Transmission device for friction pulley of rope twisting machine

A technology of friction wheel transmission and rope twisting machine, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc. It can solve the problems of high operating noise, short machine life, and affecting the effect of twisting ropes, and reduce machine manufacturing. Cost, stable running speed, and improved effect of twisting the rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

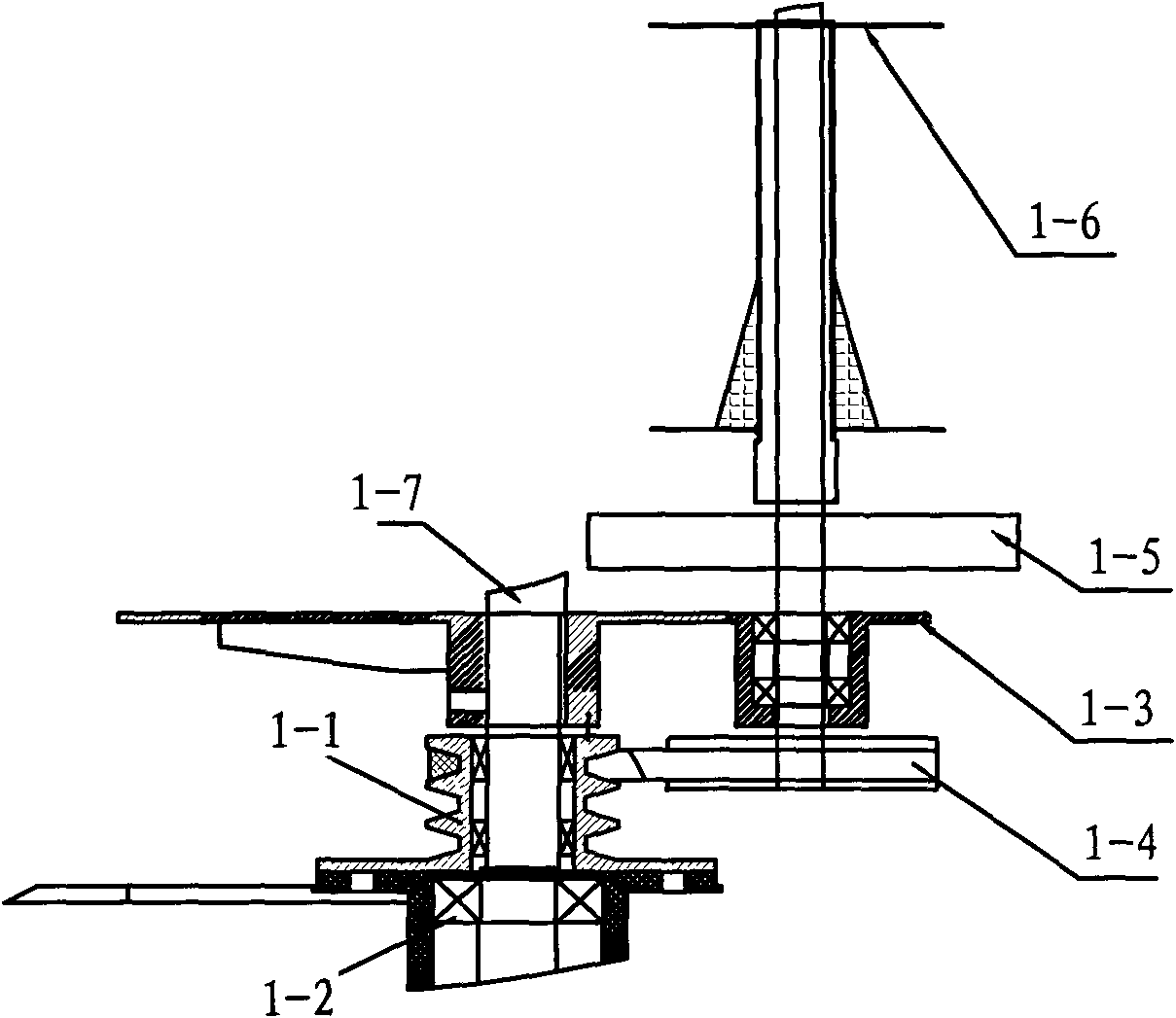

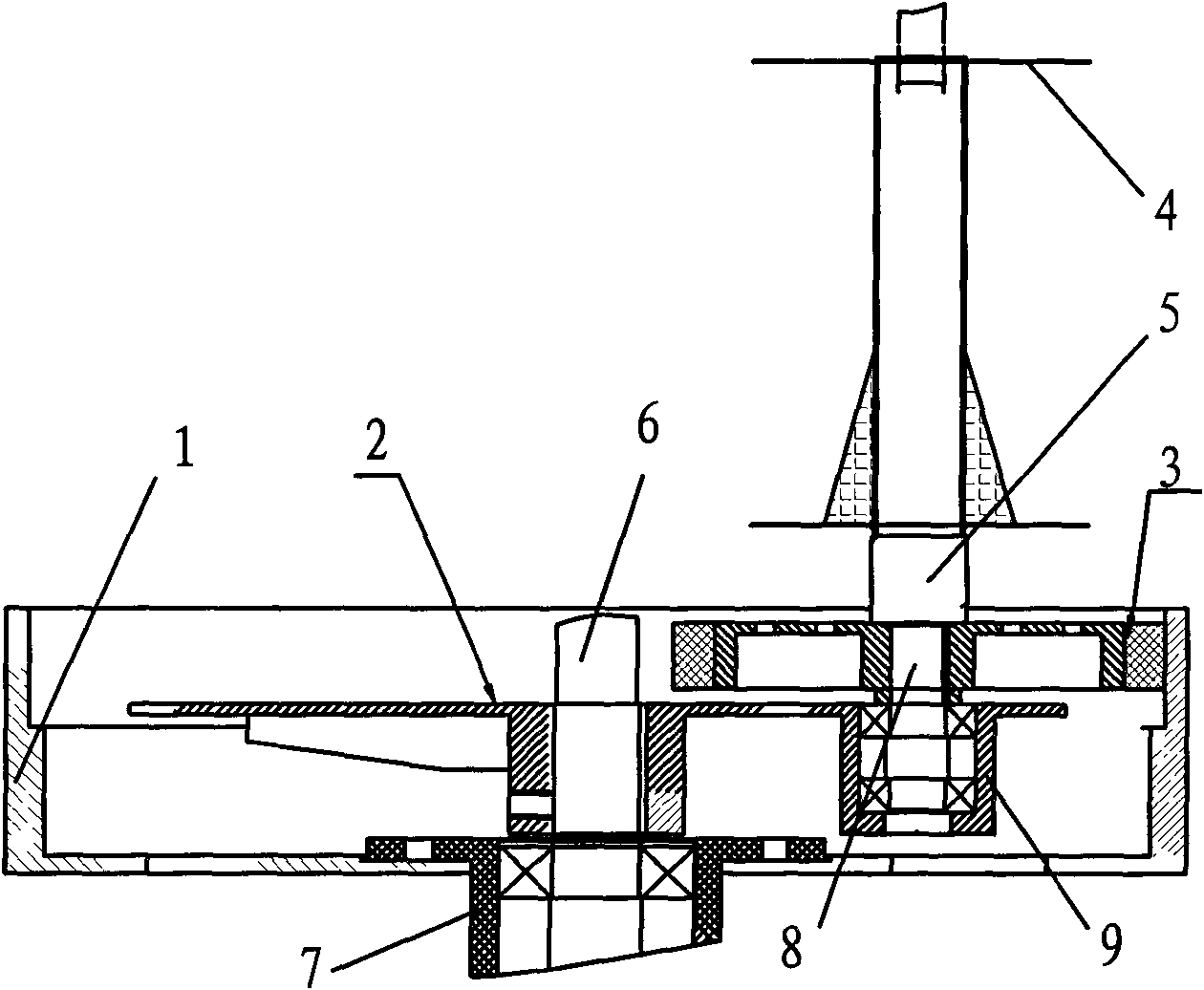

[0013] Embodiment 1: The device includes a chassis 1, a tray 2, and a rubber disc wheel 3. The tray is located at the upper end of the chassis, the rubber disc wheel is connected to the tray, and the outer wall of the rubber disc wheel is in frictional contact with the chassis.

[0014] Described chassis is pot wheel.

[0015] The said rubber disc wheel has a roulette in the center and a rubber layer on the outer wall of the roulette.

[0016] The chassis 1 is connected to the main shaft sleeve 7, the main shaft 6 is connected to the main shaft sleeve 7 through a bearing, the tray 2 is connected to the end of the main shaft 6, and the wire reel sleeve 9 is arranged on the tray 2, and the wire reel shaft 8 is connected to the wire reel shaft through a bearing On cover 9, be connected with rubber reel wheel 3 and reel seat 5 on reel axle 8, be connected with reel 4 on the reel seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com