Locking mechanism of overturning clamp

A technology of locking mechanism and overturning fixture, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of large impact force, inability to completely solve the problems of invisible solder joints, ergonomics, and potential safety hazards. The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

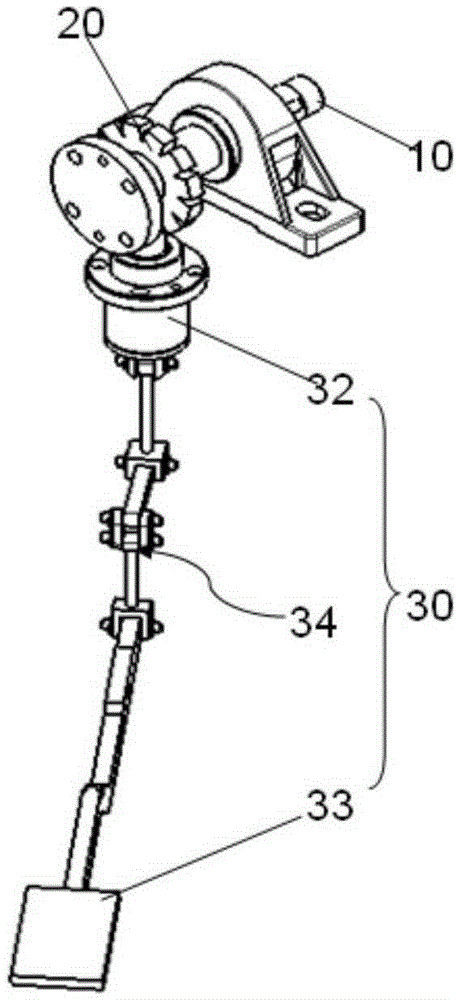

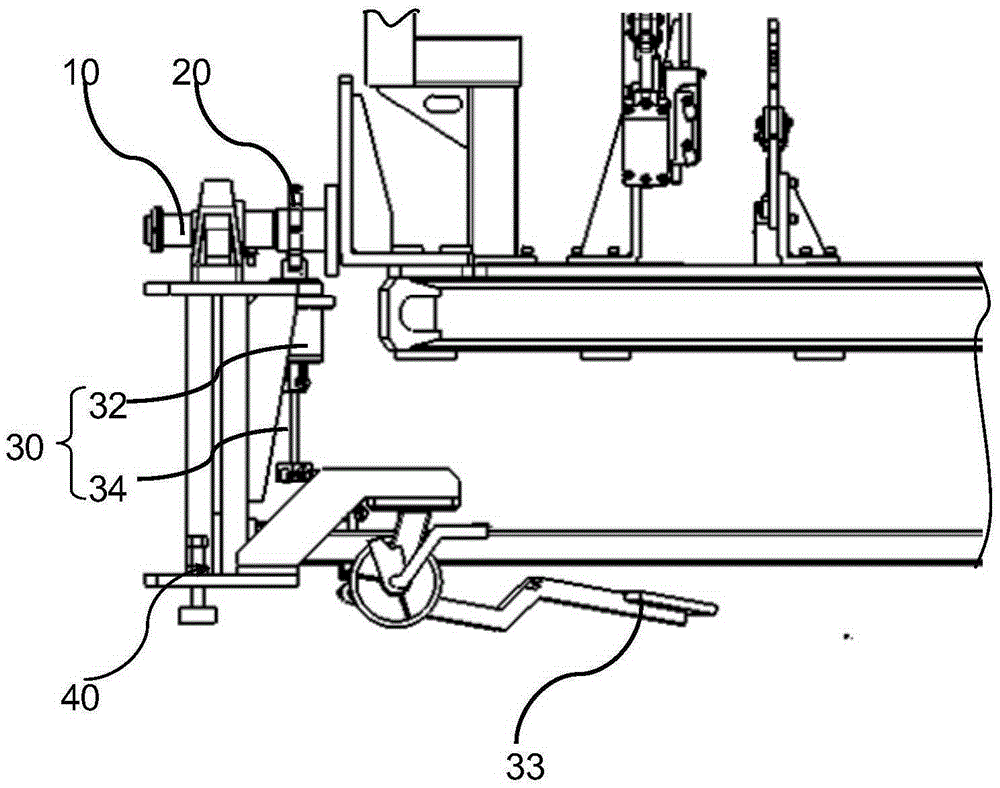

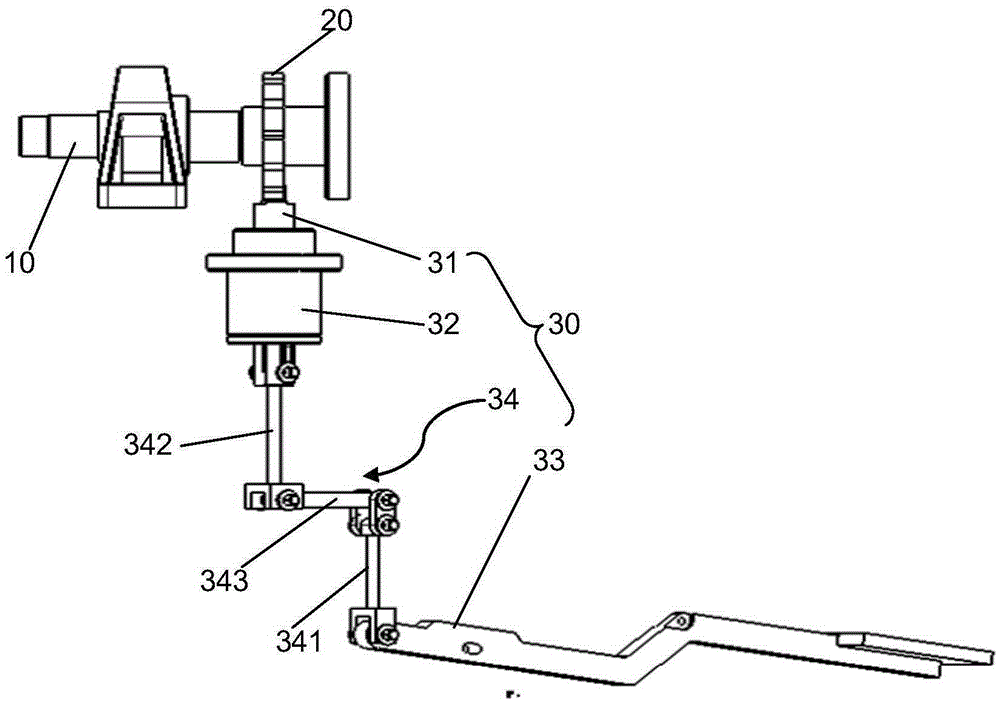

[0012] A locking mechanism for an overturning jig, comprising an indexing plate 20 fixed on the overturning shaft 10 of the fixture and a drive unit 30 fixed on the side of the fixture, the said indexing plate 20 is provided with two More than one indexing groove 21, the side of the indexing groove 21 is provided with a latch 31, the drive unit 30 drives the latch 31 to be inserted in the indexing groove 21 or the driving latch 31 is in a position to avoid the indexing groove 21 .

[0013] Such as figure 1 and 4 As shown, indexing grooves 21 arranged along the radial direction are arranged on the edge of the indexing plate 20, and the number and positions of the indexing grooves 21 are determined according to the specific use requirements of the clamp. What needs to be explained here is that the clamp turning axis 10 refers to the rotating shaft around which the fixture rotates, and the indexing plate 20 is arranged on the turning axis 10, and the indexing plate 20 rotates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com