Electro-hydraulic integrated control holding clamp lifting turnover device and control method

A flipping device and clamping technology, which is applied in the field of clamping lifting and flipping devices, can solve the problems of being unable to apply to the automatic processing of workpieces, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

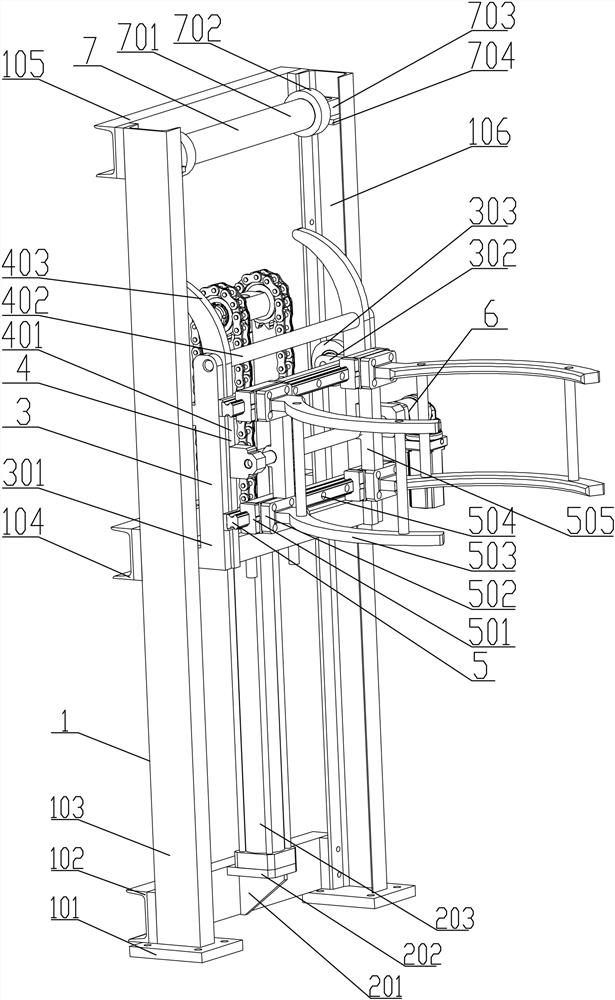

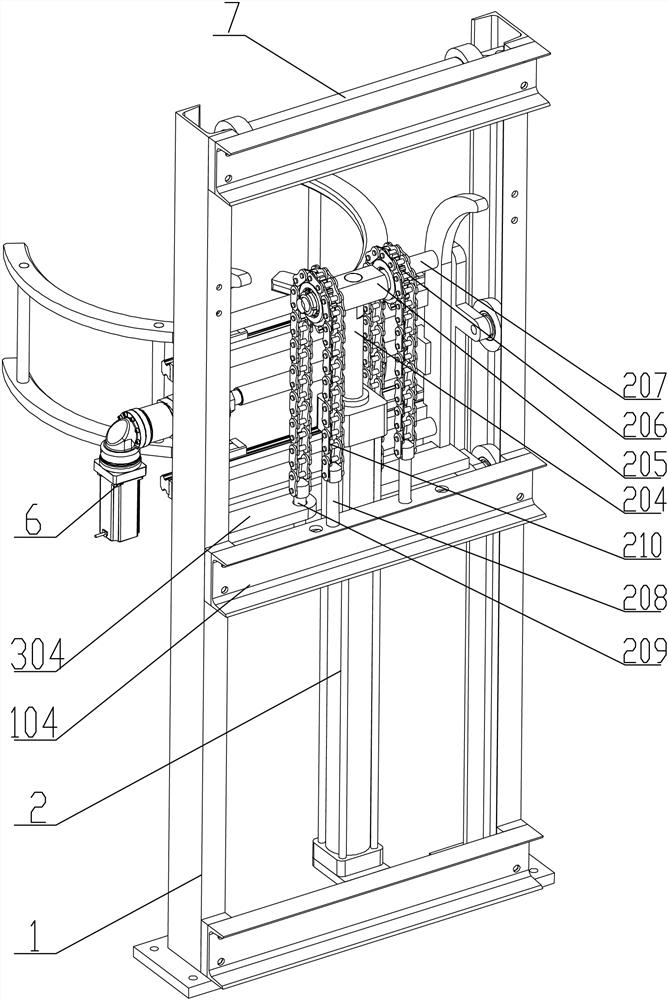

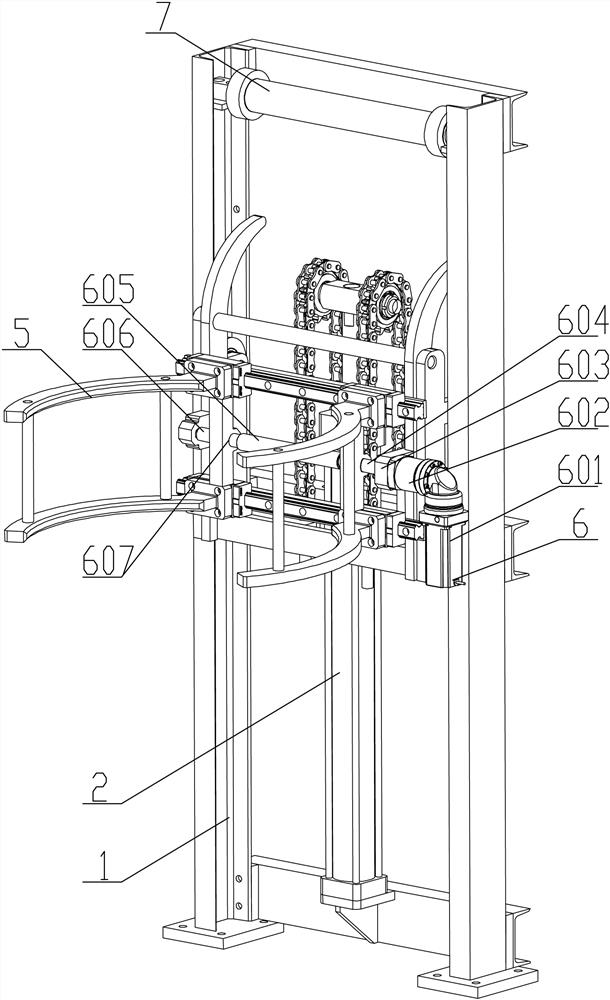

[0046] see Figure 1-5, an electro-hydraulic integrated lifting and flipping device, which includes a frame structure 1 for supporting the entire device. The frame structure 1 is equipped with a lifting carriage structure 3 through lifting and sliding. The lifting slide The frame structure 3 is connected with the chain lifting device 2 used to drive its lifting; the lifting carriage structure 3 is rotated and fitted with an overturning frame structure 4; the overturning frame structure 4 is connected with the overturning guide fixed on the top of the frame structure 1 Mechanism 7 cooperates; The outer wall of the flip frame structure 4 is equipped with a clamping arm mechanism 5 for clamping the workpiece, and the clamping arm mechanism 5 is connected with a clamping power device 6 for driving its clamping. This device can be used for the clamping of the workpiece. After clamping, it can realize the height adjustment control of its height, and can automatically turn over after...

Embodiment 2

[0056] The control method of the clamp lifting and turning device controlled by electro-hydraulic integration includes the following steps:

[0057] Step 1, start the chain lifting device 2, and move the lifting carriage structure 3 down to the height of the workpiece to be clamped;

[0058] Step 2, start the clamping power device 6, drive the reducer 602 through the servo motor 601, drive the first screw mandrel 604 and the second screw mandrel 606 through the reducer 602, and synchronously drive the arms 503 of the clamping arm mechanism 5 to move toward each other, Realize the clamping of the workpiece; wherein, during the clamping process, the clamping force is detected by the pressure sensor 9, and when the clamping force reaches the set value, the pressure sensor 9 transmits the pressure signal to the controller 8, and is controlled by the controller 8 The motor driver 11 drives the servo motor 601 to stop rotating by the motor driver 11;

[0059] Step 3: After the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com