Sewage treatment filtering device

A filter device and sewage treatment technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems that sewage cannot be recycled and purified, sewage cannot be filtered, and solid pollutants cannot be purified in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

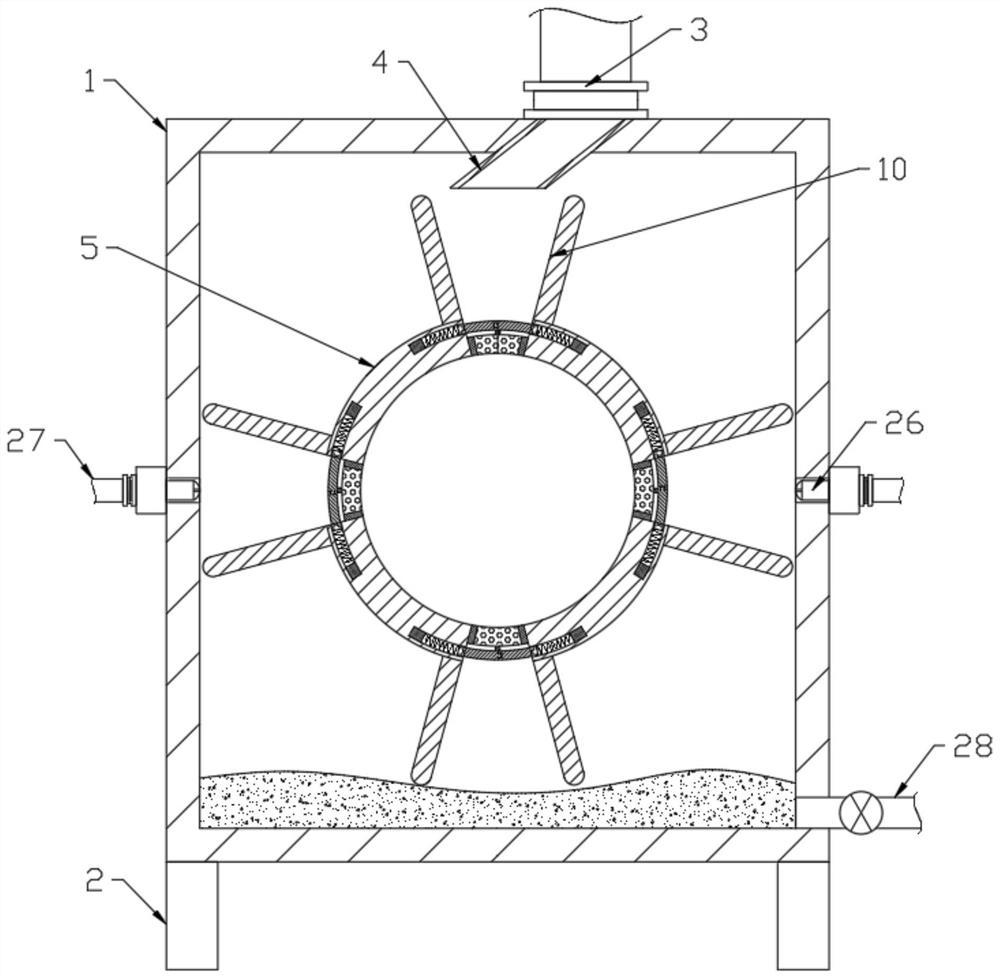

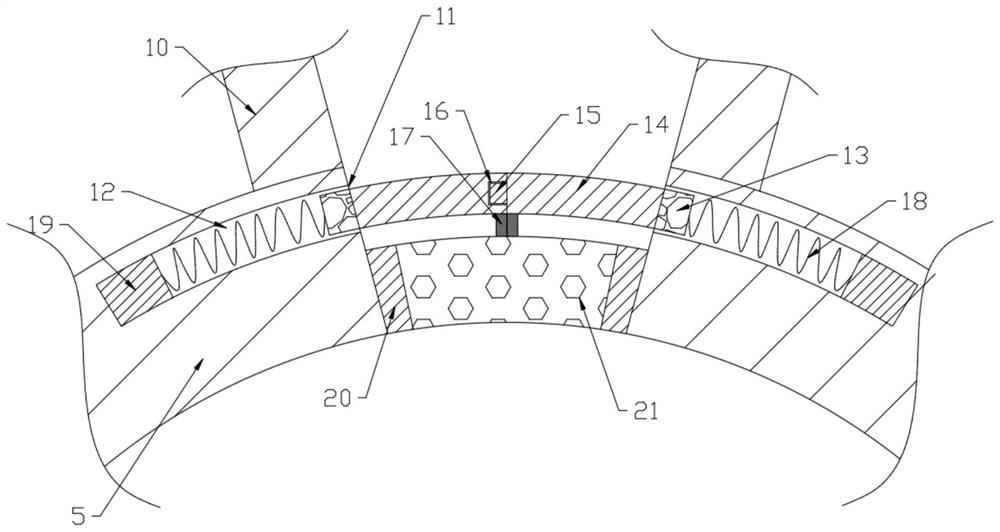

[0031] see Figure 1-6 , a sewage treatment filtering device, comprising a box body 1 and six supporting columns 2 arranged at the lower end of the box body 1 for supporting the box, the upper end of the box body 1 is provided with a water inlet port 3 connected to an external sewage pipe, and the water inlet port 3 communicates with the water inlet pipe 4, and the inside of the box body 1 is connected to the rotating drum 5, and the side end of the box body 1 is provided with a water outlet pipe 9 communicating with the drum 5, and several sets of clapboard groups are fixedly connected to the outer surface of the drum 5. The group of partitions is composed of two partitions 10, the sewage