Open type cargo hold, cam linkage type hatch cover overturning locking mechanism and overturning locking method of cam linkage type hatch cover overturning locking mechanism

A technology of flip lock and flip mechanism, which is applied in the field of cam-linked hatch cover flip lock mechanism and open cargo compartment, which can solve the problems that the hatch cover cannot be opened, cannot meet the requirements of unlocking, opening, and closing and locking, and achieves stable unlocking and opening and closed locking, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

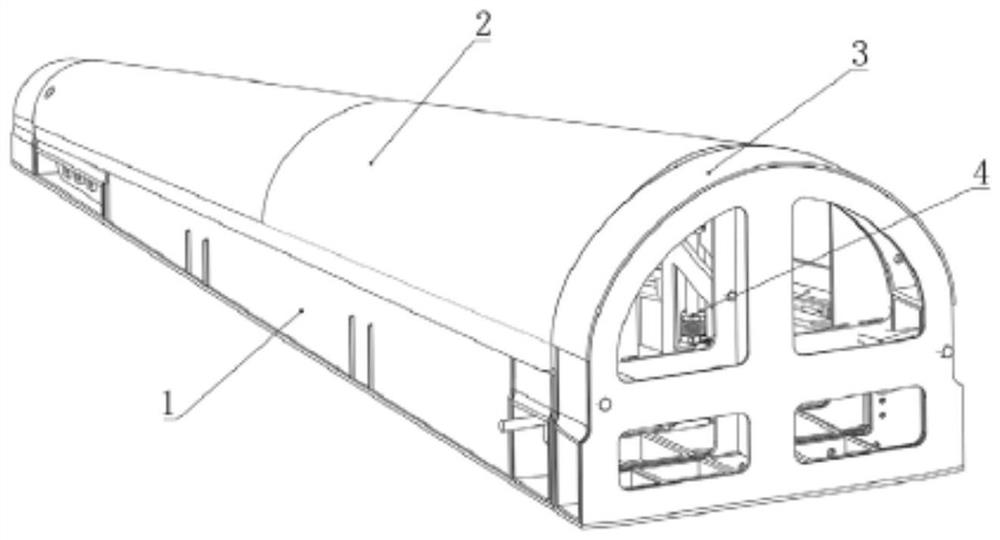

[0038] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, a kind of open cargo hold of this embodiment, it comprises cabin seat 1, hatch cover 2, cabin rear end 3 and flip lock mechanism 4, cabin seat 1 is horizontally arranged, and cabin rear end 3 is vertically arranged on The rear end of the cabin seat 1, the rear end of the cabin seat 1 is fixedly connected with the front end of the cabin rear end 3, the hatch cover 2 is horizontally arranged directly above the cabin seat 1, and the hatch cover 2 is connected to the cabin seat 1 and the cabin rear end by turning over the locking mechanism 4 Locking or unlocking between 3, the hatch cover 2 can be turned over with the rear end 3 of the cabin by turning over the locking mechanism 4;

[0039] The cabin seat 1 includes a cabin seat body 11, two pairs of lower lock bodies 12 and two pairs of reinforcing ribs 13, and the lower end surfaces of the top outer edges of the left and right sides...

