Patents

Literature

42results about How to "Realize fully automatic work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

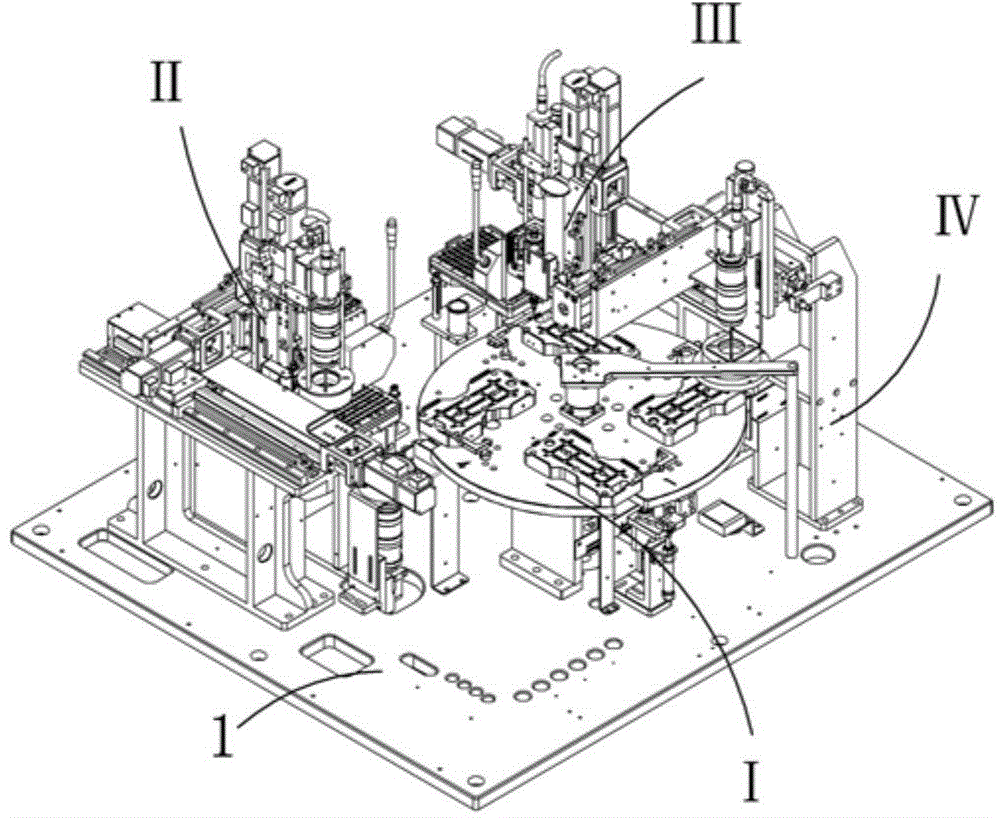

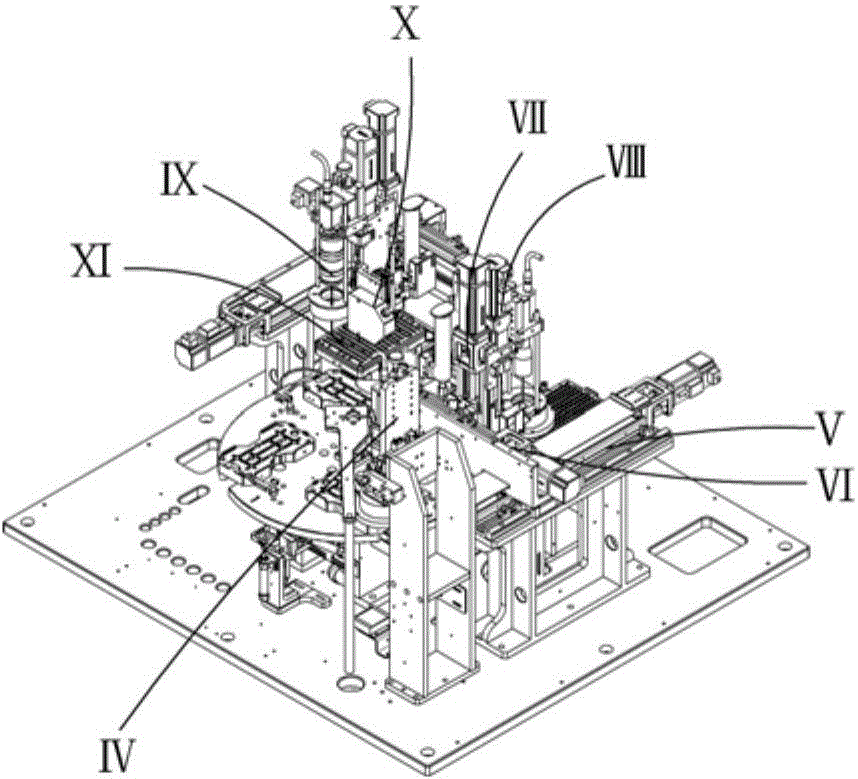

