Vertical axis wind turbine with rotating cylinders on front edge

A vertical axis and wind turbine technology, which is applied to wind turbines, wind turbines at right angles to the wind direction, and combinations of wind turbines, etc., can solve problems such as the limit value of wind energy utilization of wind turbine blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

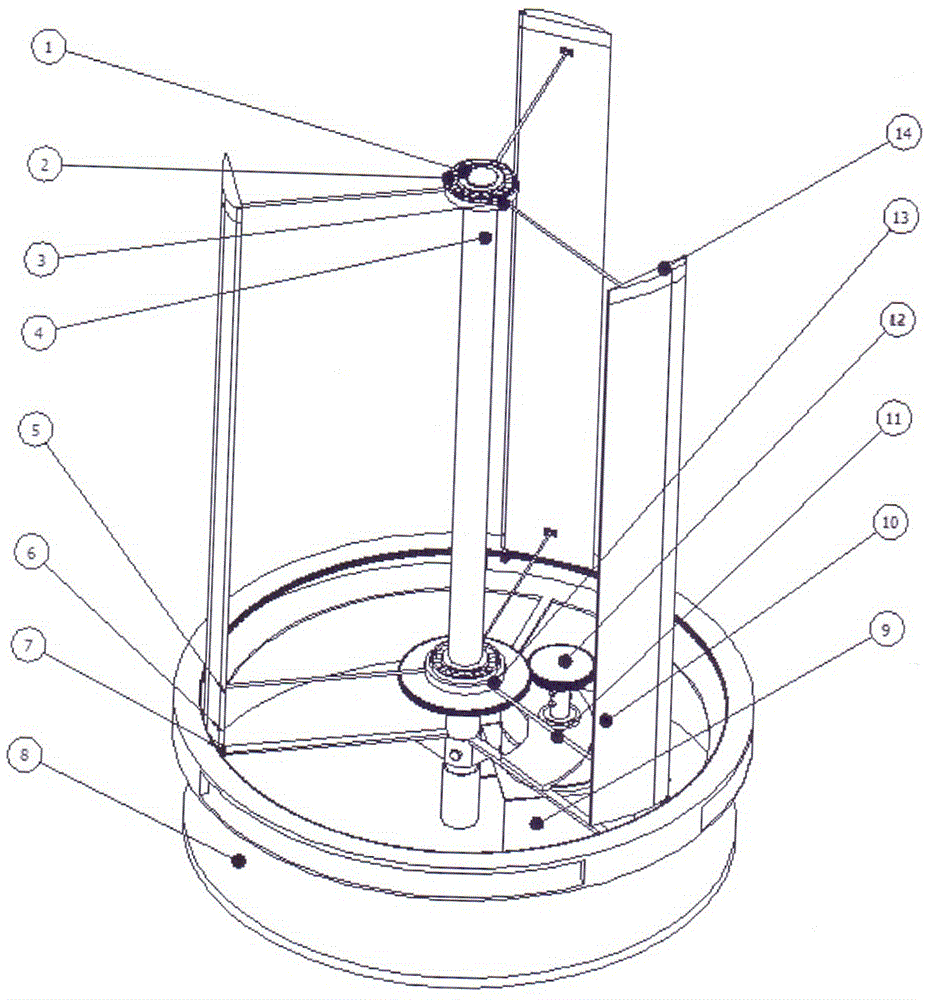

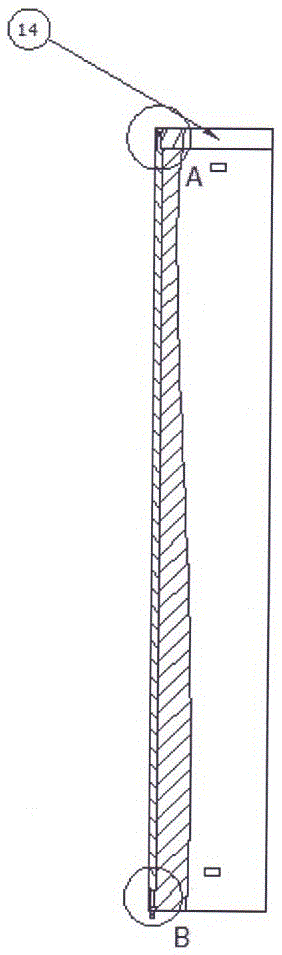

[0026] A vertical axis wind turbine with front edge rotation, including a chassis 8, a hollow column 4 is welded perpendicular to the horizontal direction above the center of the chassis 8, and upper and lower thrust bearings 2 are installed on the hollow column 4, and the thrust bearing 2 is covered with Sleeve rods, the bolts on the sleeve rods are connected to the support rods 3, welding is performed between the support rods 3 and the blades 14, the wind turbine blades 14 are vertically arranged and connected to the support rods 3, and the blades are evenly distributed along the circumference of the column to form a wind wheel. The wind wheel realizes the absorption and conversion of wind energy.

[0027] The chassis 8 can be a reinforced concrete platform, can be a steel plate, and can also be a steel frame structure. During construction, the upper surface of the chassis 8 is required to be parallel to the horizontal plane. Hollow column 4 adopts seamless steel pipe or al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com