Patents

Literature

40results about How to "Implement the flipping action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

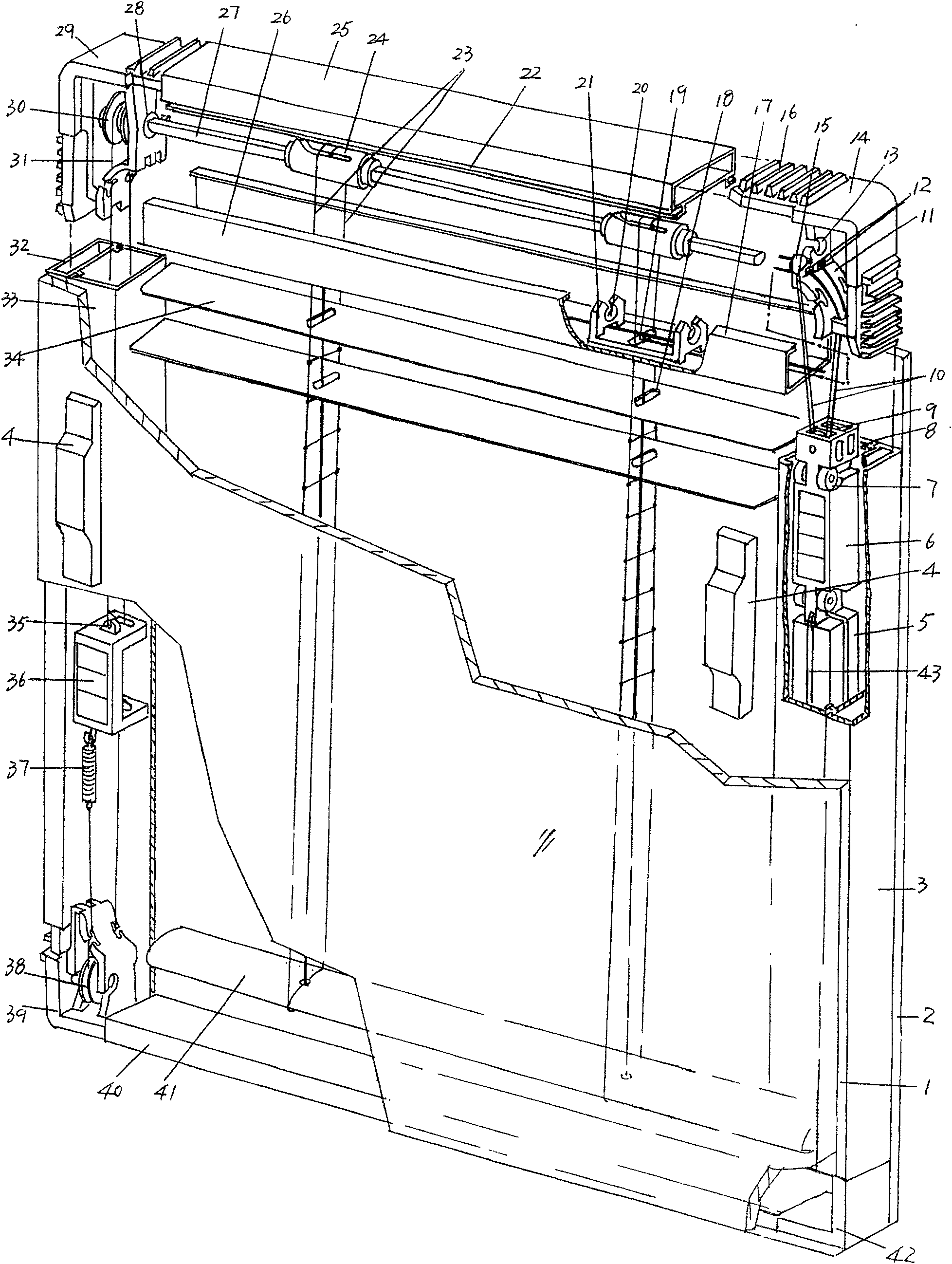

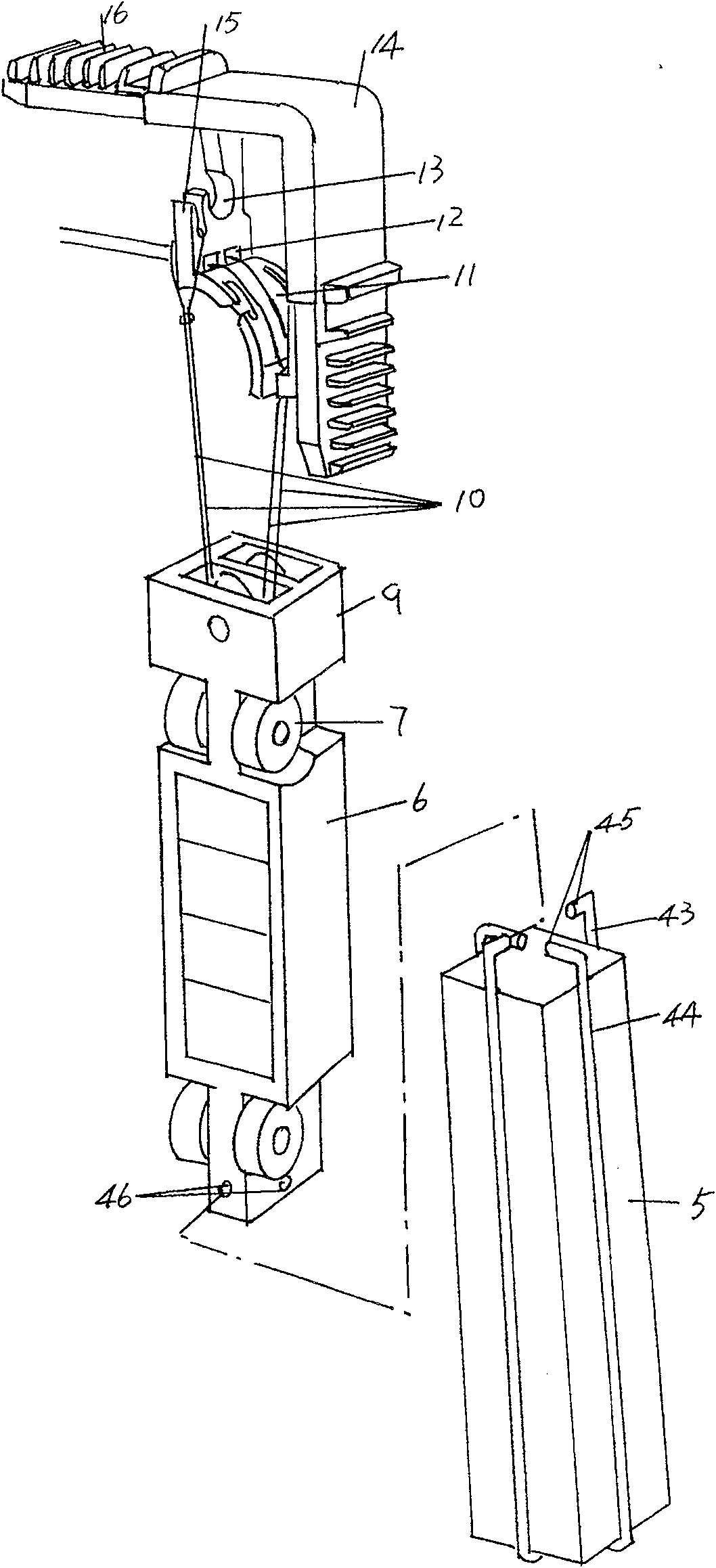

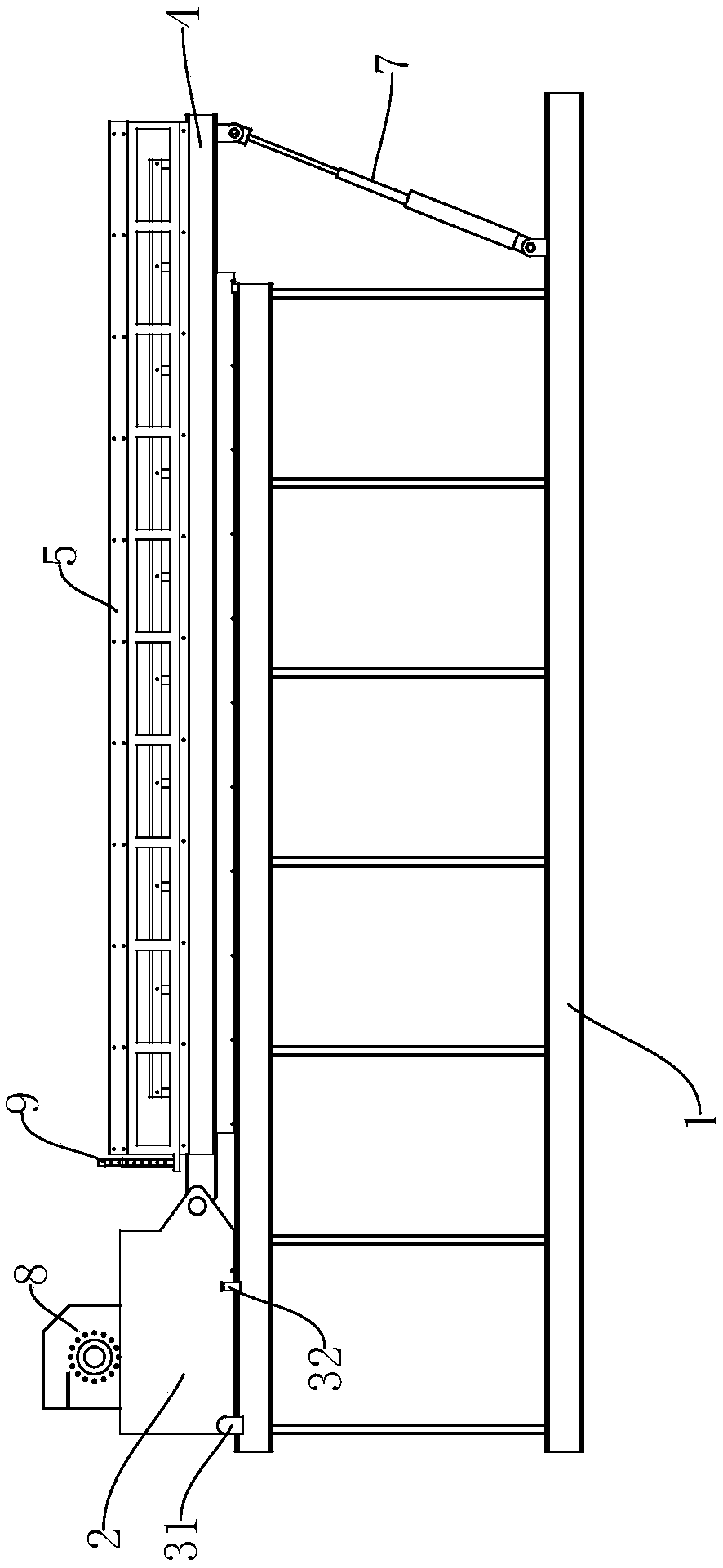

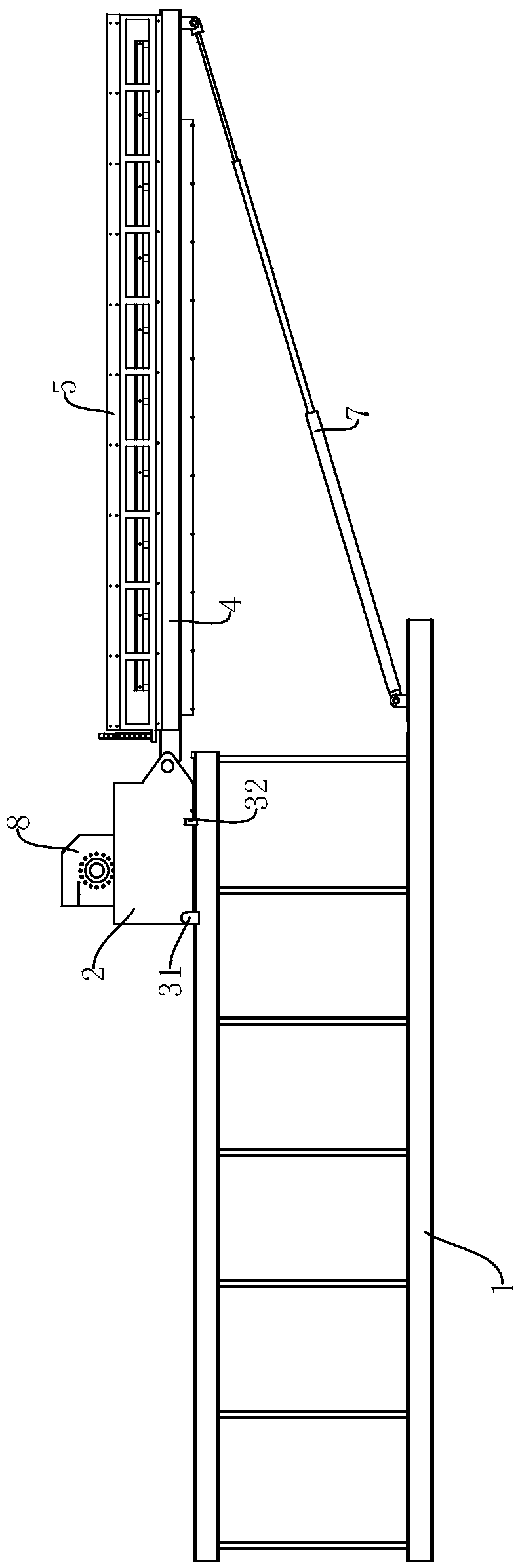

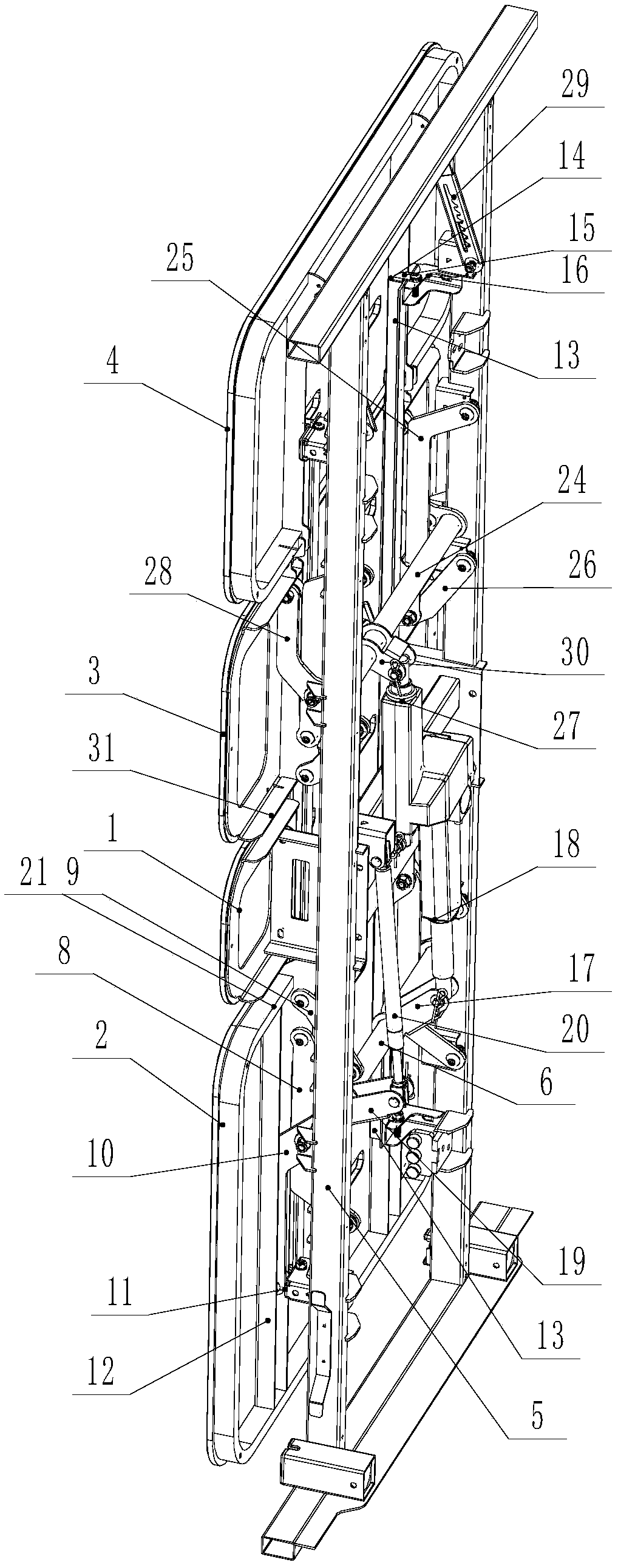

Structure-improved window shutter in hollow glass

ActiveCN100535378CImplement the flipping actionReduce manufacturing costLight protection screensWindow shutterEngineering