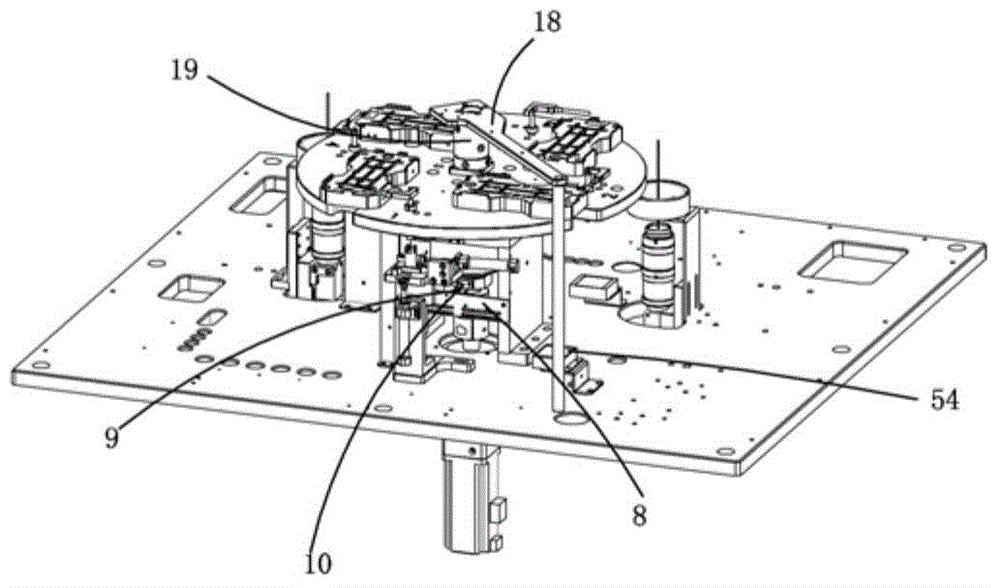

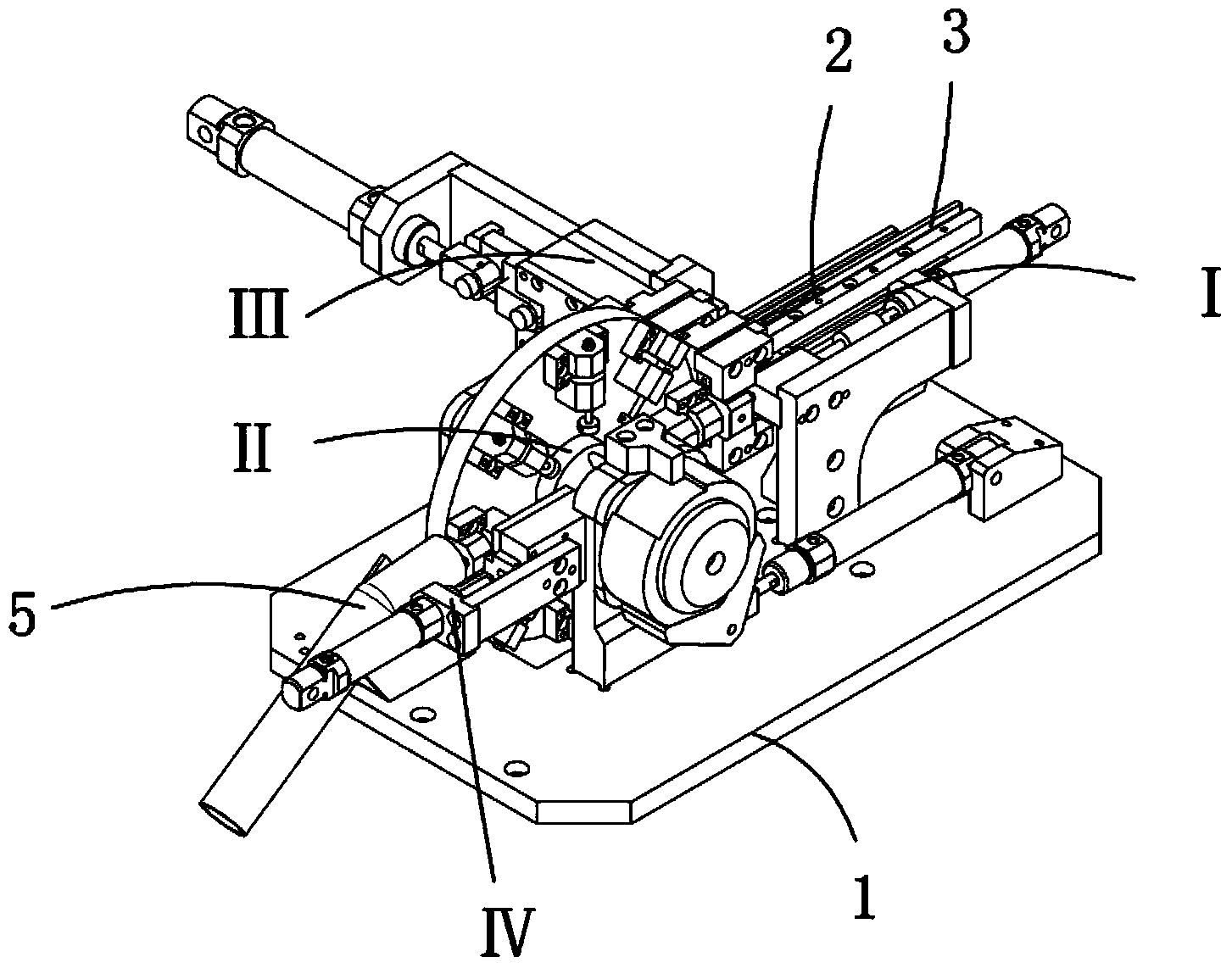

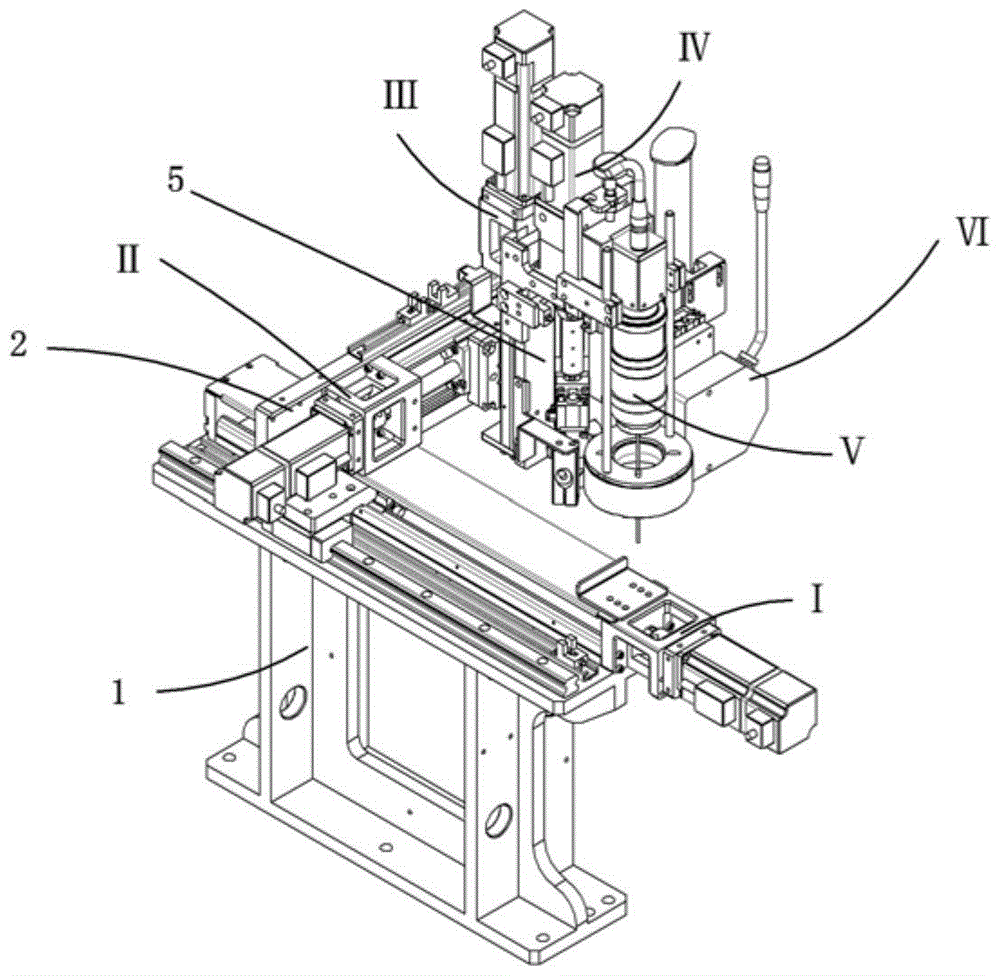

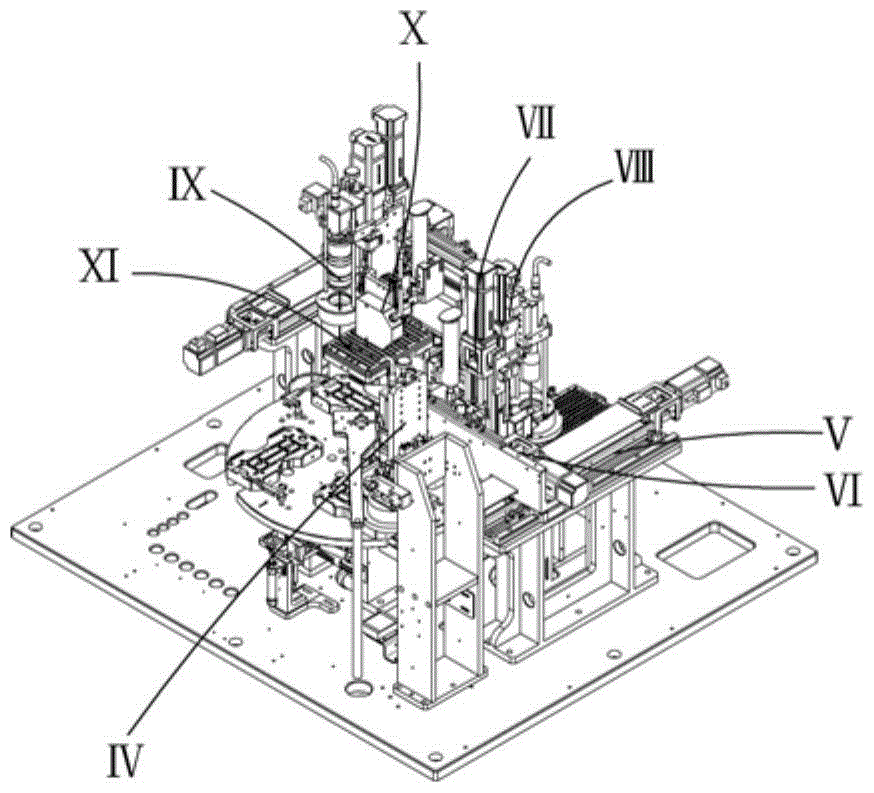

