Special-purpose collecting component for cotton type siro spinning

A collector and siro spinning technology, applied in the field of collector components, can solve the problems of excessive hairiness, inability to apply siro spinning, weak strength, etc., to achieve easy end breakage, reduce siro spinning hairiness, and enhance strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

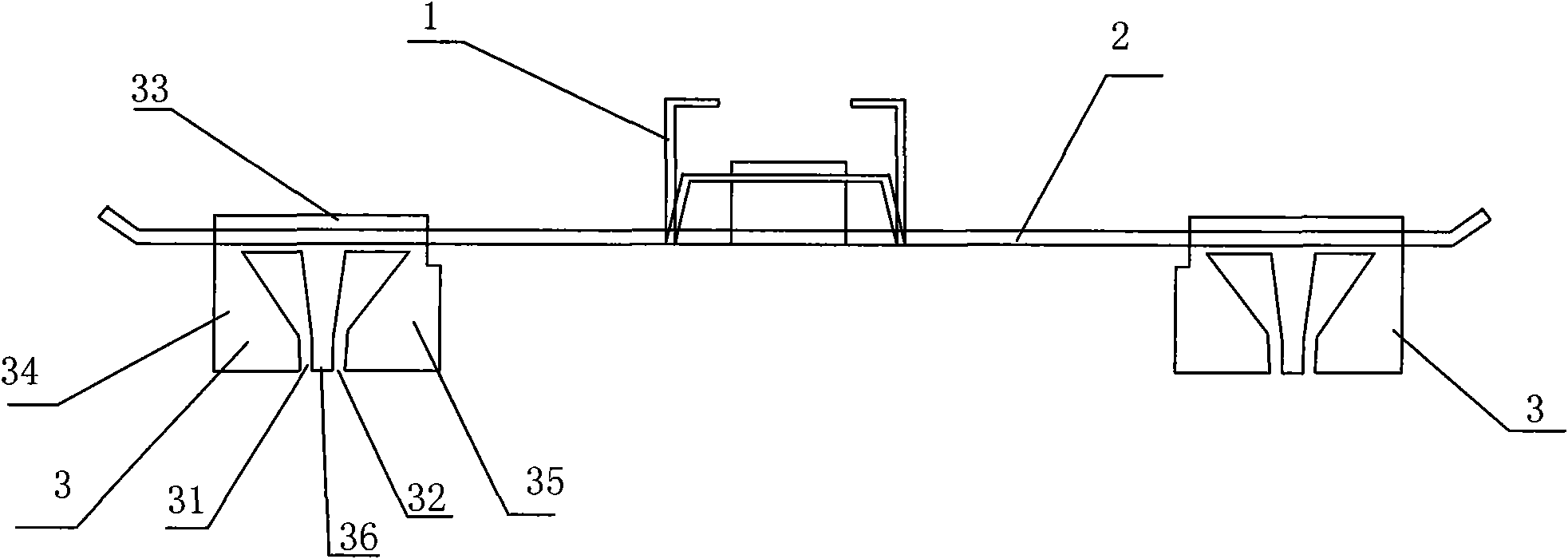

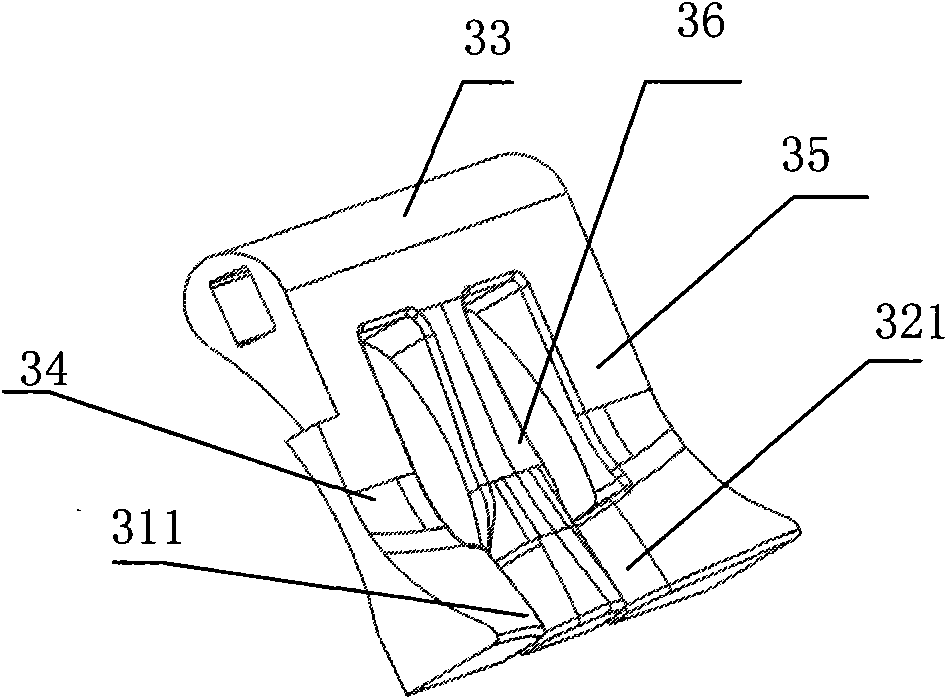

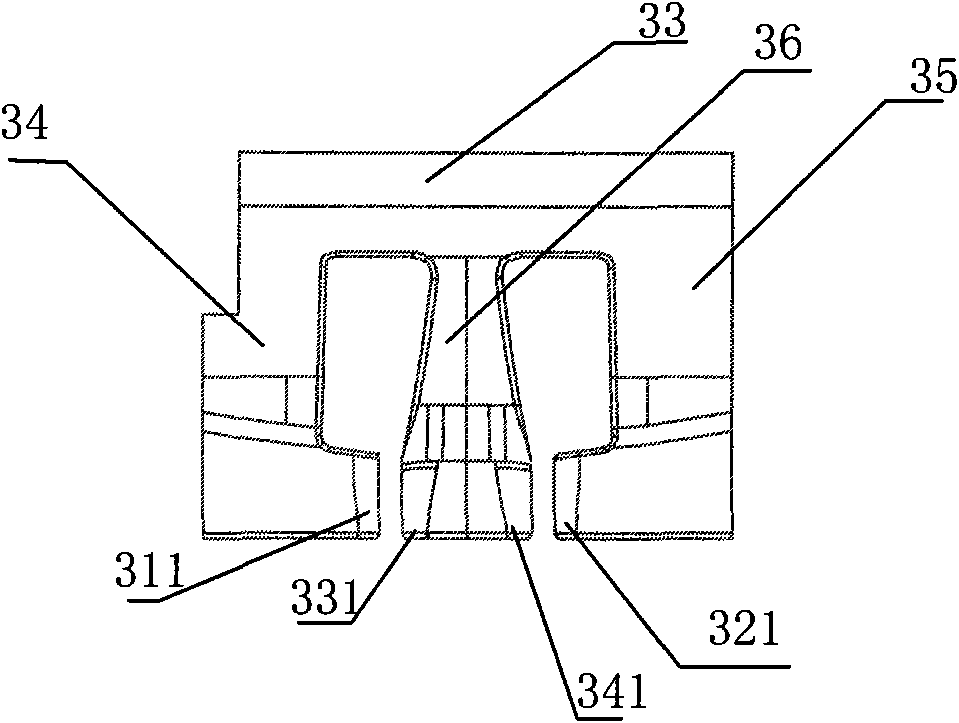

[0017] Embodiment 1: A collector assembly dedicated to cotton siro spinning, including a steel wire hook 1, a connecting shaft 2 and two collectors 3, the steel wire hook 1 is located in the middle of the connecting shaft 2, and the collectors 3 are respectively arranged on the connection On both sides of the shaft 2, the concentrator 3 is provided with A cluster port 31 and B cluster port 32 which are isolated from each other. The width of the A cluster port 31 or the B cluster port 32 is 1.5mm, and the center distance between the A cluster port 31 and the B cluster port 32 is 4mm. The width of the cluster port A is equal to that of the cluster port B. The concentrator includes a crosspiece 33, an A vertical piece 34, a B vertical piece 35, and an intermediate piece 36. The crosspiece 33 is passed on the connecting shaft 2, and the lower end of the A vertical piece 34 extends toward the middle direction and forms an A cluster opening 31 with the middle piece 36. The lower en...

Embodiment 2

