel 11, and the lower cover plate of the corbel 11 on both sides of the center plate seat 1 is provided with a mounting hole 2; the traction beam 9 The front section is provided with a coupler mounting seat 8, and a large crossbeam 5 is arranged horizontally between the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com