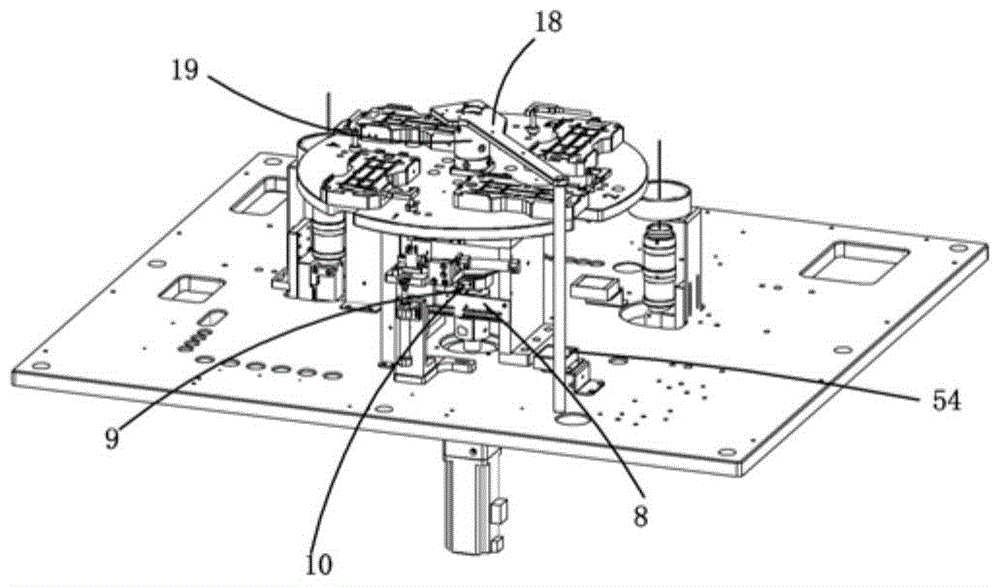

Full-automatic part assembly machine

ActiveCN104551660APrevent camera alignment and other workQuick and accurate assemblyAssembly machinesEngineeringWorkstation

