Flexible packing pipe and flexible plastic bottle

A hose and soft bottle technology, applied in packaging, transportation and packaging, dispensing devices, etc., can solve problems such as inconvenience and difficulty in toothpaste extrusion, and achieve the effect of preventing automatic dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

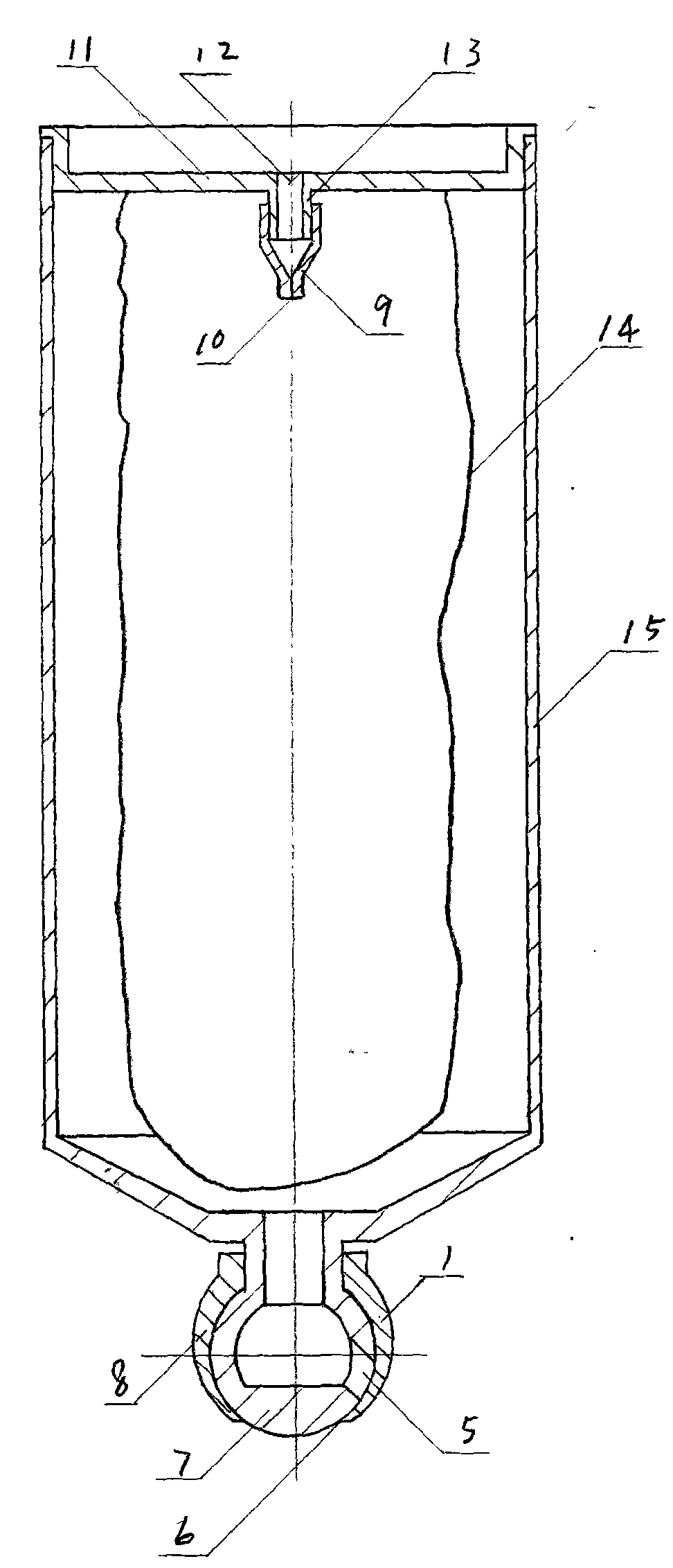

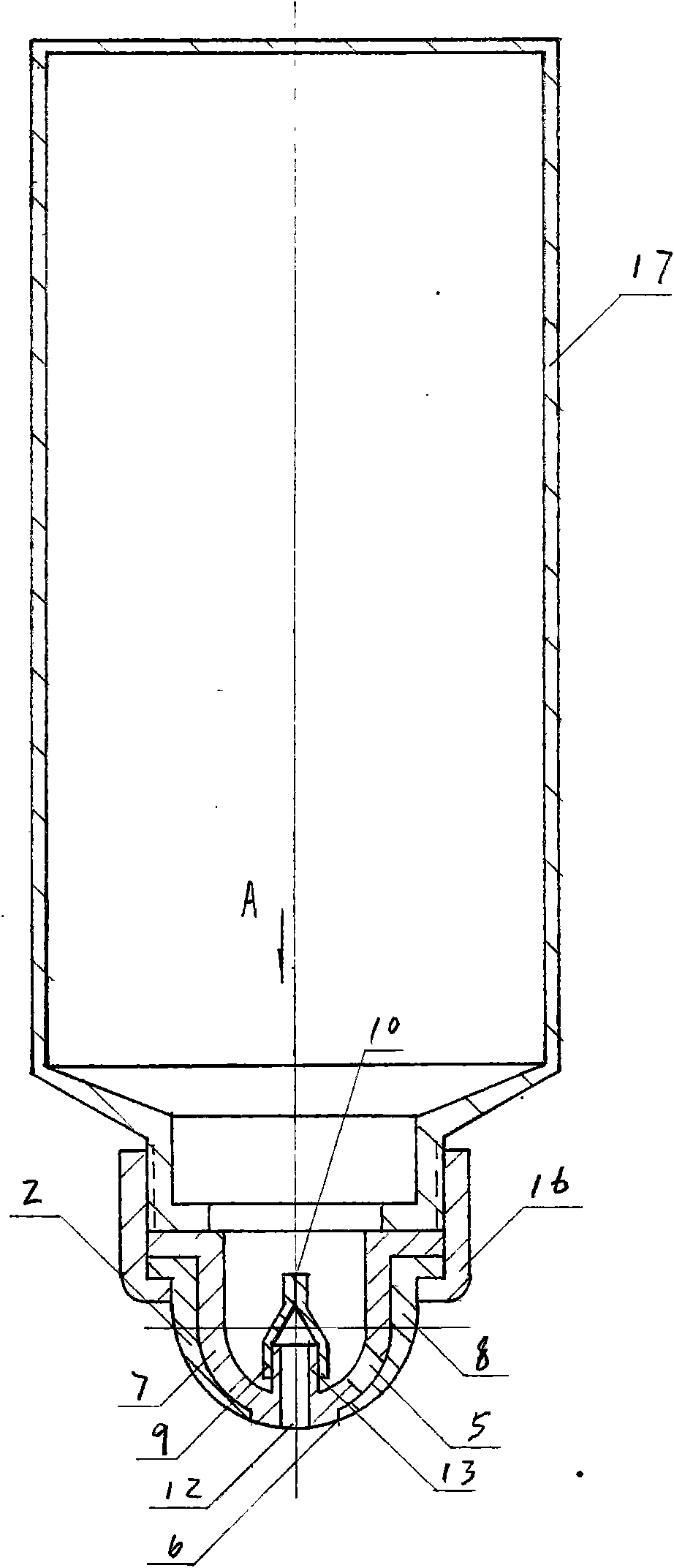

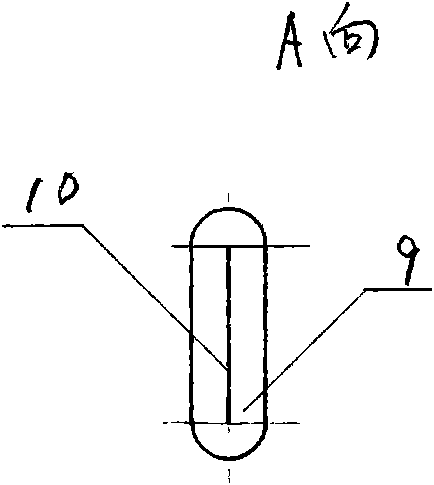

[0011] Embodiment one, hose, soft bottle and air intake structure: as figure 1 , figure 2 , image 3 Shown, said packaging hose and plastic soft bottle (15,17) have certain hardness and elasticity, a kind of packaging hose and plastic soft bottle that can spring back automatically after extrusion. The bottom of flexible pipe and soft bottle (15,17) and the front end of tongue plug 7 have air inlet 12 to communicate with air intake soft mouth 9 respectively, and air intake soft mouth 9 is to make with elastic rubber or soft plastic A kind of container sample has bottom flat soft mouth, and its bottom end cuts out the air inlet slit 10 that can inhale with blade again, constitutes a kind of flexible airtight air inlet soft mouth 9. Such as Figure 4 Shown, the tail end of soft bottle 17 has a top that is unreasonable, and the air inlet pipe 21 that side has air inlet hole 23 communicates with air inlet hole 22, and a kind of sealing sleeve 20 that does with rubber, entangles...

Embodiment 2

[0012] Embodiment two, the extrusion structure of the bottle mouth: as figure 1 , figure 2 As shown, the front end of the mouth of the hose and soft bottle (15, 17) is installed or fixed with a cork-like hollow tongue plug 7, the front end of the tongue plug 7 is blocked, and there