Cover-type nut automatic feeding equipment and feeding method

An automatic feeding and nut technology, which is applied in metal processing equipment, vibrating conveyors, transportation and packaging, etc., can solve the problem of orderly feeding of cap nuts, achieve low design cost and maintenance cost, reduce the number of labor, The effect of reducing operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

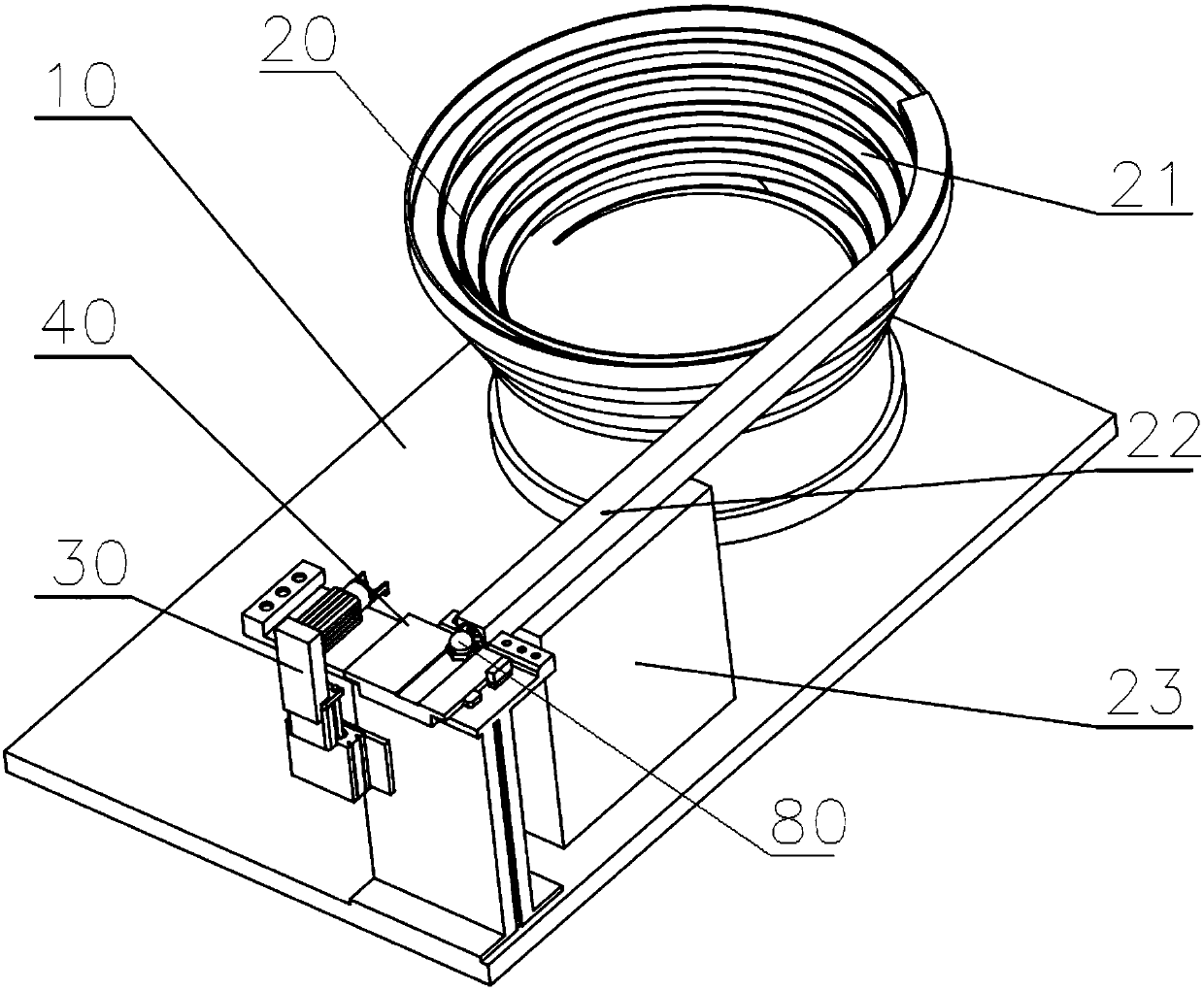