Owner:江苏中诚建材集团有限公司

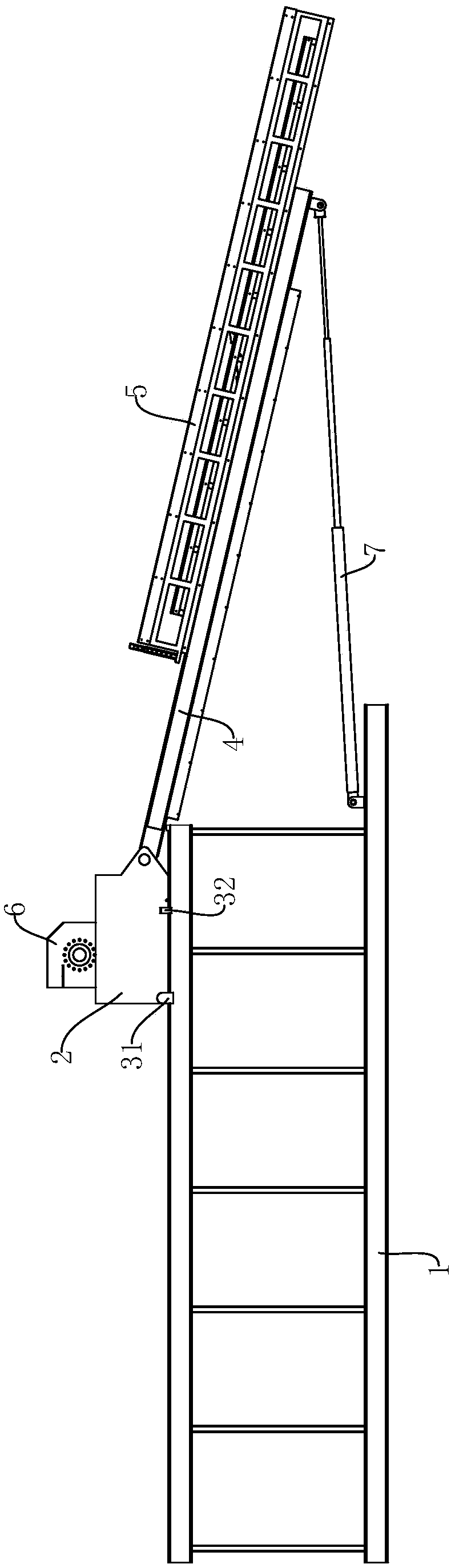

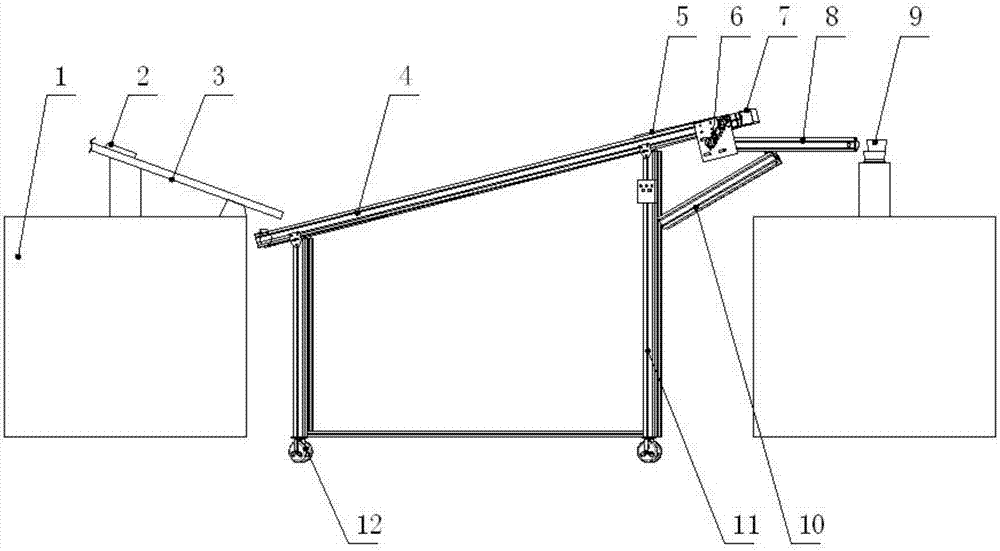

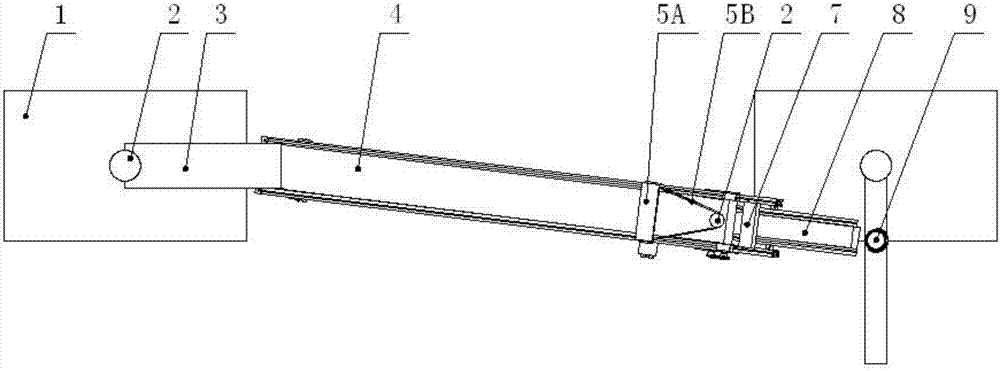

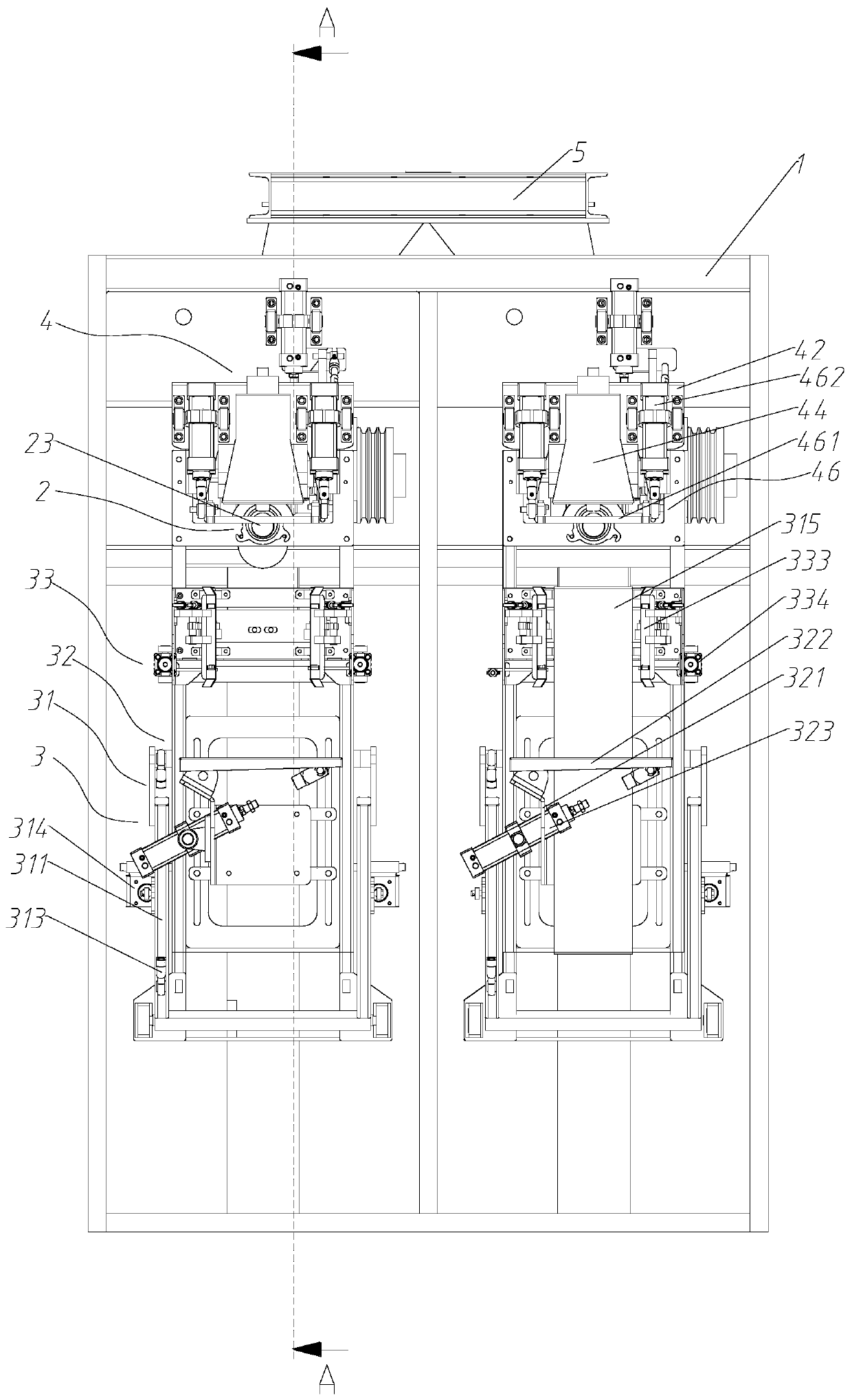

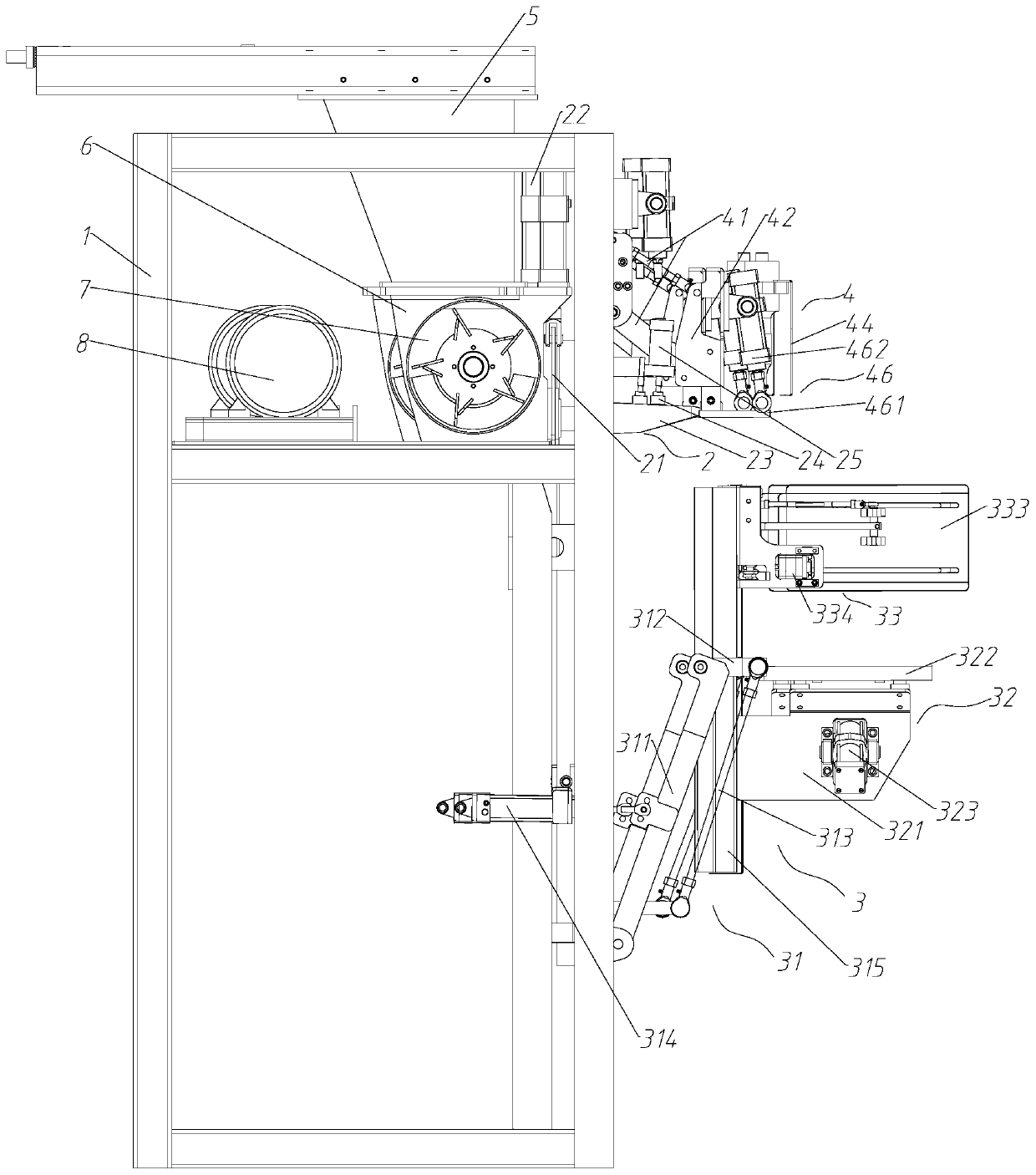

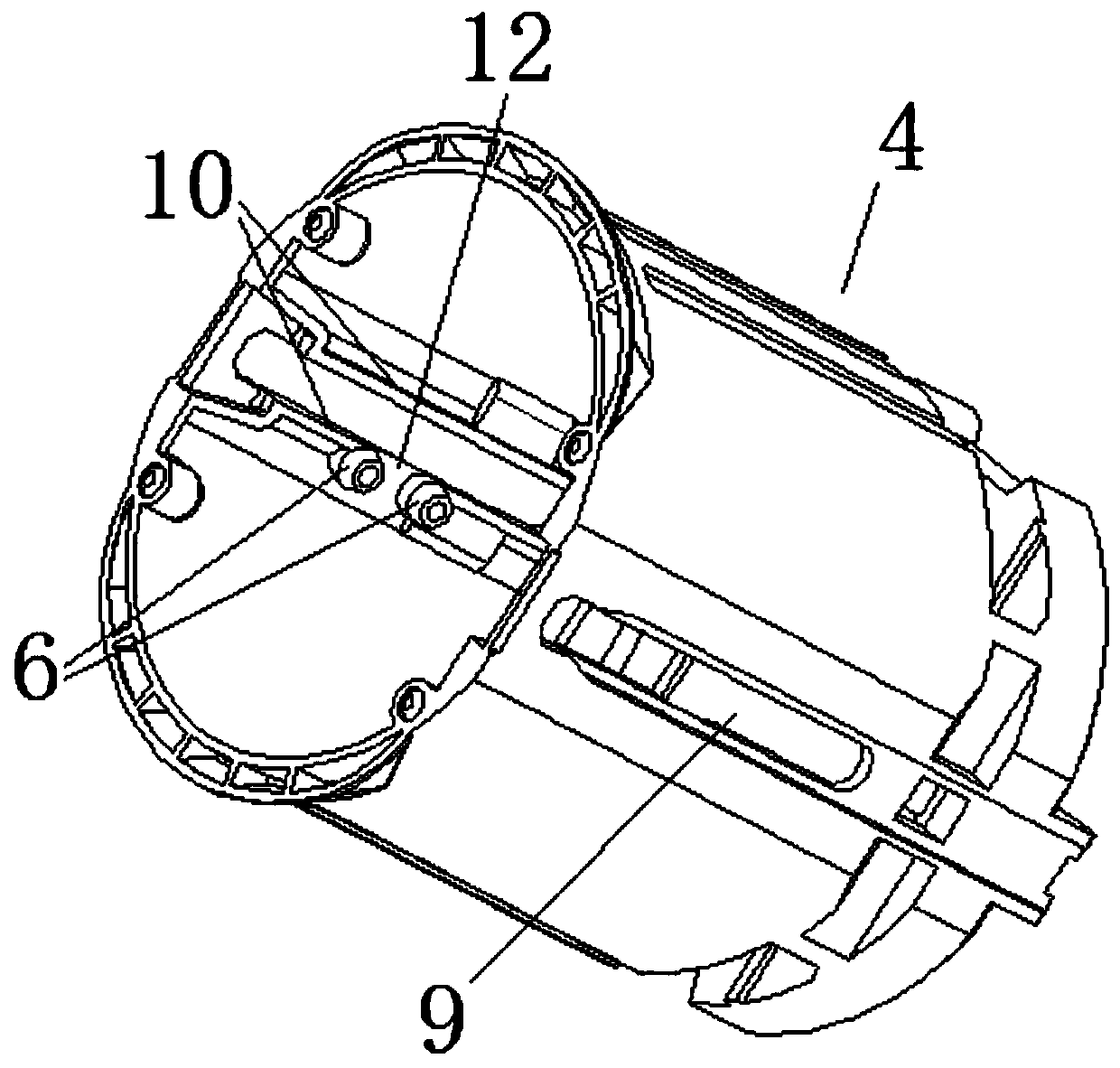

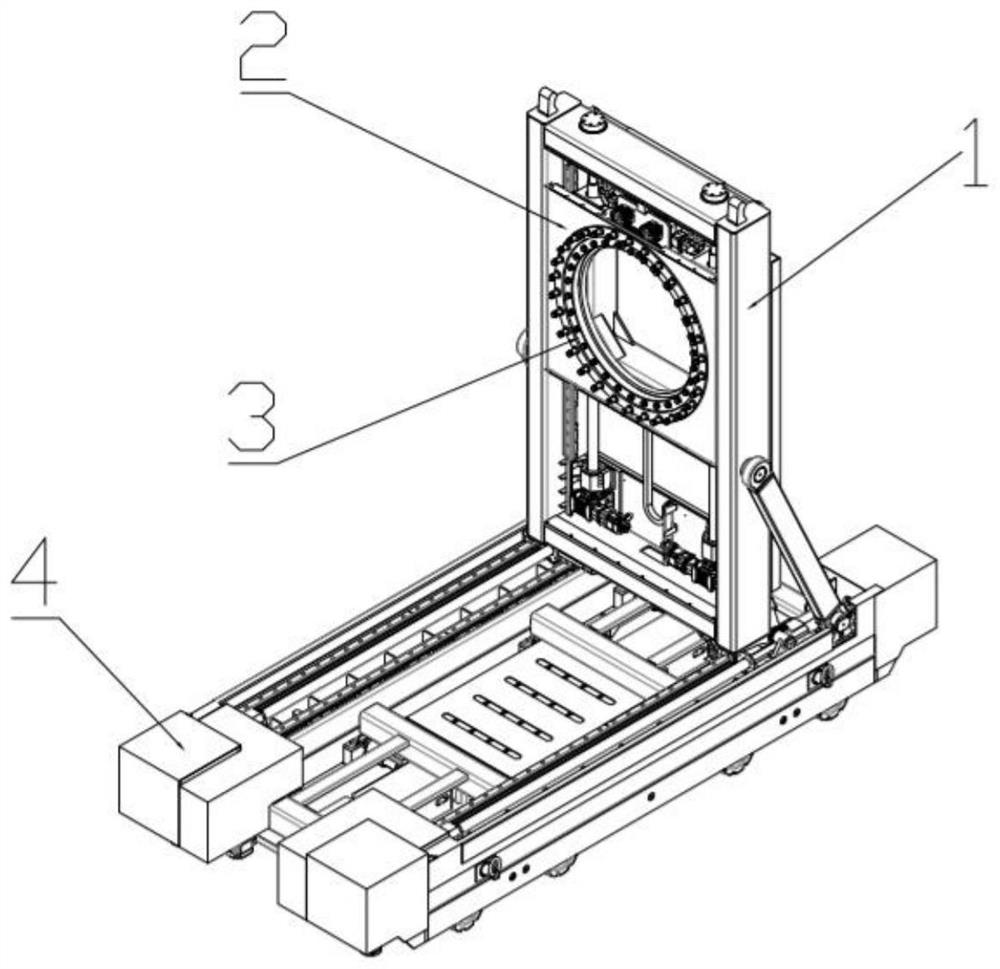

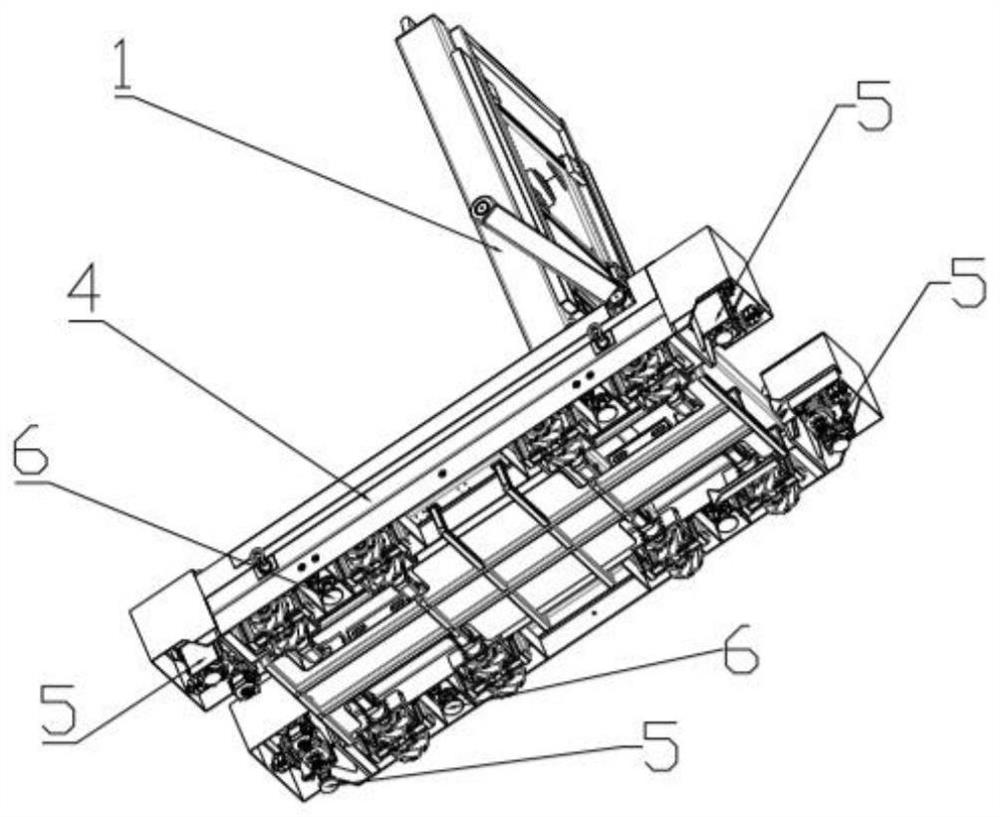

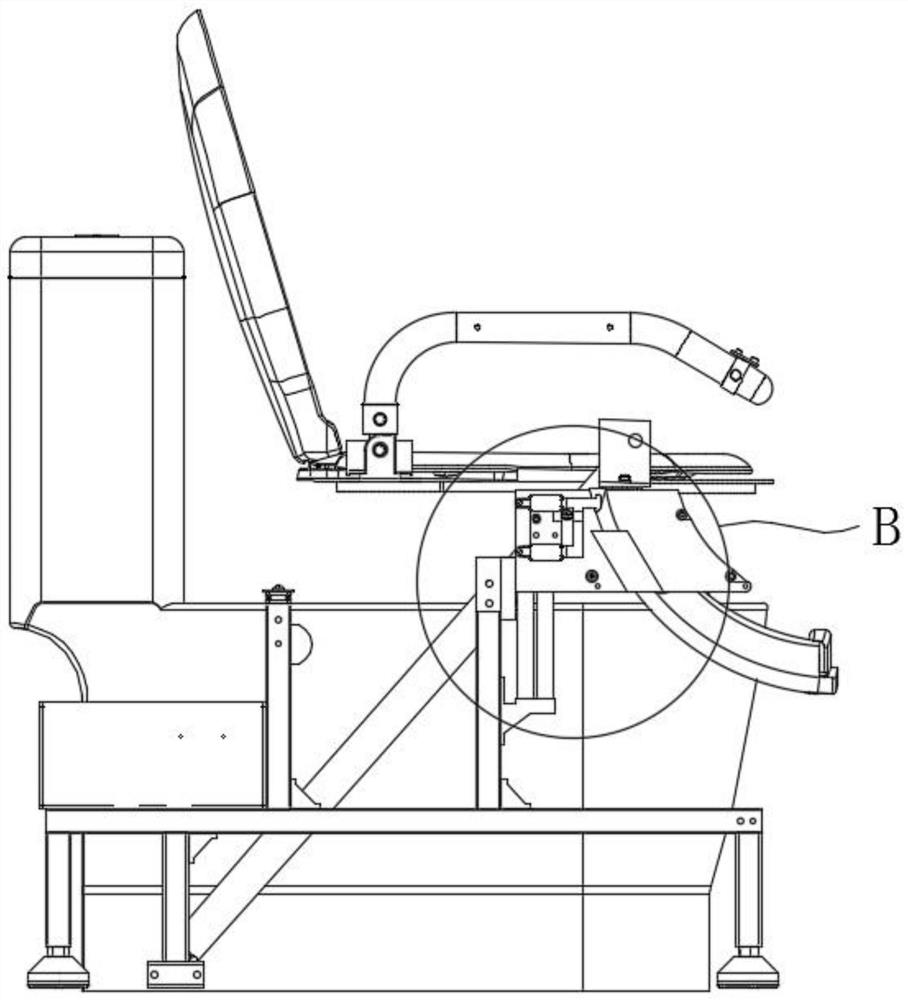

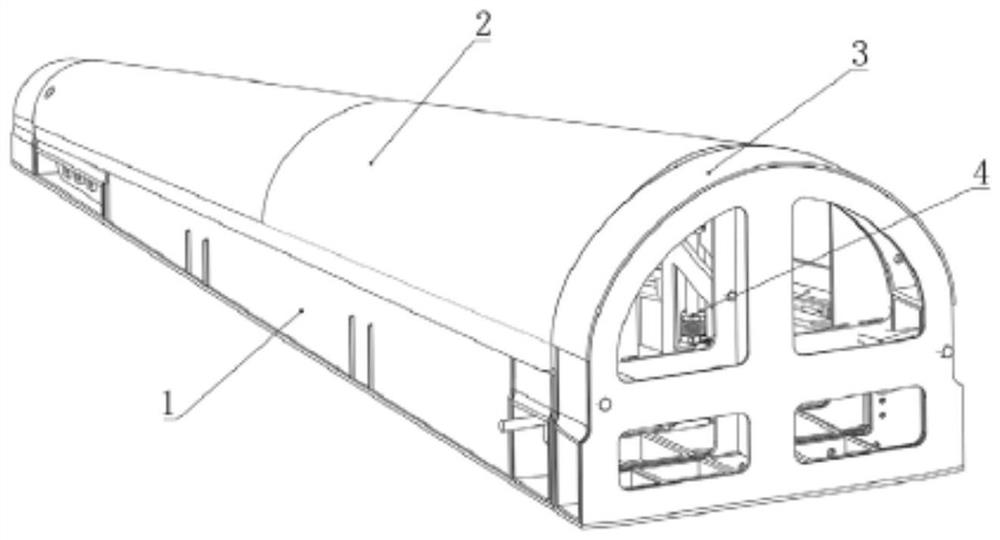

Underwater vehicle arranging and recovering device

PendingCN109606573AImplement the flipping actionRealize deploymentCargo handling apparatusPassenger handling apparatusMarine engineeringUnderwater vehicle

The invention relates to the field of underwater vehicle arranging and recovering devices and discloses an underwater vehicle arranging and recovering device. The underwater vehicle arranging and recovering device is characterized by comprising a fixed rack, a trolley, a walking assembly, a rotating bracket, a sliding bracket, a bracket driving assembly, a telescopic supporting assembly, a traction rope and a traction rope reeling and unreeling assembly arranged on the trolley for reeling and unreeling the traction rope. A first track arranged in the first direction is arranged on the fixed rack and the trolley is slidably arranged on the first track; the trolley is rotatably connected to one end of the rotating bracket, and the rotating bracket can be slidably arranged on the fixed rack in the first direction to drive the trolley and the rotating bracket to slide in the first direction on the fixed rack through the walking assembly so as to further push the rotating bracket away fromthe fixed rack. By implementing the technical scheme, the underwater vehicle arranging and recovering device is simple in structure and reasonable in arrangement, can be simply mounted on a common master ship for arranging and recovering work, is high in universality and can arrange and recover an underwater vehicle reliably.

Owner:CHINA NAT OFFSHORE OIL CORP +2

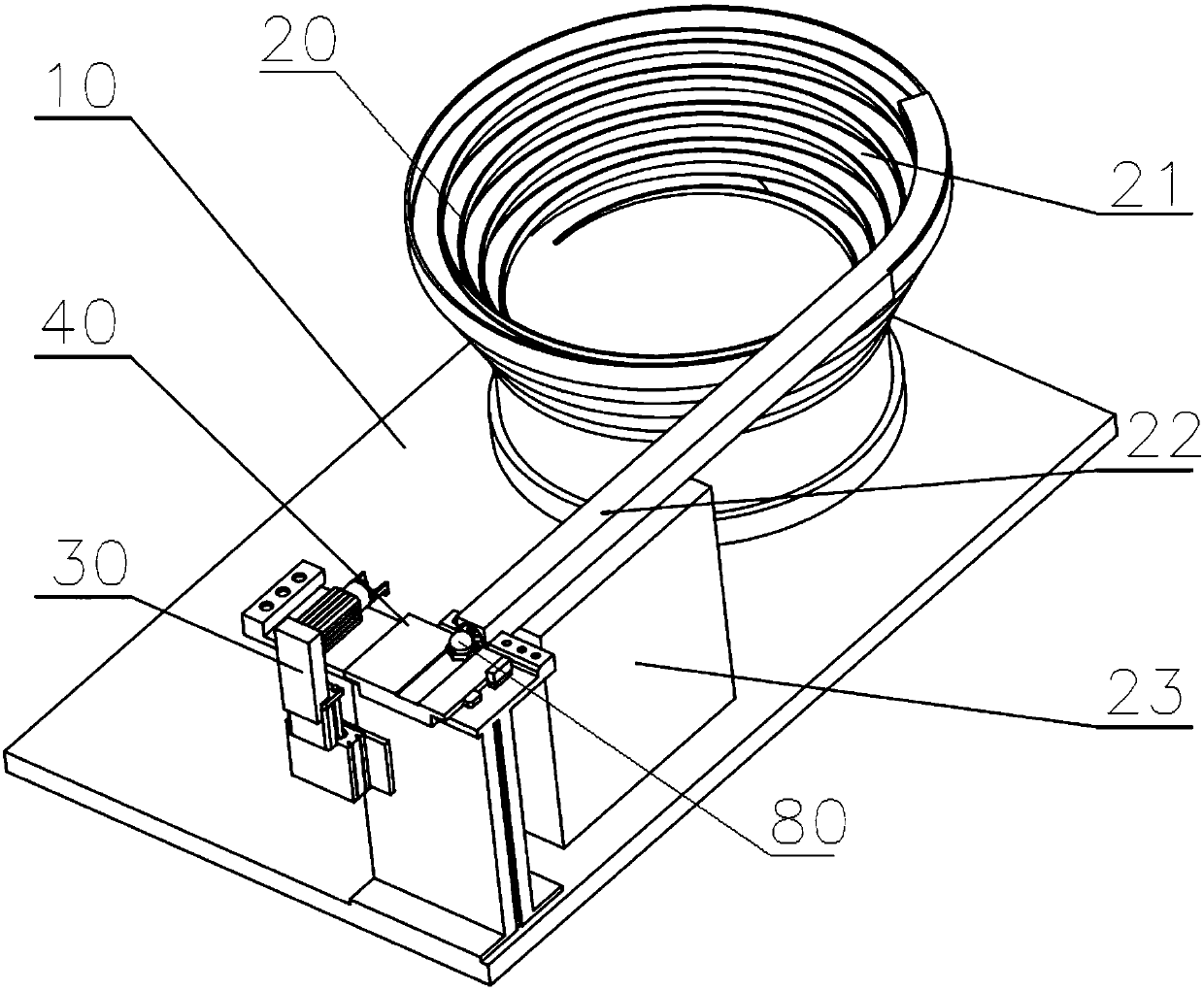

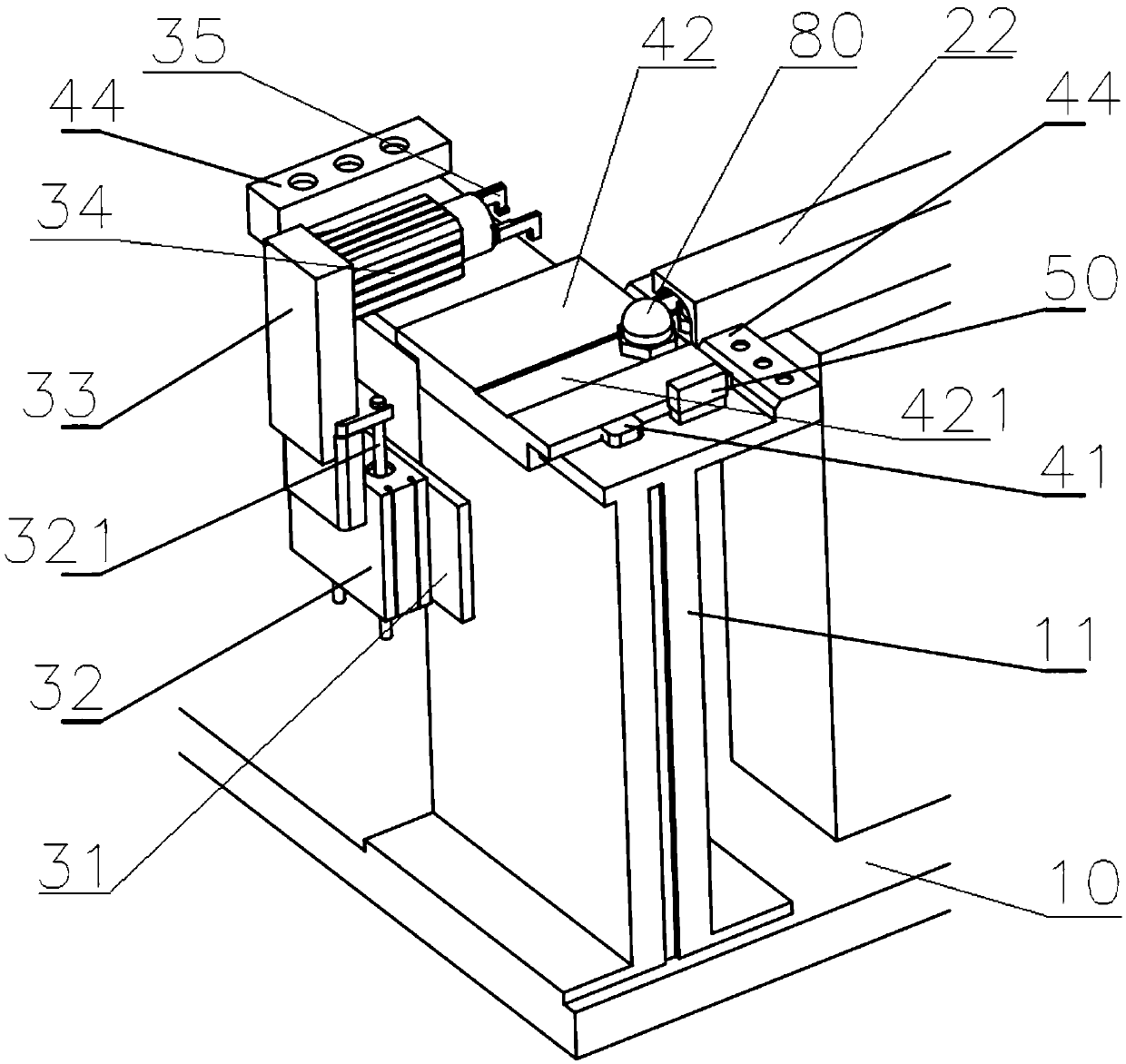

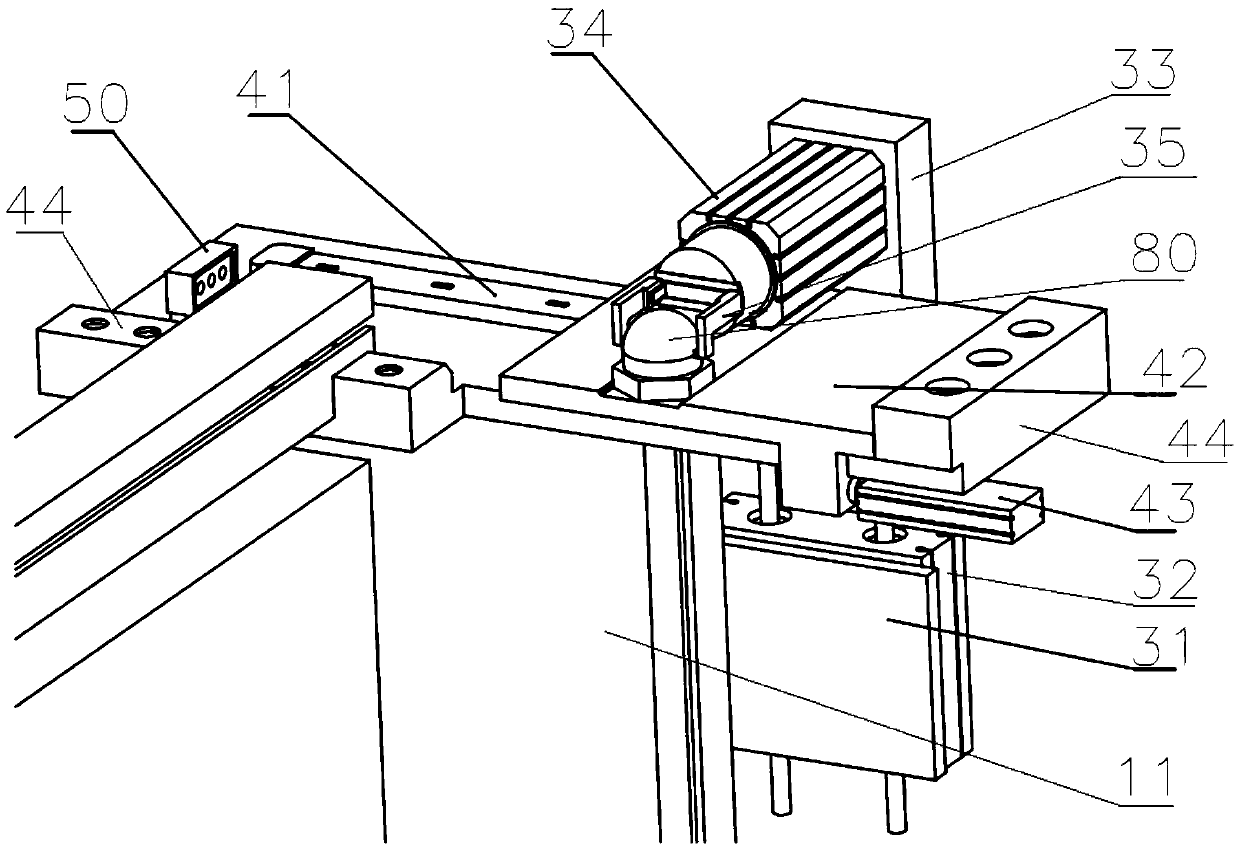

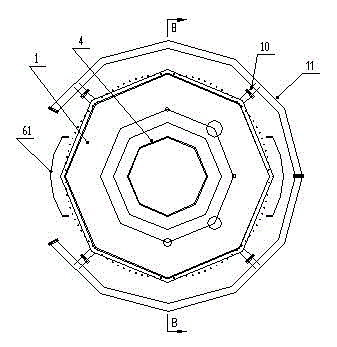

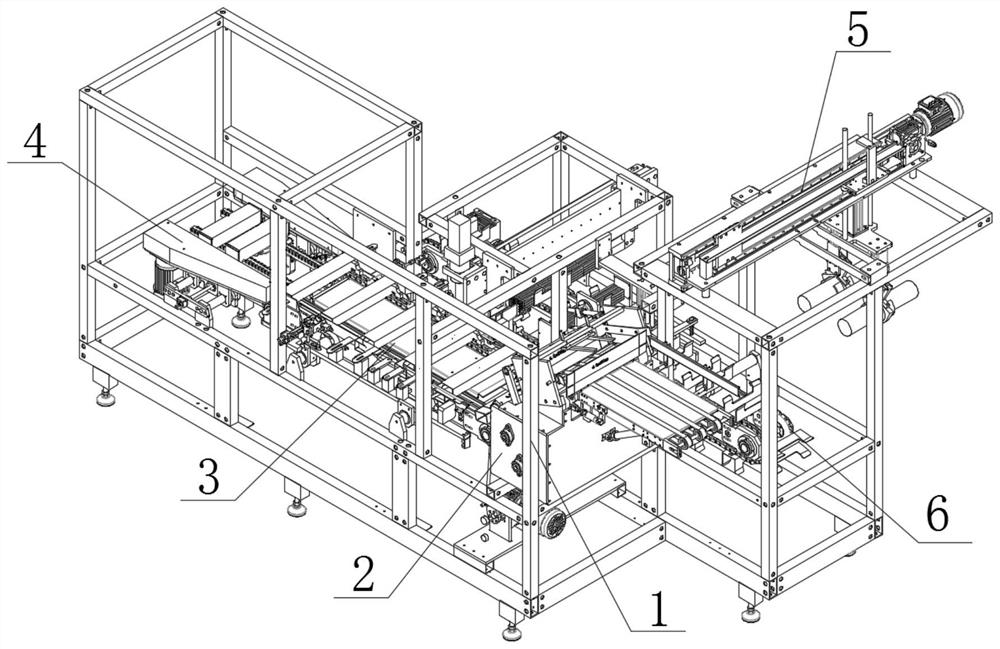

Cover-type nut automatic feeding equipment and feeding method

PendingCN109625858AAchieve crawlingImplement the flipping actionMetal working apparatusJigging conveyorsProduction lineManipulator

The invention relates to cover-type nut automatic feeding equipment and feeding method. The cover-type nut automatic feeding equipment comprises a bottom plate, a feeding mechanism, a lifting gripper,a material transferring mechanism and a material taking manipulator, wherein the feeding mechanism comprises a nut vibrating disk, a feeding rail and a linear vibrator, the lifting gripper comprisesa fixed plate, a lifting air cylinder, a connecting plate, a turnover air cylinder and a telescopic clamp, a lifting rod of the lifting air cylinder is connected with a motor of the turnover air cylinder through a connecting plate, and a rotating disc of the turnover air cylinder is connected with the telescopic clamp. The material transferring mechanism comprises a sliding rail, a material transferring plate and a material transferring air cylinder, wherein the sliding rail is arranged on the upper surface of the supporting table, the material transferring plate is connected with the slidingrail in a sliding manner, and a sliding rod of the material shifting air cylinder is connected with the material transferring plate. A groove is formed in the material transferring plate, when the material transferring plate slides to the end close to the feeding rail, the groove is connected with a feeding rail outlet, and when the material transferring plate slides to the end close to the lifting gripper, the groove is located under the telescopic clamp. The cover-type nut automatic feeding equipment can solve the problem of sequential feeding of cover-type nuts in automatic production and can be matched with a full-automatic production line for use.