are several oblique extrusion holes around the 5. A flexible soft lip sleeve 8 made of rubber wraps the tongue plug 7 and the extrusion hole 5 together, and leaves a hole formed by the mouth of the soft lip sleeve 8 at the front end of the tongue plug 7. Extrude port 6. A lip-tongue bottle mouth 1 and a lip-tongue bottle mouth 2 are formed which are elastic and can be closed and squeezed out. Such as Figure 4 , Figure 5 Shown, the bottleneck front end of soft bottle 17 is covered with soft mouth bottleneck 19, and soft mouth bottleneck 19 is the soft mouth that a kind of container sample with flexible rubber or soft plastic is made, and its bottom is used again. The blade cuts out a slit 18...

Embodiment 3

[0013] Embodiment three, air bag and separator ring: such as figure 1 Shown is a hose and soft bottle with an air bladder. An air bag 14 equal in volume is sheathed in the lumen of the flexible pipe 15 , and the pocket of the air bag 14 is fixedly connected with the bottom cover 11 and communicates with the air inlet 12 . Before the airbag 14 is used, it should be an uninflated airbag (as there is residual gas in the airbag 14, a needle tube can be inserted into the air inlet 12 and passed through the otch 10 of the air inlet soft nozzle 9 to suck it up). 15 After filling, cover the bottom cover 11 and be fixedly connected with the hose 15. The air bag 14 can separate the air that enters the hose to extrude the paste from the paste, so that the paste in the hose is not polluted by air.

[0014] Such as Figure 6 Shown is a hose and soft bottle with a divider ring. In the lumen of flexible pipe 15, there is a spacer ring 30 that can slide up and down, between the paste and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com