Reusable straw baling rope convenient for binding and loosening

A technology of straw rope and weight ratio, which is applied in the field of straw rope production, can solve the problems of poor twisting effect of straw rope, short service life of straw rope, inconvenient binding and loosening, etc., and achieves good electrical insulation, improved The effect of improving service life and working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

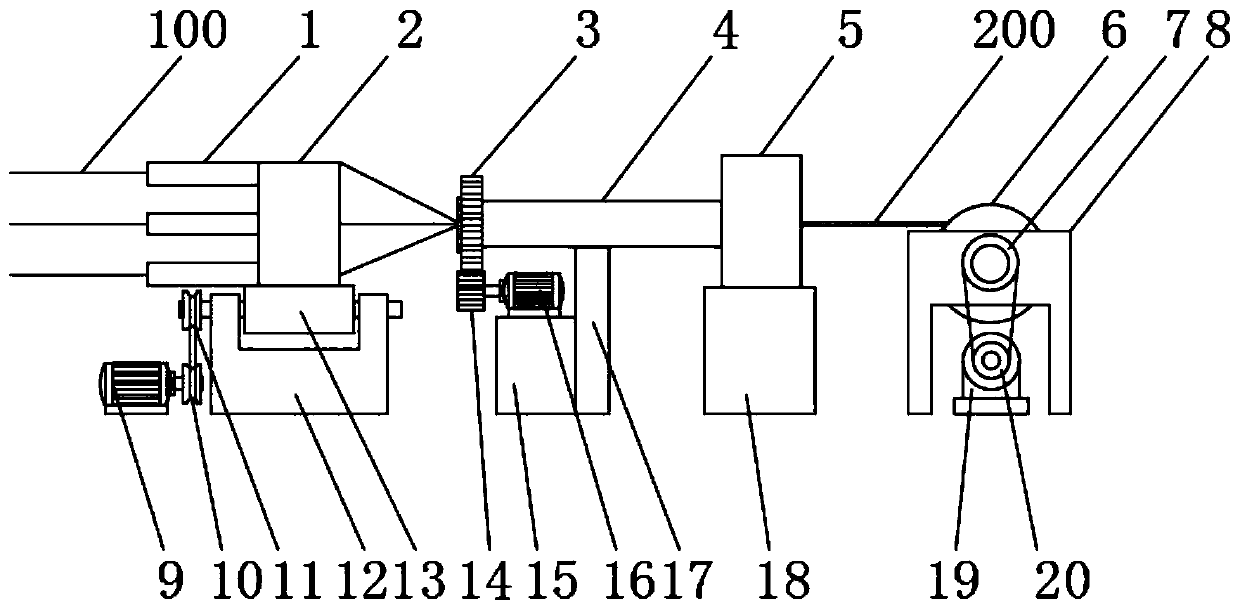

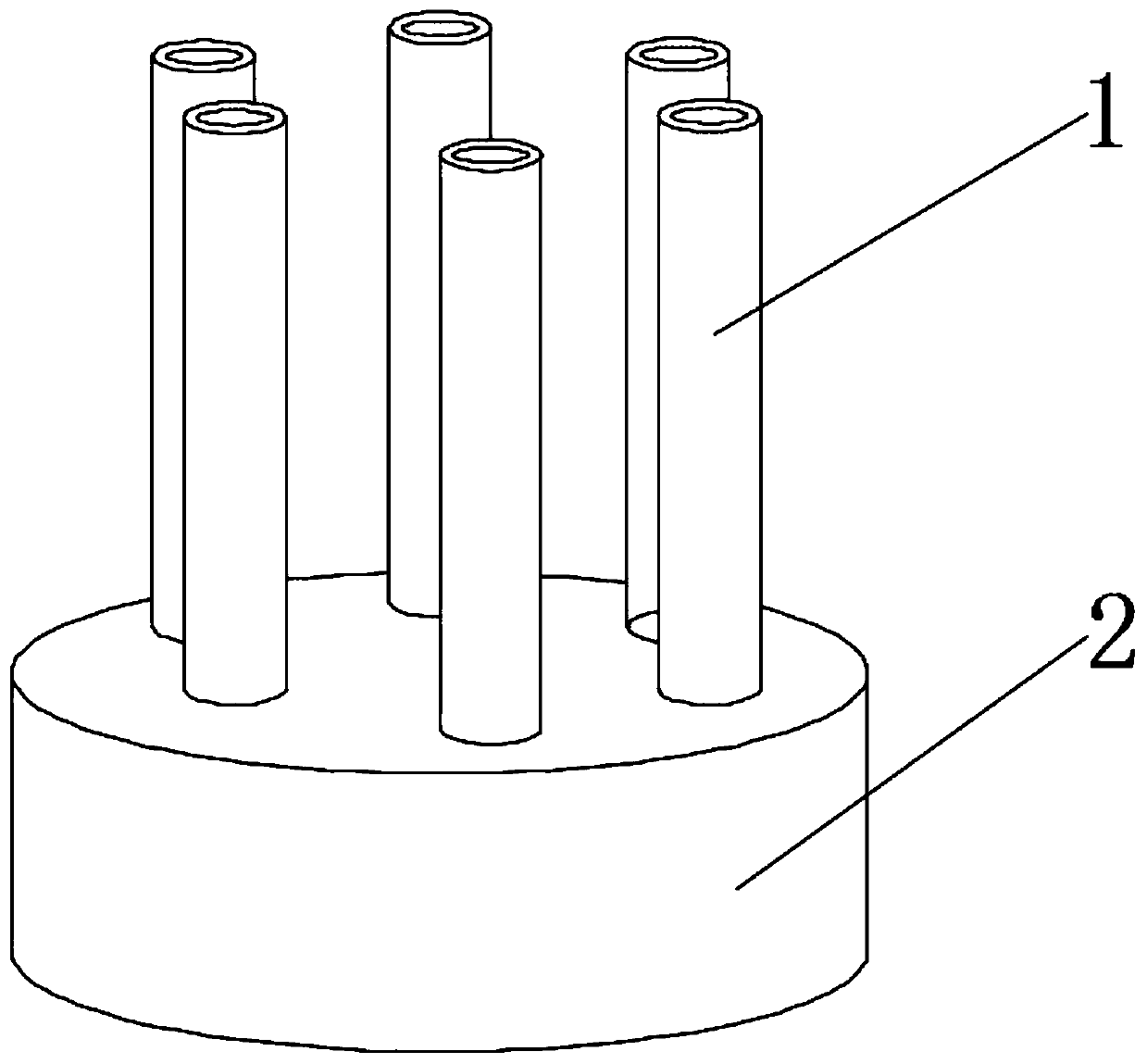

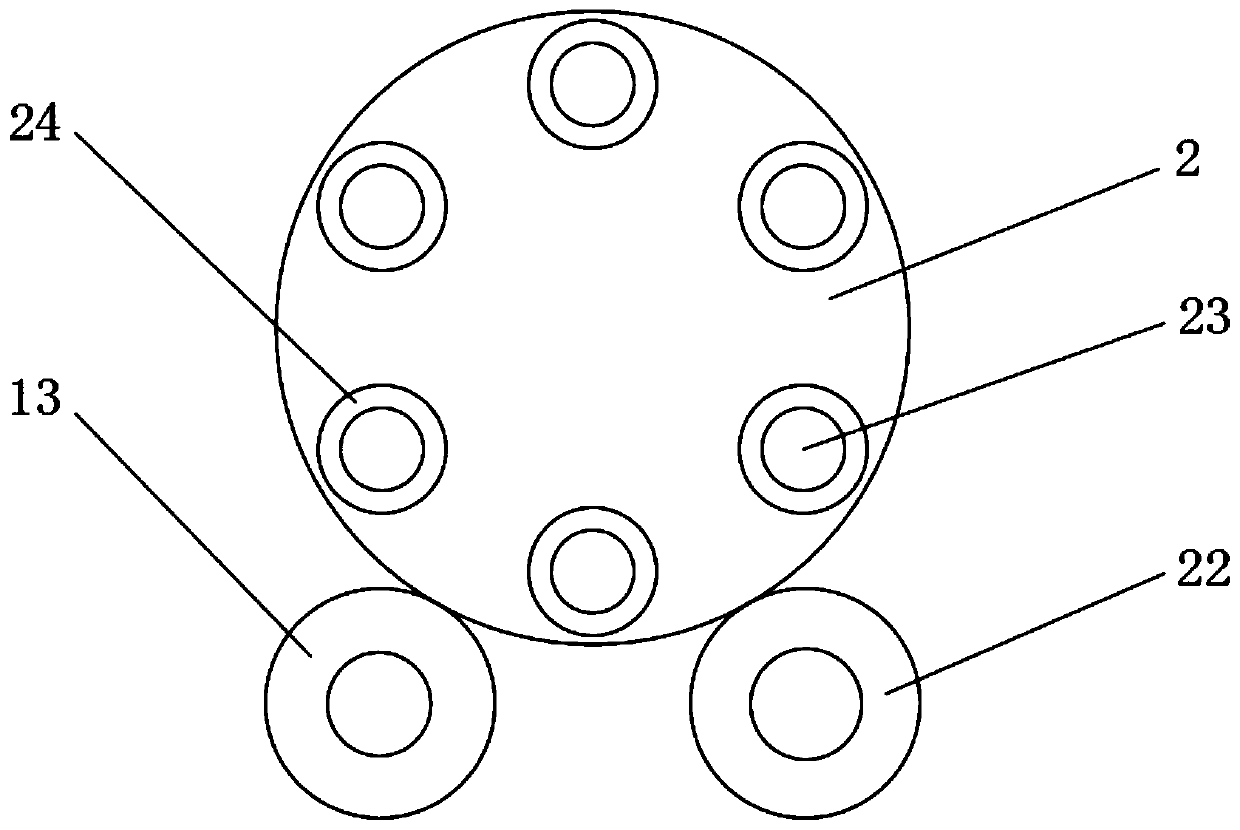

[0040] see Figure 1-7 As shown, this embodiment is a reusable straw rope that is easy to bind and loosen, prepared from the following components by weight: 40 parts of modified polypropylene, 10 parts of composite epoxy resin, 15 parts of rubber, 3 parts of plasticizer, 1 part of foaming agent, 0.6 part of stabilizer, 0.5 part of anti-aging agent, 0.6 part of anti-corrosion agent;

[0041] The reusable bale rope that is convenient for bundling and loosening is prepared by the following steps:

[0042] Step 1: taking each raw material according to parts by weight;