Owner:江苏氢璞创能科技有限公司

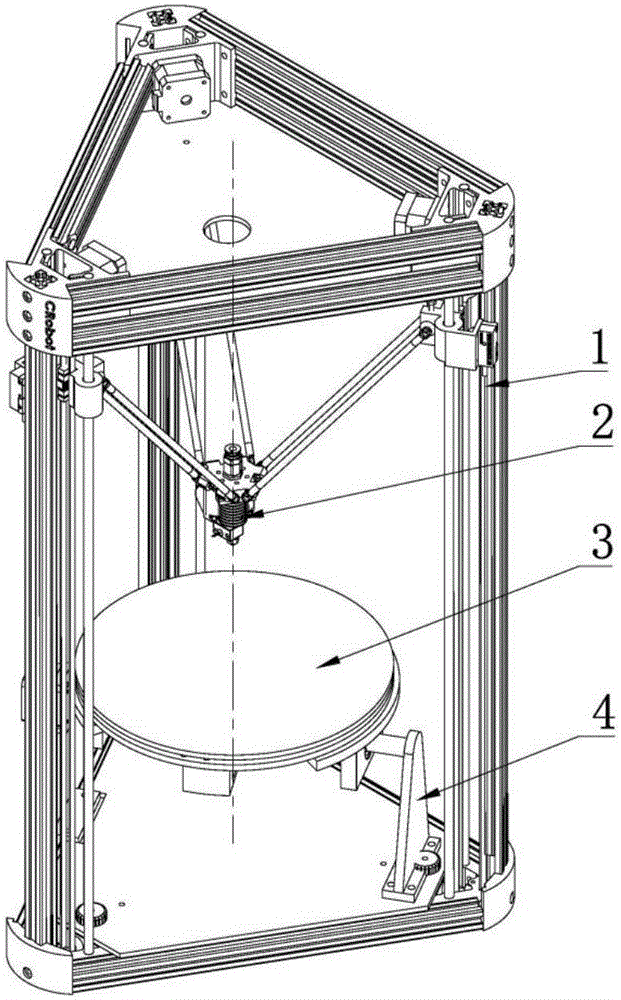

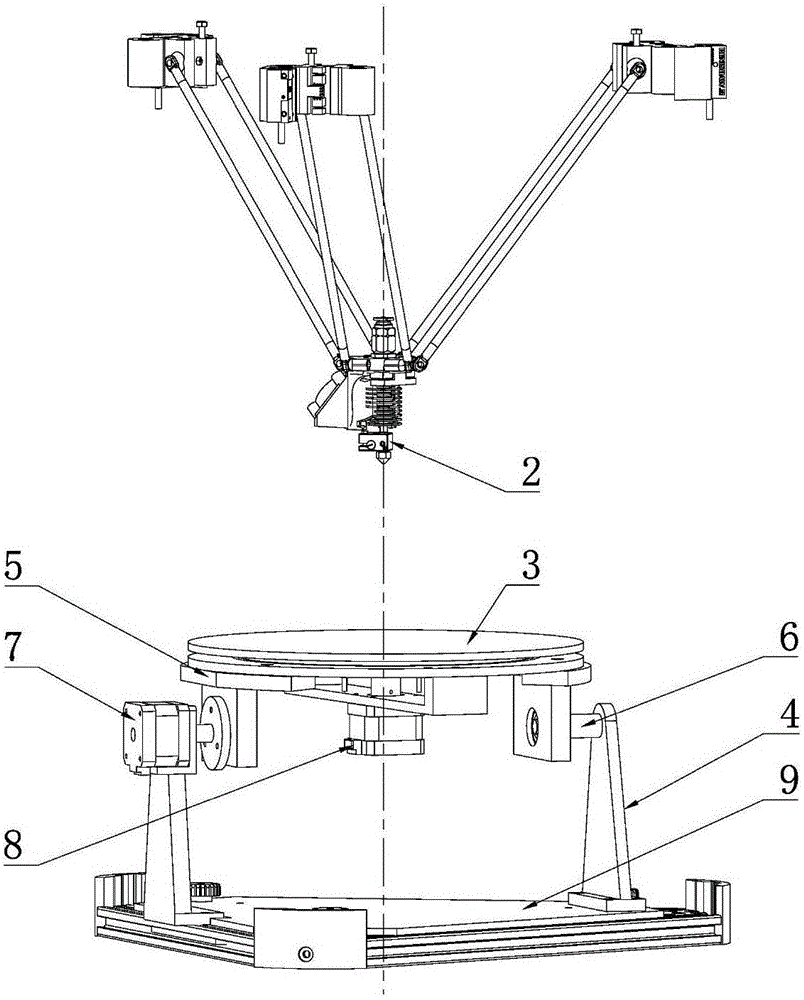

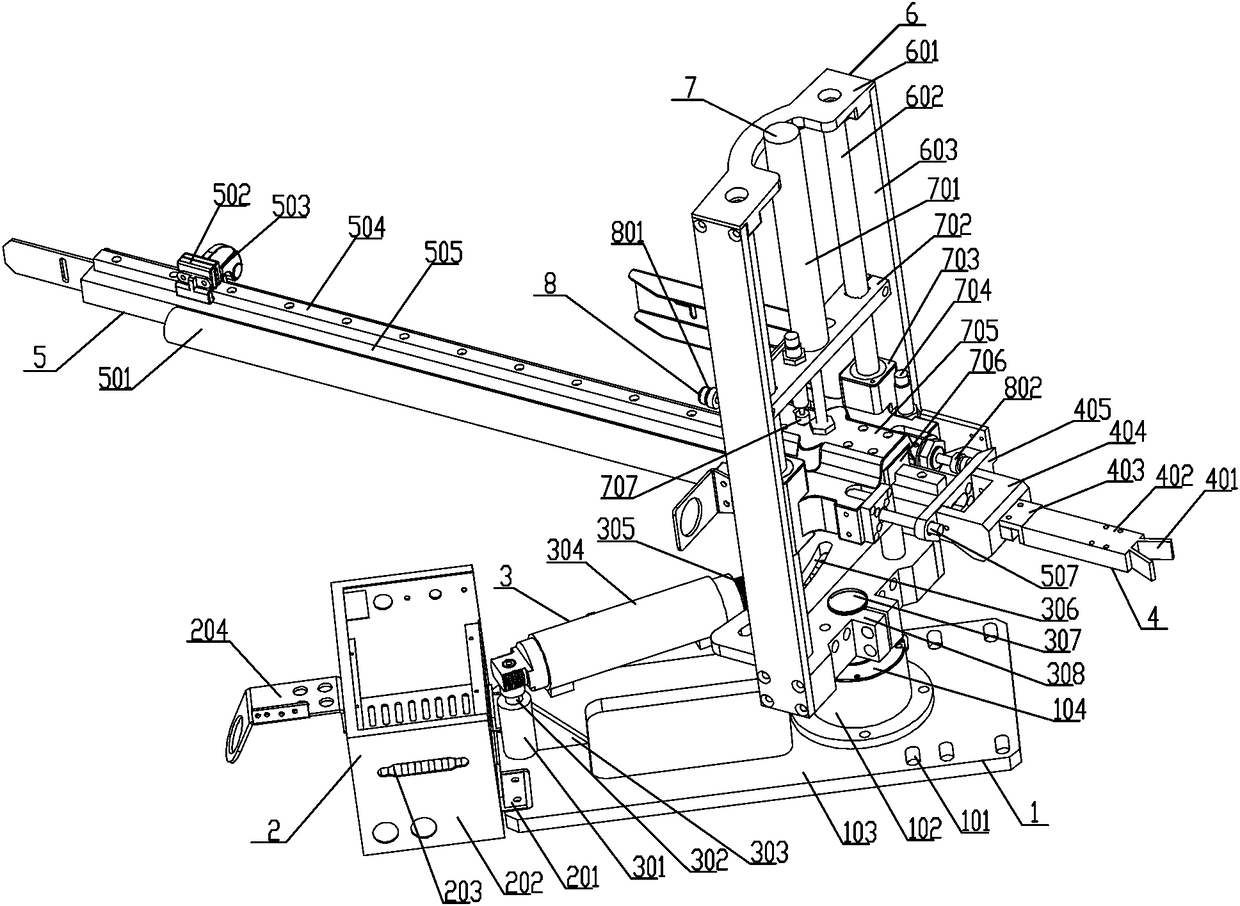

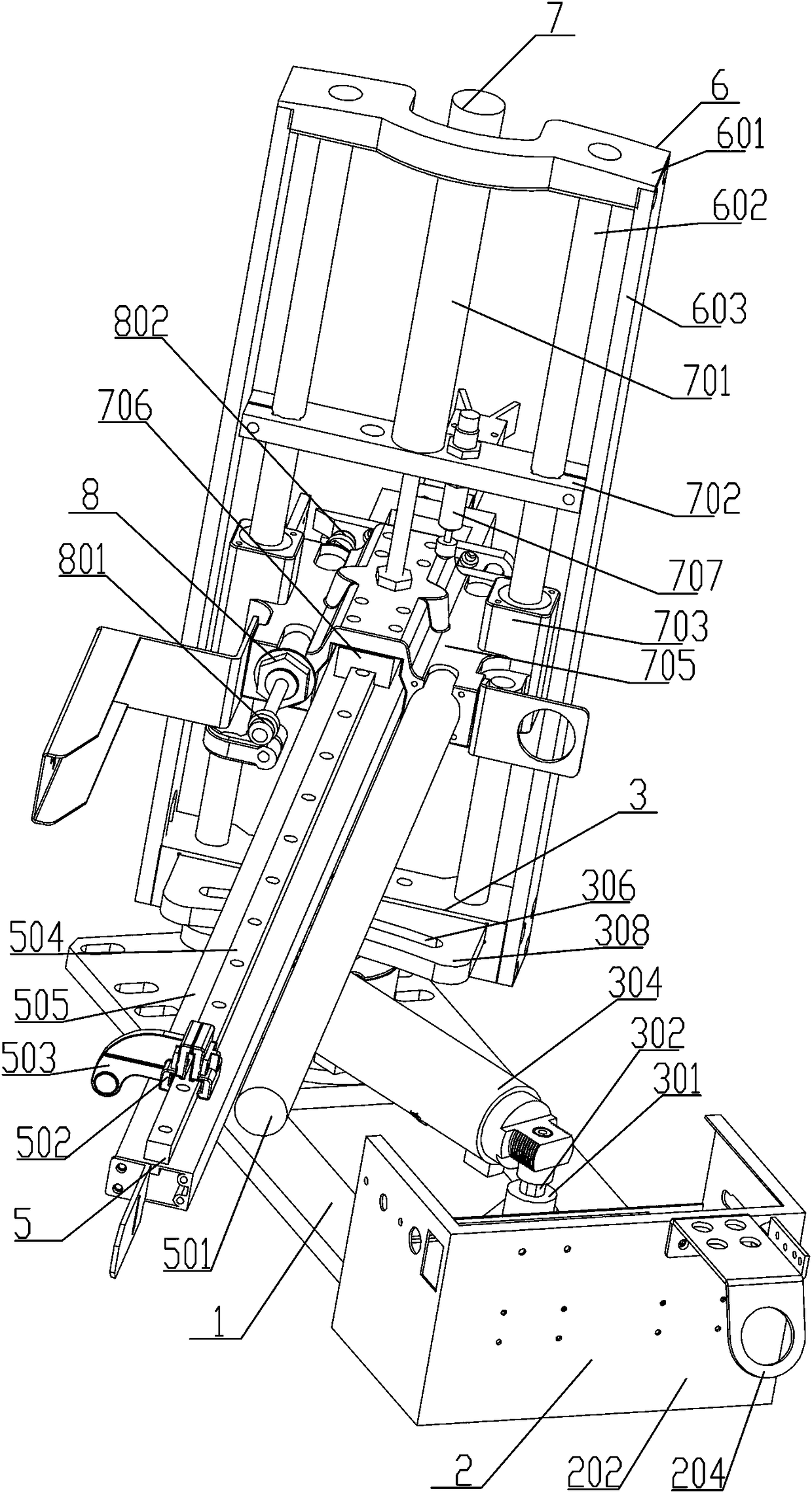

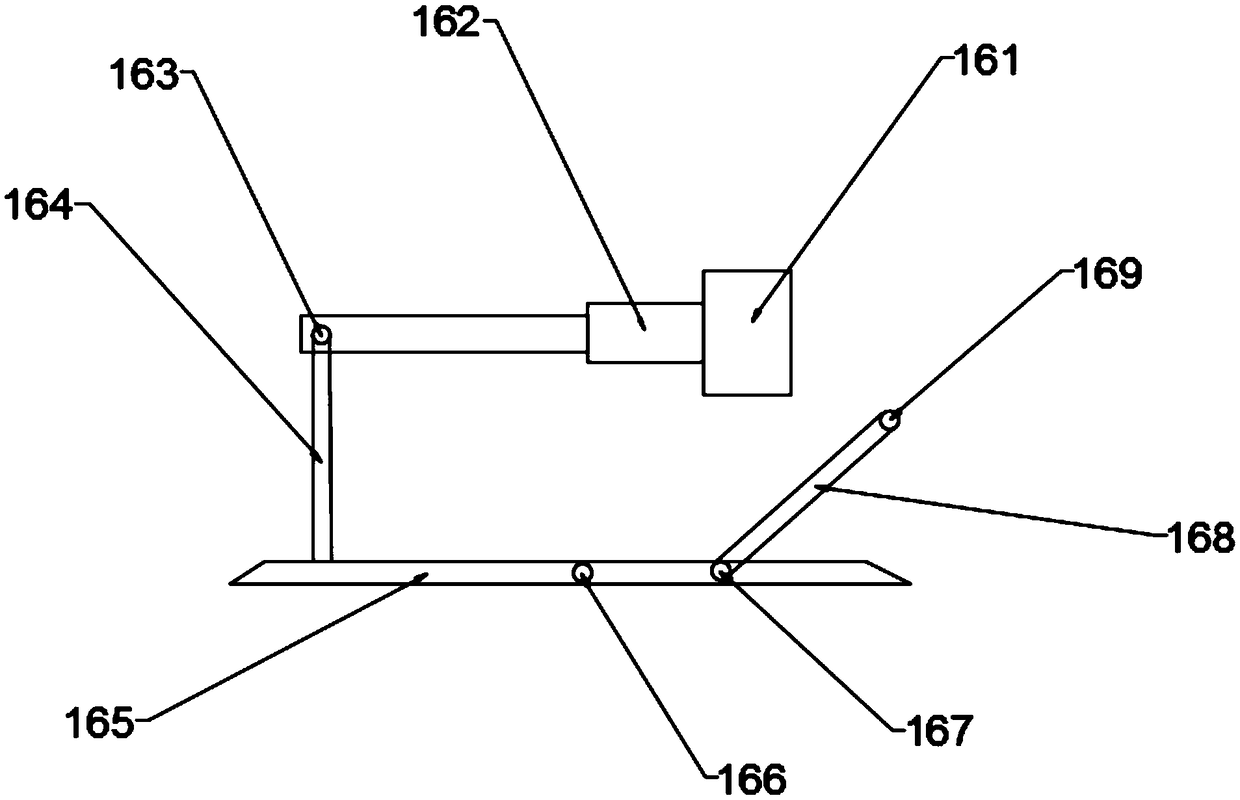

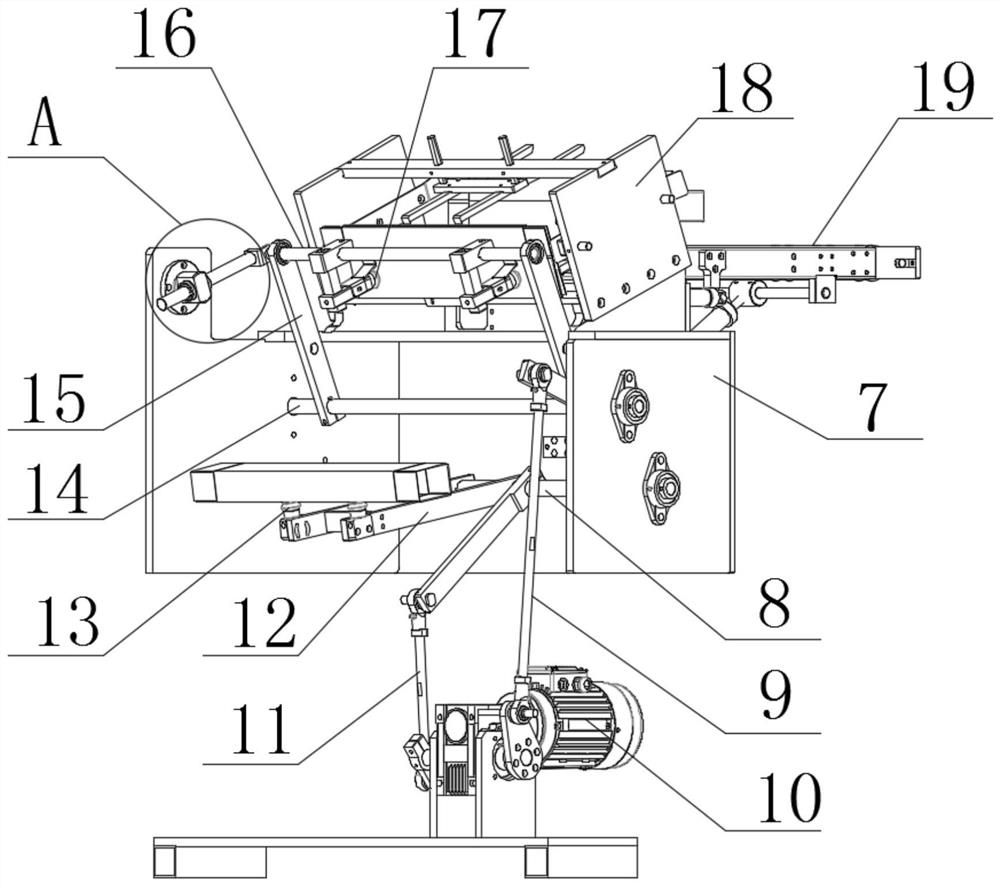

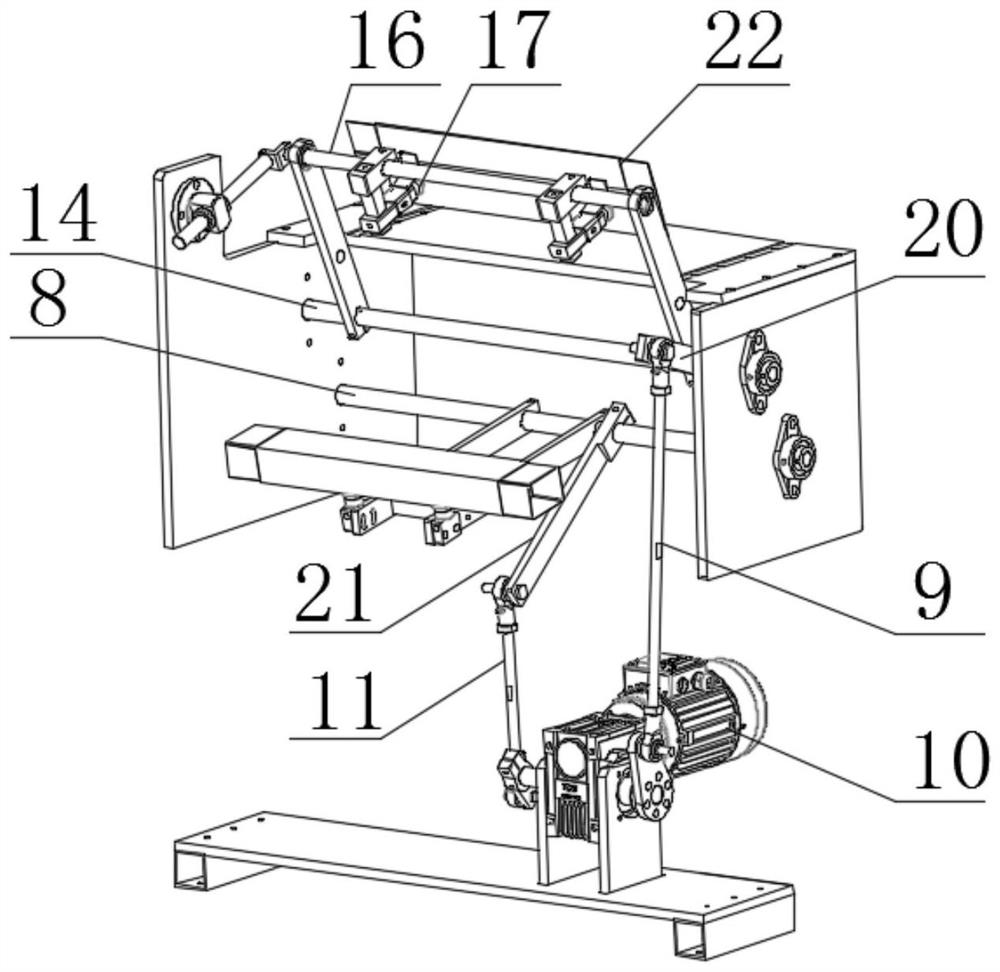

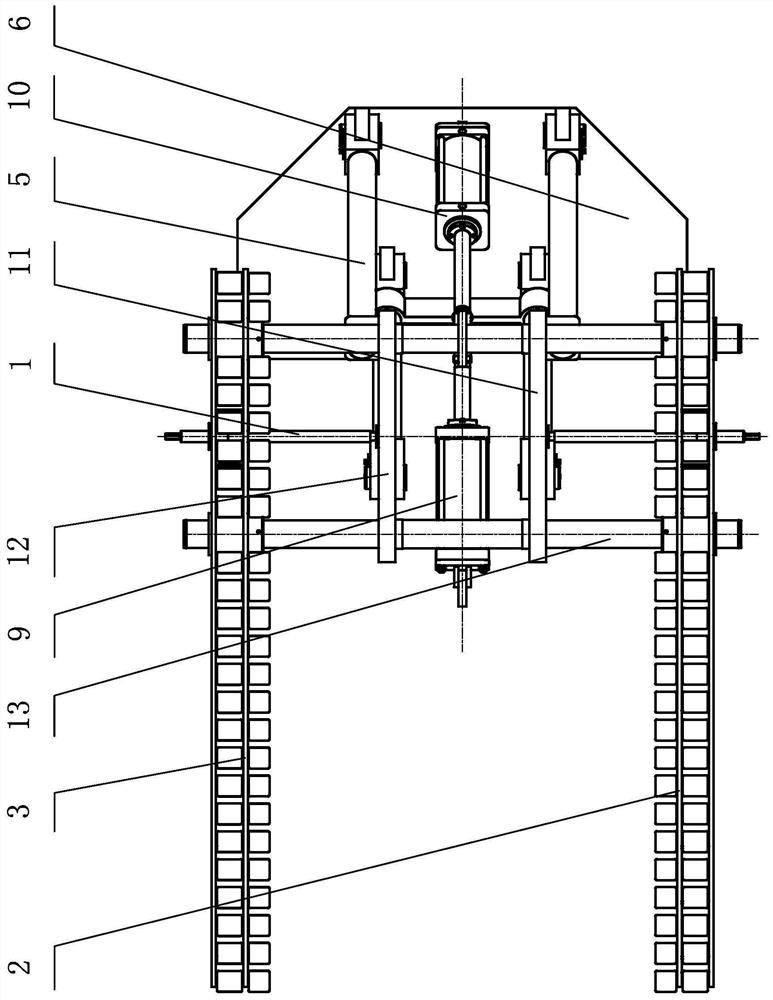

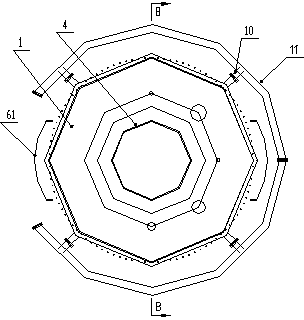

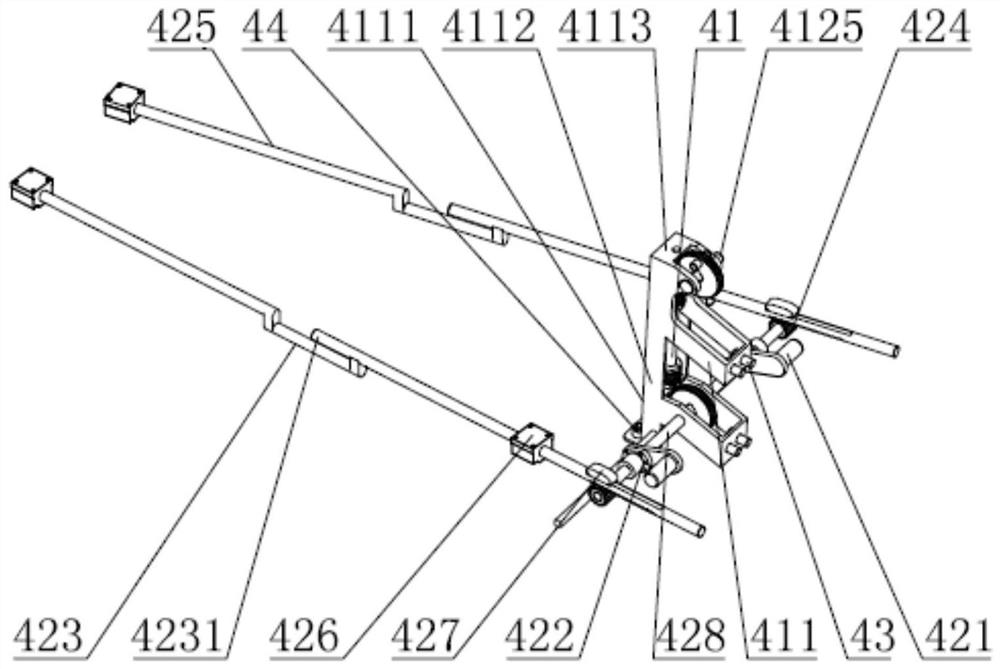

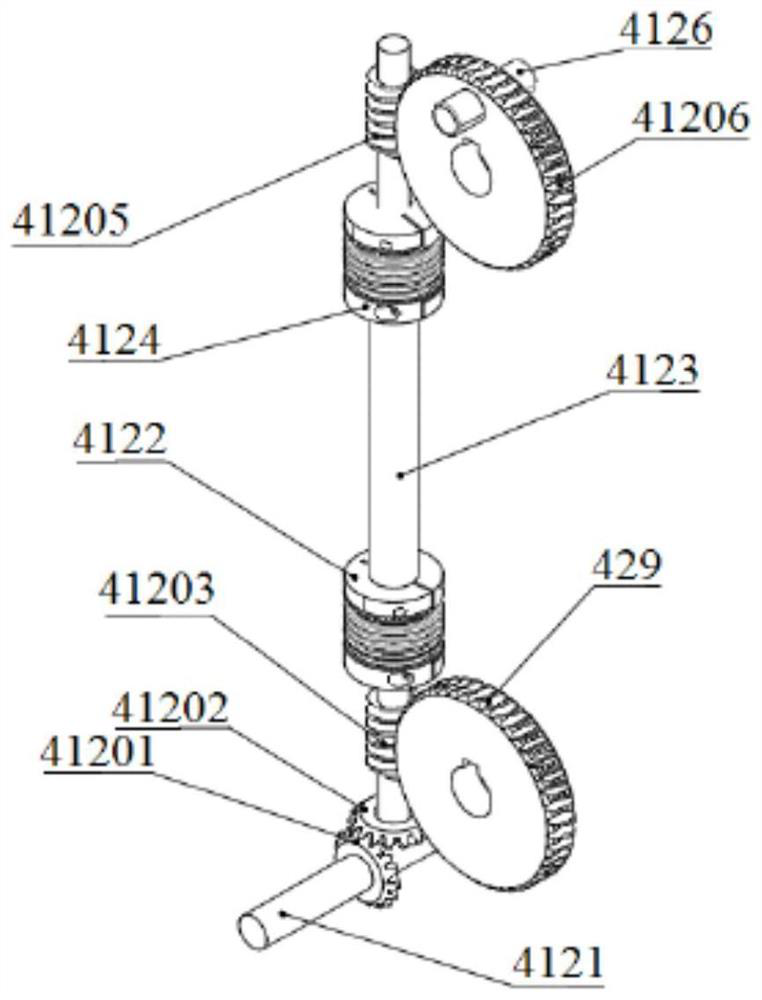

Double-rotating-shaft composite 3D printer based on Delta structure

PendingCN106738919AAchieve self-rotationImplement the flipping actionManufacturing platforms/substratesManufacturing driving meansEngineering3D printing

The invention discloses a double-rotating-shaft composite 3D printer based on a Delta structure. A double-rotating-shaft 3D printing platform is arranged. The double-rotating-shaft 3D printing platform is arranged on a 3D printer base, is located under a printing head of a 3D printer and can do self-rotation and turnover actions. By means of the double-rotating-shaft composite 3D printer, the self-rotation and turnover actions of the platform can be achieved, expandability is high, and the double-rotating-shaft composite 3D printer can meet requirements of different printing product sizes and is compact in structure, convenient and fast to install and high in practicability.

Owner:武汉古工道科技有限公司

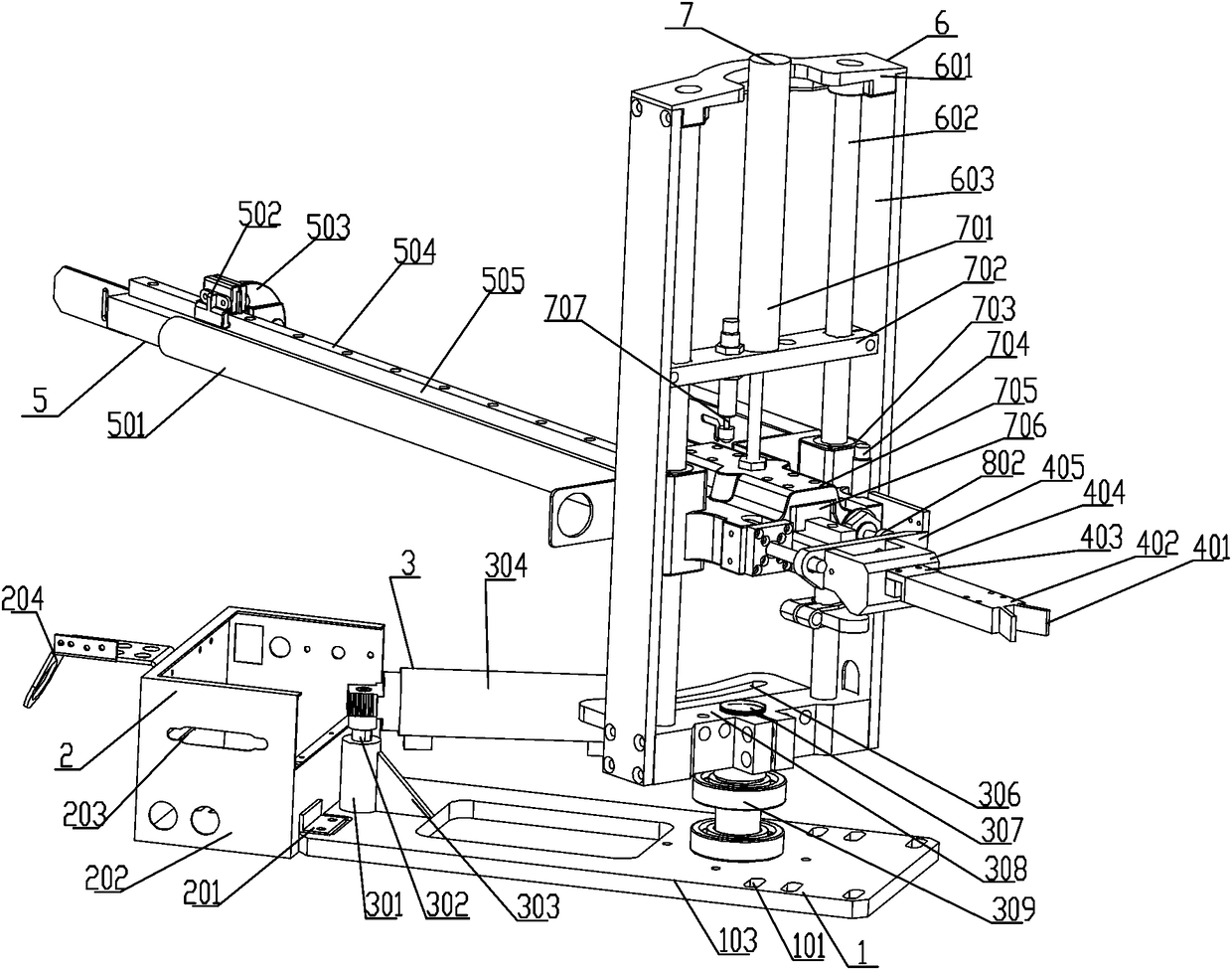

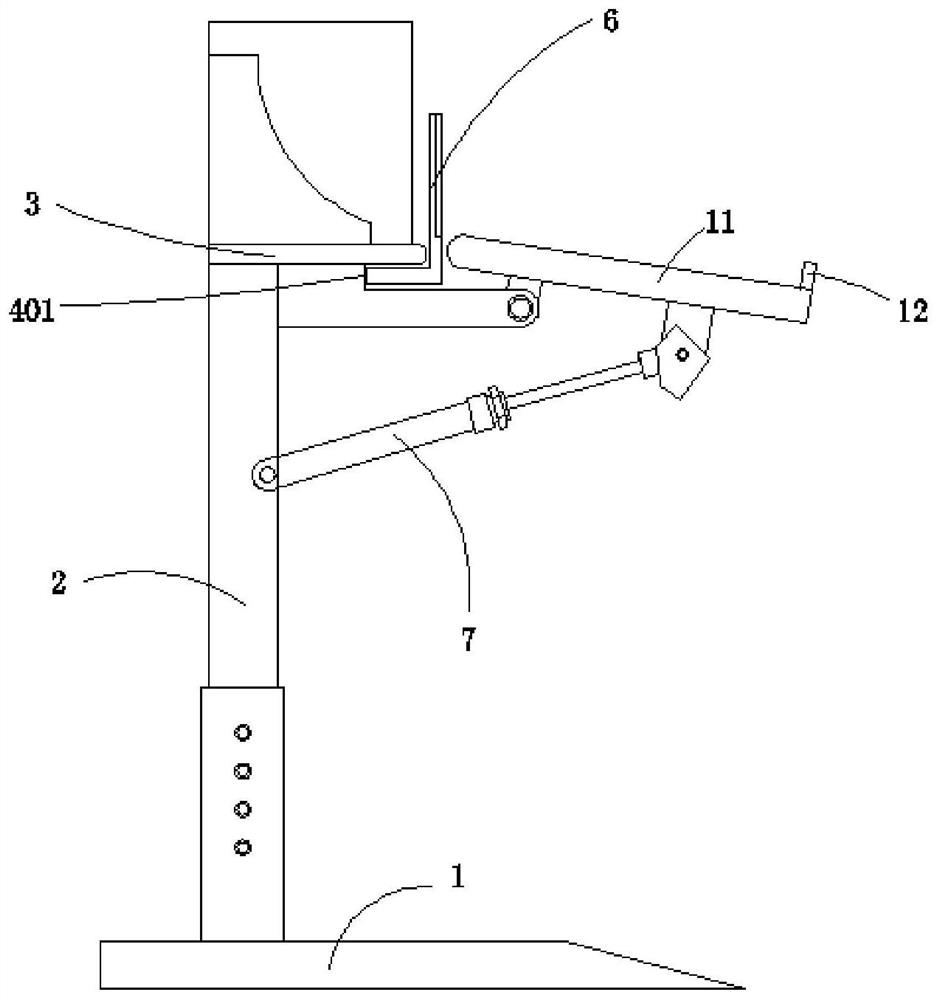

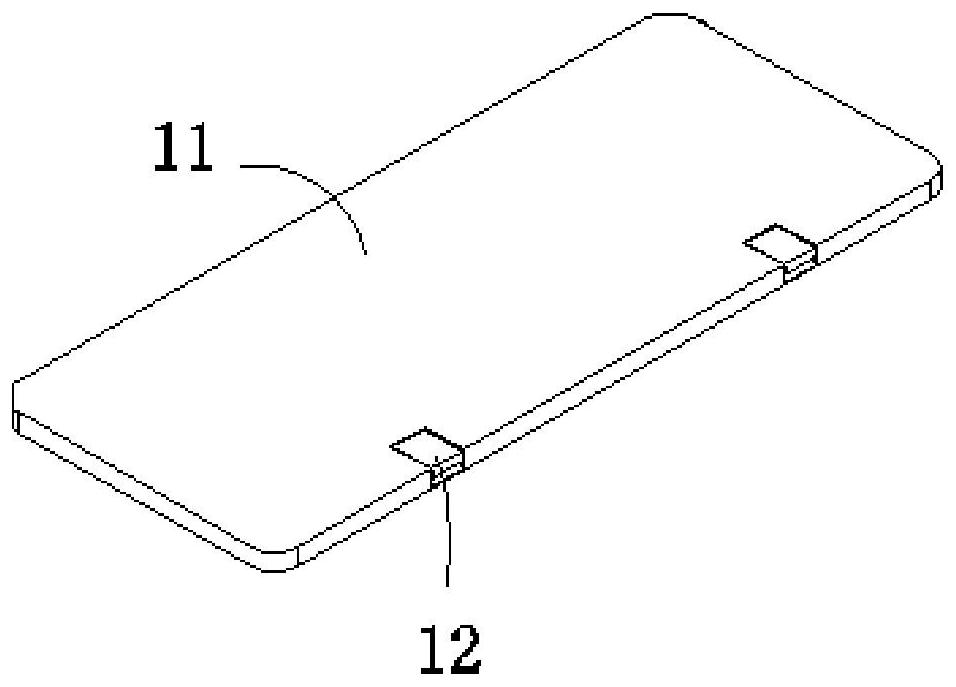

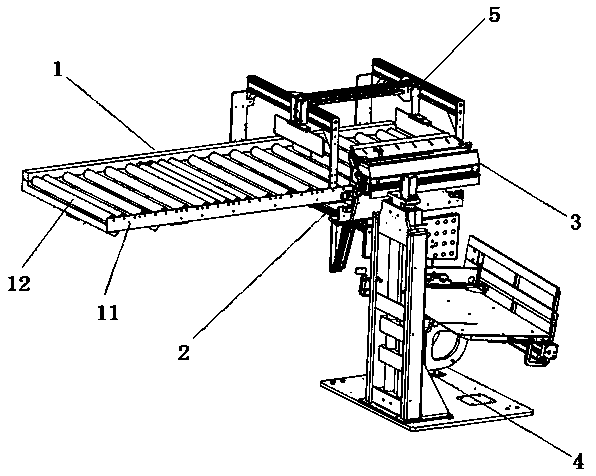

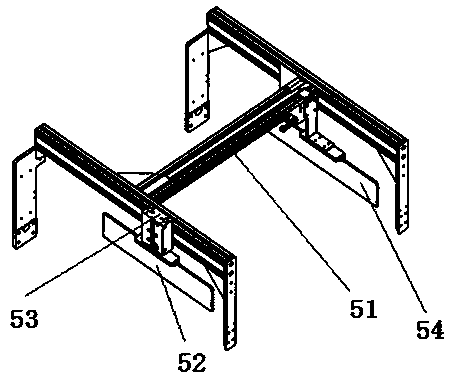

Multi-degree-of-freedom manipulator for construction engineering and operation method

PendingCN108274451AImprove work efficiencyReduce work intensityProgramme-controlled manipulatorArchitectural engineeringMulti degree of freedom

The invention provides a multi-degree-of-freedom manipulator for construction engineering and an operation method. The manipulator comprises a supporting base structure used for supporting the whole manipulator, wherein an electric control device is arranged on one side of the tail part of the supporting base structure, a rotating power device used for driving the manipulator to rotate along the vertical axis is arranged at the top of the supporting base structure, and a top frame structure is supported on a rotating base of the rotating power device; and the top frame structure is provided with a lifting mechanism used for driving the manipulator to vertically ascend and descend, a telescopic mechanism used for driving the manipulator to do telescopic motion is arranged on a lifting baseof the lifting mechanism, and a head of a telescopic beam of the telescopic mechanism is fixedly provided with a manipulator assembly used for implementing grabbing motions. The multi-degree-of-freedom manipulator can be used for operation of grabbing and accurate placing in building construction, and replaces traditional manual workers for operation, so that working efficiency is improved, laborintensity of operators is effectively reduced, and the construction quality is guaranteed.