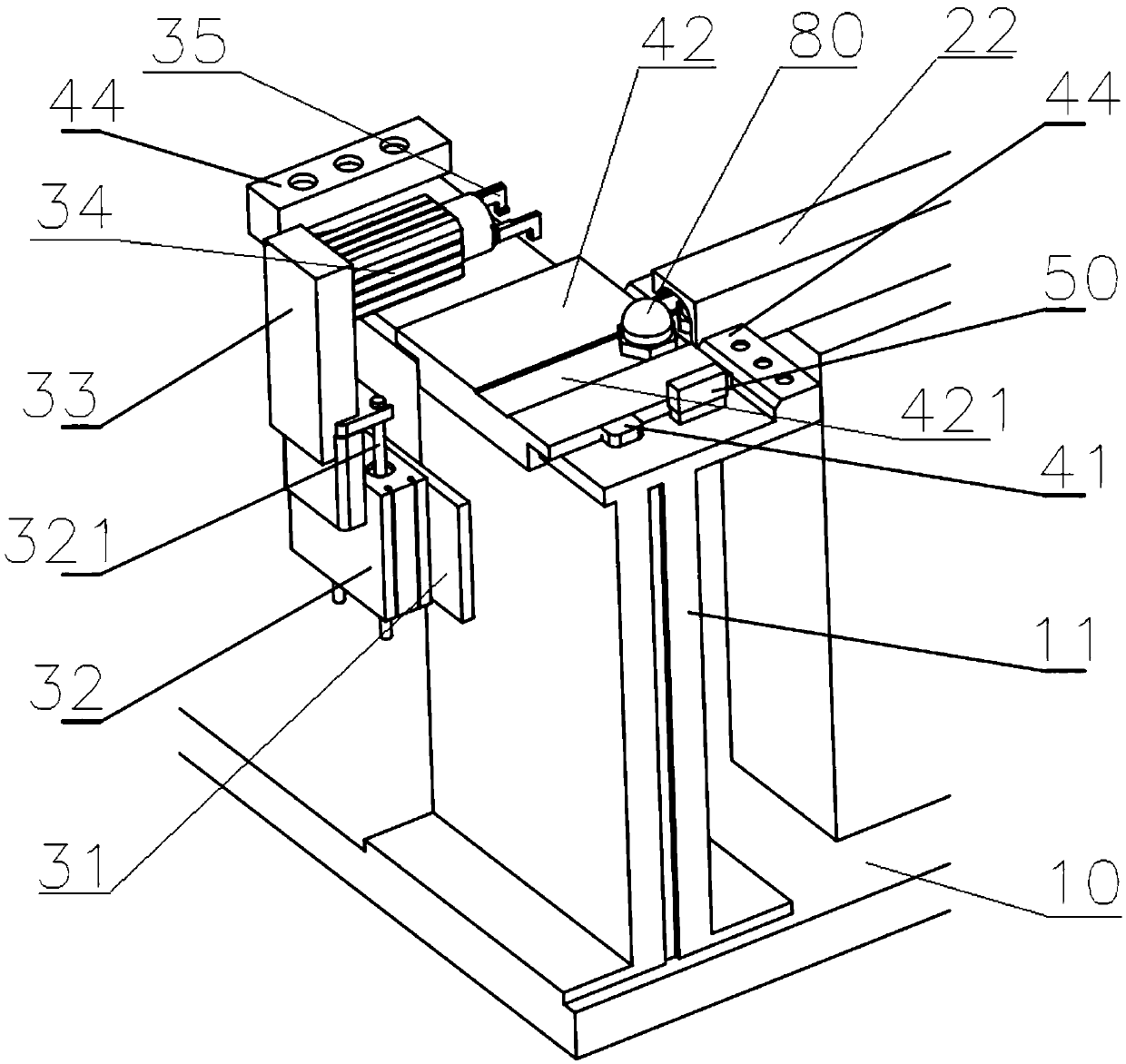

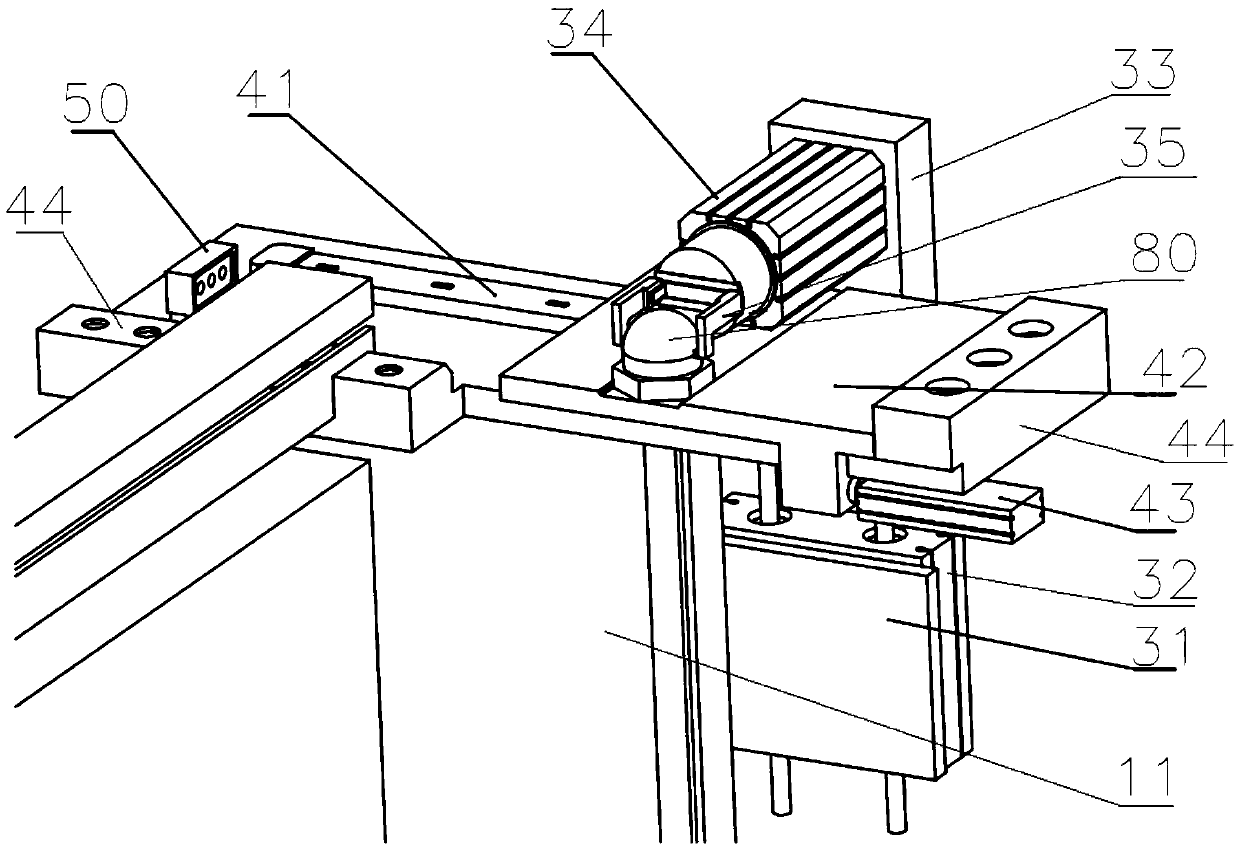

[0042] refer to figure 1 , the cap type nut automatic feeding equipment of the present invention comprises base plate 10, feeding mechanism 20, lifting handle 30, material shifting mechanism 40, photosensitive sensor 50, retrieving manipulator and control mechanism, and feeding mechanism 20 comprises nut vibrating plate 21. The feeding track 22 and the linear vibrator 23, the nut vibrating plate 21 and the linear vibrator 23 are all fixed on the bottom plate 10, and the two are connected by the feeding track 22. The feeding track 22 is a long straight track, fixed On the upper surface of the linear vibrator 23 , the inlet end connects with the edge outlet of the nut vibration plate 21 .

[0043] The nut vibrating plate 21 is a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com