Steam electric iron

An electric iron and steam technology, which is applied to hand irons, washing devices, textiles and paper making, etc., can solve the problems of poor sealing of the pressing structure, loose water retaining cover, and reducing the flexibility of the water retaining cover.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

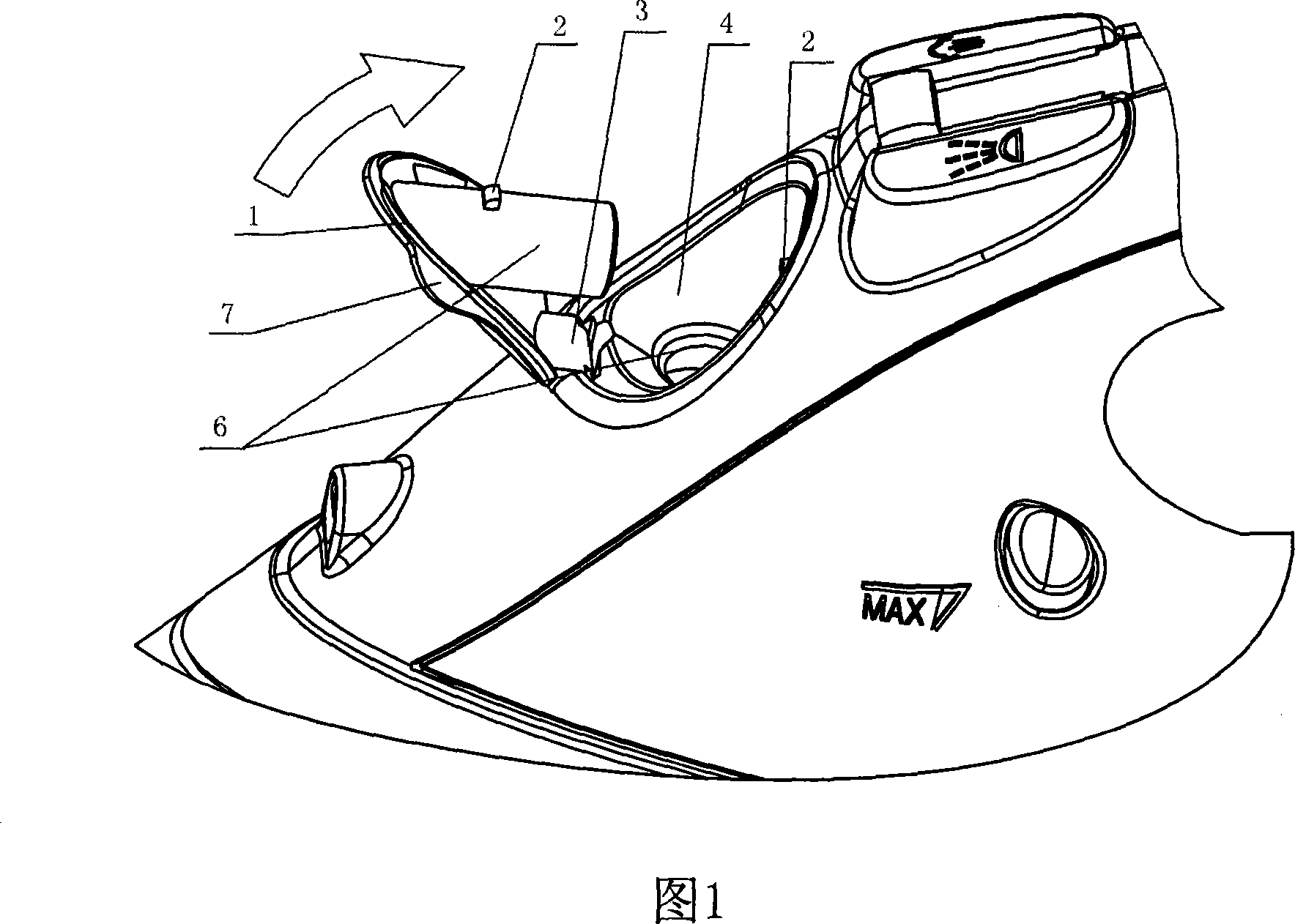

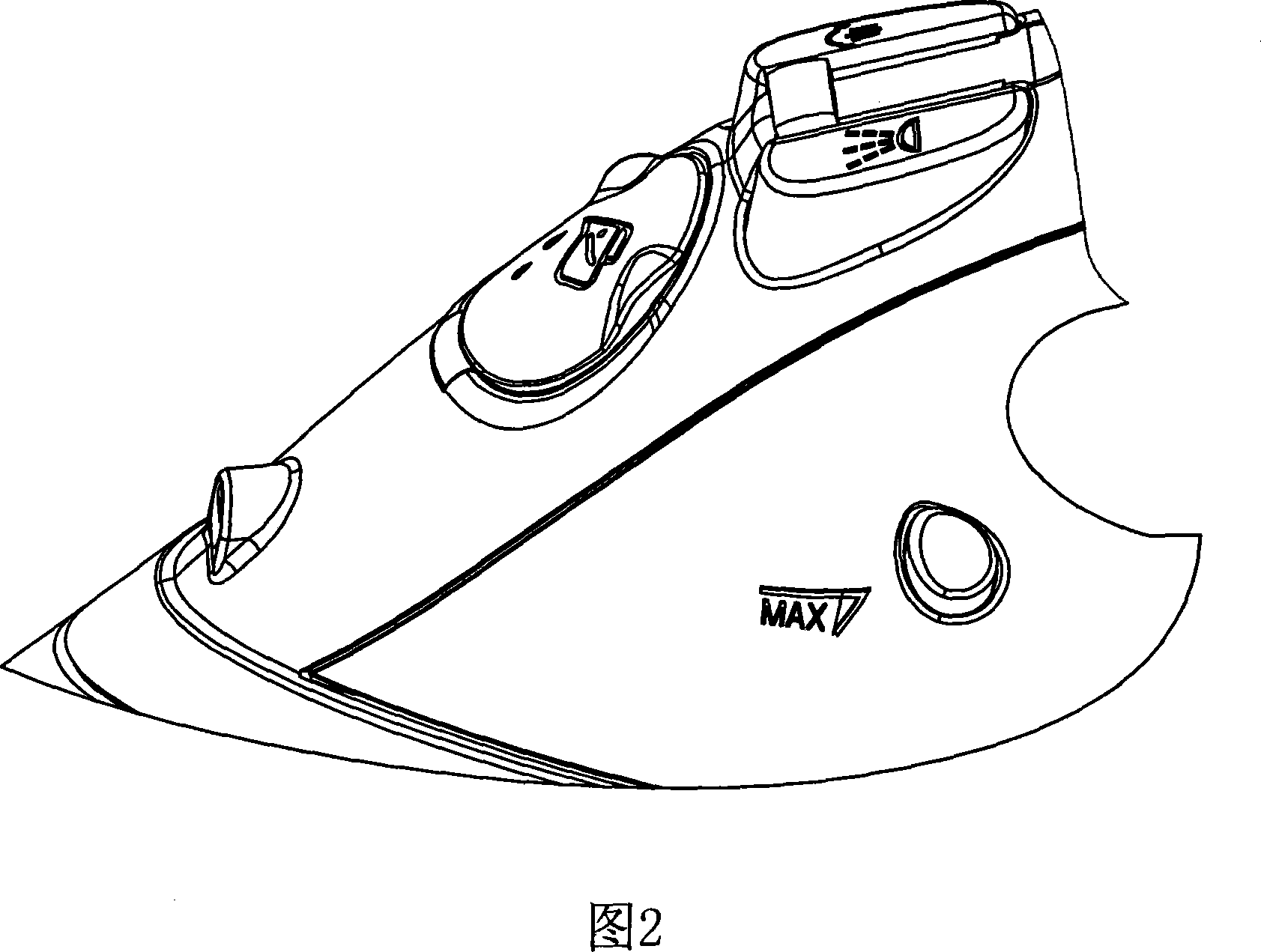

[0027] Referring to Fig. 1, the water retaining cover shown adopts a clamshell structure. One side of the water retaining cover 1 is rotatably connected to the edge of the water inlet 4 through an elastic member 3, and the water retaining cover 1 is provided with a fastening device 2, which pushes the water retaining cover 1 in the direction of the arrow, and the water retaining cover 1 rotates around the elastic member 3 to cover the water inlet 4. When the fastening device 2 is fastened up and down, the edge contact surface 6 of the water retaining cover 1 and the water inlet 4 is water-tight, as shown in FIG. 2 . When in use, the wrench 7 provided on the water retaining cover 1 is moved outward to disengage the fastening device 2, and the water retaining cover 1 is opened.

