A flame-retardant and antistatic composite yarn and its processing method and opening and twisting device

A technology of flame retardant antistatic and twisting device, which is applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of inconvenient high-speed sewing of flame retardant fibers, lack of flame retardant performance and high strength, and lack of antistatic ability, etc., to achieve sewing High processing efficiency, improved fire retardant performance and antistatic performance, good twisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

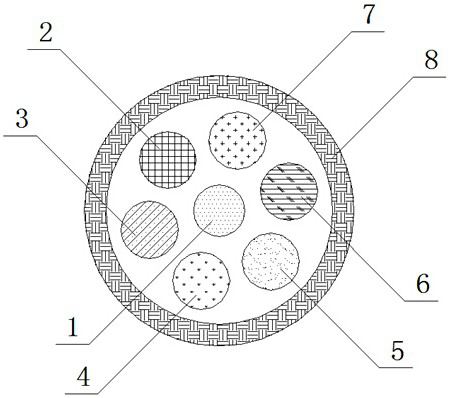

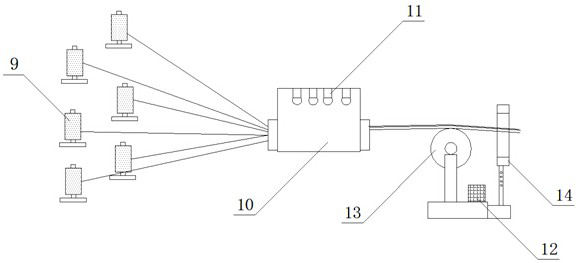

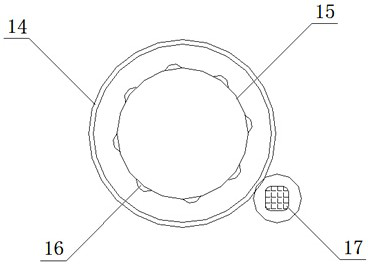

[0023] see Figure 1 to Figure 3 , a flame-retardant antistatic composite yarn opening and twisting device of the present invention, comprising a fiber releasing device 9, characterized in that: the fiber releasing devices 9 are arranged in multiple groups side by side, and the output outer ends of the fiber releasing devices 9 are arranged There is a spray chamber 10, a spray device 11 is installed inside the spray chamber 10, one end of the spray chamber 10 is a fiber inlet, the other end of the spray chamber 10 is a fiber outlet, and a guide wheel 13 is arranged outside the fiber outlet, The rear end of guide wheel 13 is equipped with auxiliary twisting device, and auxiliary twisting device comprises auxiliary twisting outer ring 14, rotating inner ring 15, air jet inclined hole 16 and driving motor 17, and the inner ring of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com