Owner:湖北乾奥建设工程有限公司

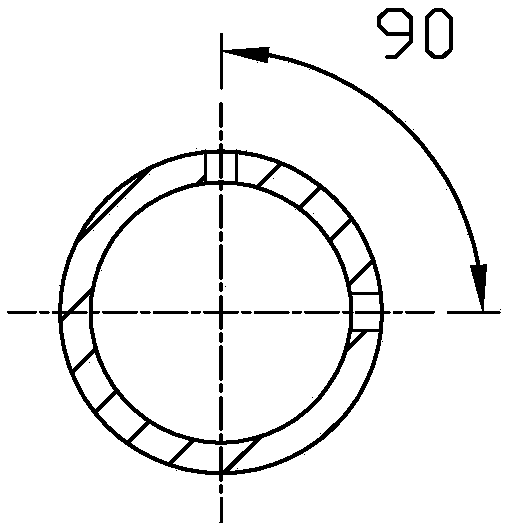

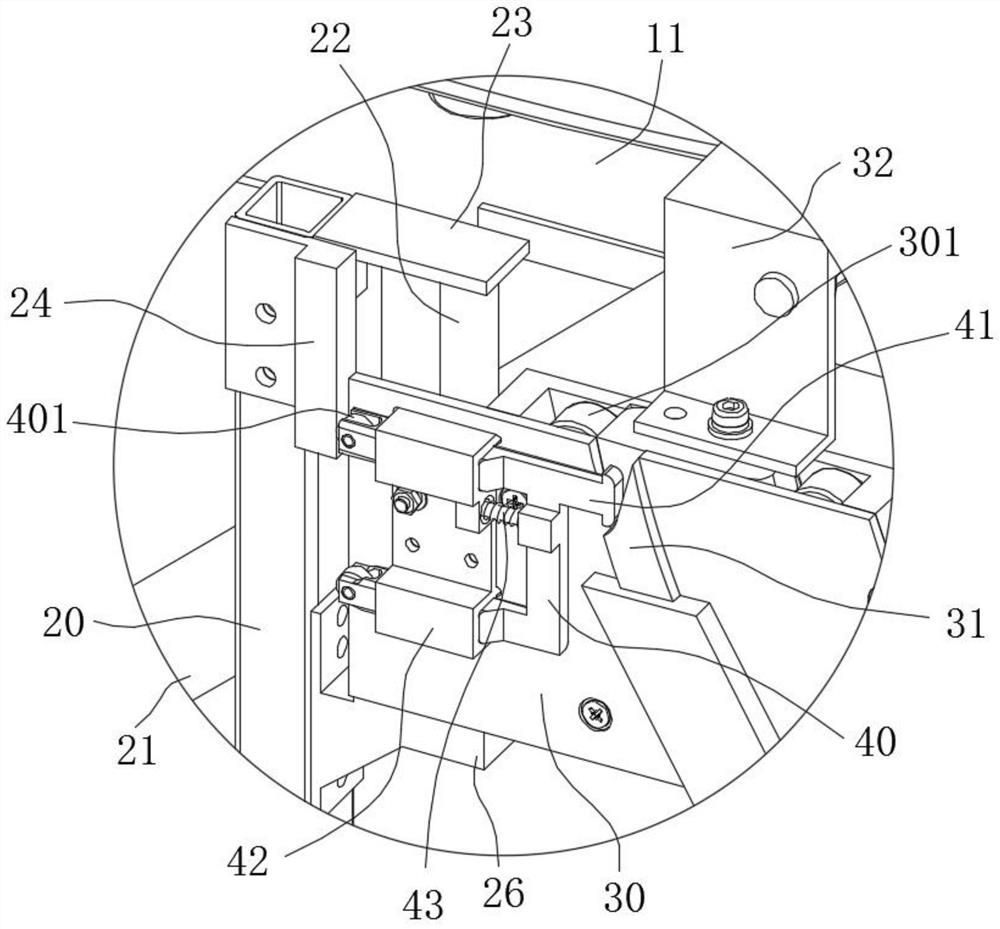

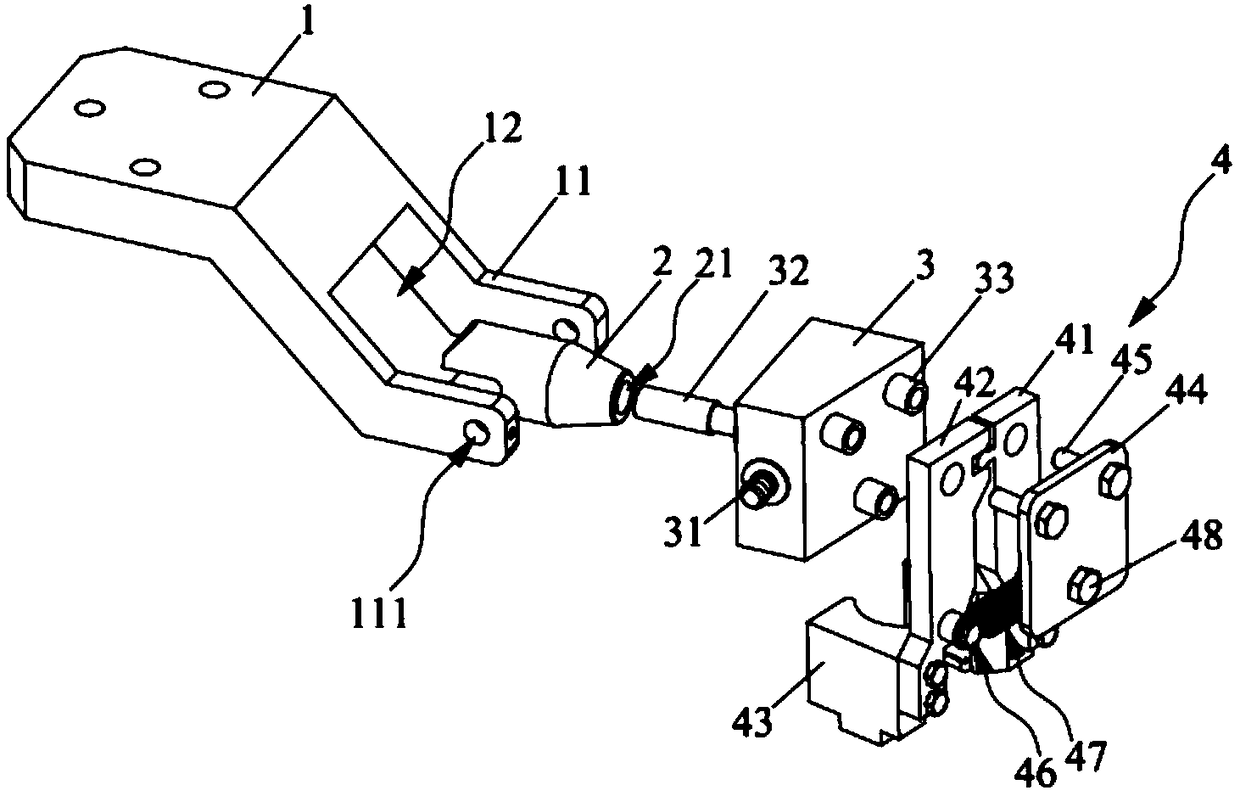

Locking mechanism of overturning clamp

InactiveCN105382477AImplement the flipping actionMeet the needs of multi-angle flipWelding/cutting auxillary devicesAuxillary welding devicesStable stateLocking mechanism

The invention relates to the field of automobile auxiliary production equipment, in particular to a locking mechanism of an overturning clamp. The locking mechanism comprises a dividing plate fixed to a clamp overturning shaft and a driving unit fixed beside the clamp. The dividing plate is provided with two or more dividing grooves in the circumferential direction of the edge of the dividing plate at intervals, and plug pins are arranged beside the dividing grooves. The driving unit drives the plug pins to be inserted into the dividing grooves or drives the plug pins to be located in the positions avoiding the dividing grooves; when the plug pins are located in the positions avoiding the dividing grooves, the overturning clamp can freely rotate around the clamp overturning shaft, when the clamp rotates to a moderate position, the driving unit drives the plug pins to be inserted into the dividing grooves, and at the moment, the plug pins limit the dividing grooves and the overturning shaft cannot rotate, so that a workpiece is welded in a clamp stable state, and overturning action of the clamp is achieved. The number and the positions of the dividing grooves can be determined according to the positions where the clamp needs to stay, the multi-angle overturning requirement of the clamp is met, and the problem that welding positions are invisible is completely solved.

Owner:CHERY AUTOMOBILE CO LTD

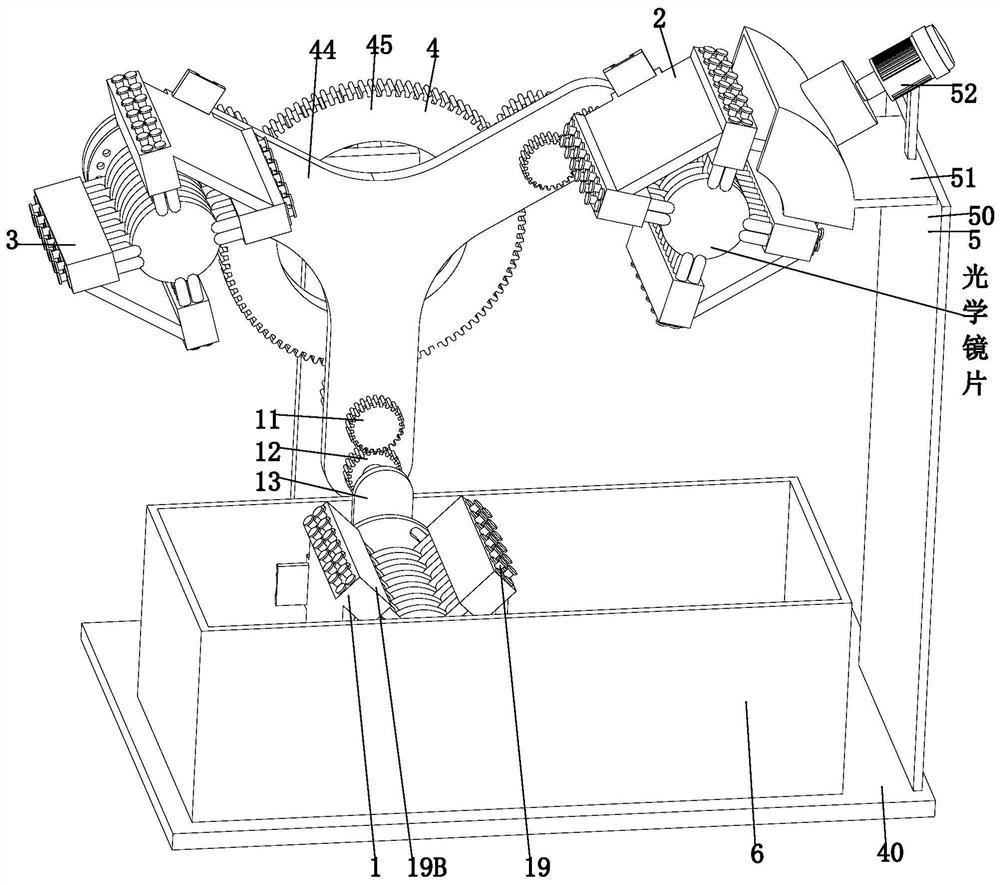

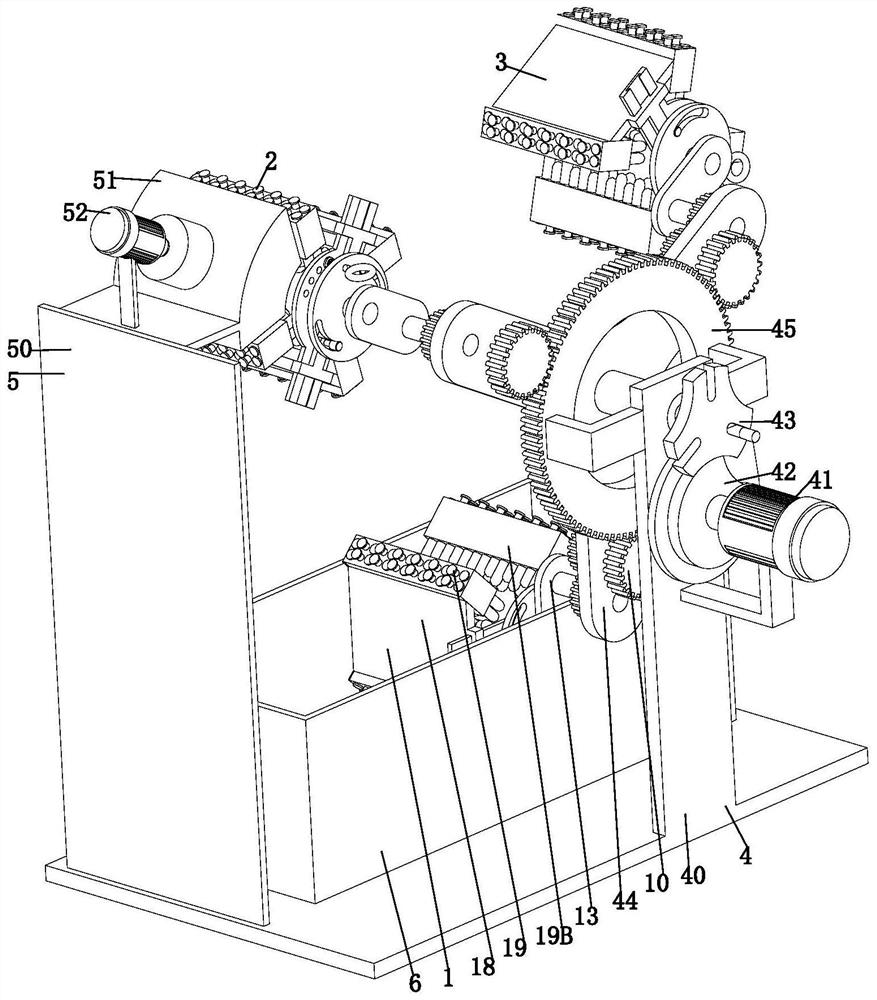

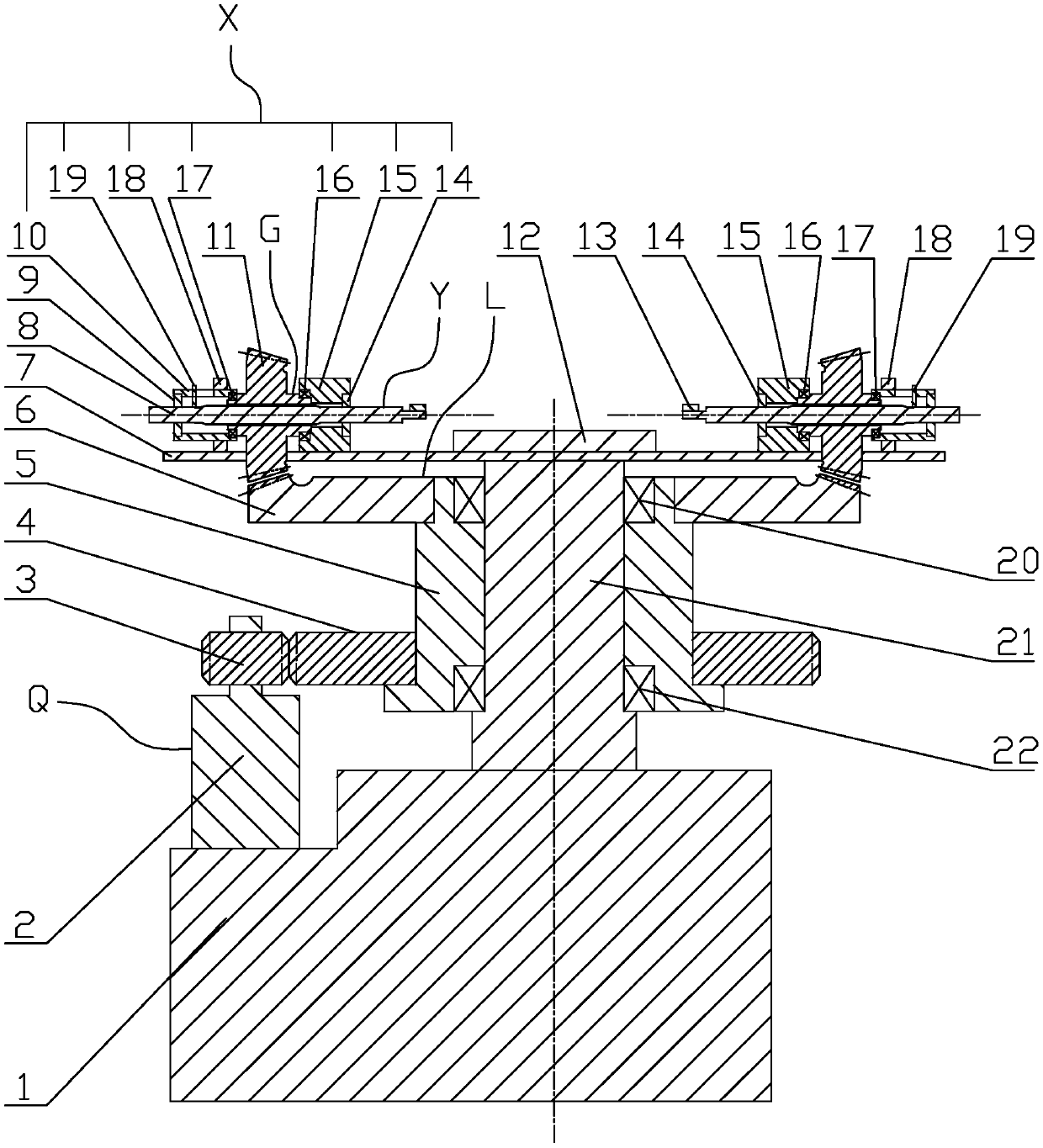

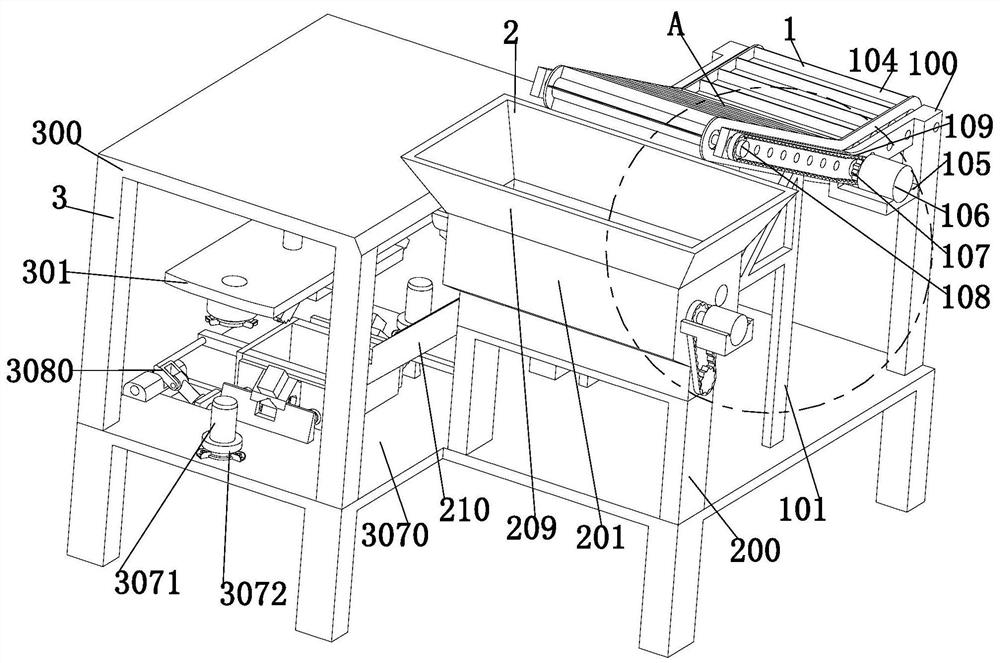

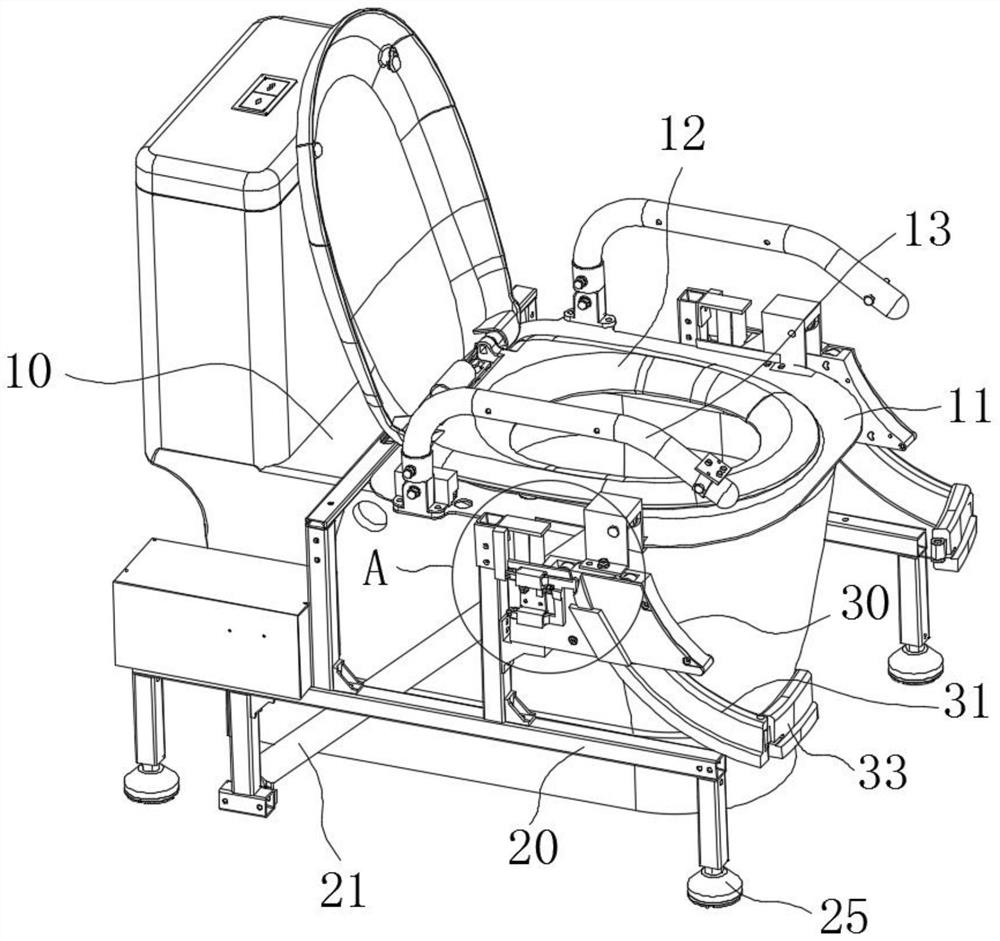

Multi-station size intelligent detection system for bearing bushes

PendingCN111167740ATo achieve the role of positioningEasy to detectUsing optical meansSortingControl engineeringMechanical engineering

The invention discloses a multi-station size intelligent detection system for bearing bushes. The multi-station size intelligent detection system comprises a working procedure detection device and a bearing bush comprehensive detection device. The working procedure detection device is connected with the bearing bush comprehensive detection device through a bearing bush transition conveying device.The working procedure detection device comprises a rack. The rack is provided with a conveying belt. The rack is provided with a bearing bush guiding mechanism located at the front end of the conveying belt. The rack is provided with a bearing bush centering mechanism located at a discharging end of the bearing bush guiding mechanism. The rack is provided with an unqualified bearing bush removingmechanism at the tail end of the conveying belt. The edge side of the rack is provided with a bearing bush working procedure visual detection mechanism matched with the bearing bush centering mechanism. By means of the multi-station size intelligent detection system, the bearing bushes can be orderly arranged and detected conveniently afterwards, bearing bush automatic detection and unqualified product removal are realized, and the authenticity and reliability of the quantity of detected bearing bushes are ensured.

Owner:LYNCWELL INNOVATION INTELLIGENT SYST ZHEJIANG CO LTD +1

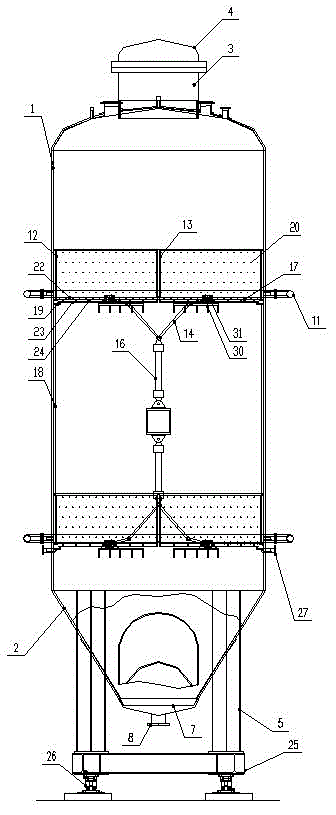

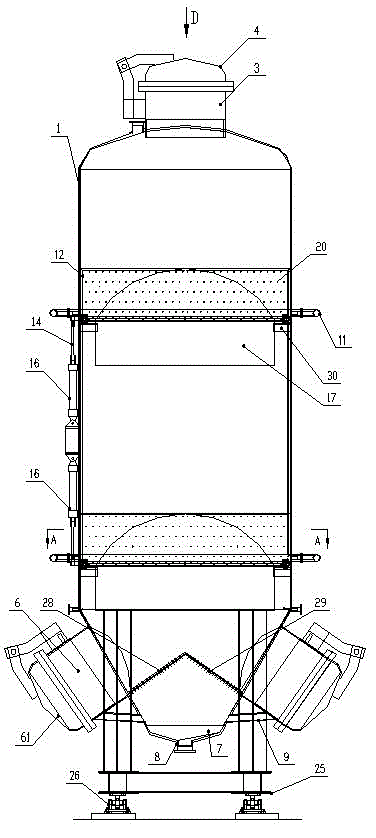

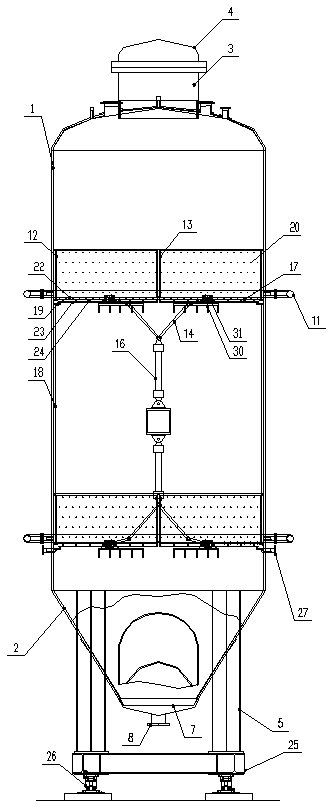

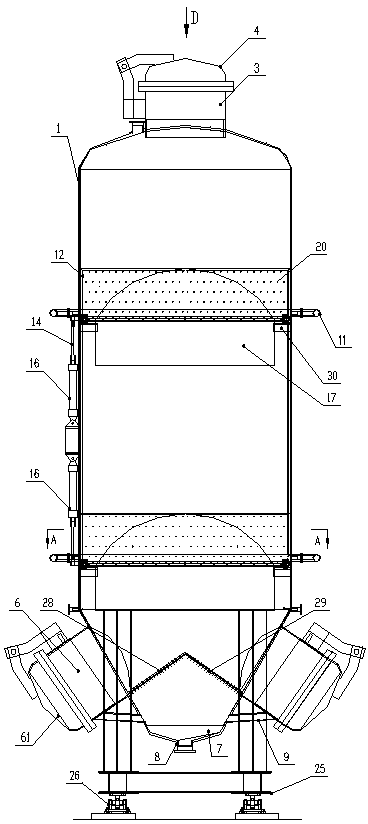

Palm fruit yeast killing technology

InactiveCN102746942AReduce stack heightAvoid high-speed vertical fallsFatty-oils/fats productionYeastPalm fruit

The invention discloses a palm fruit yeast killing technology. The technology comprises the following steps: 1, feeding a material from a material inlet; 2, opening a movable turnover plate after completing the first material feeding to enable the material to fall into a tank under the movable turnover plate, continuously feeding the material from the material inlet, and closing the movable turnover plate after completing the second material feeding; 3, continuously feeding the material from the material inlet, and closing the fast opening door of the material inlet after completing the third material feeding; 4, letting steam in the tank until the pressure reaches 0.05-0.35MPa and the temperature reaches 120-350DEG C, and waiting for 3-30min; 5, opening a steam discharge valve, waiting for 3-30min, closing the steam discharge valve, and repeatedly step 4 until yeast killing requirements are reached; 6, opening the steam discharge valve, waiting until the pressure in the tank returns to zero, opening a water discharge valve, and waiting until a deposition liquid in the lower part of the tank is evacuated; and 7, sequentially opening the fast opening doors of material outlets and the movable turnover plate, and closing the movable turnover plate after completing the first material discharge and the second material discharge. According to the technology, the material feeding and the material discharge are carried out in a grading and batch mode, so material bridging and caking are avoided, material unloading is convenient, and destructive impact of the material to the bottom of the tank is prevented.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