[0043] Step 2: adding each raw material to a screw extruder, and extruding at a temperature of 220-250°C to obtain melt-extruded plastic fibers;

[0044] Step 3: putting the melt-extruded plastic fiber into a water tank to cool to obtain a plastic monofilament fiber;

[0045] Step 4: Put the plastic monofilament fiber into the drafting machine for drafting, and then introduce it into the forming roller for final...

Embodiment 2

[0053] see Figure 1-7 As shown, this embodiment is a reusable straw rope that is easy to bind and loosen, prepared from the following components by weight: 50 parts of modified polypropylene, 15 parts of composite epoxy resin, 22 parts of rubber, 5 parts of plasticizer, 2 parts of foaming agent, 0.9 part of stabilizer, 0.8 part of anti-aging agent, 0.7 part of anti-corrosion agent;

[0054] The reusable bale rope that is convenient for bundling and loosening is prepared by the following steps:

[0055] Step 1: taking each raw material according to parts by weight;

[0056] Step 2: adding each raw material to a screw extruder, and extruding at a temperature of 220-250°C to obtain melt-extruded plastic fibers;

[0057] Step 3: putting the melt-extruded plastic fiber into a water tank to cool to obtain a plastic monofilament fiber;

[0058] Step 4: Put the plastic monofilament fiber into the drafting machine for drafting, and then introduce it into the forming roller for fina...

Embodiment 3

[0066] see Figure 1-7 As shown, this embodiment is a reusable straw rope that is easy to bind and loosen, prepared from the following components by weight: 60 parts of modified polypropylene, 20 parts of composite epoxy resin, 30 parts of rubber, 6 parts of plasticizer, 3 parts of foaming agent, 1.2 parts of stabilizer, 1.0 part of anti-aging agent, 0.8 part of anti-corrosion agent;

[0067] The reusable bale rope that is convenient for bundling and loosening is prepared by the following steps:

[0068] Step 1: taking each raw material according to parts by weight;

[0069] Step 2: adding each raw material to a screw extruder, and extruding at a temperature of 220-250°C to obtain melt-extruded plastic fibers;

[0070] Step 3: putting the melt-extruded plastic fiber into a water tank to cool to obtain a plastic monofilament fiber;

[0071] Step 4: Put the plastic monofilament fiber into the drafting machine for drafting, and then introduce it into the forming roller for fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com