enters the box body 1 through the water inlet 3, and the rotating drum 5 is rotated by itself through the partition 10 and the water inlet pipe 4; between the two partitions 10 There are through grooves 11, and the side of the several through grooves 11 close to the axis of the drum 5 is fix...

Embodiment 2

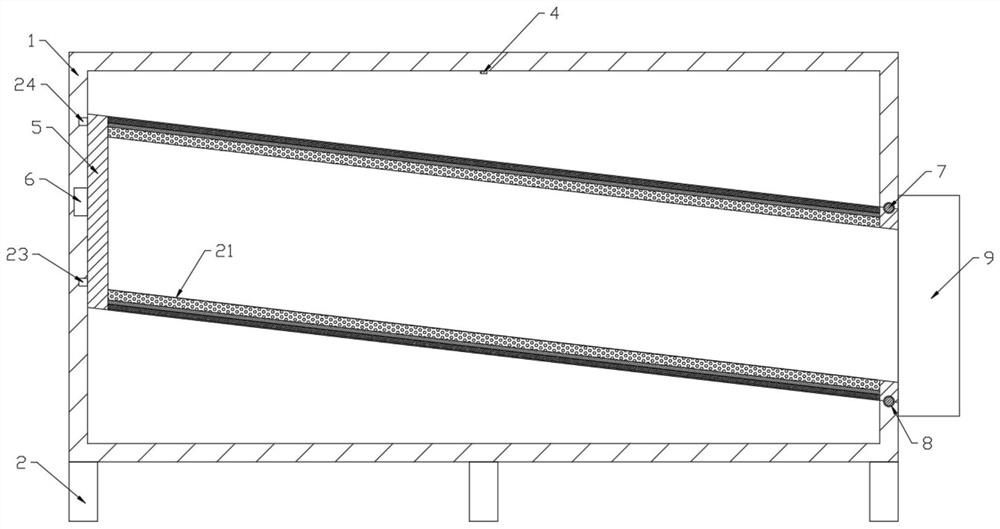

[0043] Further improvements are made on the basis of Embodiment 1, and the improvements are as follows: the side of the drum 5 near the water outlet pipe 9 is provided with a number of balls 7, and the balls 7 are rollingly connected with the drum 5 and the box body 1, and the box body 1 Hemispherical grooves 8 for the balls 7 to roll are provided on the rotating cylinder 5. When the rotating cylinder 5 rotates on the side wall of the casing 1, the rotating cylinder 5 rotates so that the balls 7 are in the hemispherical grooves 8 on the casing 1 and the rotating cylinder 5. Rolling in the middle, the rolling of the ball 7 makes the drum 5 rotate more smoothly on the casing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com