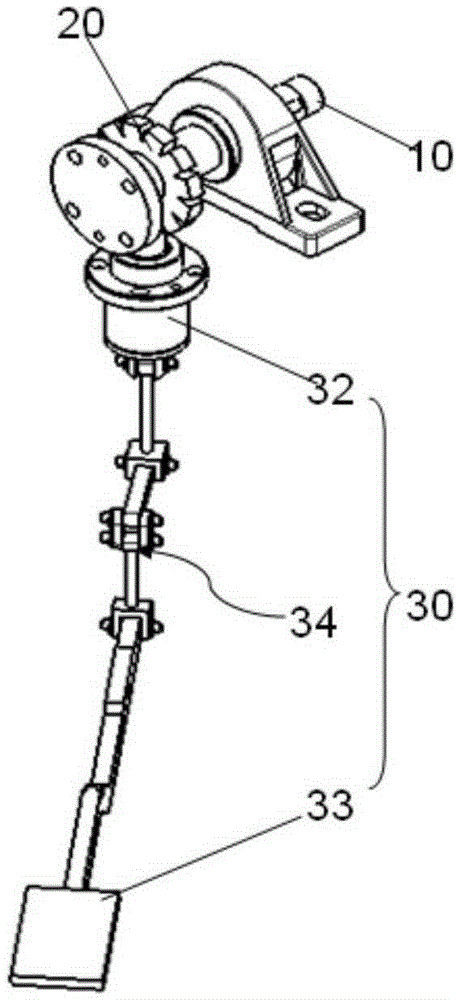

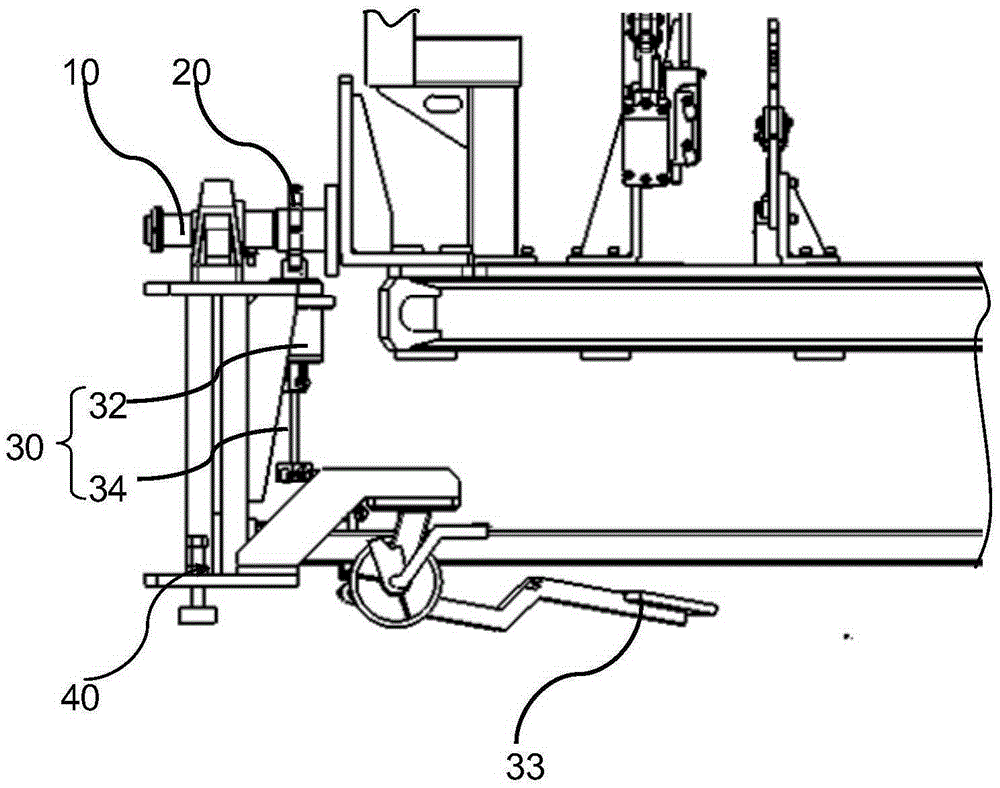

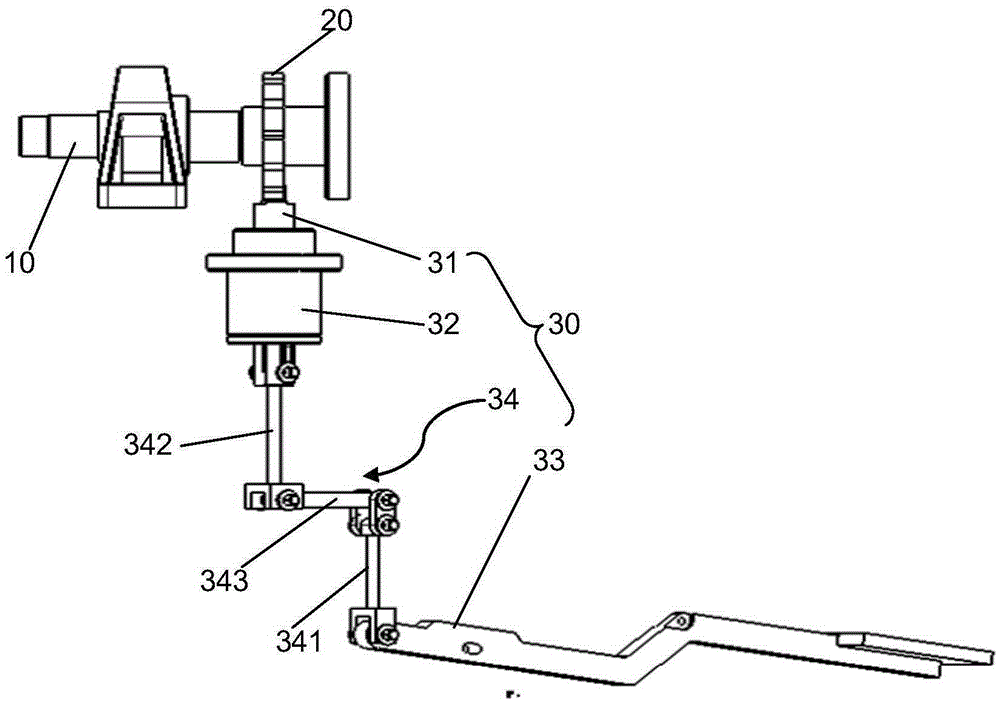

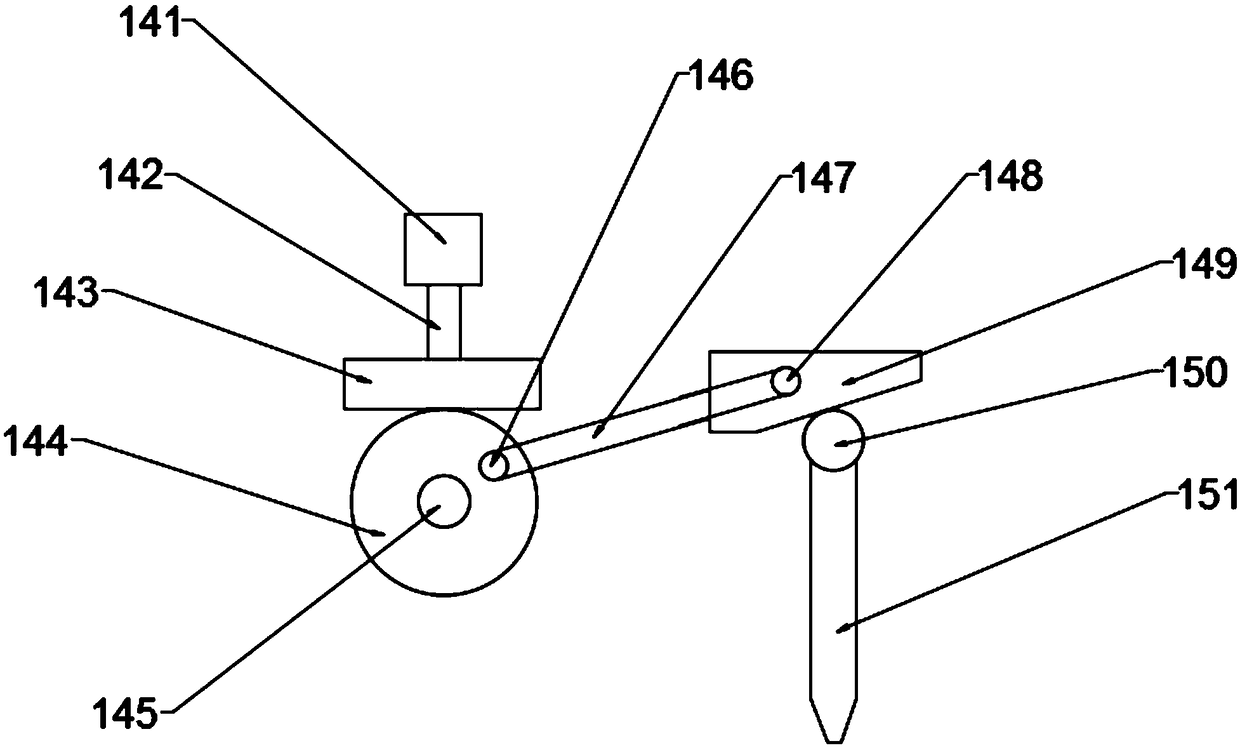

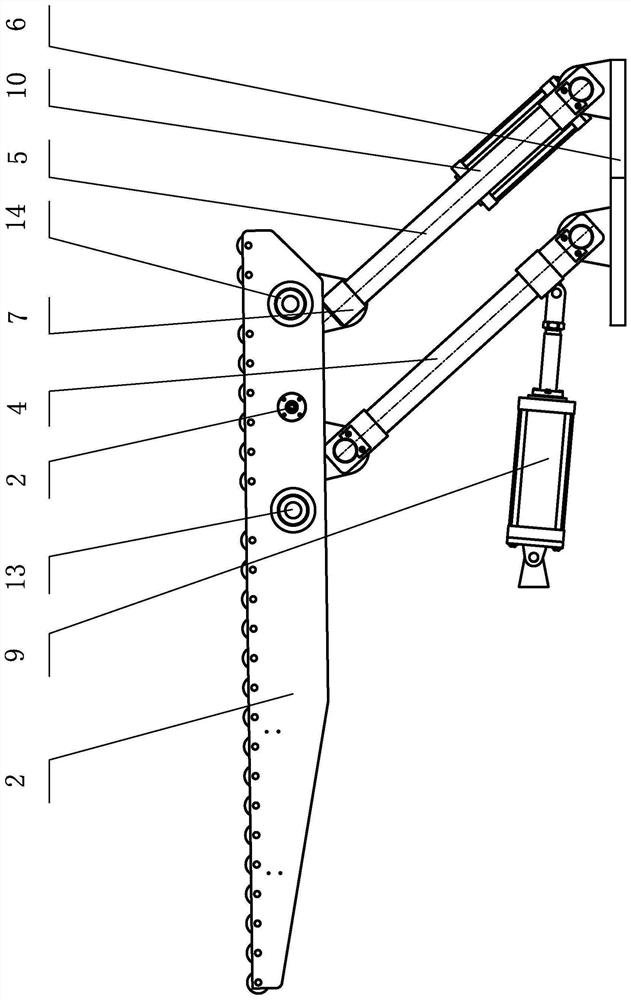

Pedestrian-controlled sod cutter

InactiveCN109006206ANo manual operationImprove drafting efficiencyHops/wine cultivationTurf growingSprocketPedestrian

The invention discloses a pedestrian-controlled sod cutter comprising a frame, a sprocket wheel mechanism, a cut-out mechanism and an overturn mechanism; the sprocket wheel mechanism is arranged on the left side of the frame; the cut-out mechanism is arranged on the right side of the sprocket wheel mechanism; a grass cutter head is arranged on the right side corresponding position of the cut-out mechanism; a fixed column is arranged on top of the grass cutter head; a first motor is arranged so as to automatically convey the sod from the forward direction to the rear direction of the sod cutter, and no manual operation is needed; a second motor is arranged so as to allow the cutter to cut off the sod at a regular fixed time period, thus automatically cutting off the sod at equal length; anelectric push rod is arranged so as to push a telescopic rod to move left and right in the horizontal direction, thus driving a second connecting rod to move left and right, further driving a turnoverpanel to turn rightwards around a transfer column, turning the sod on the turnover panel, and reducing the manual overturn packing time.

Owner:HEFEI XIAKANG ELECTRONICS COMMERCE CO LTD

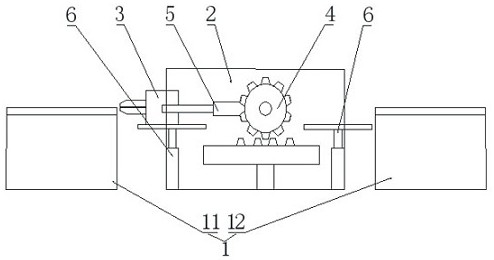

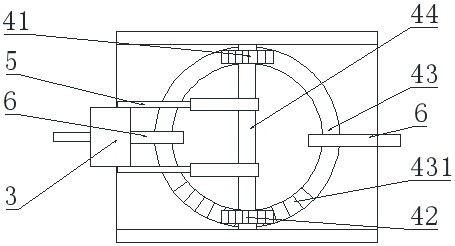

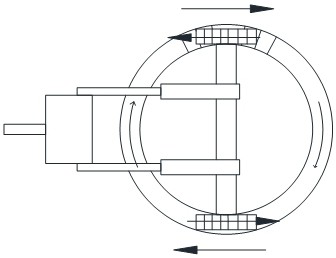

Communication circuit board overturning and conveying device

ActiveCN112678485AImplement the flipping actionSimple structurePrinted circuit manufactureConveyor partsCircular discGear wheel

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

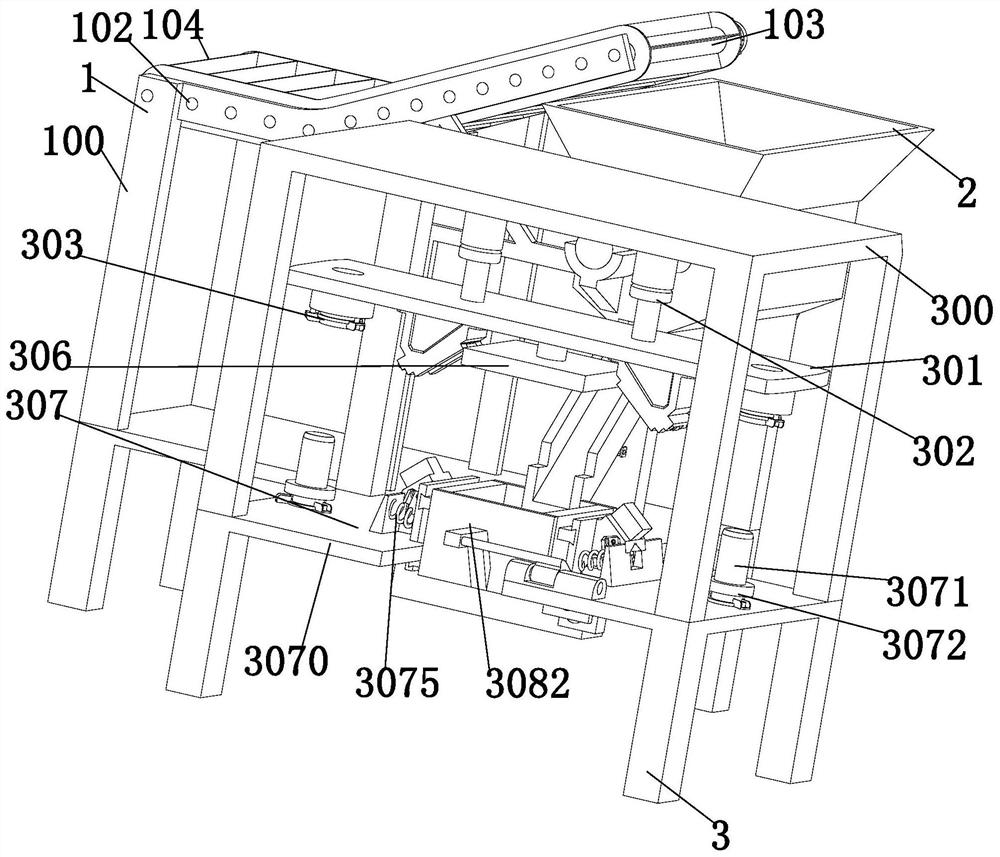

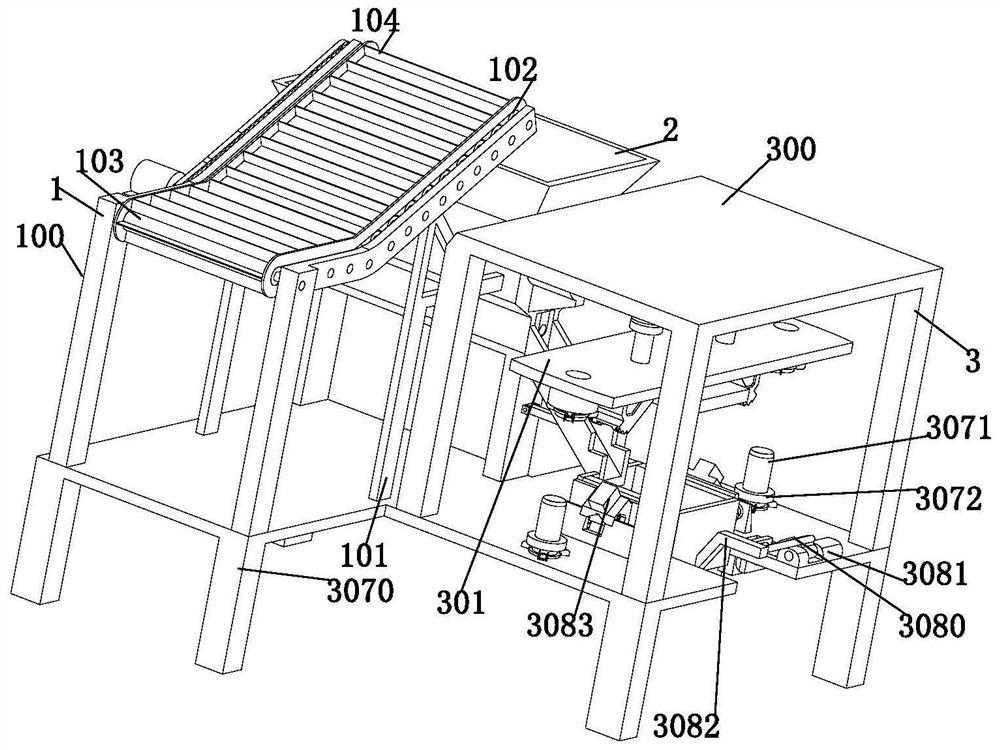

Numerical control machining center stamping waste recycling system

ActiveCN110961437AInconvenient to carryAvoid offsetSolid waste disposalGrain treatmentsNumerical controlProcess engineering

The invention provides a numerical control machining center stamping waste recycling system comprising a conveying mechanism, a smashing mechanism and a briquetting mechanism. The briquetting mechanism is provided with the crushing mechanism, the crushing mechanism is located right behind the briquetting mechanism, the conveying mechanism is located on the left side of the crushing mechanism and the conveying mechanism is installed on the briquetting mechanism. The problems of the existing waste recycling system in use that the collecting conveying line, the main conveying line and the recycling line all directly adopt conveying belts for conveying, most of stamping waste is fragmentary and is prone to jumping in the conveying process, the stamping waste often falls out of the two sides ofthe conveying belt in the conveying process, later-period cleaning is quite inconvenient, the hands of workers are prone to being hurt and many unsafe factors exist can be solved.

Owner:徐州标特福数控科技有限公司

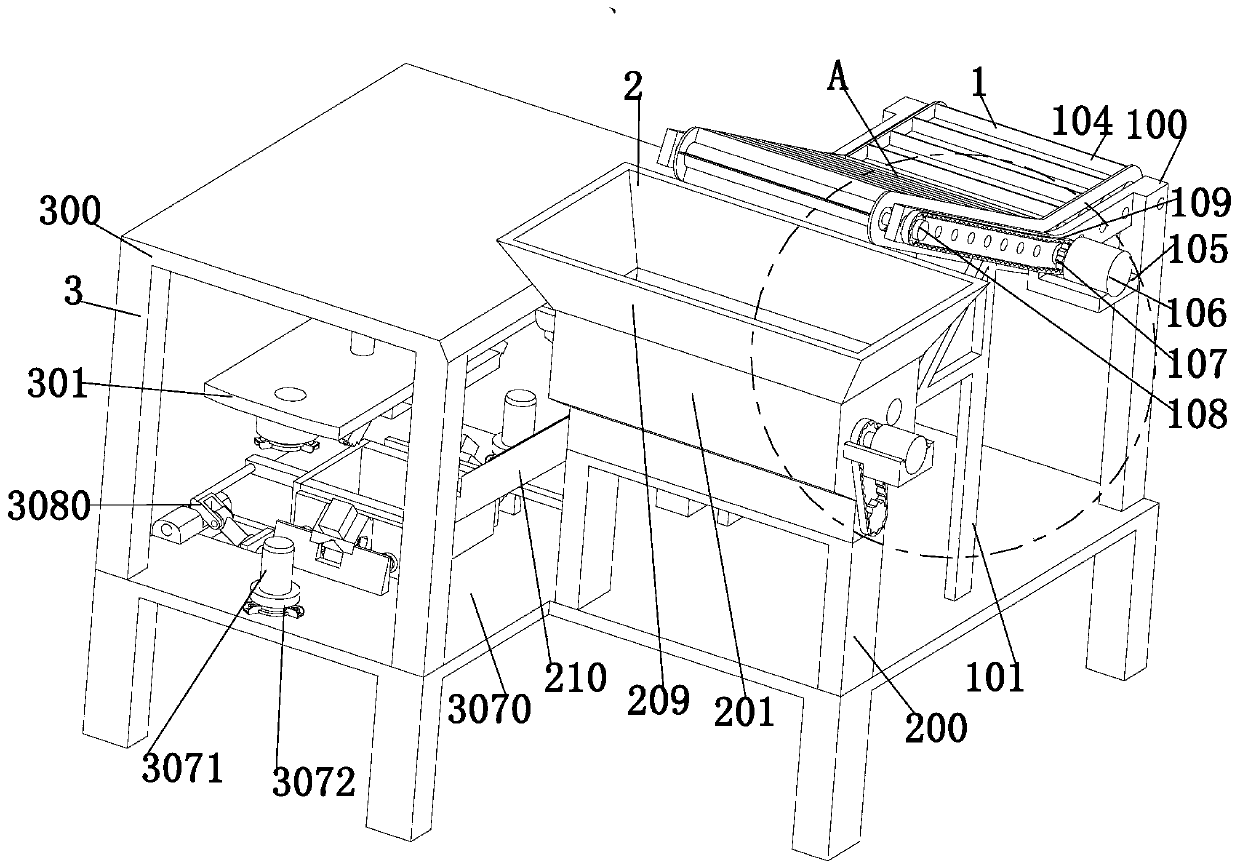

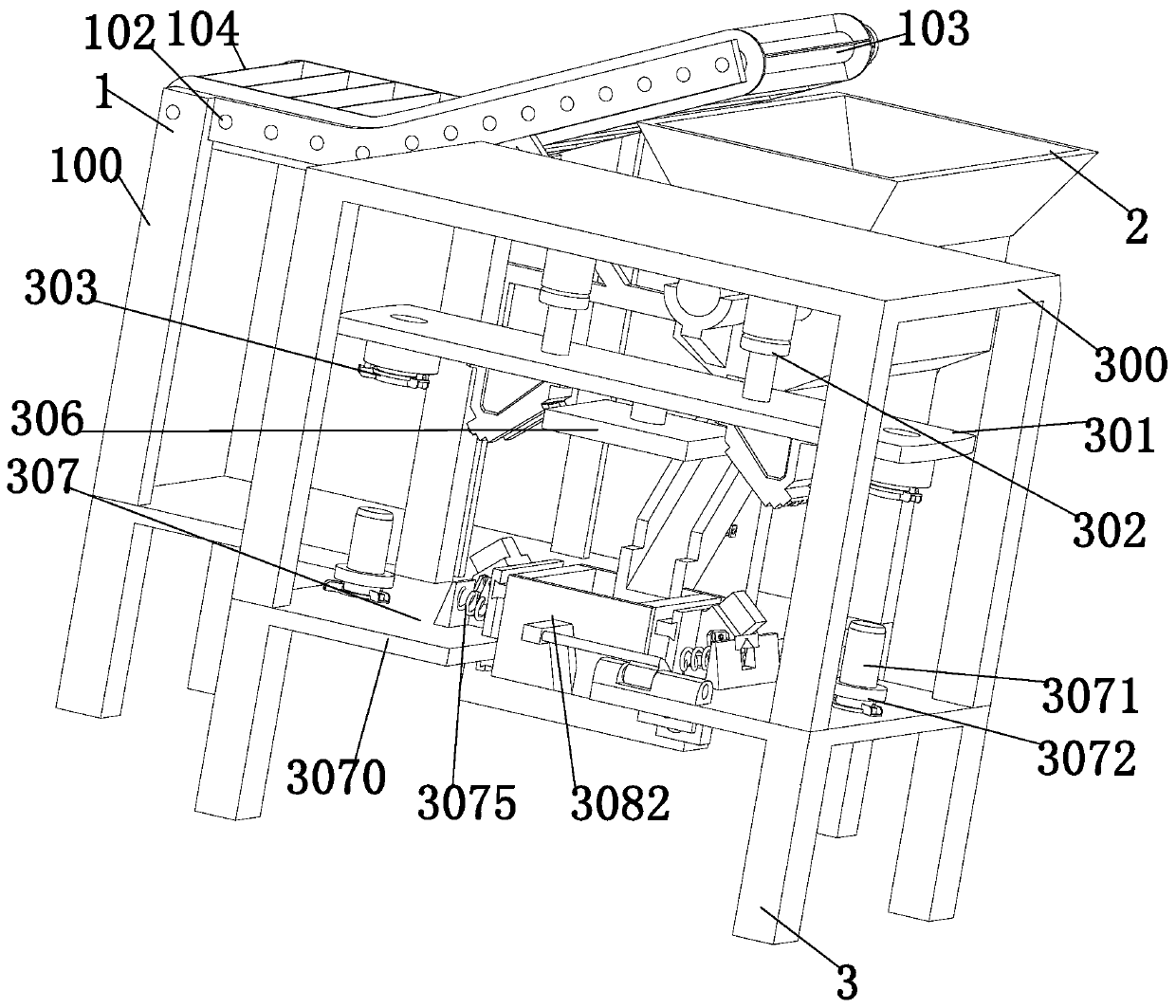

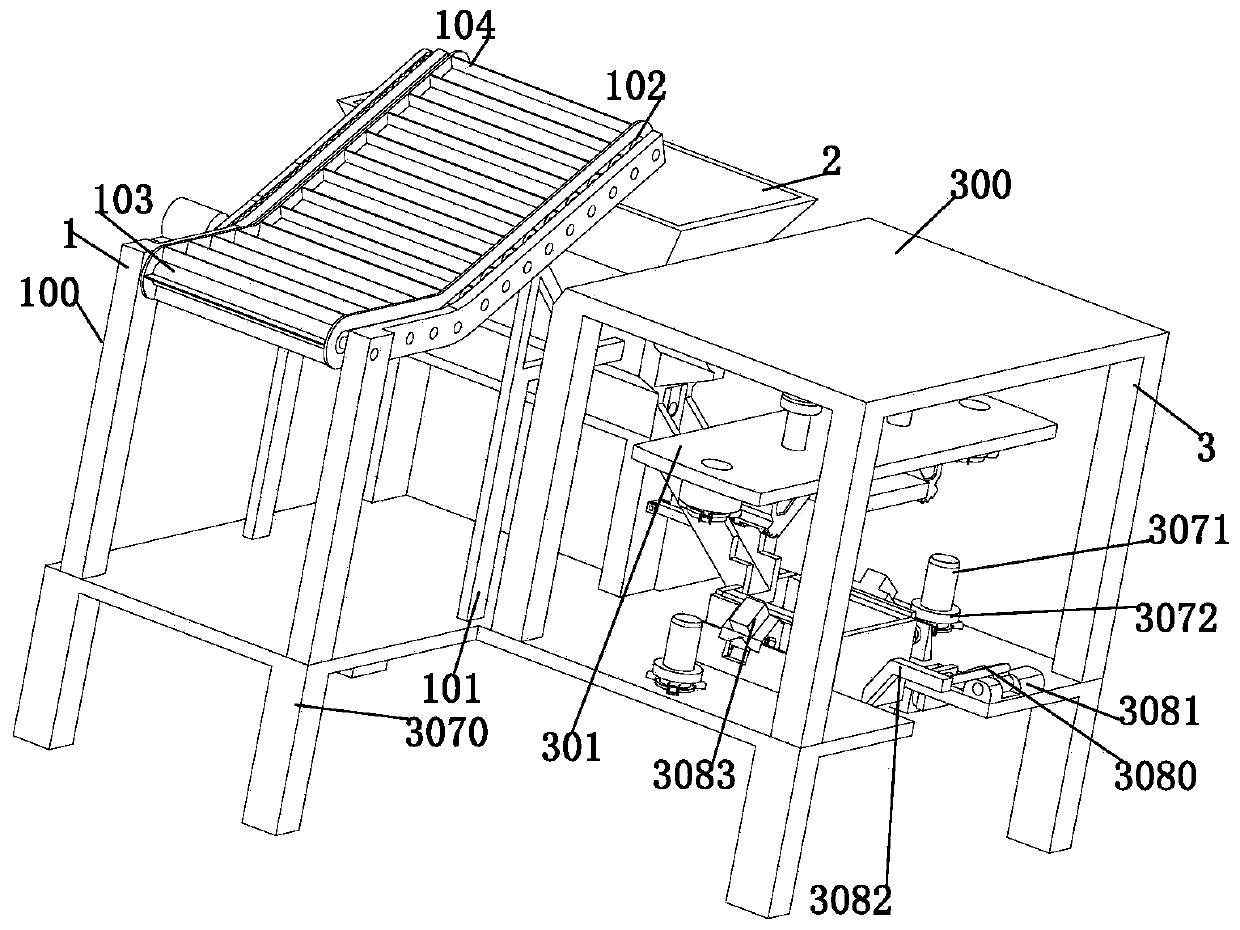

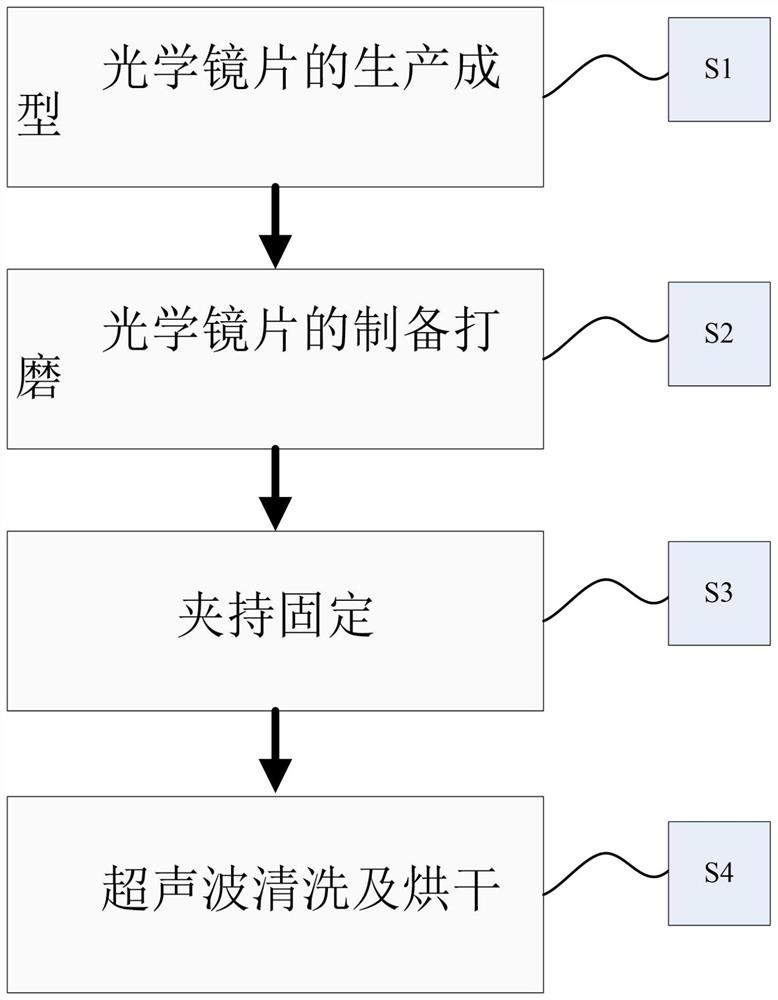

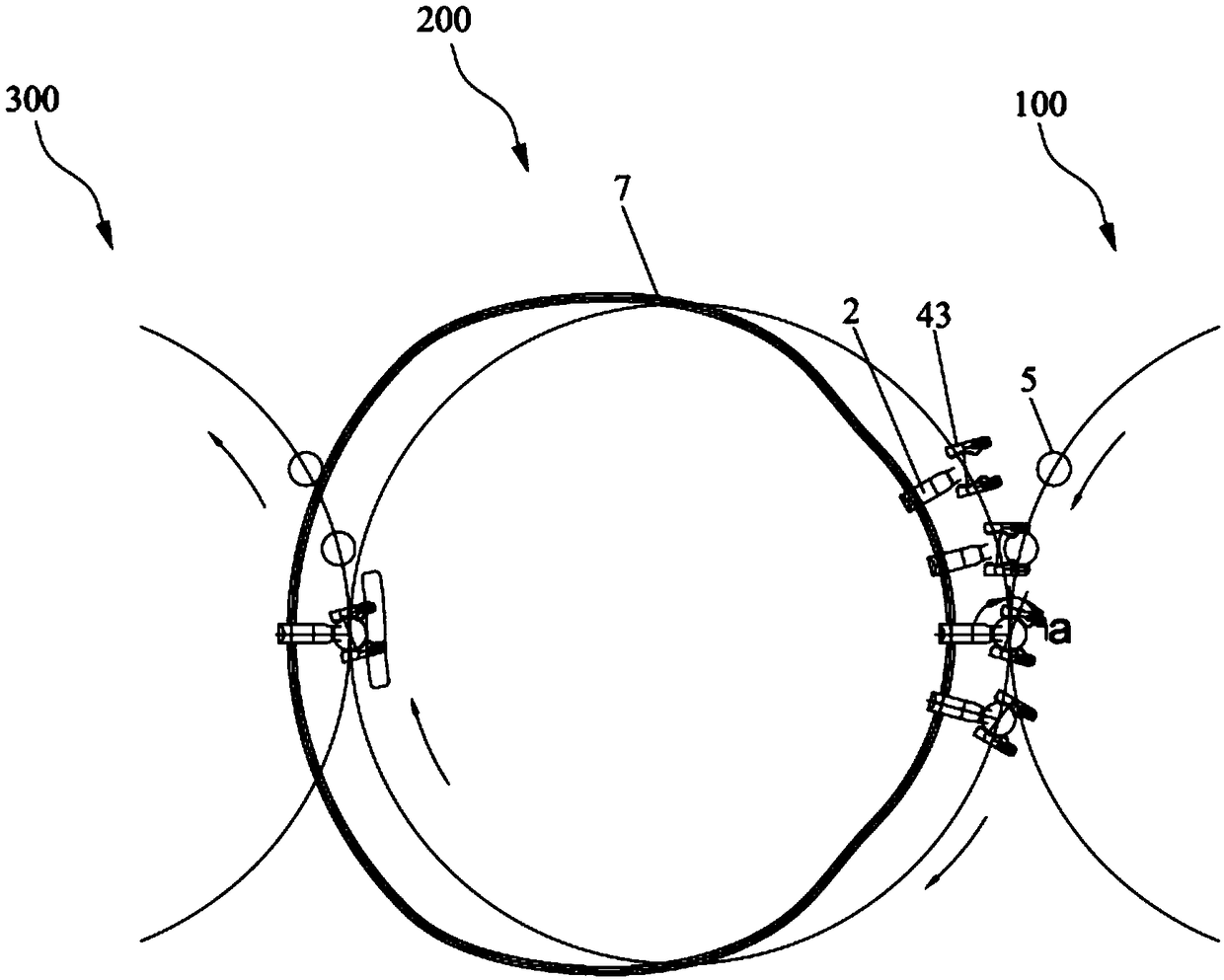

High-definition optical lens ultrasonic cleaning method

InactiveCN113182269AMeet the clamping needsWon't hurtDrying gas arrangementsFlexible article cleaningMegasonic cleaningEngineering

The invention provides a high-definition optical lens ultrasonic cleaning method. A first rotary clamping mechanism, a second rotary clamping mechanism, a third rotary clamping mechanism, a driving mechanism, a drying mechanism and a cleaning tank are included. The high-definition optical lens ultrasonic cleaning method solves the following problems existing in the existing ultrasonic cleaning process of the optical lens, wherein the problems include the problem that a clamping device of the optical lens cannot be adjusted according to the model and size of the optical lens, and when the optical lens is clamped, the surface of the lens is likely to be scratched to cause damage to the lens, the problem that due to the fact that the optical lens cannot be overturned in the cleaning process, the cleaning is not thorough, and the ultrasonic cleaning effect is reduced, and the problem that due to the fact that during traditional cleaning operation, the lens is placed in a cleaning machine to be cleaned, then the cleaned lens is taken out and then transferred into drying equipment, the cleaning process is tedious, the cleaning process is increased, and then the cleaning efficiency of the optical lens is reduced.

