Multi-degree-of-freedom manipulator for construction engineering and operation method

A technology of construction engineering and manipulators, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of unfavorable long-term operations, low work efficiency, and high labor intensity of operators, so as to reduce work intensity, improve work efficiency, and ensure work The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

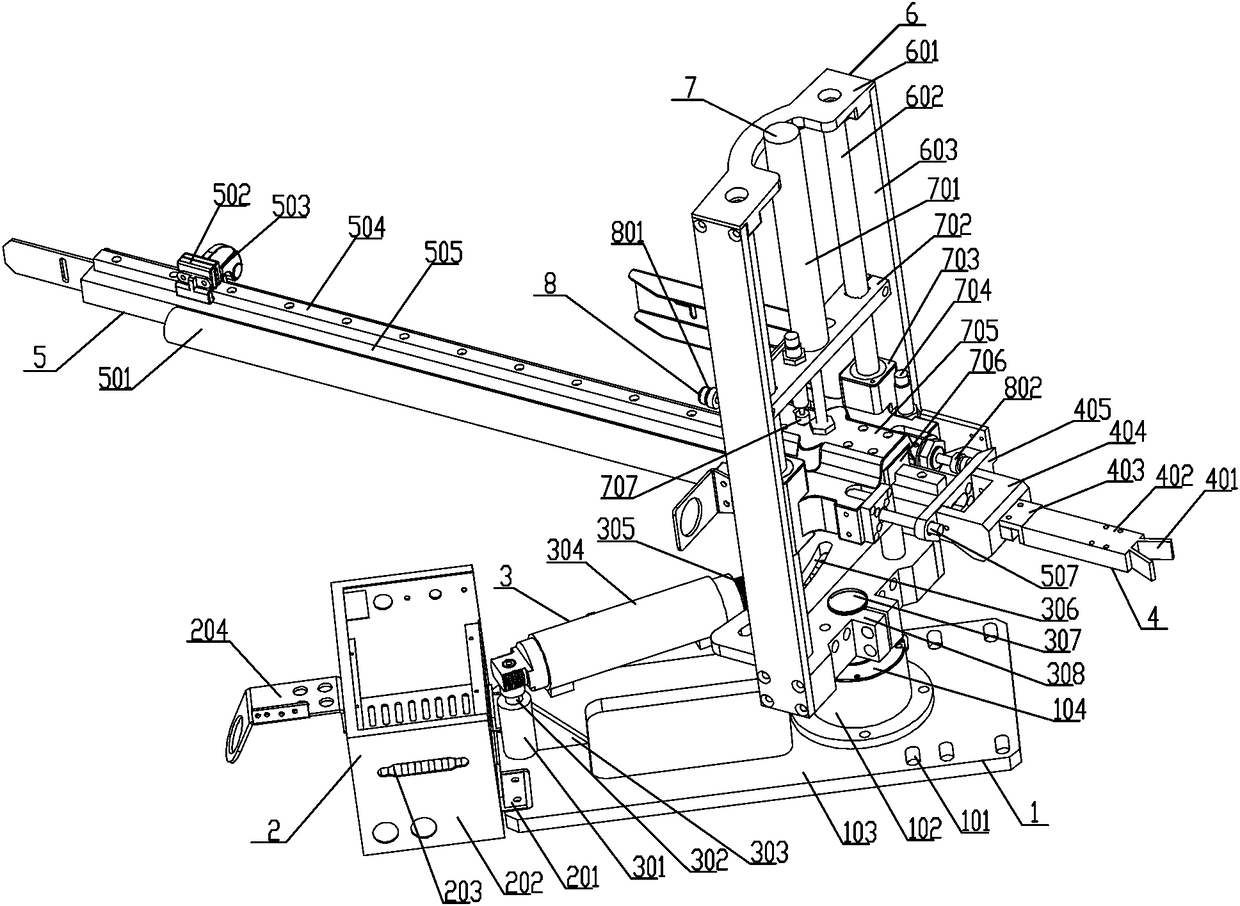

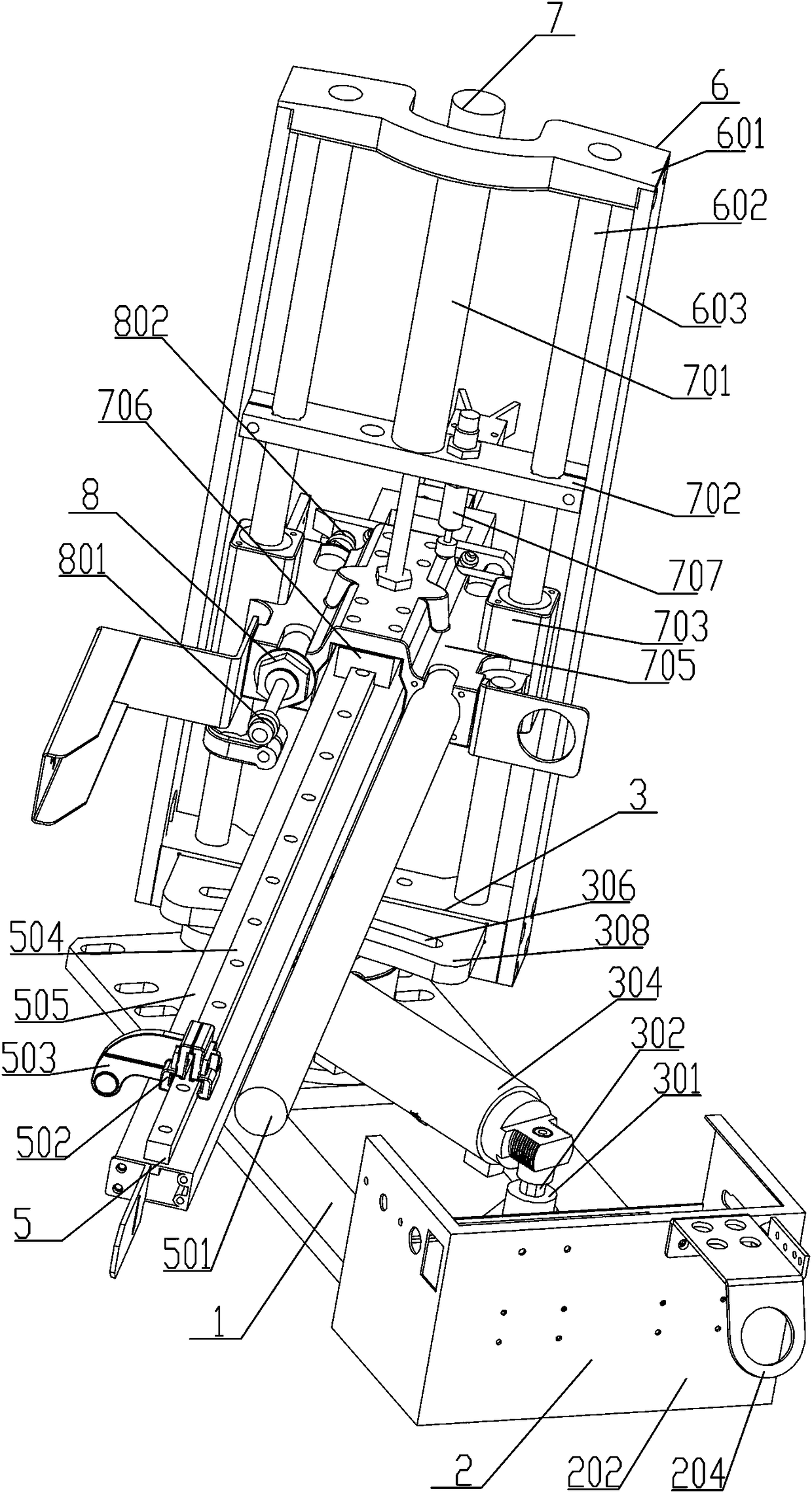

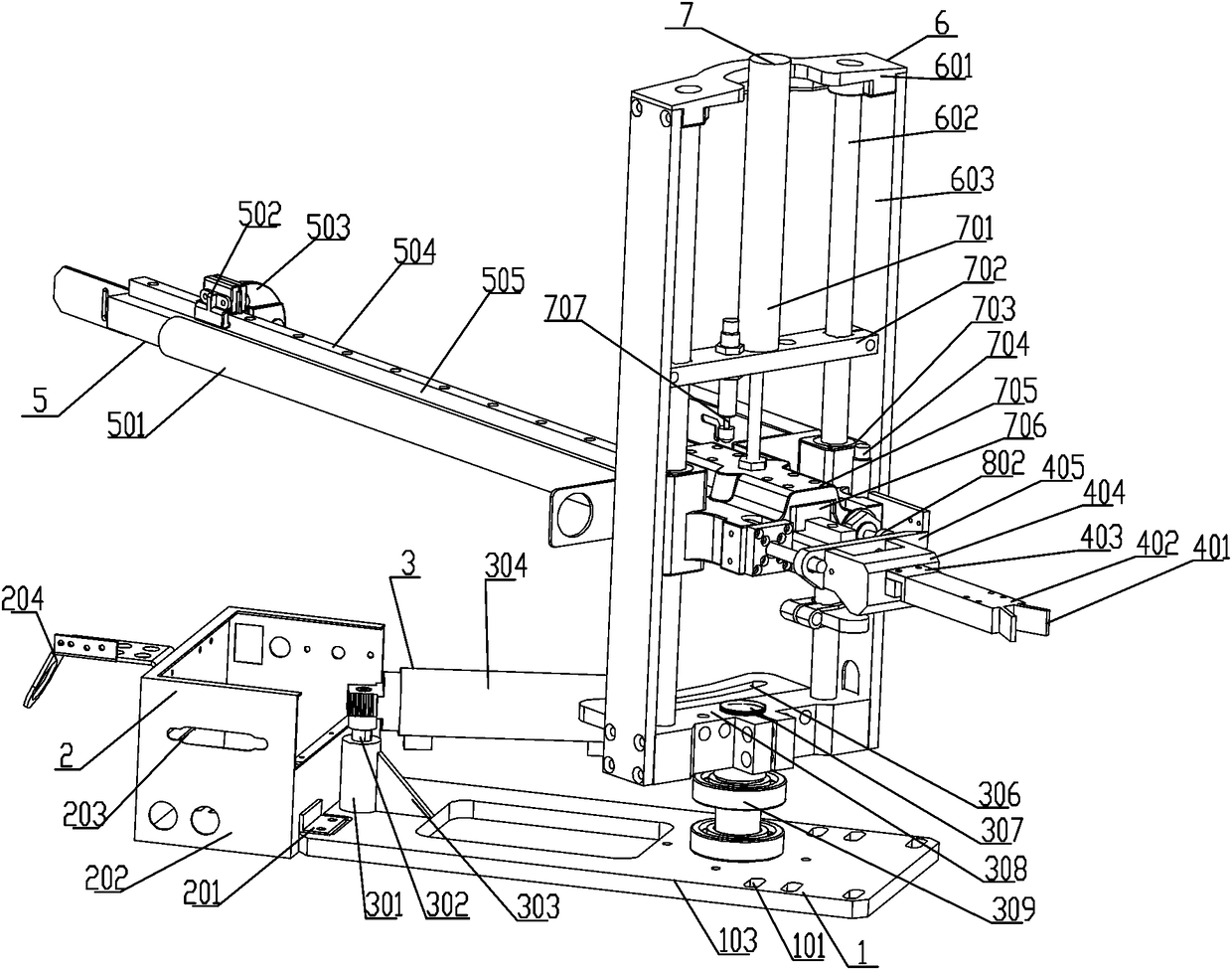

[0034] see Figure 1-4 , a multi-degree-of-freedom manipulator for construction engineering, which includes a support base structure 1 for supporting the entire manipulator, an electric control device 2 is installed on the tail side of the support base structure 1, and is useful for installing on the top of the