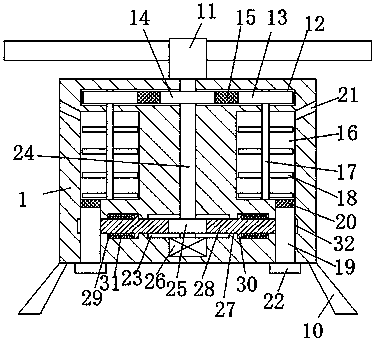

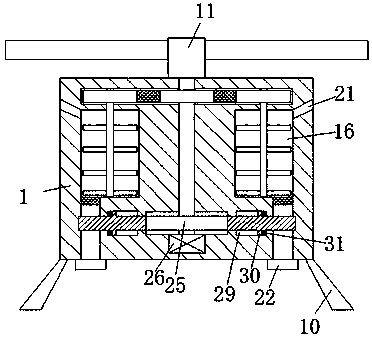

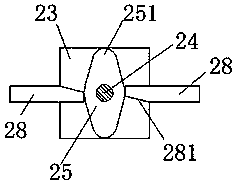

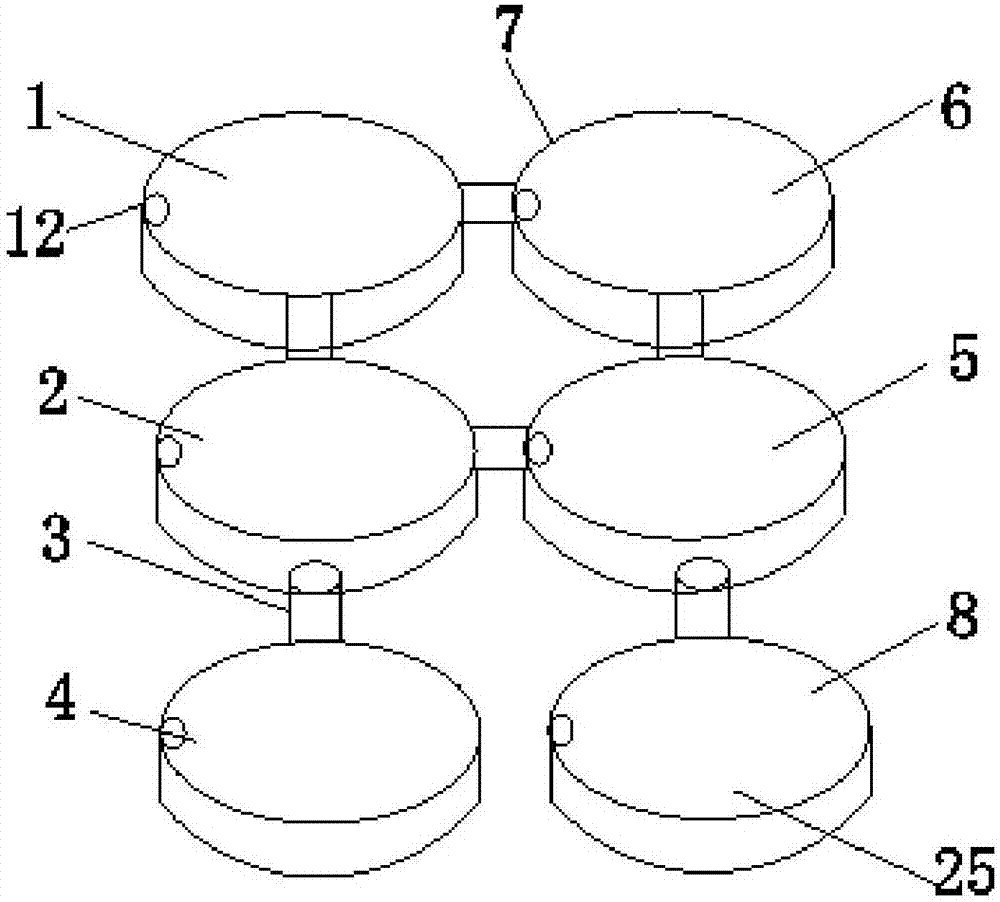

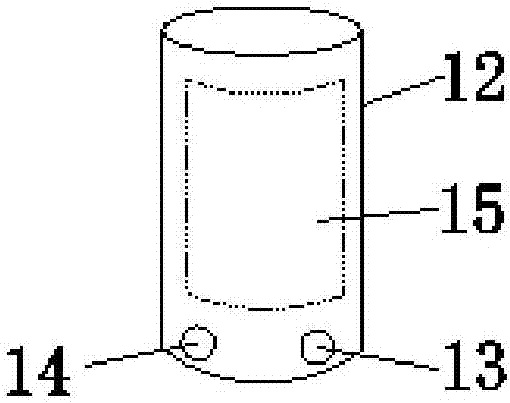

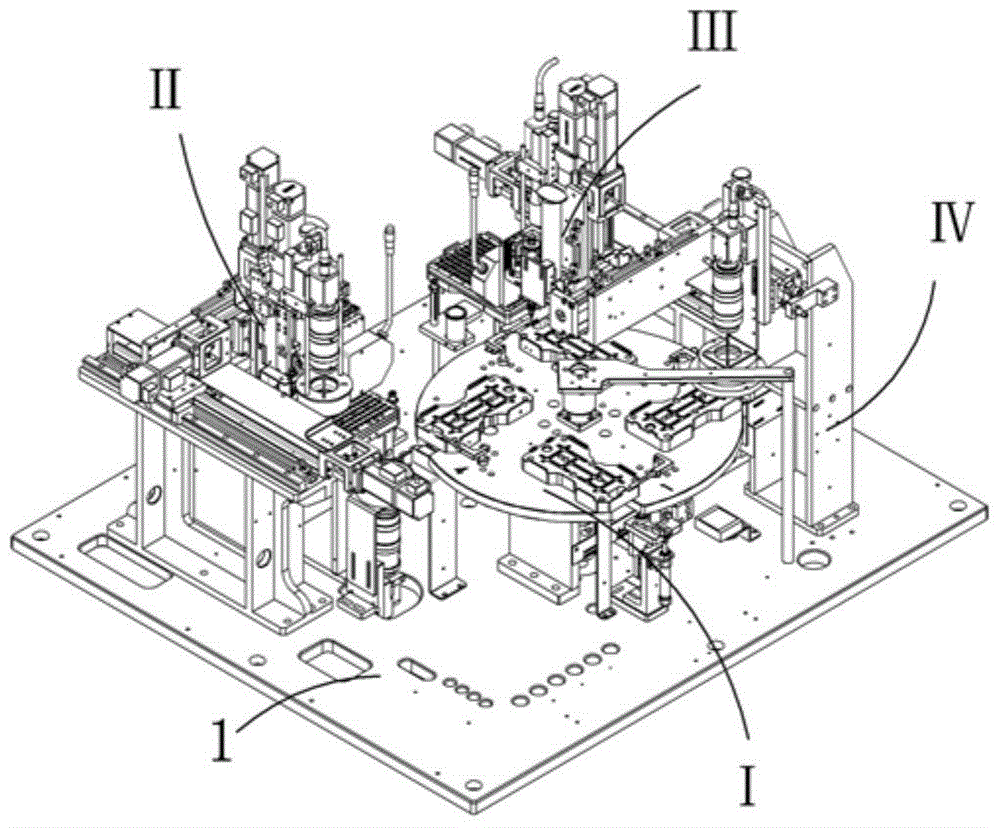

The invention relates to a full-automatic part assembly machine. A rotary plate mechanism is mounted at the center of the bottom plate, a first part assembly workstation and a second part assembly workstation are identical in structure and mounted on the left rear portion and the right rear portion of the bottom plate respectively, and a detecting workstation is mounted on the front portion of the right side of the bottom plate. An operator places a workpiece on a carrier, a rotary motor rotates the carrier on a rotary plate to the first part assembly workstation, and a small part a is assembled onto the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the second part assembly workstation, and a small part b is assembled on the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the detecting workstation, a CCD on the detecting workstation takes pictures and detects whether the assembled workpiece is qualified or not; after detection, the rotary motor rotates the rotary plate to the initial position. The full-automatic part assembly machine is simple to operate, the small parts can be quickly and accurately assembled to the workpiece, labor is saved, production efficiency is improved, and production cost of enterprises is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