Owner:湖北省优迈科技有限公司

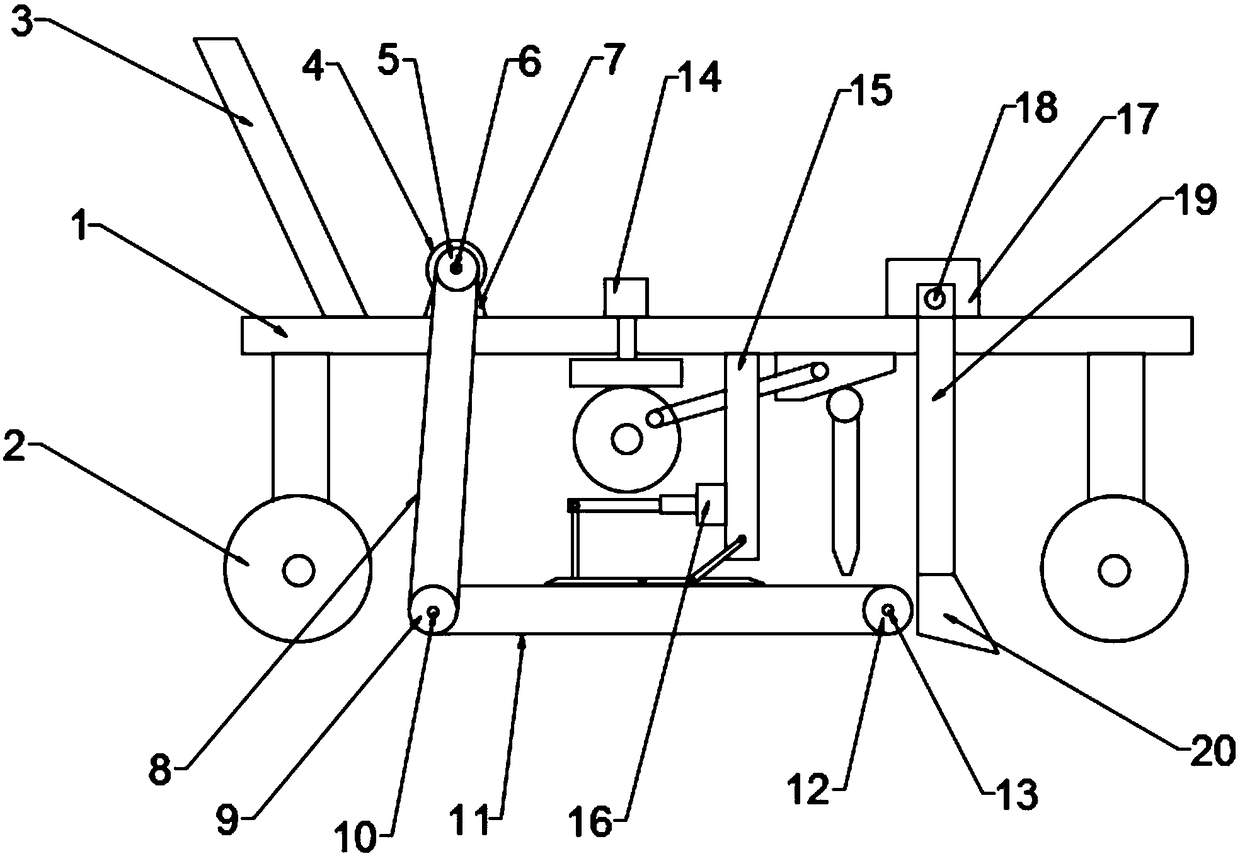

Workpiece automatic overturning device

InactiveCN107399593AAchieve positioningImplement the flipping actionConveyor partsEngineeringConveyor belt

The invention relates to an automatic workpiece turning device, which includes a cabinet body, a material board, a first conveyor belt and a second conveyor belt. A conveyor belt, the feed end of the first conveyor belt corresponds to the discharge end of the material plate, the discharge end of the first conveyor belt is equipped with a turning mechanism, and the workpiece is turned over by the turning mechanism and sent to the second conveyor belt, and the second conveyor belt goes out An automatic feeder is installed under the material end. The device realizes accurate workpiece positioning and turning action through a positioning mechanism and a turning mechanism, and has a simple structure and a reasonable design. The invention has the advantages of simple structure, scientific and reasonable design, and ingenious conception, which reduces the transport frequency between workpiece processes, saves space, reduces the collision of workpieces, ensures the stability of products and equipment, saves physical strength of employees, reduces costs, and improves production efficiency.

Owner:天津华伟精工电子有限公司

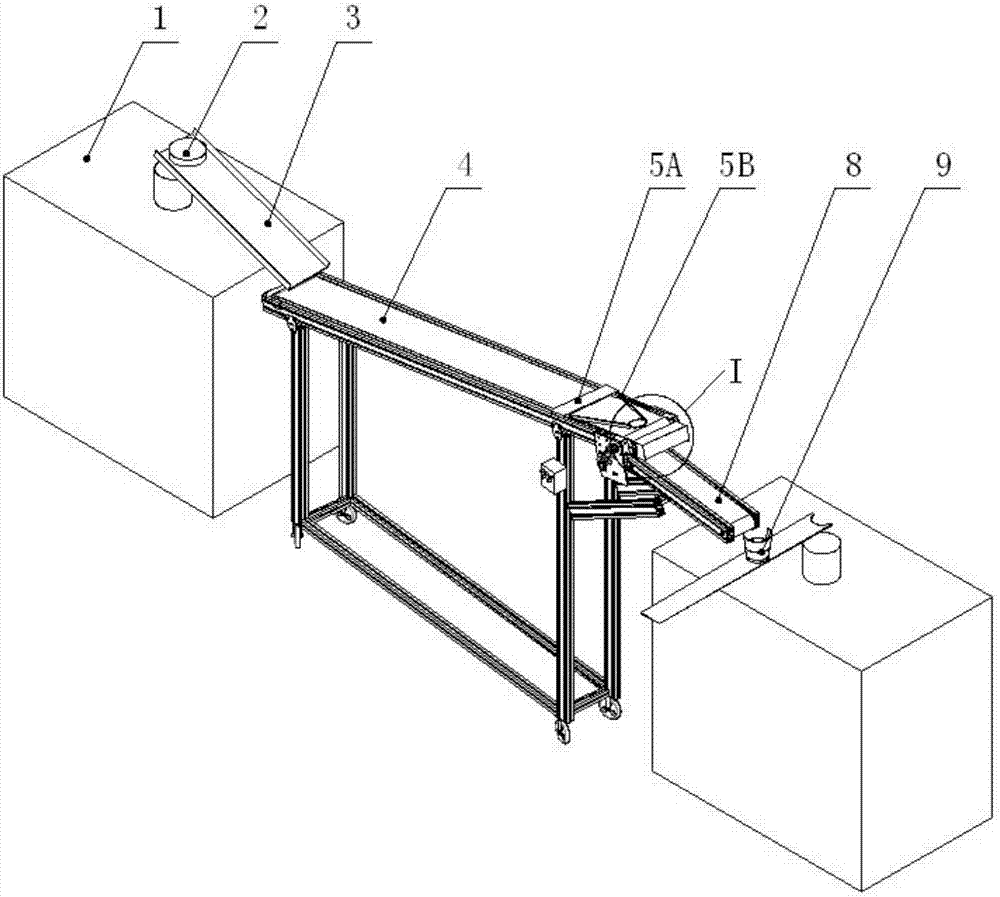

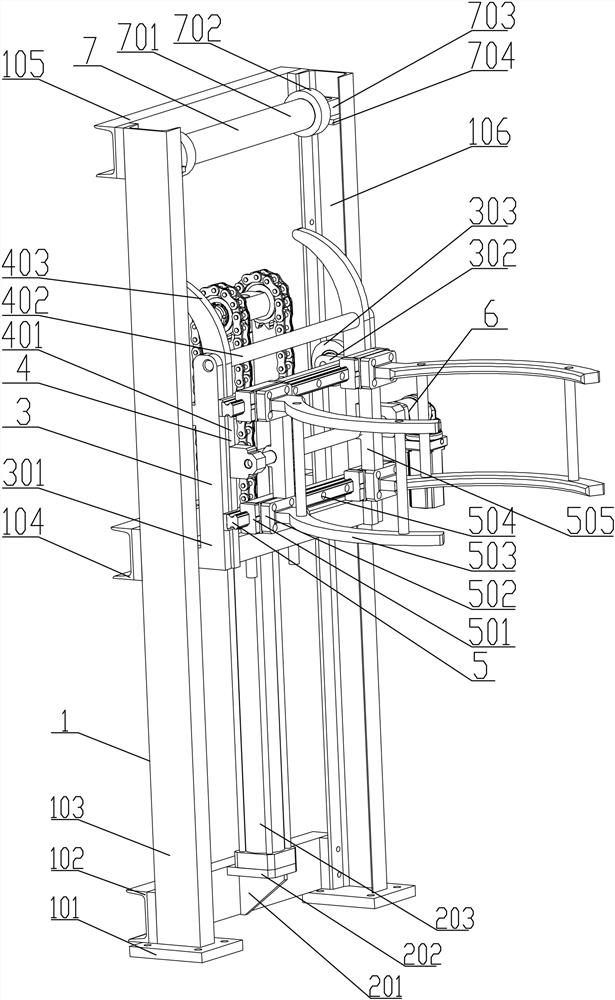

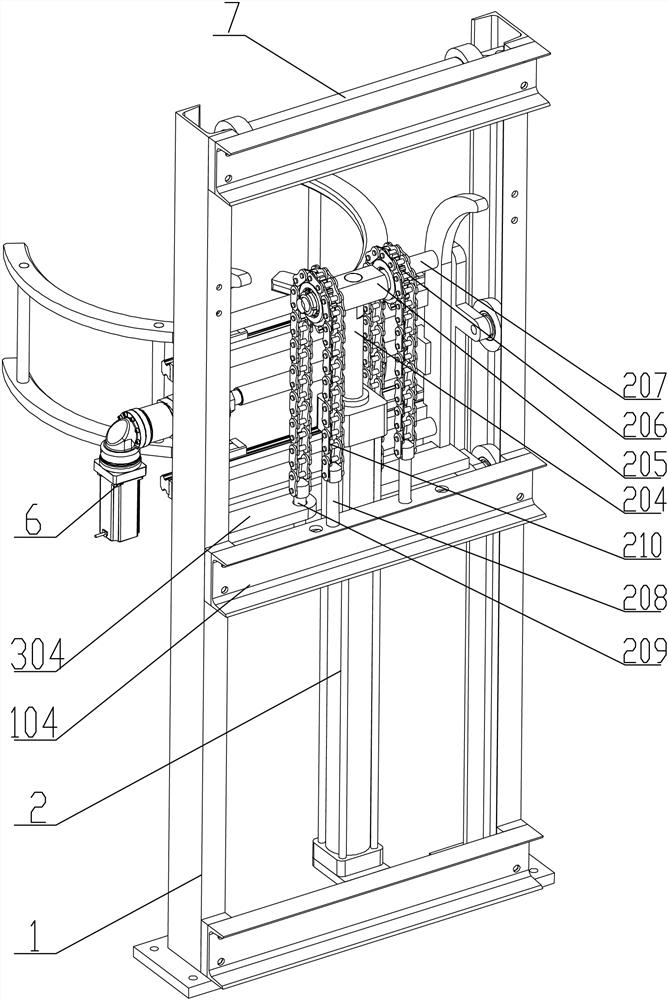

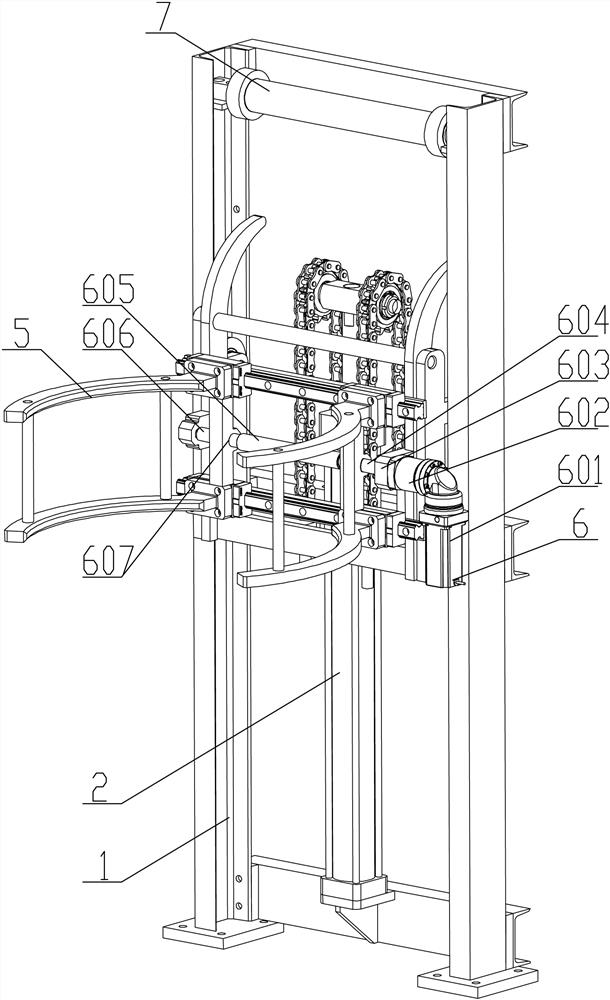

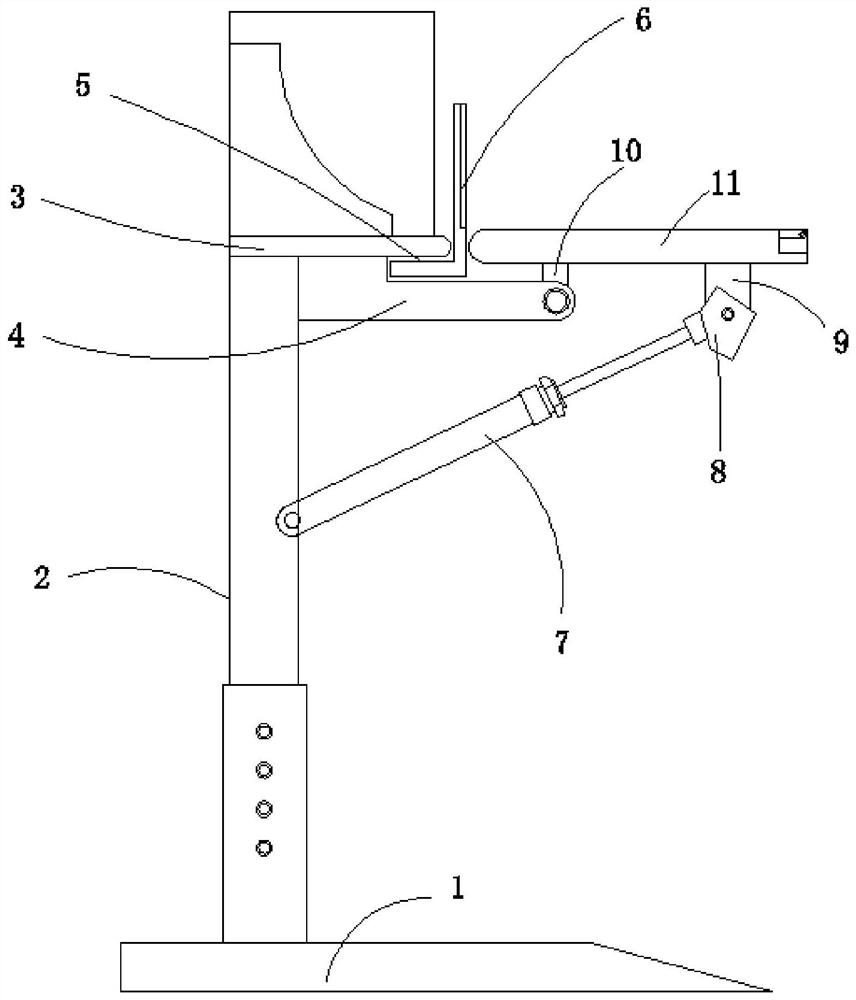

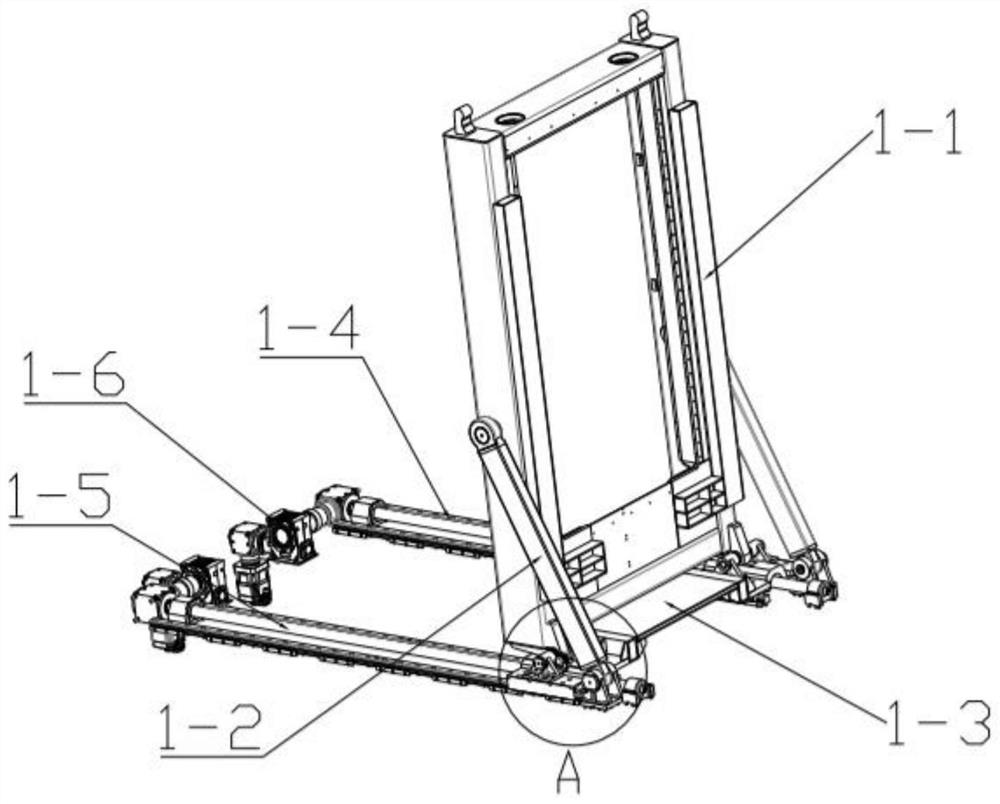

Electro-hydraulic integrated control holding clamp lifting turnover device and control method

ActiveCN114229417ARealize Regulatory ControlRealize automatic controlConveyor partsChain typeControl theory

The invention provides an electro-hydraulic integrated control clamping lifting turnover device and a control method, the electro-hydraulic integrated control clamping lifting turnover device comprises a rack structure used for supporting the whole device, the rack structure is matched with a lifting sliding frame structure in a lifting sliding mode, and the lifting sliding frame structure is connected with a chain type lifting device used for driving the lifting sliding frame structure to ascend and descend; the lifting sliding frame structure is rotationally matched with an overturning frame structure. The turnover frame structure is matched with a turnover guide mechanism fixed at the top end of the rack structure; a clamping arm mechanism used for tightly holding a workpiece is installed on the outer side wall of the overturning frame structure and connected with a clamping power device used for driving the clamping arm mechanism to clamp the workpiece. The device can be used for clamping a workpiece, lifting adjustment control of the height of the device can be achieved after clamping, the device can be automatically turned over after the height reaches a certain height, and then adjustment of the turning angle of the device is achieved.

Owner:FUJIAN POLYTECHNIC OF INFORMATION TECH

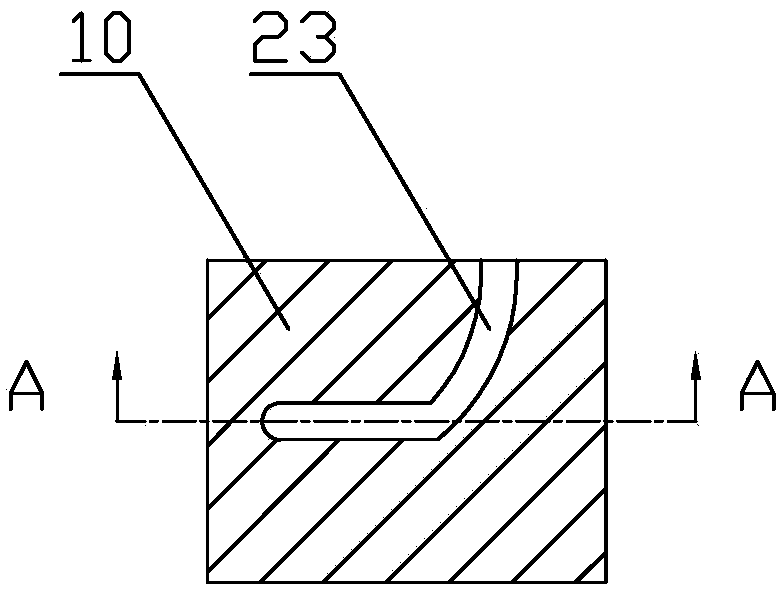

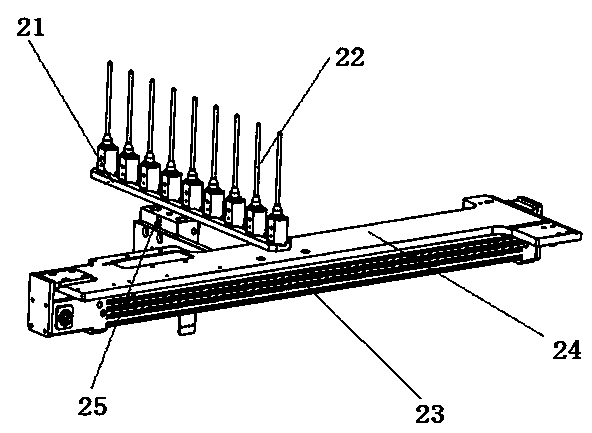

Tool device integrating linear motion and rotating motion and control mode

PendingCN109514221ACompact structureImprove reliabilityMetal working apparatusControl modeEngineering

The invention discloses a tool device integrating linear motion and rotating motion. The tool device comprises a supporting platform, a transmission mechanism, a movement mechanism and an installing platform; the transmission mechanism is fixed to the supporting platform; the movement mechanism is driven by the transmission mechanism and used for conveying a workpiece to the installing platform; the supporting platform is upwards, sequentially and fixedly provided with a supporting shaft, a platform plate and the installing platform; the movement mechanism is fixed to the platform plate and comprises a ball screw structure and a guiding structure, one end of a screw in the ball screw structure is used for fixing the workpiece, the screw is provided with a guiding pin, and rotation of a ball nut is driven by the transmission mechanism; and the guiding structure comprises a guiding cylinder fixed to the platform plate, the guiding cylinder is provided with a guiding groove, the guiding groove comprises a guiding threaded groove and a linear groove, the guiding cylinder penetrates through the screw, and the guiding pin is movably arranged in the guiding groove. According to the tool device integrating linear motion and rotating motion, combination of rotating motion and linear motion can be achieved, the tool requirements on different rotating angles and linear motion are achievedthrough one mechanism, and the tool device is applied to automatic assembling of precise parts of multiple products.

Owner:DONGHUA MACHINERY

Heat seal packaging machine

InactiveCN110901969AUniform shapeMake sure the connection is firmWrapper twisting/gatheringSolid materialEngineeringPhysics

The invention belongs to the technical field of powder packaging equipment and provides a heat seal packaging machine. The heat seal packaging machine comprises a main rack, a filling nozzle and a bagsupporting mechanism; the filling nozzle is arranged on the main rack; the bag supporting mechanism is arranged on the main rack and located below the filling nozzle; the bag supporting mechanism comprises a bag pushing rack, a bag supporting bottom plate and bag blocking side plates; the bag pushing rack is arranged on the main rack; the bag supporting bottom plate is arranged on the bag pushingrack; and the two bag blocking side plates are arranged on the bag pushing rack; and the bag supporting bottom plate and the two bag blocking side plates form a material supporting space. By means ofthe above technical schemes, the problem that a material bag deforms and leaks materials in a powder packaging process in the prior art is solved.

Owner:唐山鑫宏达机械设备有限公司

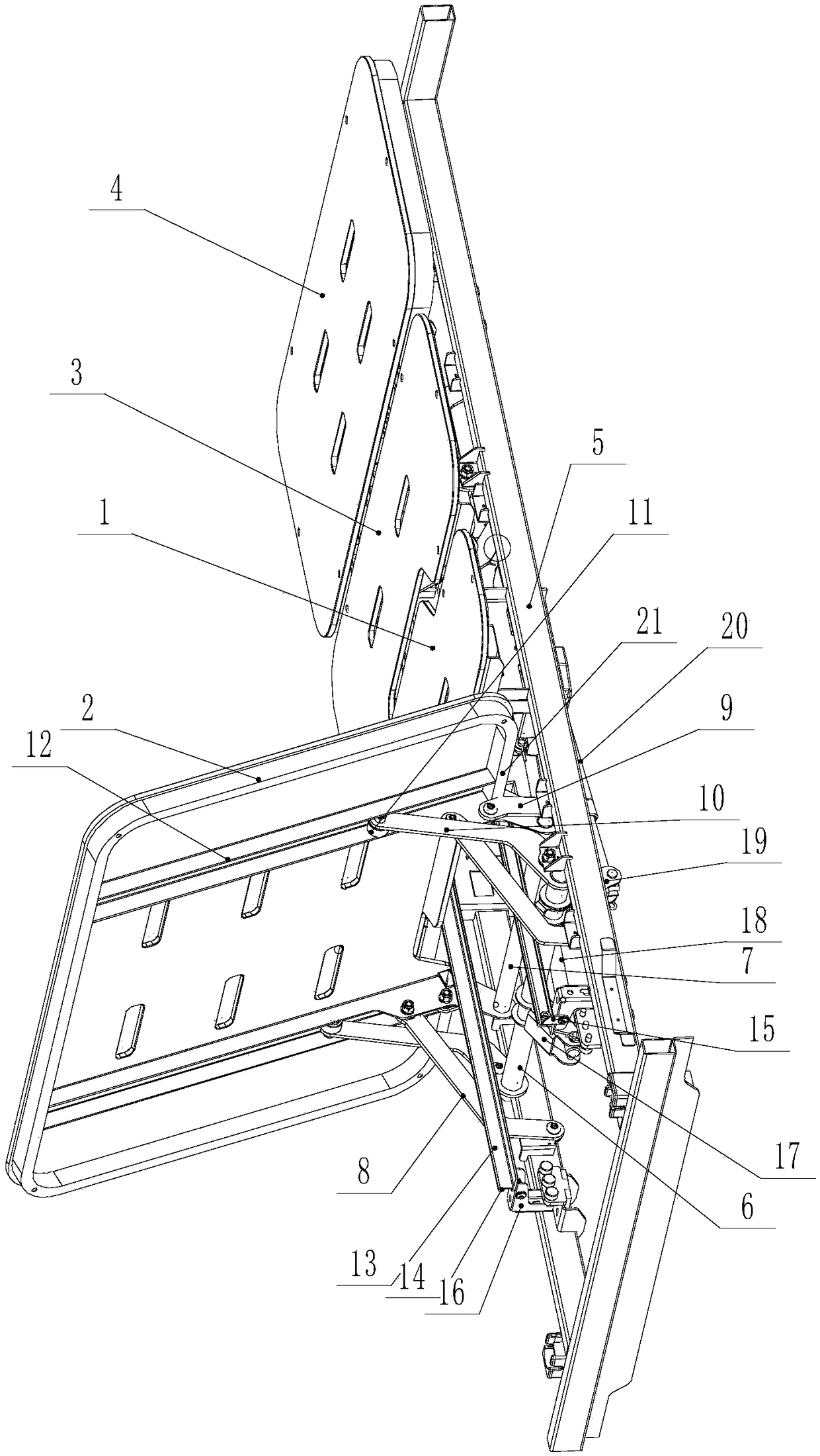

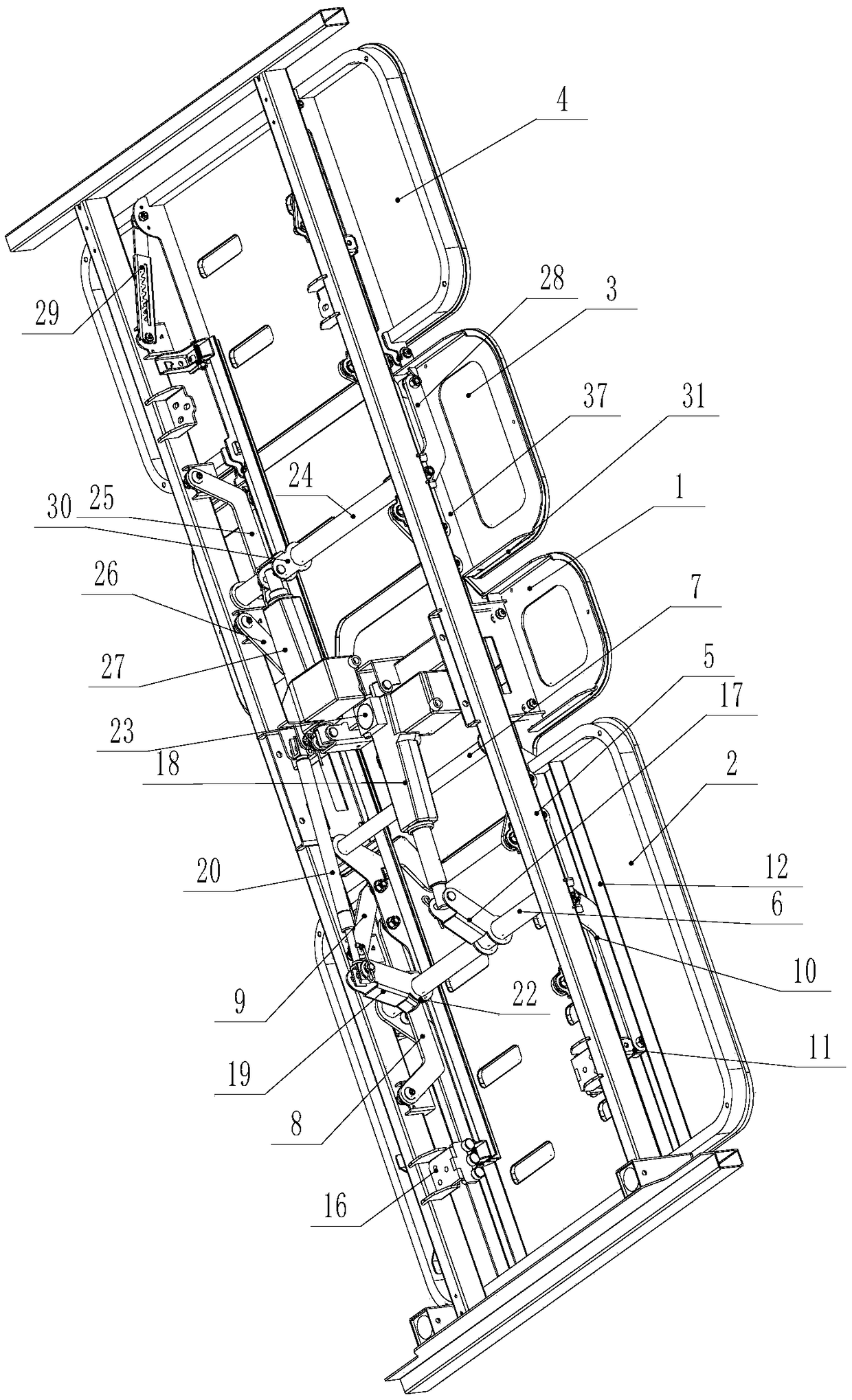

Automatic buffering medical bed board assembly

The invention discloses an automatic buffering medical board assembly. The automatic buffering medical bed board assembly comprises a bed frame, a back board, a middle bed board, a thigh board and a shank board. A medical bed further comprises a damper, a back board turning driving device comprises a first driving shaft, back board driving arms and a first linear power device, a first driving armand a driven arm are fixed to the first driving shaft, the first linear power device and the damper are hinged between the first driving arm and the bed frame as well as between the driven arm and thebed frame respectively, a buffering force exerting bush is fixed to the first driving shaft and provided with a laying-down buffering poking block and a returning poking block which are spaced circumferentially, the laying-down buffering poking block and the driven arm extrude, touch and compress the damper when the back board is laid down, and the returning poking block and the driven arm extrude and touch to lengthen and return the damper when the back board is lifted and turned. The back board of the medical bed board assembly can be rapidly laid down and has a buffering function, and therefore the automatic buffering medical bed board assembly is higher in adaptability, meanwhile can improve safety, and reduces the risk of finger or palm pinching.

