Nutrition pot sowing and burying device

A nutrient bowl and seeding tube technology, which is applied to watering devices, planting methods, and sowing seeders, can solve the problems of wasting farming time, high labor costs, and increasing labor costs, and achieves improved transplant efficiency, reduced personnel input, and reduced labor costs. The effect of agricultural production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

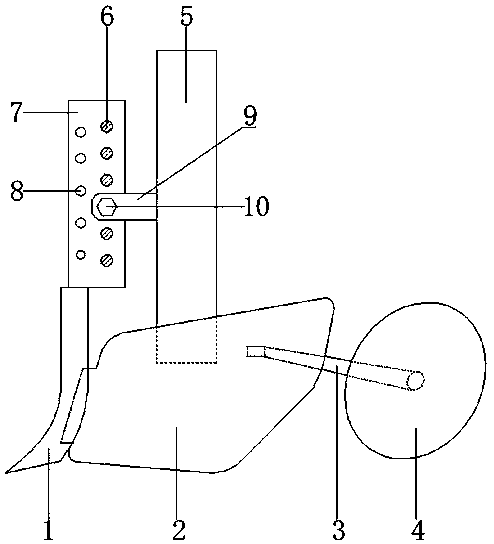

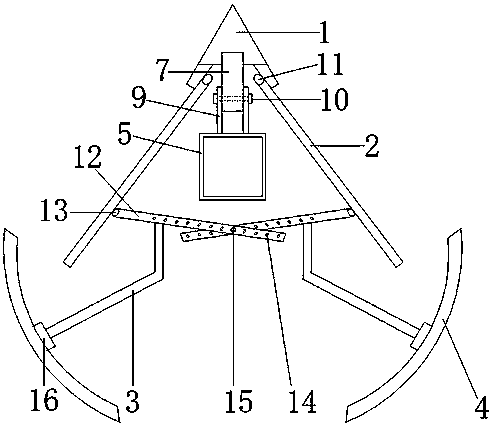

[0043] Such as figure 1 , 2 The nutrient pot sowing and burying device shown includes a ditching plough 1, a ploughshare 2, a soil covering wheel 4, and a seeding tube 5. The top of the ditching plough 1 is fixedly connected with a fixed plate 7, and the rear two sides are respectively connected with a loose leaf A11 A ploughshare 2 is movably connected. The fixed plate 7 is provided with a number of traction holes 8 and a number of adjustment holes A6. The side of the seed tube 5 is fixedly connected with a connecting ear 9 which is connected to the adjustment hole A6 by a bolt 10; after any ploughshare 2 The inner side of each part is connected with an adjusting rod 12 through a loose leaf B13, and the middle part of the adjusting rod 12 is rotatably connected with a soil covering wheel 4 through a connecting rod 3.

[0044] In order to realize the adjustable length of the adjusting rod 12 and thus the opening of the ploughshare 2, the corresponding adjusting rod 12 on each plou...

Embodiment 2

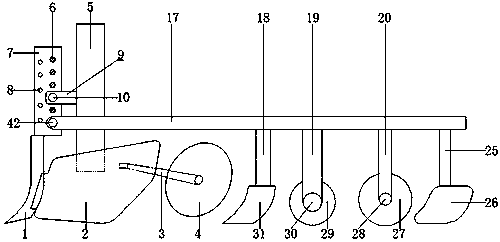

[0050] Such as image 3 , 4 A nutrient pot sowing and burying device shown in, 13, and 14, which includes a ditching plough 1, a plowshare 2, an earth-covering wheel 4, and a seeding tube 5. It is movably connected to a ploughshare 2 through loose leaf A11, a number of traction holes 8 and a number of adjustment holes A6 are opened on the fixed plate 7, a connecting ear 9 is fixedly connected to the side of the seeding tube 5, and the connecting ear 9 is connected to the adjustment hole A6 by a bolt 10; An adjusting rod 12 is connected to the inner side of the rear part of a ploughshare 2 through a loose leaf B13, and the middle part of the adjusting rod 12 is rotatably connected with an earth-covering wheel 4 through the connecting rod 3.

[0051] In order to realize the adjustable length of the adjusting rod 12 and thus the opening of the ploughshare 2, the corresponding adjusting rod 12 on each ploughshare 2 is provided with evenly distributed adjusting holes B14, and the adjus...

Embodiment 3

[0061] Such as Figure 5 , 6 A nutrient pot sowing and burying device shown in, 13, and 14, which includes a ditching plough 1, a plowshare 2, an earth-covering wheel 4, and a seeding tube 5. It is movably connected to a ploughshare 2 through loose leaf A11, a number of traction holes 8 and a number of adjustment holes A6 are opened on the fixed plate 7, a connecting ear 9 is fixedly connected to the side of the seeding tube 5, and the connecting ear 9 is connected to the adjustment hole A6 by a bolt 10; An adjusting rod 12 is connected to the inner side of the rear part of a ploughshare 2 through a loose leaf B13, and the middle part of the adjusting rod 12 is rotatably connected with an earth-covering wheel 4 through the connecting rod 3.

[0062] In order to realize the adjustable length of the adjusting rod 12 and thus the opening of the ploughshare 2, the corresponding adjusting rod 12 on each ploughshare 2 is provided with evenly distributed adjusting holes B14, and the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com