Glass bead broadcasting device used for ruling machine

A glass bead and spreader technology, used in roads, road repairs, roads, etc., can solve the problems of polluting glass beads, easy rusting of the box, affecting the appearance of marking lines, etc., to avoid easy rusting, beautiful appearance, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

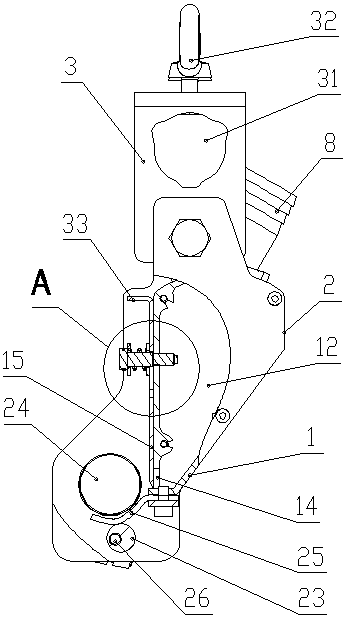

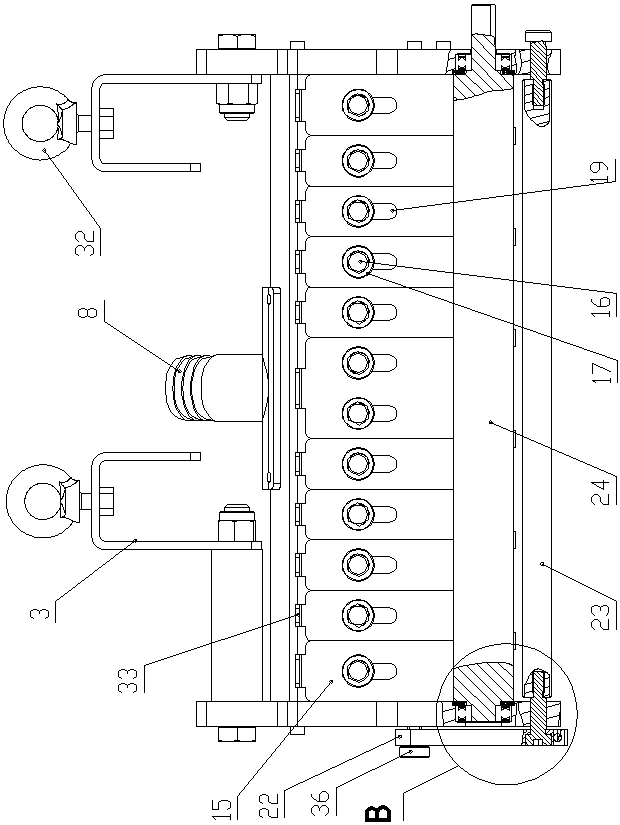

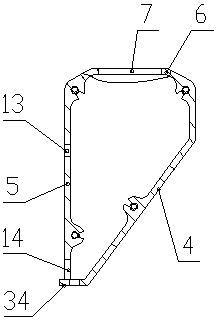

[0029] Such as Figure 1 to Figure 6 Shown, take the direction of progress of the present invention as the forward direction, that is, take figure 1 The left side of the left side is the forward direction of the present invention. The glass bead spreader for the scribing machine of the present invention includes a box body 1, a side plate 2, a mounting bracket 3, a width adjustment mechanism and a flow adjustment mechanism. The box body 1 passes through the profile Cold-drawn molding, the longitudinal cross-sectional profile of the box body 1 along the front and rear horizontal directions is a right-angled trapezoid, the left and right ends of the box body 1 are open, the side where the oblique waist of the right-angled trapezoid is located serves as the sliding plate 4 of the box body 1, and the lower bottom of the right-angled trapezoid The side is used as the discharge plate 5 of the box body 1, the front side of the sliding plate 4 is bent into a horizontal structure 34, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com