Owner:JIANGSU SAIKANG MEDICAL EQUIP

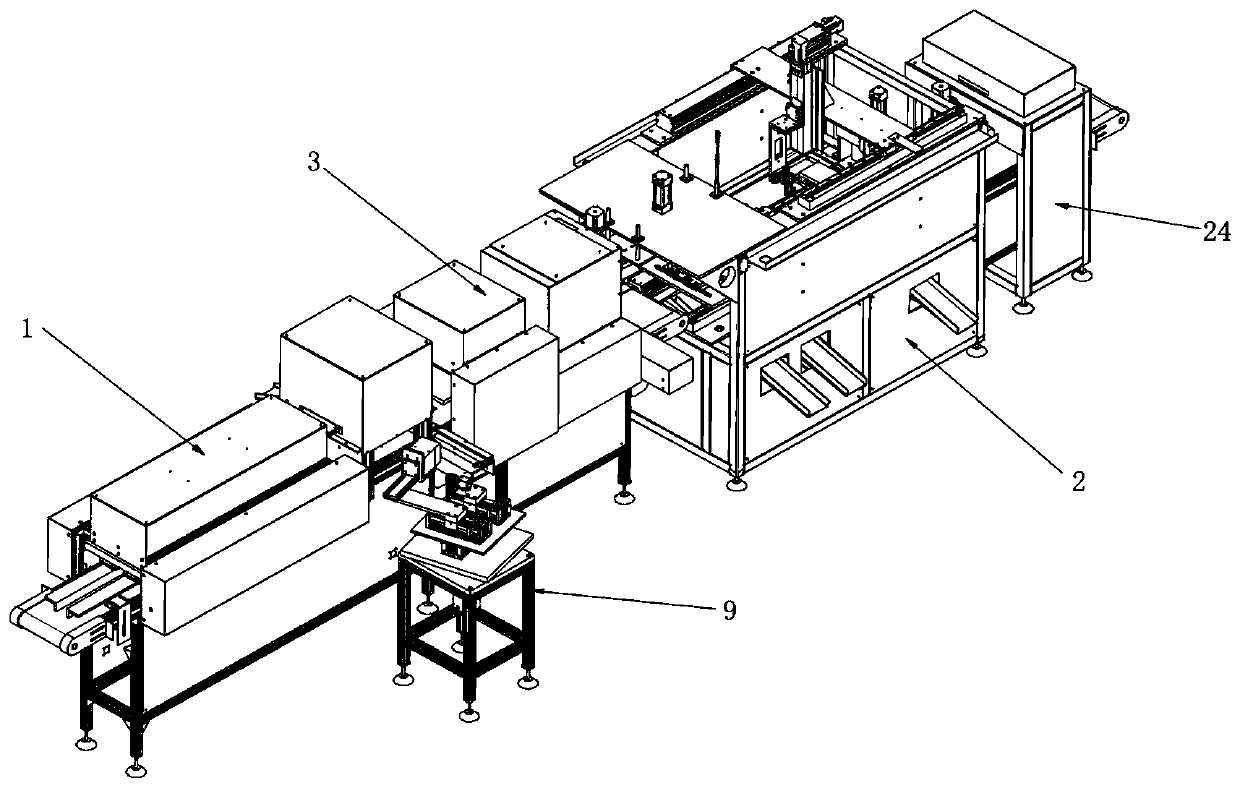

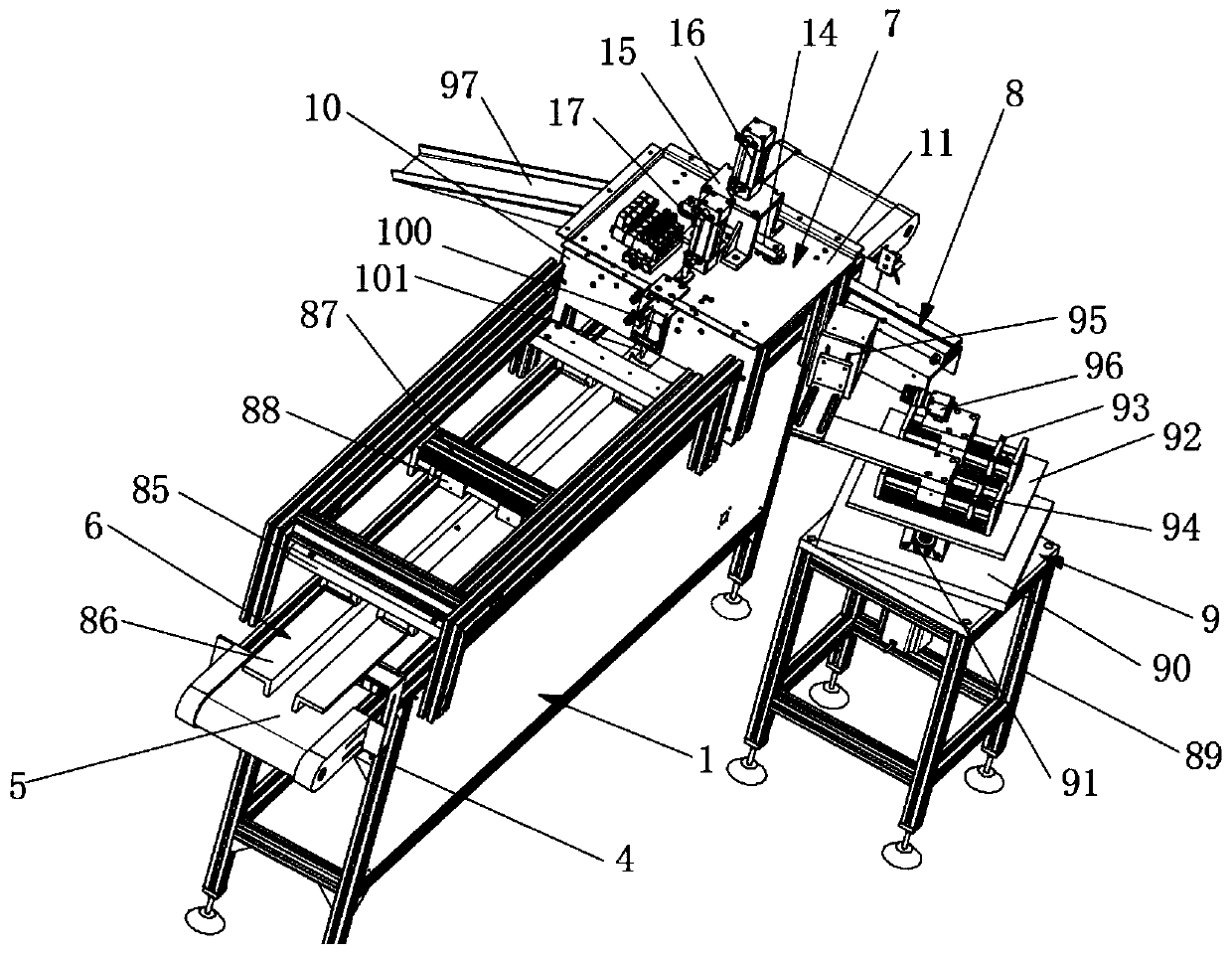

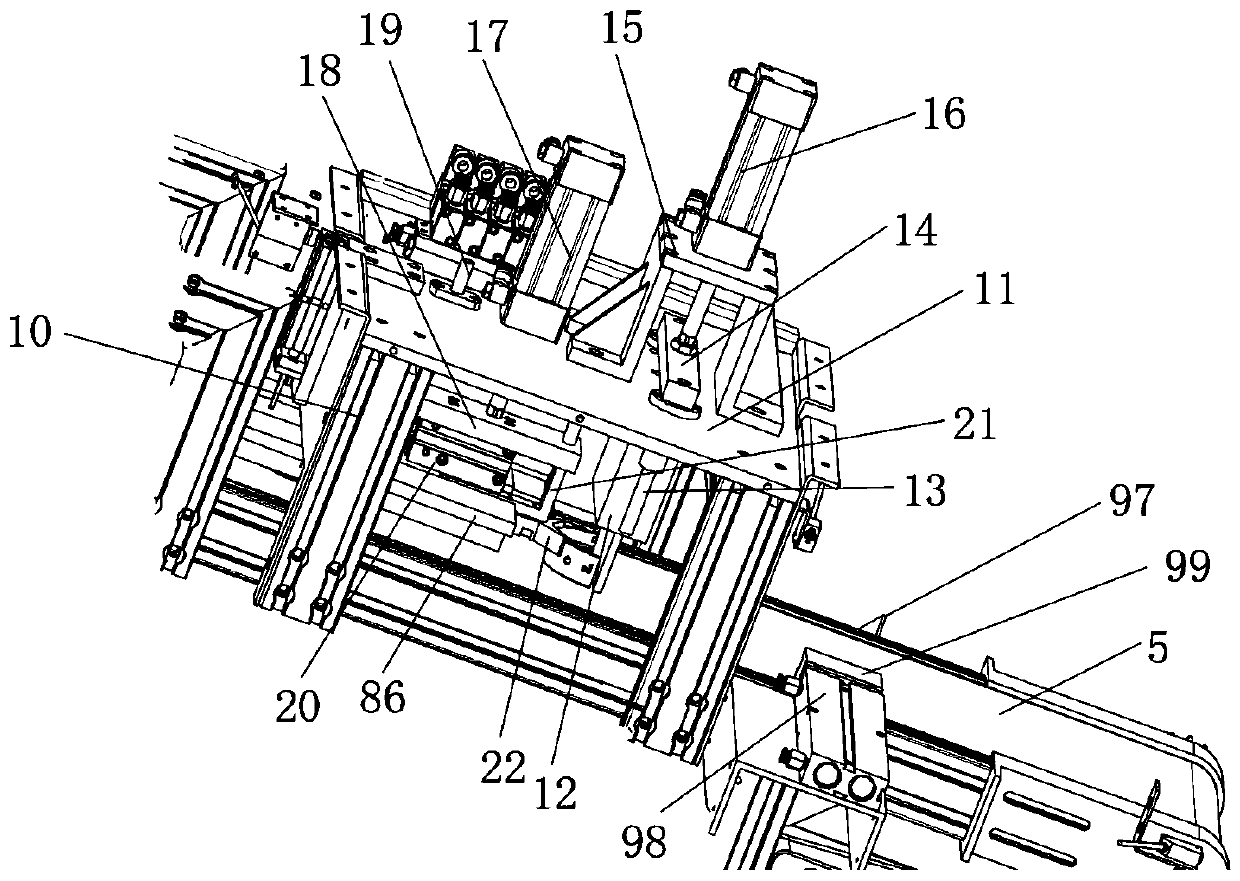

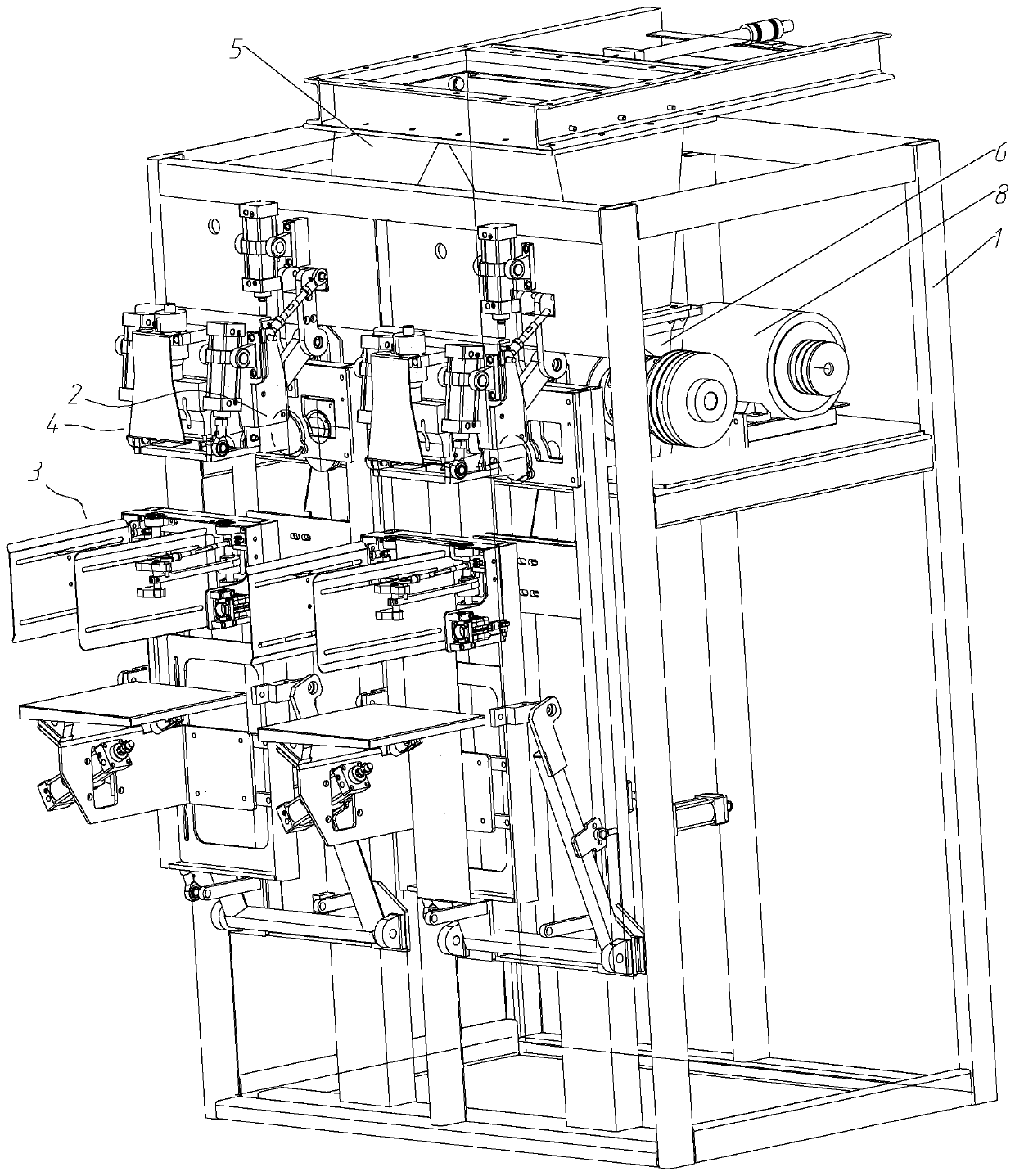

Welding rod packing equipment

PendingCN112224496AHigh degree of automationSimple and compact structureRod-shaped articlesStructural engineeringManufacturing engineering

The invention provides welding rod packing equipment. The welding rod packing equipment comprises: a rack; a welding rod packaging box opening device which is used for opening a packaging box; a conveying and folding device which is used for conveying and folding the packaging box and specifically comprises a conveyor belt and a folding mechanism; and a welding rod tidying and conveying device which is used for tidying the welding rods and pushing the tidied welding rods into the packaging box. In the embodiment of the invention, automatic box opening, folding and gluing of the welding rod packaging box can be achieved, so that the automation degree is high, the structure is simple and compact, the box opening speed is high, and the efficiency is high; automatic grabbing and feeding of welding rods and tidying and aligning of the welding rods can be achieved, and the tidied welding rods can be automatically loaded into a box, so that work efficiency is improved, and labor cost is reduced; the welding rod packing equipment can clamp and convey the folded and glued welding rod packaging box and consolidate the glued welding rod packaging box to make bonding of the welding rod packaging box tighter and firmer.

Owner:天津惠坤诺信包装设备有限公司

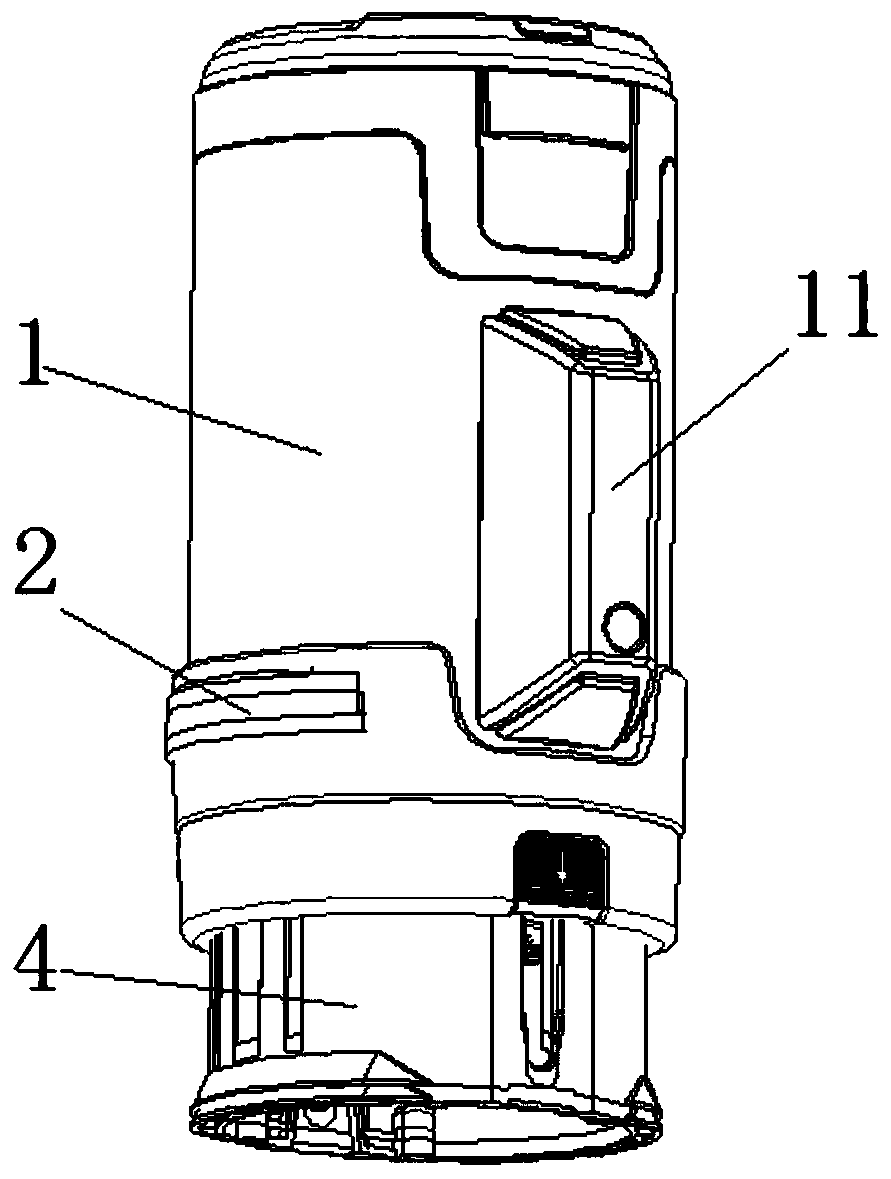

Reversible type seal

PendingCN109835071ASimple structureImplement the flipping actionStampingManufacturing technologyEngineering

The invention provides a reversible type seal, and relates to the technical field of seal manufacturing. The technical problem of a complex reversible structure of a seal existing in the prior art issolved. The reversible type seal includes a shell body, an ink cartridge, a reversible structure and a seal body; the reversible structure is arranged in the shell body, and the seal body is located between the ink cartridge and an opening of the shell body; the reversible structure includes a spring, a supporting frame, pushing structures and a seal fixing plate, and the spring is arranged between the supporting frame and the shell body; and the seal body is arranged on the seal fixing plate, the seal fixing plate is arranged in the supporting frame, the supporting frame is supported on a table surface and presses the shell body, and the seal body can be reversed from a state of being in contact with the ink cartridge and sealed to an object to be sealed under the action of the pushing structures. According to the reversible type seal, the reversal operation can be realized only through a simple structure, and a general structure needed for reversing the seal is greatly simplified.

Owner:中创印信(北京)科技发展有限公司

Turnover desk with lifting function

InactiveCN112438496AVersatileImplement the flipping actionSchool benchesVariable height tablesEngineeringDisplay board

The invention relates to a turnover desk with a lifting function, which comprises a base and supporting legs adjustably arranged on the base, the supporting legs comprise the left supporting leg and the right supporting leg, a fixed desk plate is fixedly arranged on the upper portions of the left supporting leg and the right supporting leg, and a turnover fixing plate is fixedly arranged at the bottom of the fixed desk plate and located on the outer sides of the left supporting leg and the right supporting leg. The right part of the turnover fixed plate protrudes out of the fixed table plate;a slot is formed between the turnover fixing plate and the fixed table plate; and an l-shaped display board can be inserted into the slot. Driving air cylinders are hinged to the inner sides of the middles of the left supporting leg and the right supporting leg respectively, a piston rod of each driving air cylinder is hinged to a turnover connecting plate a through a piston rod fixing block, a turnover connecting plate b is hinged to the right end of the turnover fixing plate, and a turnover table plate is arranged on the turnover connecting plate a and the turnover connecting plate b. And when the turnover table plate is in a horizontal state, the upper surface of the turnover table plate is flush with the upper surface of the fixed table plate. The turnover desk is simple in structure,convenient to use and wide in application range.

Owner:FOSHAN XINJUNAN SMART HOME CO LTD

A bagged diaper flipping system

ActiveCN108974459BMeet space constraintsIncrease flexibilityIndividual articlesProcess engineeringIndustrial engineering

The invention relates to a novel bagged paper diaper turning and sorting system. The novel bagged paper diaper turning and sorting system comprises a conveying assembly, a side pushing assembly, a turning assembly and a sorting assembly, wherein the conveying assembly comprises a conveying support, a plurality of conveying rollers which are distributed side by side are mounted on the conveying support, and a stop mechanism is arranged at a discharging port of the conveying support; the side pushing assembly is arranged at the bottom end of the discharging portion of the conveying support; theturning assembly is arranged at the discharging end of the conveying support and is located beside the side pushing assembly; and the sorting assembly is arranged at the discharging end of the conveying support and is located beside the turning assembly. The novel bagged paper diaper turning and sorting system has the advantages the compact structural design is adopted, so that the problem of limited spaces of factories is solved for most paper diaper production enterprises in the automatic upgrading process, and the cost used for re-building factories in the automatic upgrading process is avoided; meanwhile, equipment layout is facilitated, and the flexibility is high; and in addition, bagging can be conducted vertically and laterally, and thus, the application range of the whole system is greatly widened.