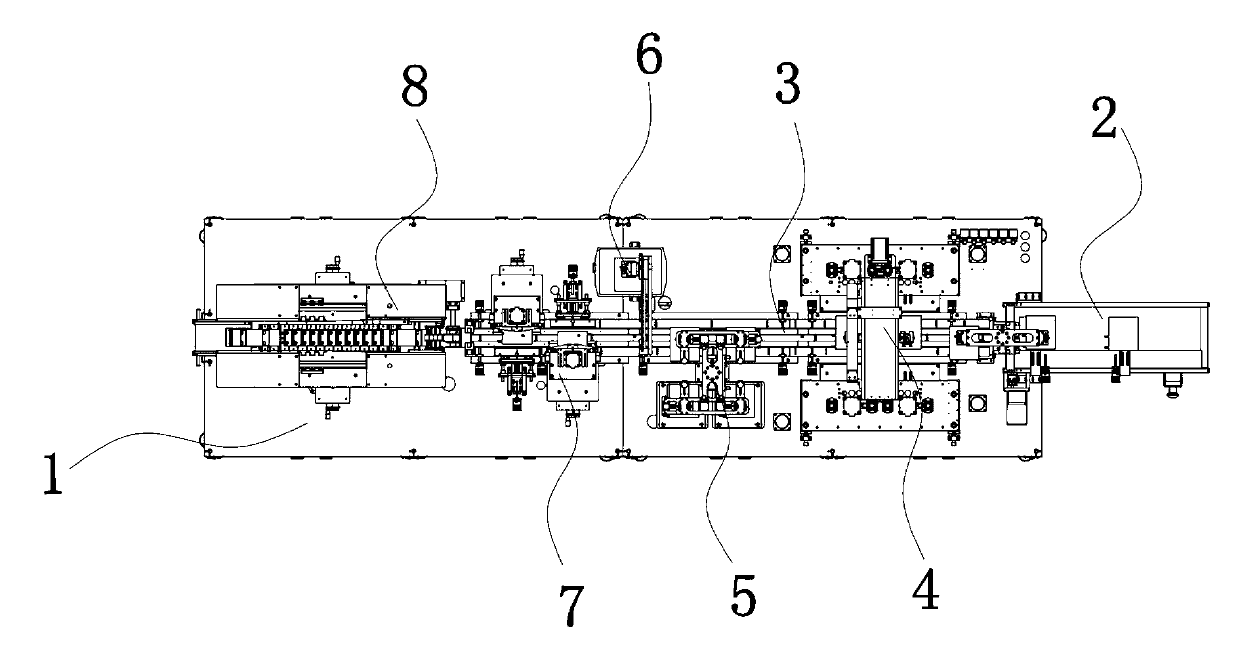

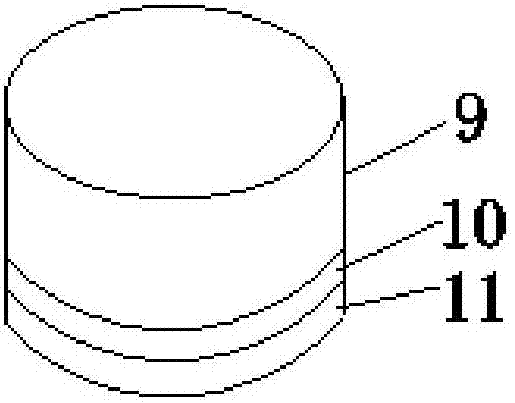

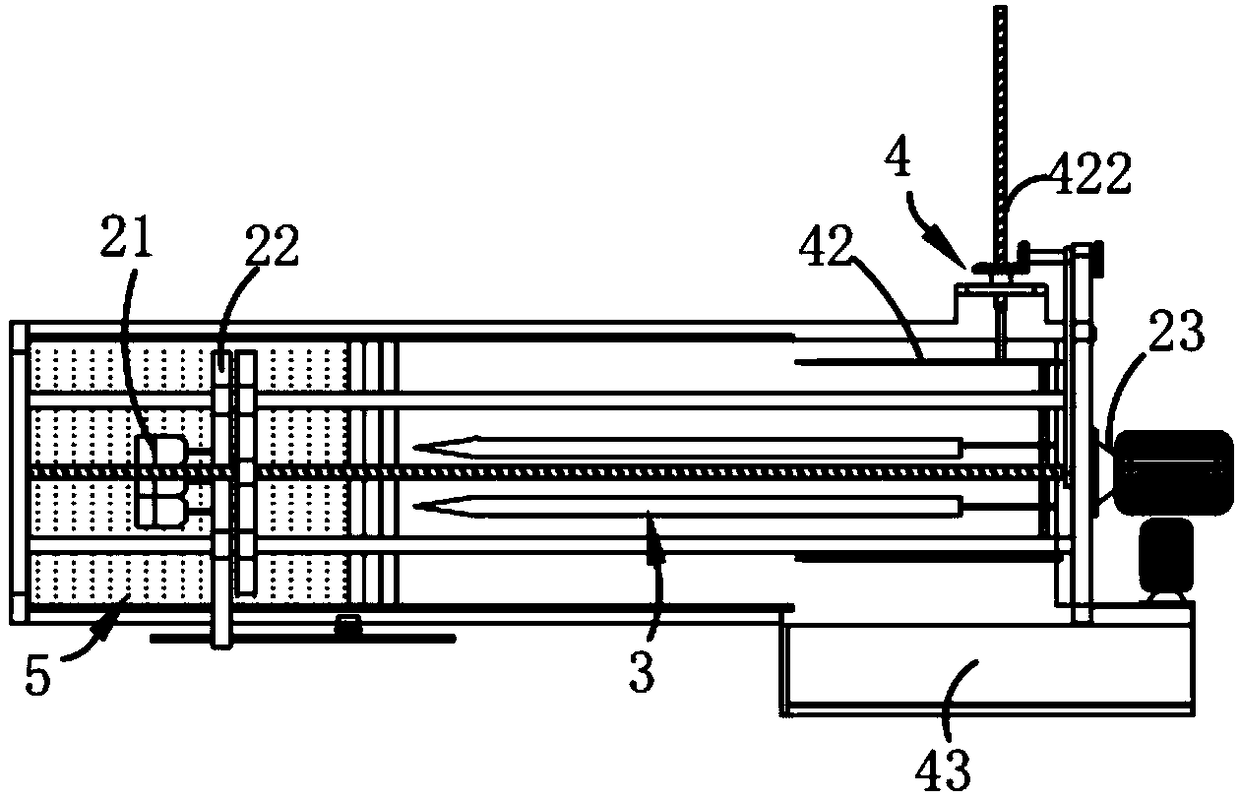

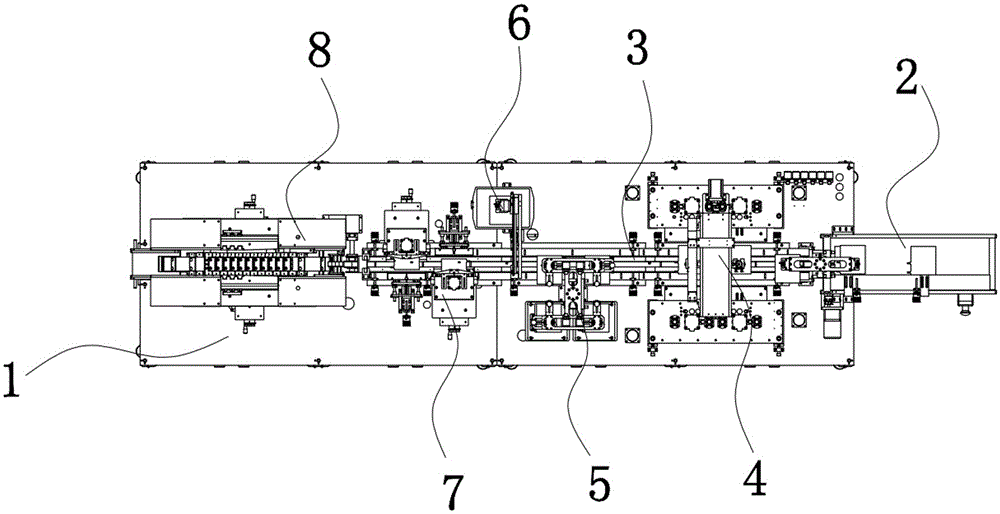

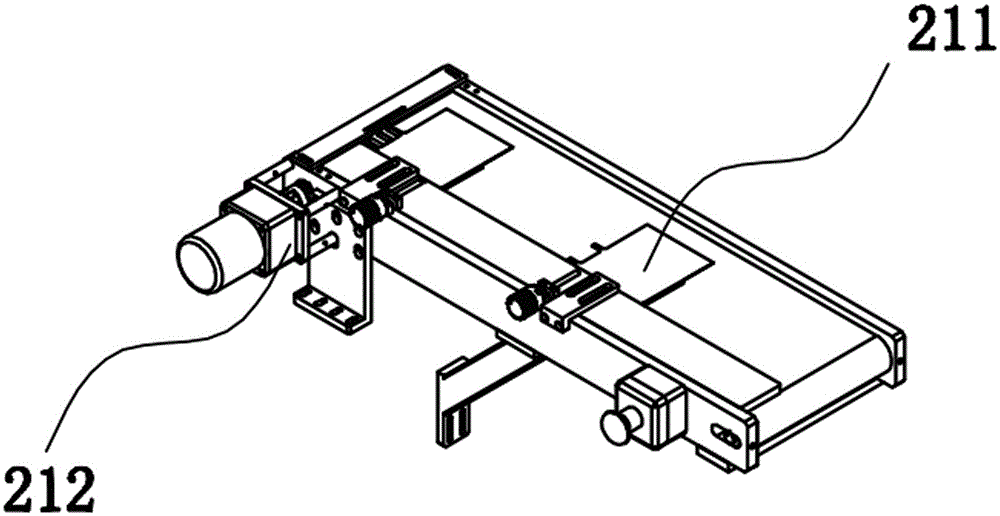

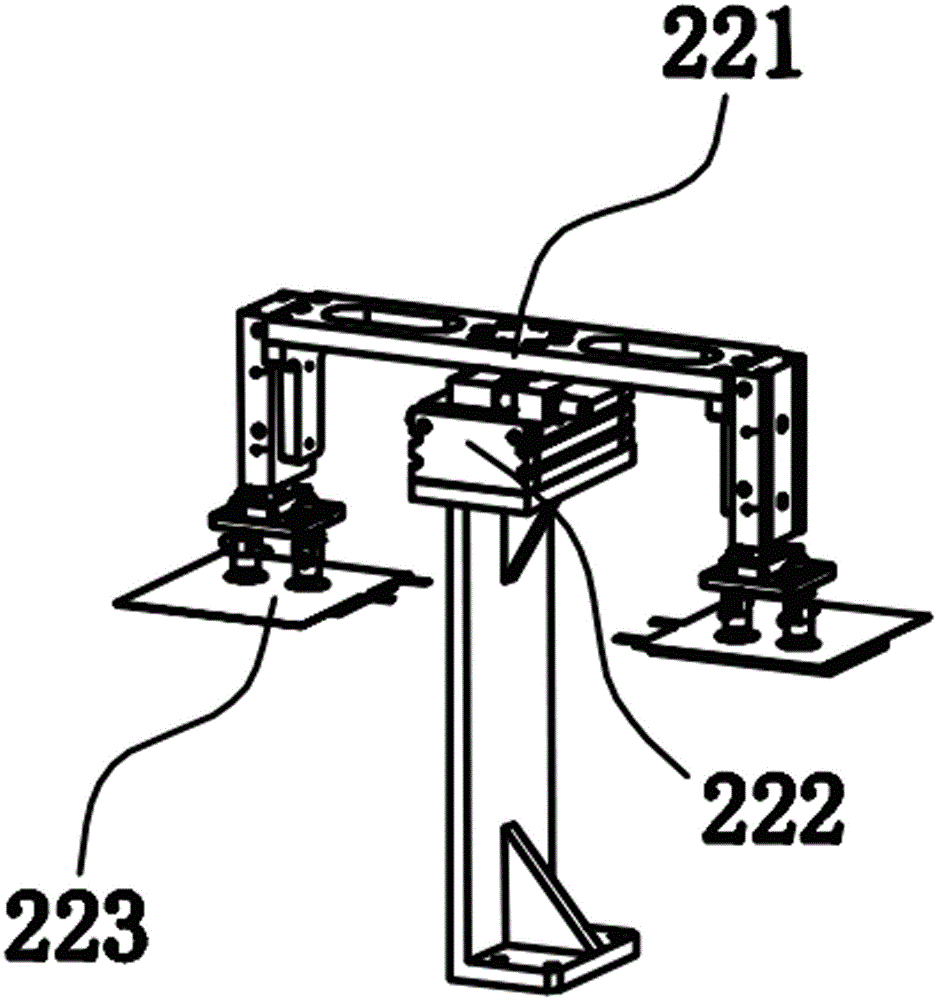

Automatic five-in-one lithium battery forming machine

InactiveCN103123982AIncrease productivityImprove finishing accuracyFinal product manufactureElectrolyte accumulators manufactureControl systemButt joint

The invention provides an automatic five-in-one lithium battery forming machine which belongs to the field of lithium battery manufacturing equipment. The automatic five-in-one lithium battery forming machine comprises a worktable, wherein the worktable comprises a feeding mechanism, the feeding mechanism is connected with a material delivering mechanism, a fine sealing mechanism, a test mechanism, an unqualified product removal mechanism and a single trimming mechanism are respectively arranged above the material delivering mechanism, the tail end of the material delivering mechanism is also connected with a flanging ironing mechanism, the worktable is also provided with a framework consisting of a plurality of stand columns, and the framework is also connected with a control system. The automatic five-in-one lithium battery forming machine is has the advantages that the structure is compact, the appearance is attractive, a previous procedure and devices of a subsequent procedure can be conveniently in butt joint by linearly arranging all procedures, and the production efficiency of products can be improved.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