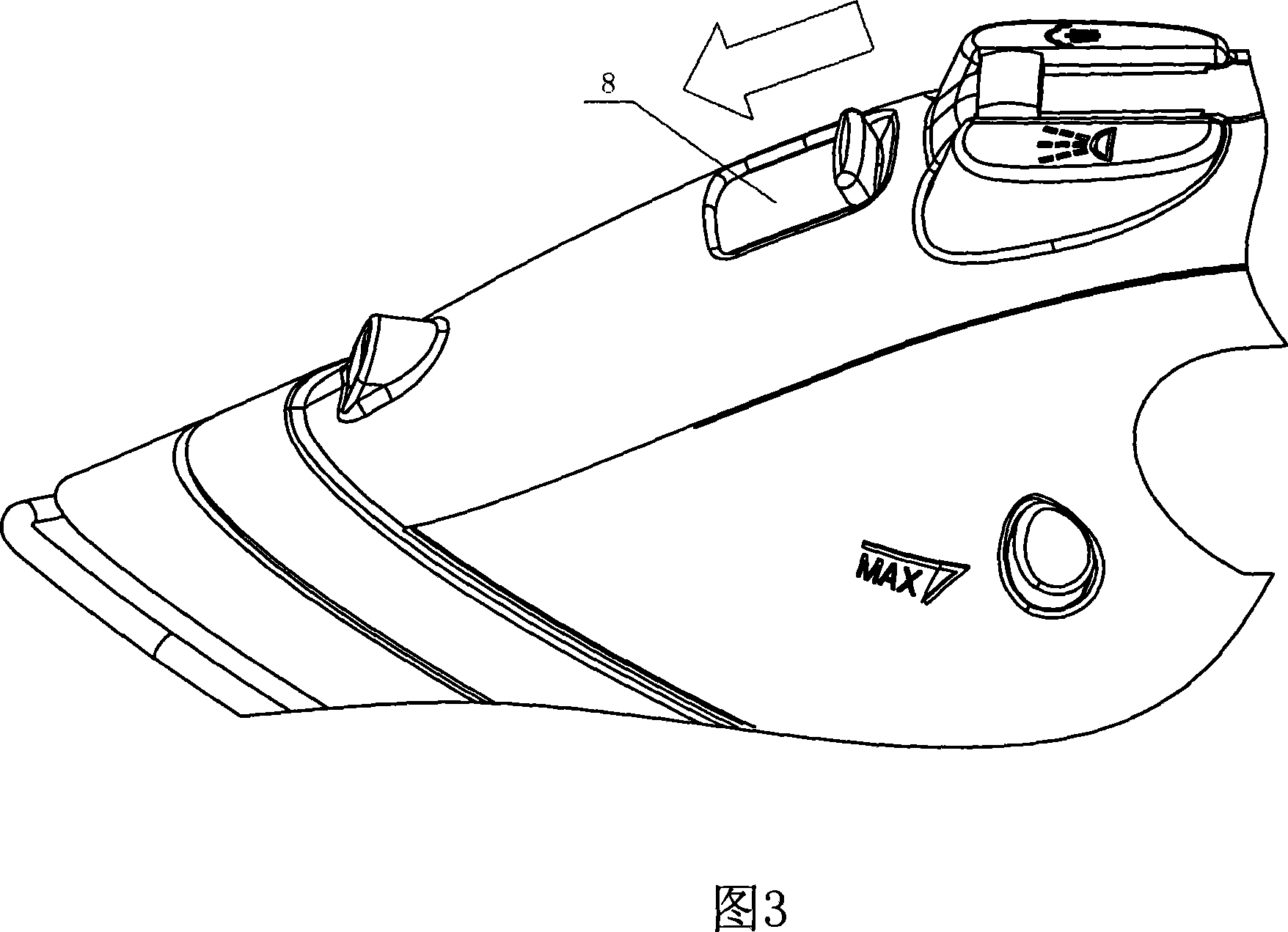

[0028] Referring to Fig. 3, the water retaining cover shown adopts a push-pull structure. A slideway matching the shape of the water retaining cover 8 is provided on the housing near the water inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com