Owner:NANTONG UNIVERSAL MACHINERY

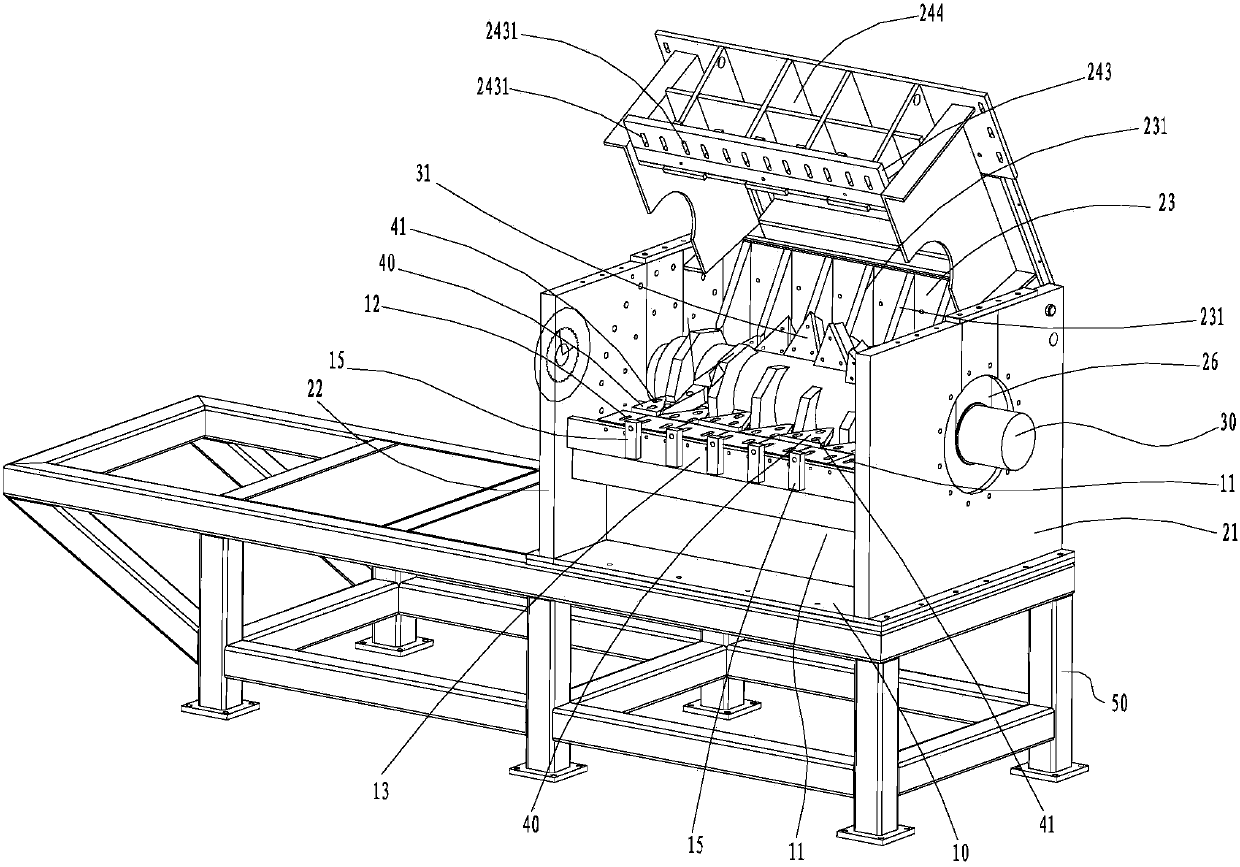

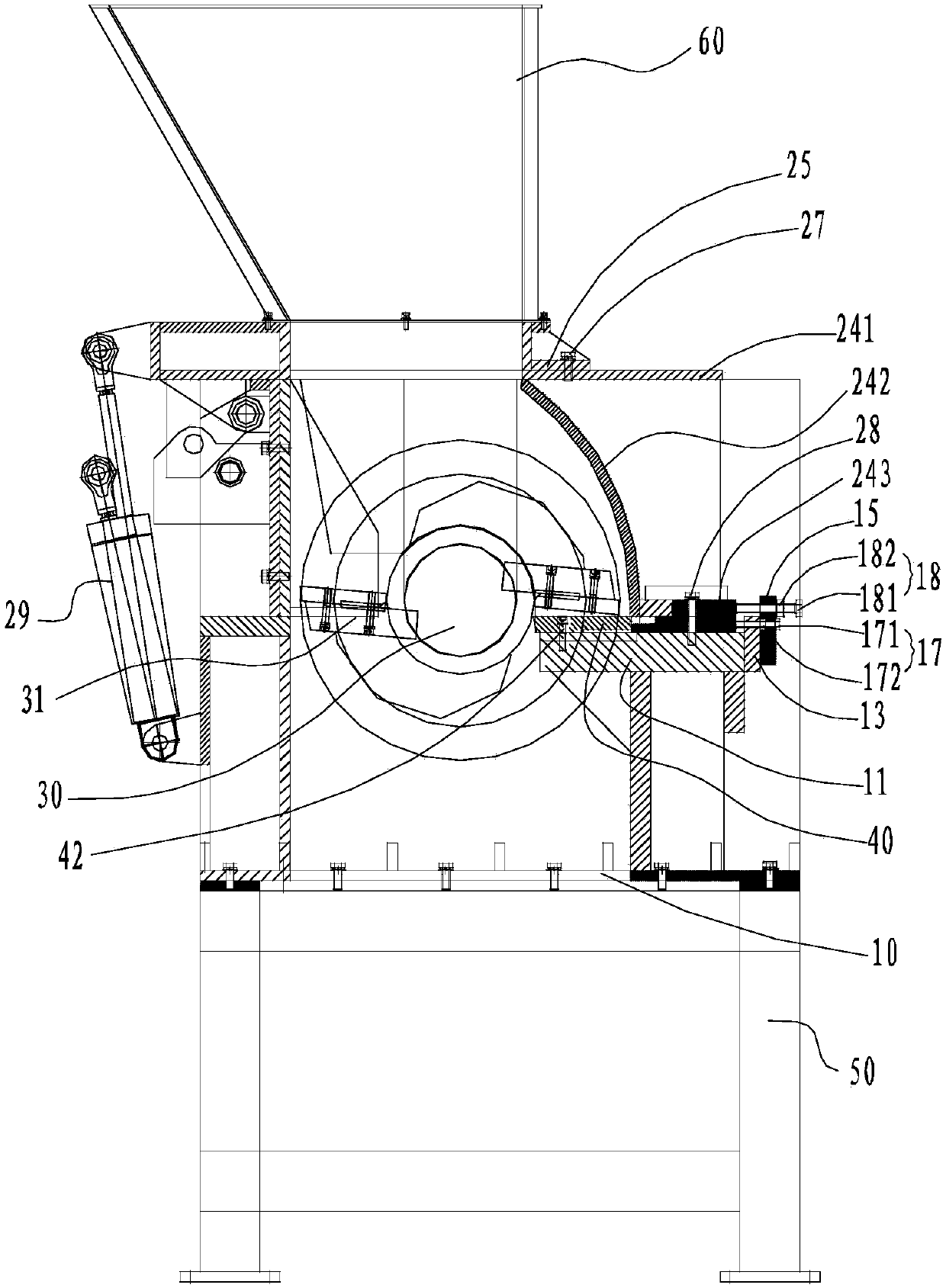

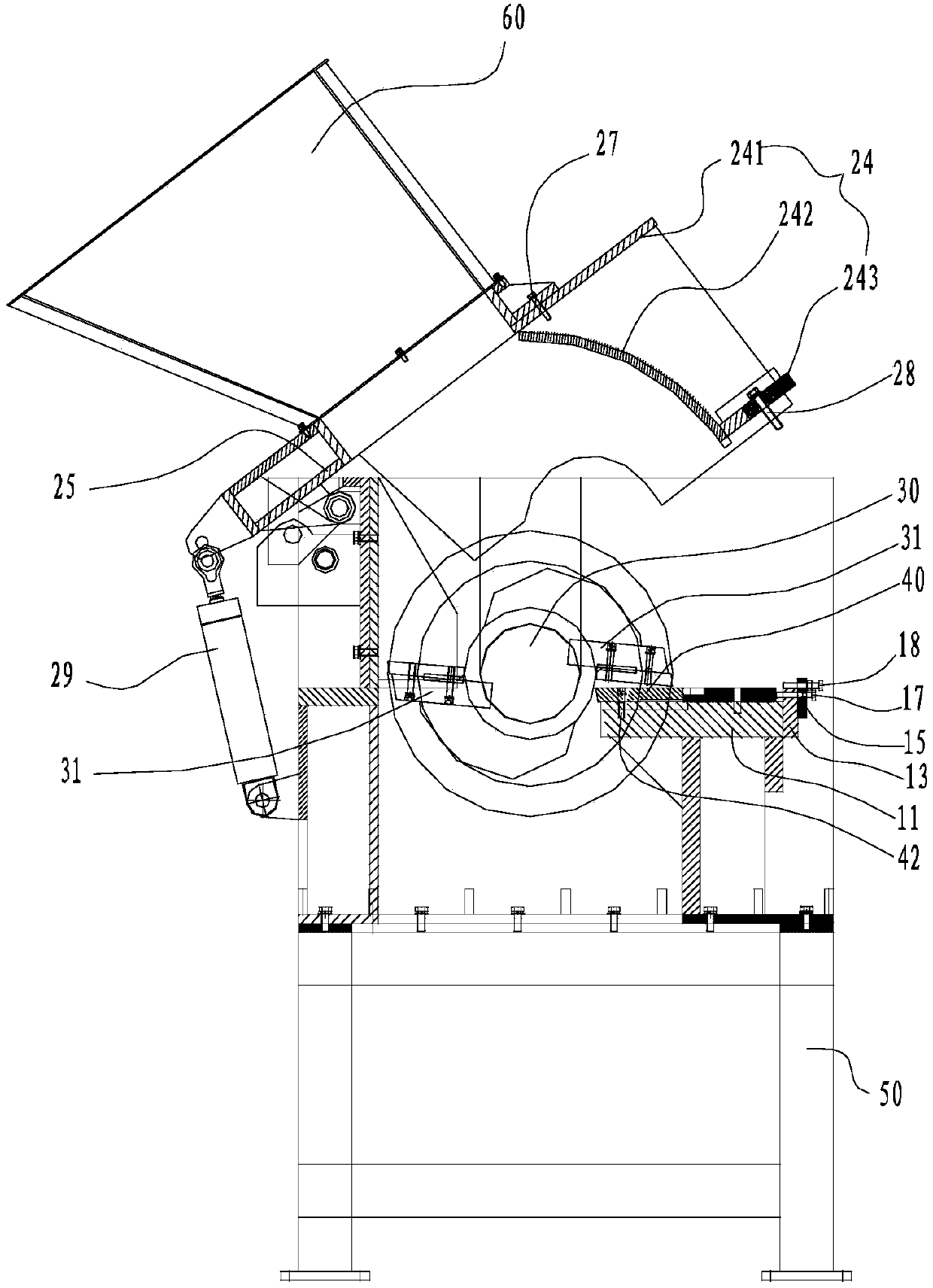

A single shaft shredder

The invention discloses a single-shaft shredding machine. The single-shaft shredding machine comprises a base, a first supporting plate, a second supporting plate, a first side plate, a second side plate, a carrier plate, a rotating shaft, a movable cutter body and a fixed cutter body, wherein the first supporting plate and the second supporting plate are arranged on the base side by side at intervals; bearing holes are formed in the first supporting plate and the second supporting plate; the two ends of the first side plate are respectively connected to the first supporting plate and the second supporting plate; the carrier plate is rotatably connected to the first side plate and is connected to the second side plate; the second side plate is detachably connected to the base; the rotating shaft is rotatably arranged the first supporting plate and the second supporting plate through the bearing holes; and one end of the rotating shaft extends out from the bearing holes and then is connected to a torque output mechanism. The single-shaft shredding machine has the beneficial effects that the second side plate and the carrier plate are easy to overturn and open together around the first side plate; and the maintenance efficiency of the fixed cutter body and the movable cutter body on the rotating shaft is high.

Owner:GUANGZHOU 3E MACHINERY

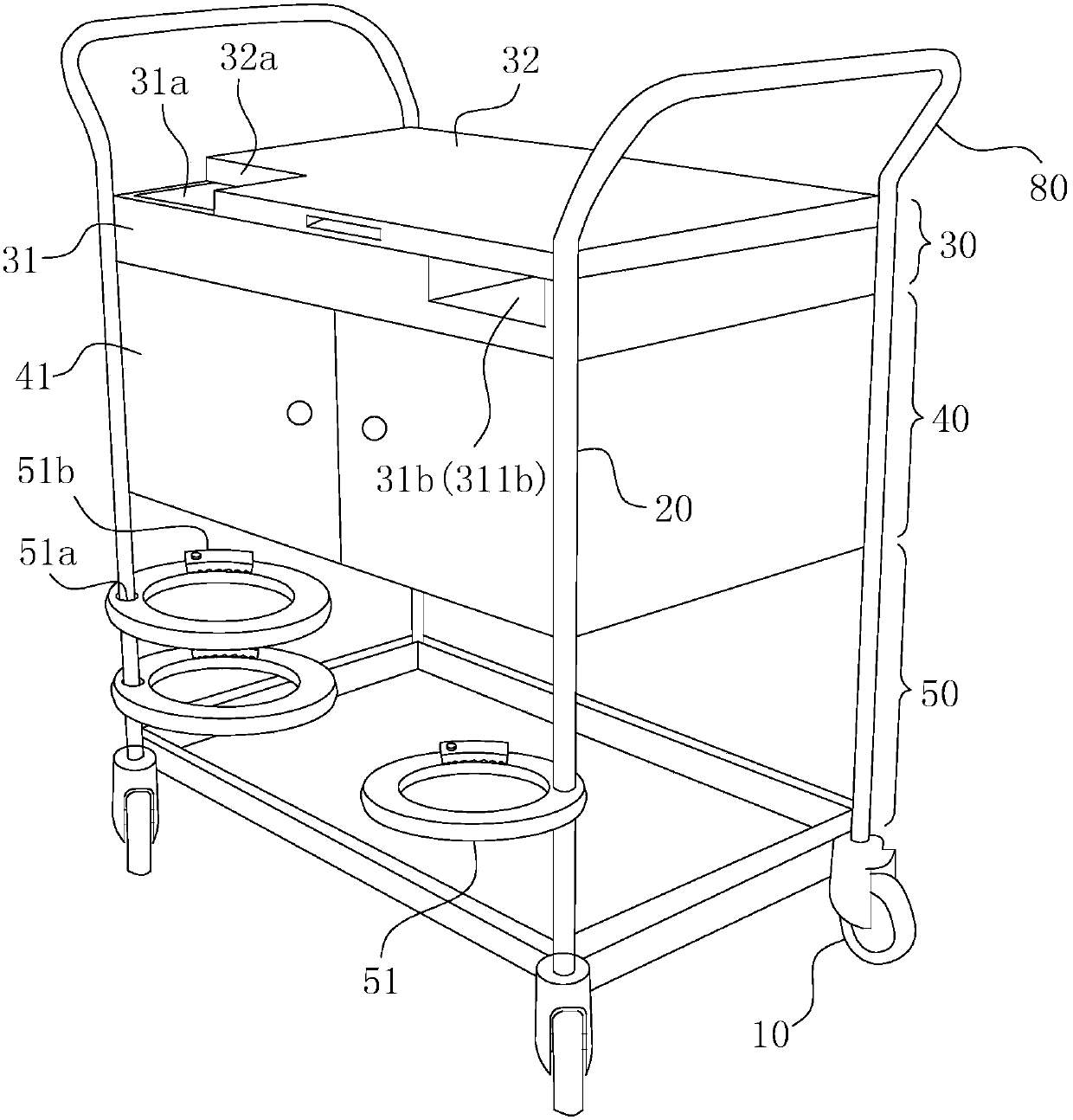

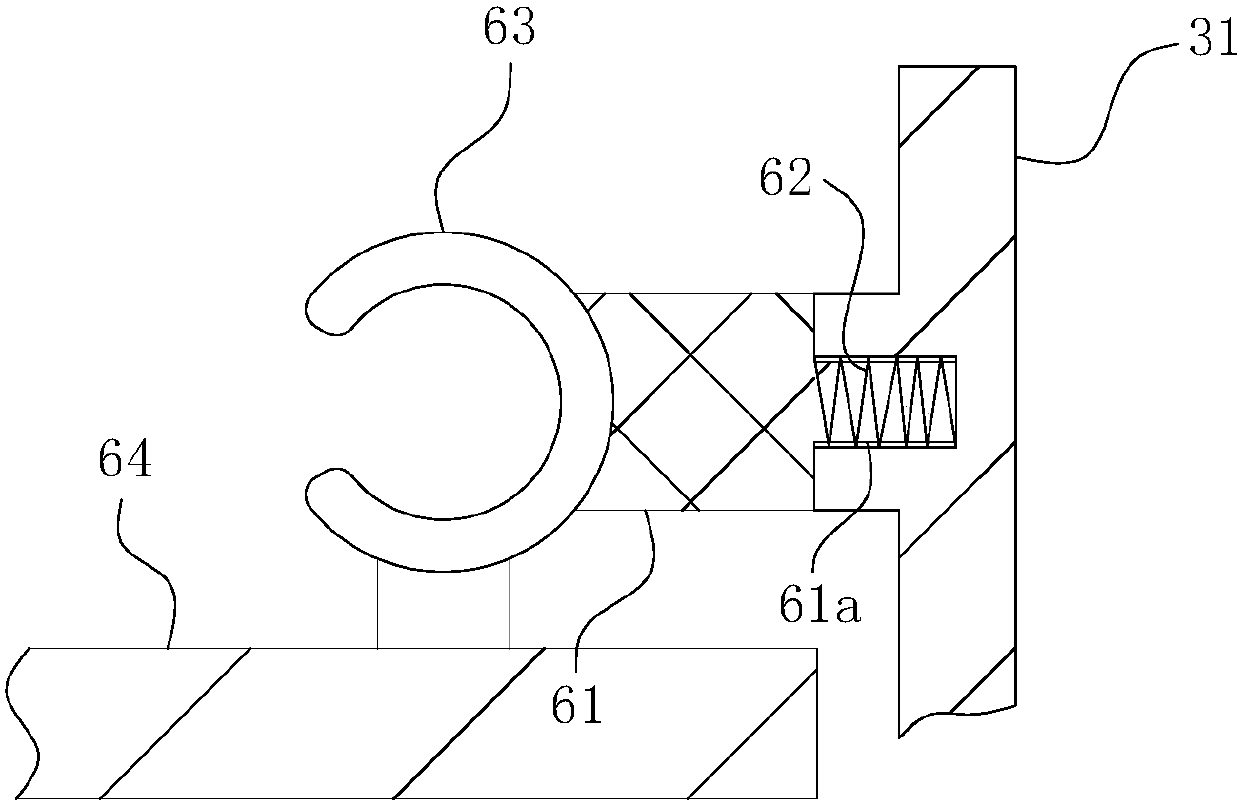

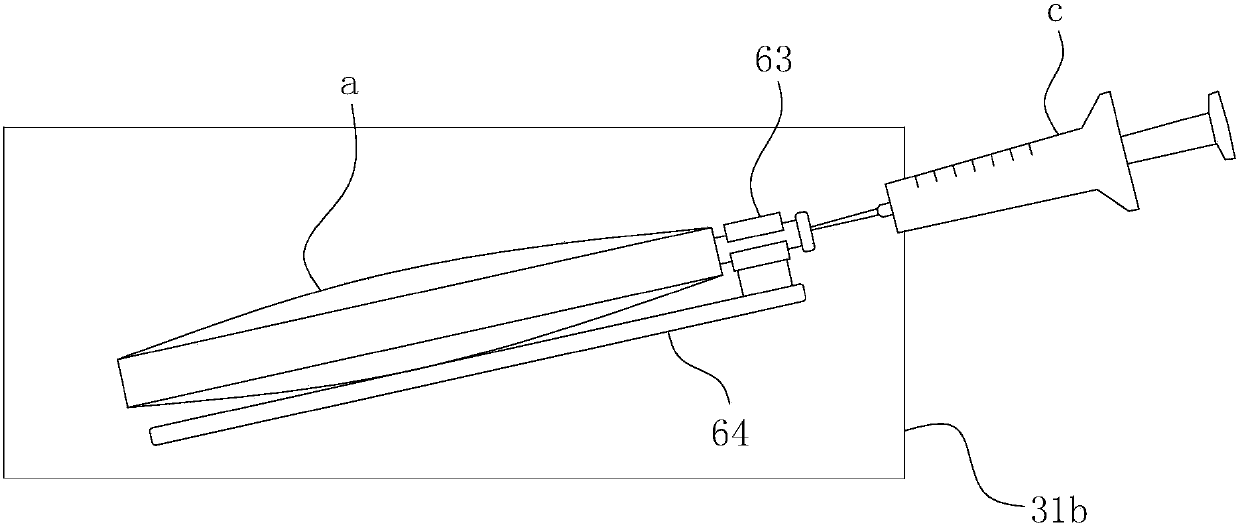

picc special drug changing cart

InactiveCN105919758BEasy to operateImprove work efficiencySurgical furnitureNursing accommodationDressing changeMedical waste

The invention belongs to the field of clinical medical appliances, and in particular relates to a special dressing cart for PICC. The invention includes a car body and wheels at the bottom of the car body; the car body uses four vertical columns as support columns, and arranges a medical supplies placement layer, a spare item storage layer and a medical Garbage storage layer; the medical supplies storage layer includes a square-shaped storage box, which is divided into multiple storage areas corresponding to different medical supplies by partitions, and one side of the storage box is hinged to open and close the storage box The cover of the box; the spare item storage layer is a split cabinet structure; the medical waste storage layer includes at least three fixing rings for placing garbage bags and sharps boxes; space. The operation of the invention is simple and reliable, and the work efficiency is high, which can realize refined, standardized and fast clinical PICC dressing changing requirements.

Owner:HEFEI NO 2 PEOPLES HOSPITAL

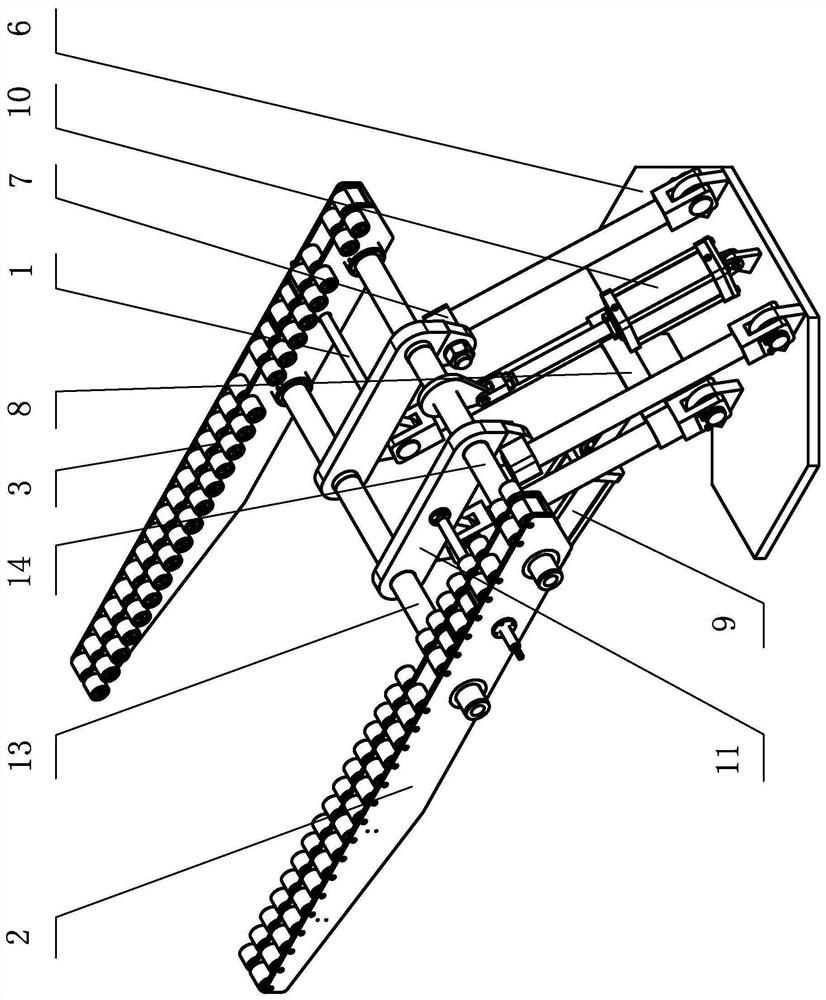

Parallel connecting rod type tire unloading device

The invention discloses a parallel connecting rod type tire unloading device. The parallel connecting rod type tire unloading device comprises a left supporting arm, a right supporting arm and a quadrilateral translation turnover mechanism which are installed on a rack through a left distance adjusting mechanism and a right distance adjusting mechanism, the turnover mechanism comprises front swingarms and rear swing arms which are symmetrical left and right, the lower ends of the front swing arms and the lower ends of the rear swing arms are hinged to a machine base, the upper ends of the front swing arms are hinged to the front bottom of the rack, and the rear swing arms are hinged to the rear bottom of the rack through sliding blocks sliding on the rear swing arms; and a transverse rodis connected between the left front swing arm and the right front swing arm, a translation driving cylinder hinged to a cylinder base is arranged in front of the transverse rod, a cylinder rod extending backwards of the translation driving cylinder is hinged to the transverse rod, an overturning driving cylinder is arranged between the left rear swing arm and the right rear swing arm, the lower end of the overturning driving cylinder is hinged to the machine base, and a cylinder rod extending upwards of the overturning driving cylinder is hinged to the rear bottom of the rack. According to thedevice, the three actions of entering and exiting, lifting and overturning are integrated, the mechanism is simple, the number of parts is small, installation is convenient, and efficiency is high.

Owner:GUILIN RUBBER MACHINERY CO LTD

Palm fruit yeast killing technology

InactiveCN102746942BReduce stack heightAvoid high-speed vertical fallsFatty-oils/fats productionBiotechnologyAgricultural science

The invention discloses a palm fruit yeast killing technology. The technology comprises the following steps: 1, feeding a material from a material inlet; 2, opening a movable turnover plate after completing the first material feeding to enable the material to fall into a tank under the movable turnover plate, continuously feeding the material from the material inlet, and closing the movable turnover plate after completing the second material feeding; 3, continuously feeding the material from the material inlet, and closing the fast opening door of the material inlet after completing the third material feeding; 4, letting steam in the tank until the pressure reaches 0.05-0.35MPa and the temperature reaches 120-350DEG C, and waiting for 3-30min; 5, opening a steam discharge valve, waiting for 3-30min, closing the steam discharge valve, and repeatedly step 4 until yeast killing requirements are reached; 6, opening the steam discharge valve, waiting until the pressure in the tank returns to zero, opening a water discharge valve, and waiting until a deposition liquid in the lower part of the tank is evacuated; and 7, sequentially opening the fast opening doors of material outlets and the movable turnover plate, and closing the movable turnover plate after completing the first material discharge and the second material discharge. According to the technology, the material feeding and the material discharge are carried out in a grading and batch mode, so material bridging and caking are avoided, material unloading is convenient, and destructive impact of the material to the bottom of the tank is prevented.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A stamping waste recycling system of CNC machining center

ActiveCN110961437BInconvenient to carryAvoid offsetSolid waste disposalGrain treatmentsNumerical controlProcess engineering

The invention provides a numerical control machining center stamping waste recycling system comprising a conveying mechanism, a smashing mechanism and a briquetting mechanism. The briquetting mechanism is provided with the crushing mechanism, the crushing mechanism is located right behind the briquetting mechanism, the conveying mechanism is located on the left side of the crushing mechanism and the conveying mechanism is installed on the briquetting mechanism. The problems of the existing waste recycling system in use that the collecting conveying line, the main conveying line and the recycling line all directly adopt conveying belts for conveying, most of stamping waste is fragmentary and is prone to jumping in the conveying process, the stamping waste often falls out of the two sides ofthe conveying belt in the conveying process, later-period cleaning is quite inconvenient, the hands of workers are prone to being hurt and many unsafe factors exist can be solved.

Owner:徐州标特福数控科技有限公司

Multi-degree-of-freedom series-parallel posture-adjusting assembly robot

PendingCN114700965AImplement the flipping actionGuaranteed lifting accuracyManipulatorRotation - actionControl engineering

The invention relates to a multi-degree-of-freedom series-parallel attitude-adjusting assembly robot which comprises a pitching dumping module, an orientation rotation module, a lifting module, an omni-directional moving module, supporting legs and a supporting parking module, the pitching dumping module is arranged on an omni-directional moving frame of the omni-directional moving module, and the orientation rotation module is arranged on the lifting module in a sliding mode through a rotation supporting frame; supporting legs are evenly distributed at the corners of the omni-directional moving module, and a supporting parking module is arranged in the middle of each set of supporting legs. The pitching dumping module can drive the posture adjusting component to turn over back and forth by 0-95 degrees through a crank sliding block, the direction rotation module can achieve 360-degree rotation action, meanwhile, the lifting module is driven through a lead screw and a nut, enough thrust can be provided, it can be guaranteed that the lifting process is flexible and stable, in addition, the supporting legs have six degrees of freedom, and the supporting legs are convenient to use. Movement, pitching, rolling, yawing and the like of the supporting legs in three directions can be achieved, and safety and reliability of the posture adjusting component in the posture adjusting process are guaranteed.

Owner:YANSHAN UNIV

A toilet aid

The invention discloses a toilet aid, which comprises a seat cushion supporting base and two toilet auxiliary mechanisms, the two toilet auxiliary mechanisms are arranged symmetrically with respect to the seat cushion support base, and the toilet auxiliary mechanism comprises a bracket, An electric push rod, a first track rod, a guide, a connector and a lock assembly; one end of the electric push rod is connected to the bracket, the other end of the electric push rod is connected to the shaft of the connector, and the first track rod It is fixed with the cushion support seat through a connecting piece; the guide rail vertically arranged on the support, the upper and lower sides of the guide rail are respectively provided with an upper limit block and a lower limit block, and the guide piece is sleeved on the guide rail and Can move up and down along the guide rail, the inside of the guide is provided with an arc-shaped guide groove, the first track bar is passed through the guide slot, and the lock assembly is arranged on the first track bar between the guides. It guarantees the safety and auxiliary effect of the elderly in the whole process of going to the toilet, and has good stability.

Owner:JIANGSU JICUI MICRO NANO AUTOMATION SYST & EQUIP TECH RES INST CO LTD

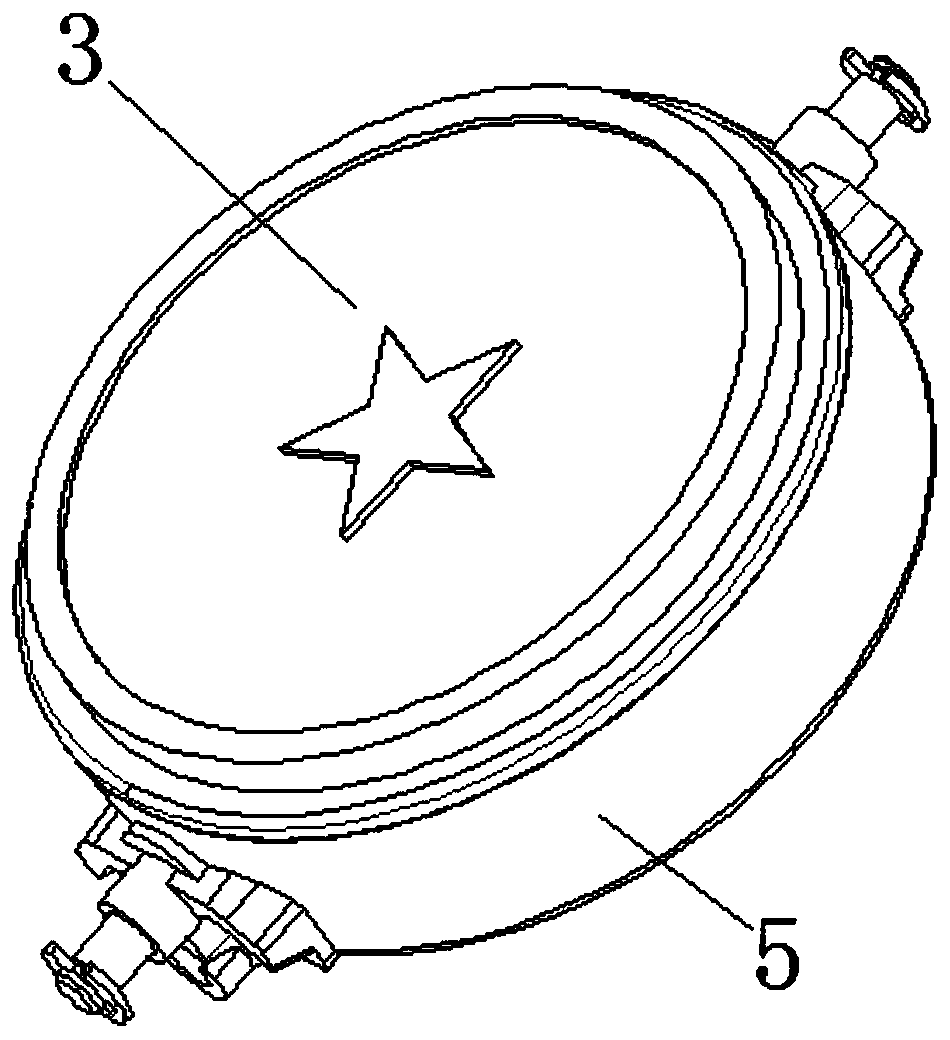

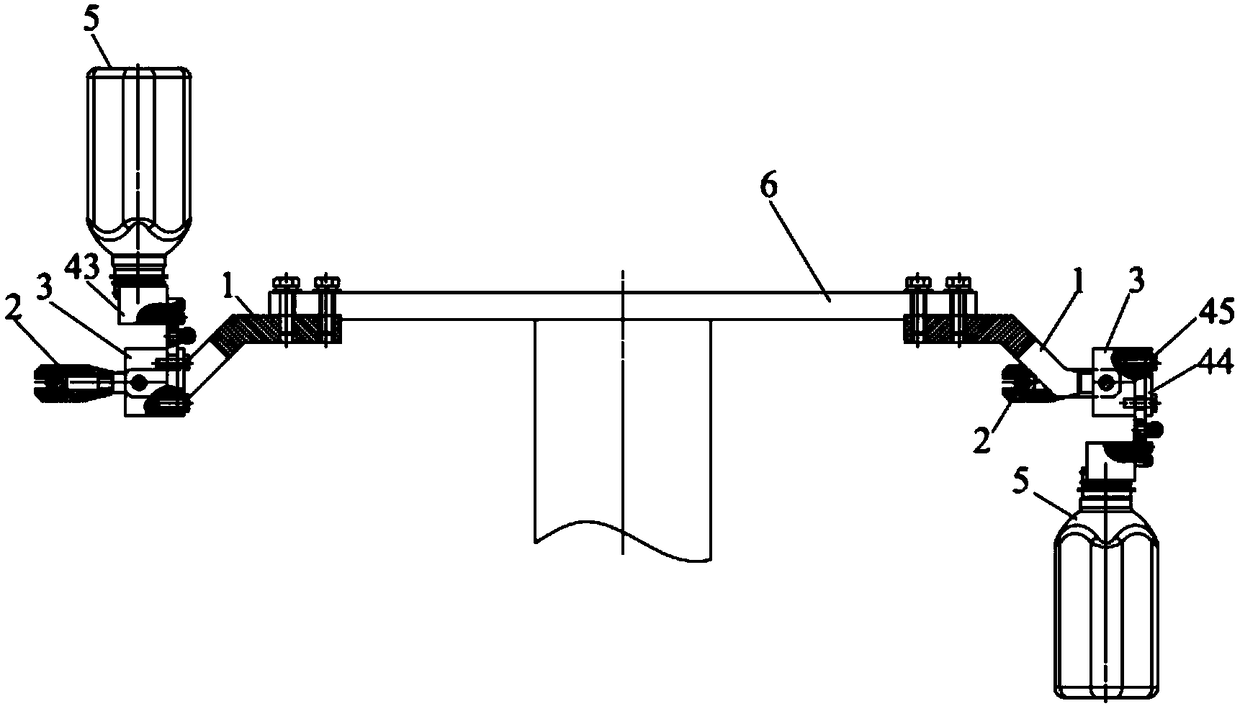

Vertical turnover star wheel clamp and conveyer line

PendingCN109230415ASolve the cleaning and disinfection time is too shortImplement the flipping actionConveyorsConveyor partsEngineeringBottle

The invention discloses a vertical turnover star wheel clamp and a conveyer line, and belongs to the technical field of packaging equipment. The vertical turnover star wheel clamp comprises a mountingframe, a turnover plate and a wheel clamp assembly, wherein the turnover plate can be rotationally arranged on the mounting frame, the turnover plate comprises a first mounting face, the first mounting face is an inclined plane, the first mounting face is provided with the wheel clamp assembly, and the wheel clamp assembly can overturn relative to the mounting frame in the vertical direction. Theturnover plate is provided with the wheel clamp assembly, thereby achieving the turnover movement of bottle products clamped on the wheel clamp assembly, and satisfying the requirement for the bottlestate when the bottle products are cleaned or after cleaning is completed, and the invention further provides the conveyer line, which can achieve the transportation of the bottle products.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Open type cargo hold, cam linkage type hatch cover overturning locking mechanism and overturning locking method of cam linkage type hatch cover overturning locking mechanism

ActiveCN114412282AFirmly connectedAchieve unlockCosmonautic vehiclesNon-mechanical controlsCamControl theory

The invention discloses an open type cargo hold and cam linkage type hatch cover turnover locking mechanism and a turnover locking method thereof, and relates to the technical field of hatch cover connecting mechanisms of freight airships, reusable carriers and the like. The hatch cover connecting mechanism solves the problems that an existing hatch cover connecting mechanism cannot meet rapid and stable unlocking opening, closing unlocking and closing locking, and a hatch cover cannot be opened possibly due to the fact that a locking mechanism and a turnover mechanism operate at the same time. The power output end of the overturning transmission assembly is matched with the cam, and overturning of the hatch cover is achieved under driving of the overturning transmission assembly; the locking or unlocking of the cabin cover and the cabin seat is realized through the front end locking execution assembly under the driving of the front end locking transmission assembly; and under the driving of the rear end locking transmission assembly, the locking or unlocking of the cabin cover and the cabin rear end is realized through the rear end locking execution assembly. According to the invention, reliable connection of cargoes, pallets and the hatch cover body in the ascending process is met, meanwhile, the functions of rapid and stable unlocking and opening, closing and unlocking and closing and locking are achieved, and linkage type unlocking and overturning can be achieved.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com