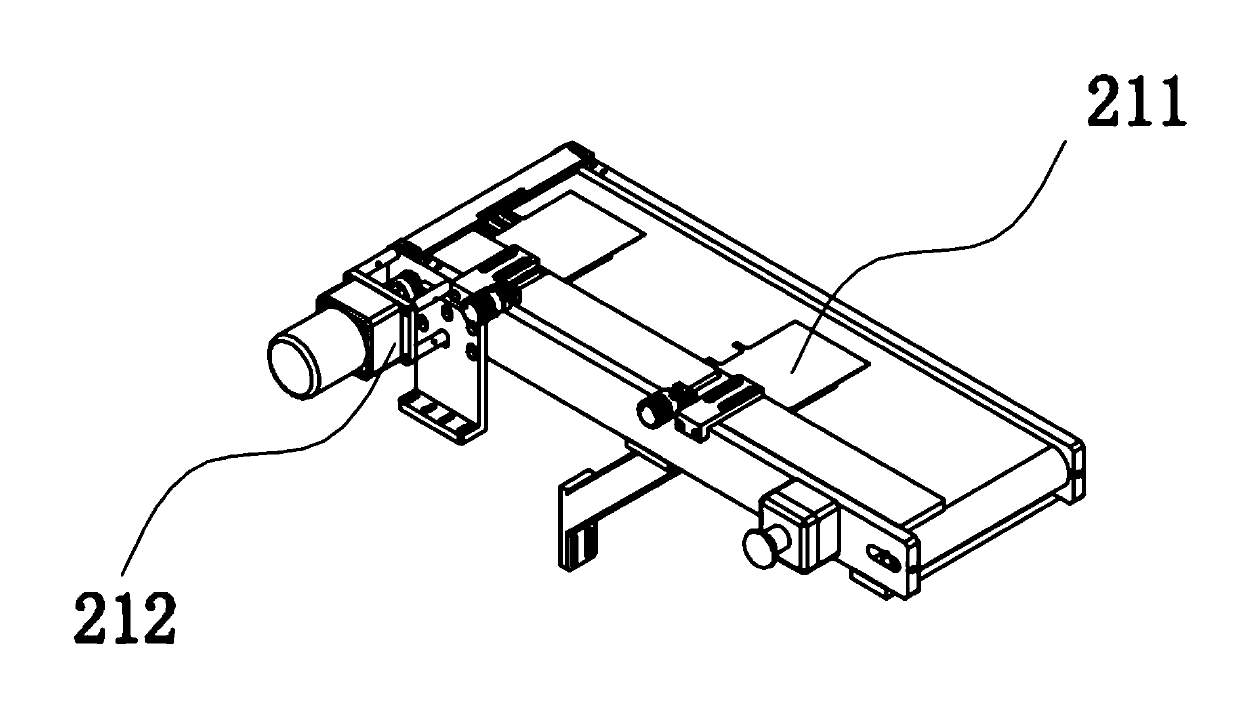

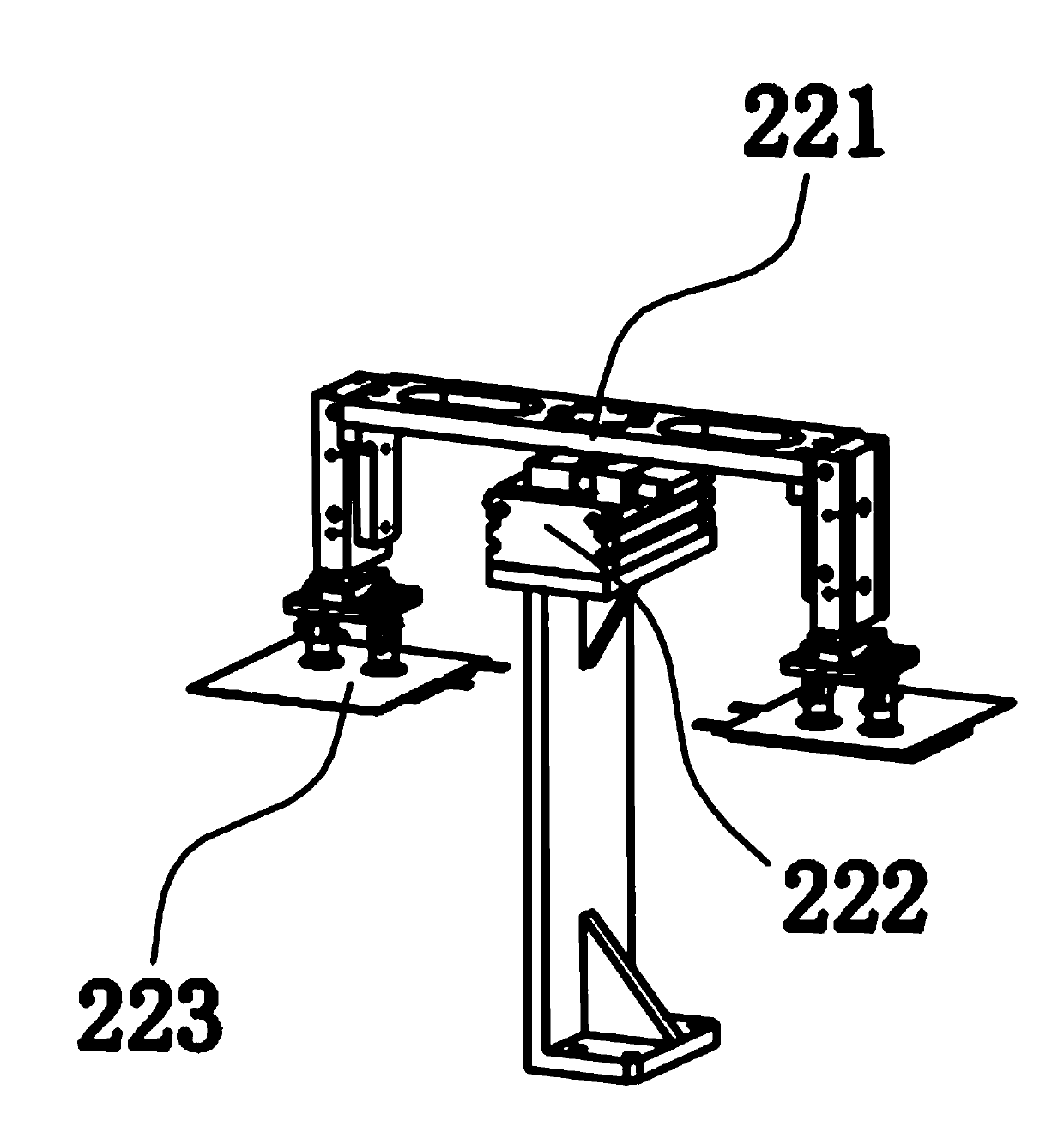

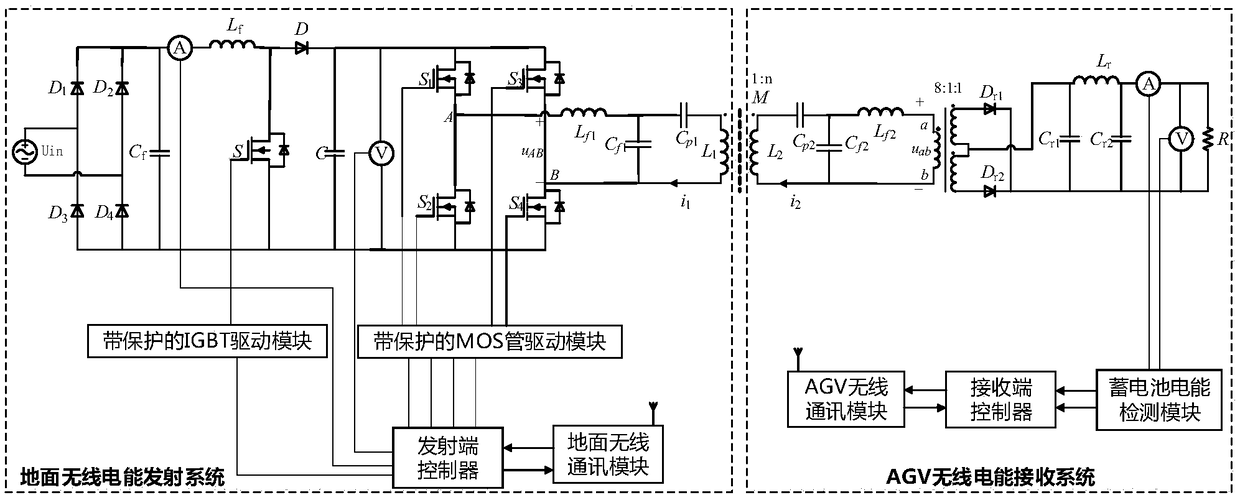