specific Embodiment approach 2

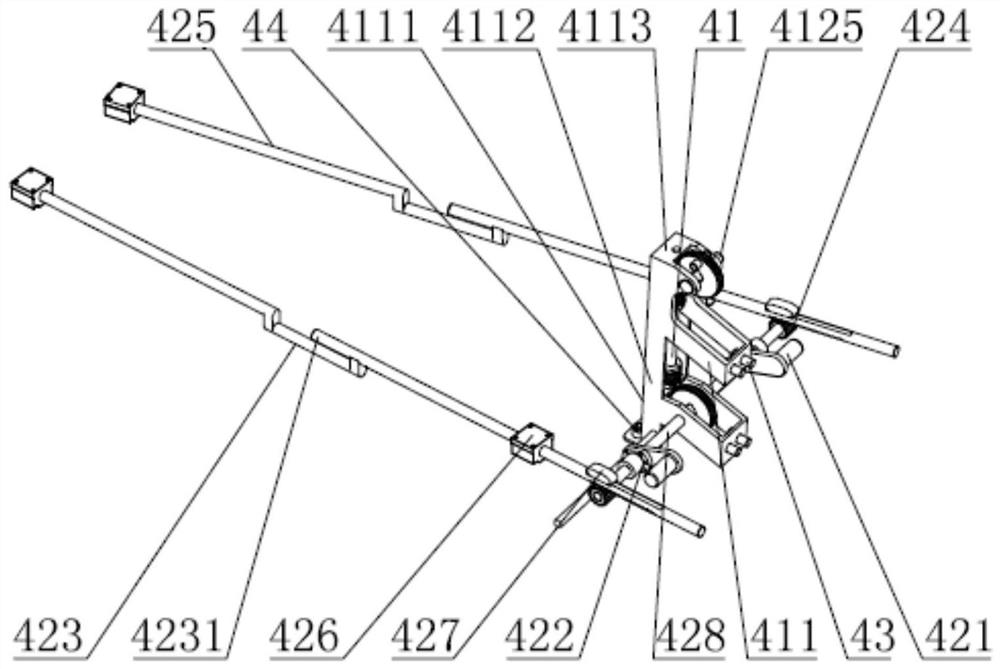

[0043] Specific implementation mode two: combination Figure 1 to Figure 10 Describe this embodiment, a cam-linked hatch cover flip locking mechanism of this embodiment, which includes a flip locking mechanism 4, and the flip locking mechanism 4 includes a flip mechanism 41 and a locking mechanism 42;

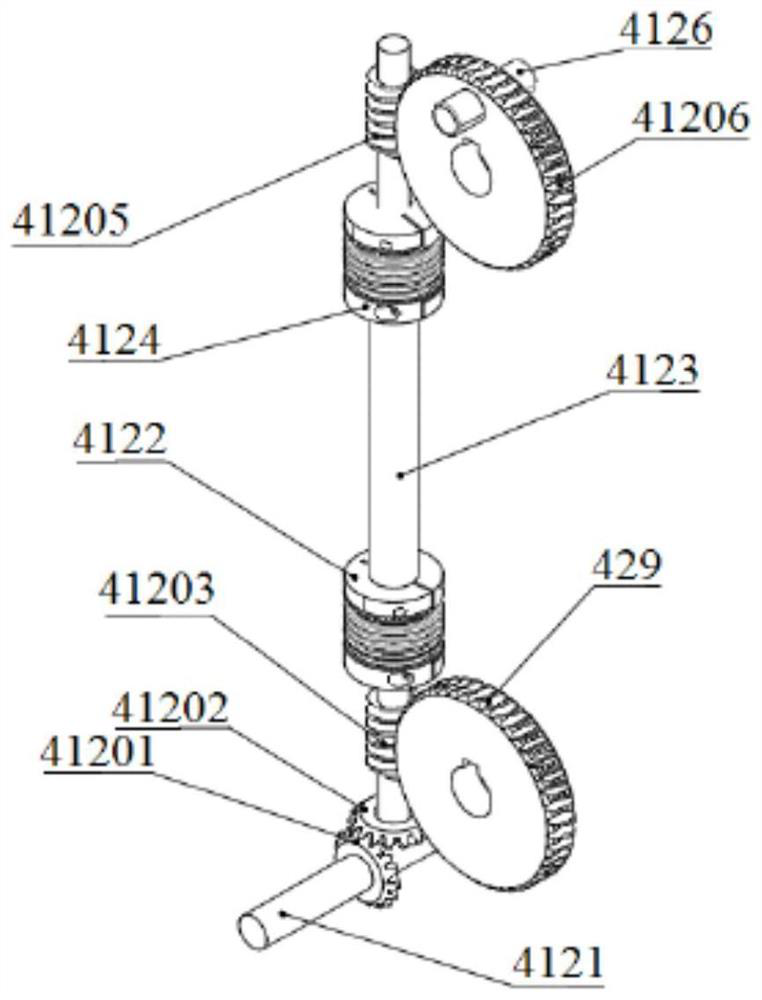

[0044] Turning mechanism 41 comprises turning shell 411 and turning transmission assembly, and turning shell 411 is vertically arranged on the interior of cabin seat 1 near cabin rear end 3 side, and turning shell 411 bottom is fixedly connected with cabin seat 1, and turning transmission assembly is arranged on turning shell On 411, the power output end of the overturning transmission assembly cooperates with the cam 23 of the hatch cover 2, and the overturning of the hatch cover 2 is realized under the drive of the overturning transmission assembly;

[0045] The locking mechanism 42 includes a front-end lock execution assembly, a front-end lock transmission assembly, a rear-e...

specific Embodiment approach 3

[0046] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the reversible shell 411 of this embodiment includes a web 4111, two wing plates 4112 and two end plates 4113, the web 4111 is arranged vertically, and the left and right ends of the web 4111 are respectively fixedly connected to two vertically opposite ends. The set wing plate 4112, the upper and lower ends of the web plate 4111 are respectively fixedly connected to two horizontally opposite end plates 4113, and the web plate 4111, the two wing plates 4112 and the two end plates 4113 are integrated structures. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com