[0020] Embodiment 2: A collector assembly dedicated to cotton siro spinning, including a steel wire hook 1, a connecting shaft 2 and two collectors 3, the steel wire hook 1 is located in the middle of the connecting shaft 2, and the collectors 3 are respectively arranged on the connection On both sides of the shaft 2, the concentrator 3 is provided with A cluster port 31 and B cluster port 32 which are isolated from each other. The width of the A cluster port 31 or the B cluster port 32 is 2 mm, and the center distance between the A cluster port 31 and the B cluster port 32 is 7mm. The width of the cluster port A is equal to that of the cluster port B. The concentrator includes a crosspiece 33, an A vertical piece 34, a B vertical piece 35, and an intermediate piece 36. The crosspiece 33 is passed on the connecting shaft 2, and the lower end of the A vertical piece 34 extends toward the middle direction and forms an A cluster opening 31 with the middle piece 36. The lower end...

Embodiment 3

[0021] Embodiment 3: A collector assembly dedicated to cotton siro spinning, including a steel wire hook 1, a connecting shaft 2 and two collectors 3, the steel wire hook 1 is located in the middle of the connecting shaft 2, and the collectors 3 are respectively arranged on the connection On both sides of the shaft 2, the concentrator 3 is provided with A cluster port 31 and B cluster port 32 which are isolated from each other. The width of the A cluster port 31 or the B cluster port 32 is 2.5mm, and the center distance between the A cluster port 31 and the B cluster port 32 is 11mm. The width of the cluster port A is equal to that of the cluster port B. The concentrator includes a crosspiece 33, an A vertical piece 34, a B vertical piece 35, and an intermediate piece 36. The crosspiece 33 is passed on the connecting shaft 2, and the lower end of the A vertical piece 34 extends toward the middle direction and forms an A cluster opening 31 with the middle piece 36. The lower e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com