support base structure 1 The rotating power device 3 that drives the manipulator to rotate along the vertical axis is supported and installed on the rotating base 308 of the rotating power device 3. The top frame structure 6 is installed on the top frame structure 6 for driving the manipulator to move vertically. Mechanism 7, the telescopic mechanism 5 for driving the telescopic movement of the manipulator is installed on the lifting base 705 of the lifting mechanism 7, and the head of the telescopic beam 505 of the telescopic mechanism 5 is fixedly installed with the manipulator assembly 4 for grasping action. Through the above-mentioned multi-degree-of-freedom manipul...

Embodiment 2

[0045] A method for using a multi-degree-of-freedom manipulator for construction engineering, comprising the following steps:

[0046] Step1: Fix and install the support base structure 1 at the position where the grabbing operation is required;

[0047] Step2: Start the rotary power cylinder 304 of the rotary power device 3, drive the top frame structure 6 to rotate around the main shaft 307 through the rotary power cylinder 304, and then rotate the manipulator assembly 4 to the position where the object needs to be grasped;

[0048] Step3: Start the lifting mechanism 7, drive the lifting base 705 to lift along the vertical guide rod 602 through the lifting cylinder 701, and adjust the height of the manipulator assembly 4 to make it the same as the height of the object to be grasped;

[0049] Step4: Start the telescopic mechanism 5, drive the telescopic beam 505 to slide along the horizontal guide sleeve 706 through the telescopic cylinder 501, and then telescopically move the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com