Workpiece automatic overturning device

An automatic turning and workpiece technology, applied in the field of parts processing, can solve the problems of serious parts bumping, low work efficiency, and lower appearance quality, and achieve the effects of reducing bumps, saving space, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

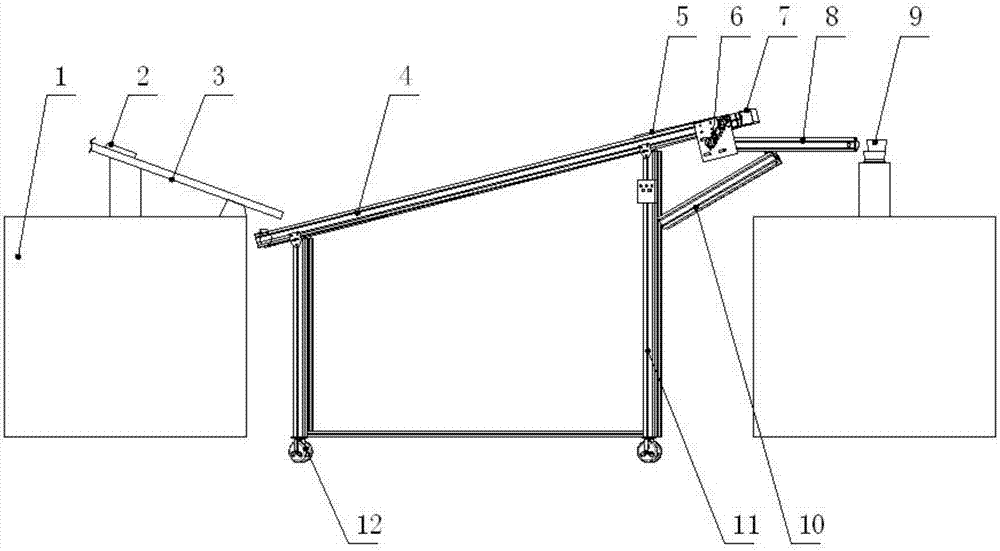

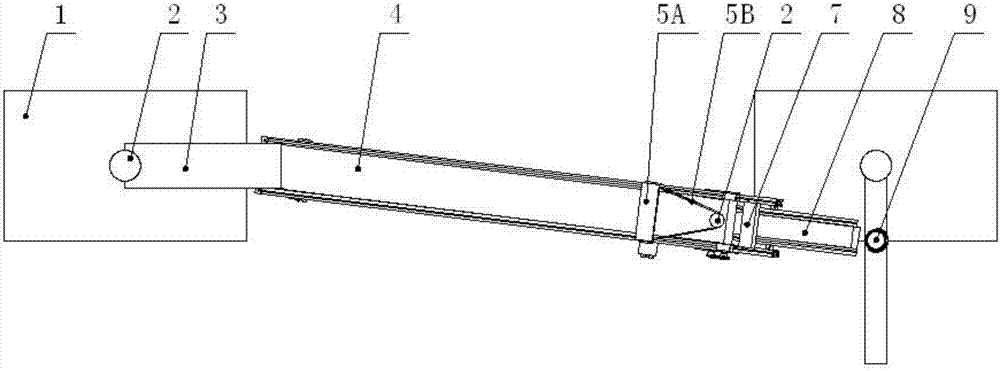

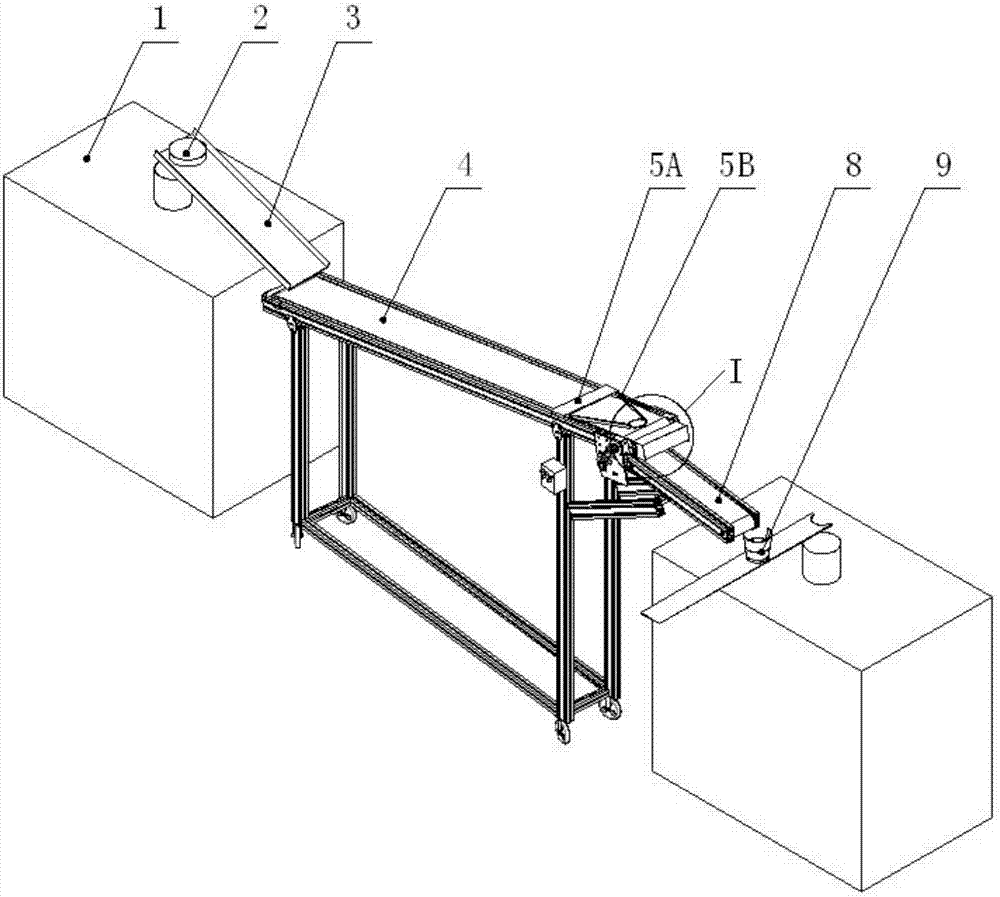

[0024] A workpiece automatic turning device, such as Figures 1 to 3 As shown, it includes a cabinet body 1, a material plate 3, a first conveyor belt 4, and a second conveyor belt 8. A material plate inclined downward is installed on the cabinet body, and a first inclined upward plate is installed at the discharge port of the material plate. Conveyor belt, the feed end of this first conveyor belt is corresponding to the discharge end of material board, and the discharge end of this first conveyor belt is equipped with turning mechanism 7, and this turning mechanism comprises turning box 7B and turning over bar 7A, as Figure 4 As shown, the flipping gear bar is vertically worn in the flip box, and the second conveyor belt is installed horizontally below the flip mechanism, and the automatic feeder 9 is installed below the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com