Preparation device and method of long-fiber-reinforced thermoplastic resin composite material

A resin composite material and enhanced thermoplastic technology, which is applied in the field of composite material preparation, can solve the problems of inability to prepare long fiber reinforced polymers, large fiber length and strength damage, waste of chemical impregnation, etc., to improve quality and production efficiency, Less damage to mechanical strength and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

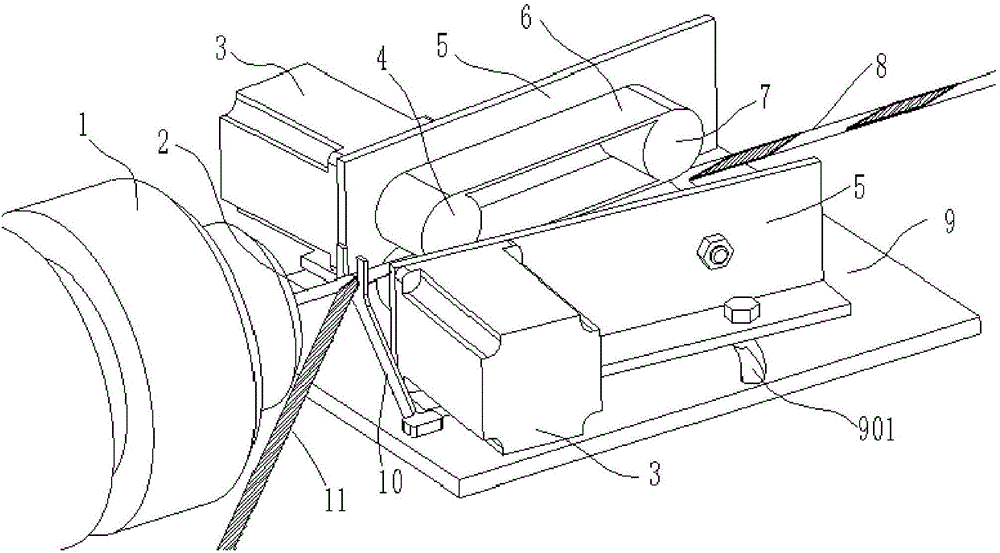

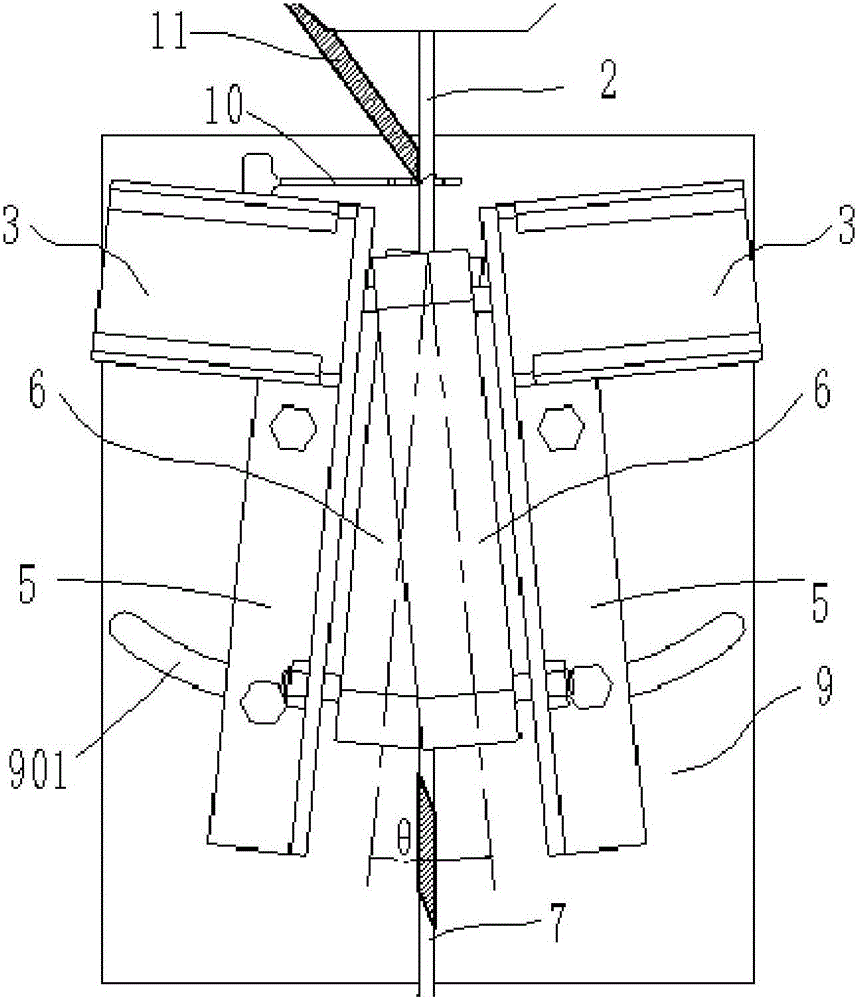

[0026] Such as figure 1 , 2 shown. The invention discloses a long-fiber-reinforced thermoplastic resin composite material preparation device, which comprises a base 9 and two sets of conveyor belt mechanisms arranged on the base 9; each set of conveyor belt mechanisms of the two sets of conveyor belt mechanisms includes a conveyor belt bracket 5, The driving wheel 4 and the driven wheel 7 arranged on the conveyor belt support 5, the motor 3 driving the driving wheel 4 to rotate, and the conveyor belt 6 which is sleeved between the driving wheel 4 and the driven wheel 7 and is tensioned by them, the surface of the conveyor belt 6 is formed On the transmission surface, the bottom of the conveyor belt bracket 5 near the end of the driving wheel 4 is hinged on the base 9, and the bottom of the conveyor belt bracket 5 near the end of the driven wheel 7 is fixed in an arc-shaped groove 901 on the base 9 by a bolt, so that The conveyor belt bracket 5 at this end of the driven wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com