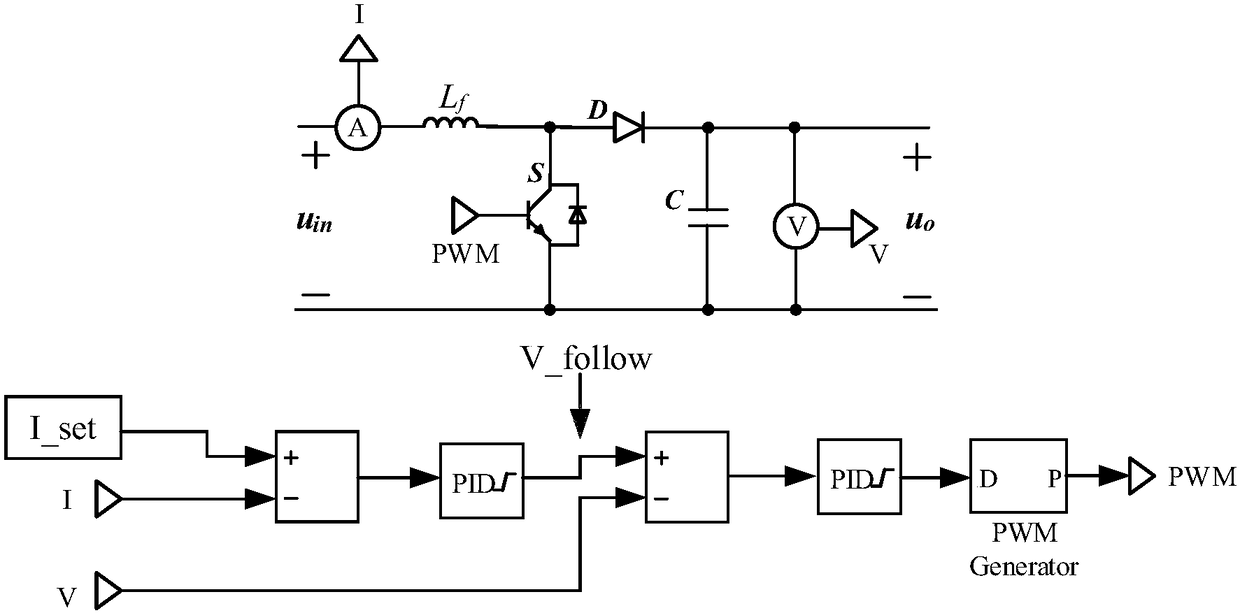

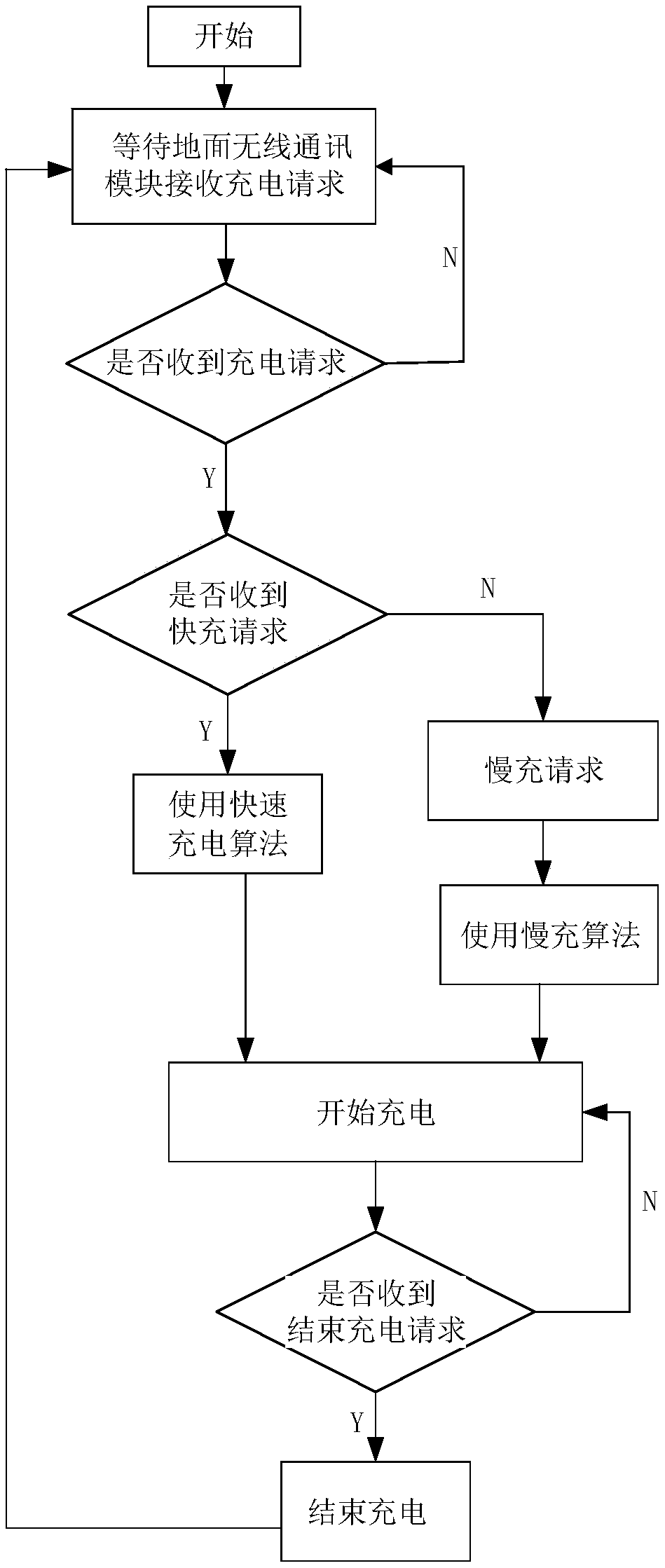

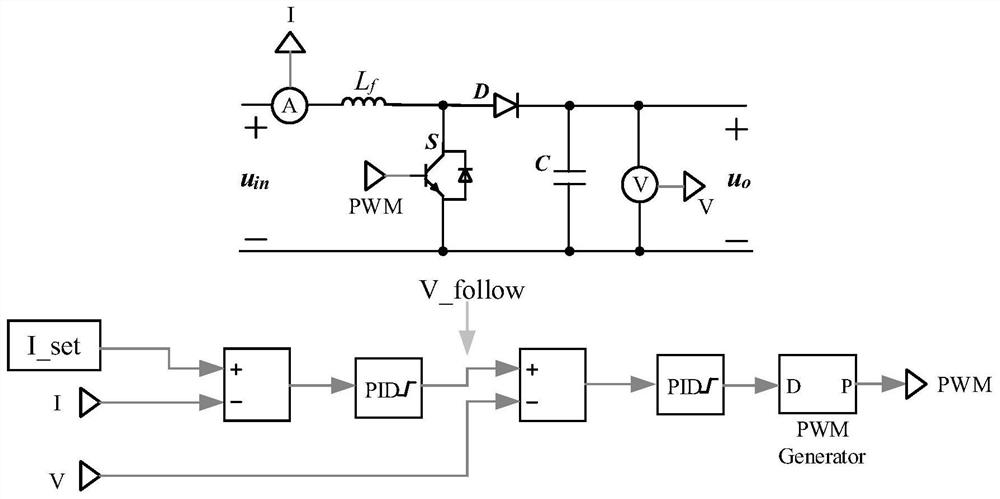

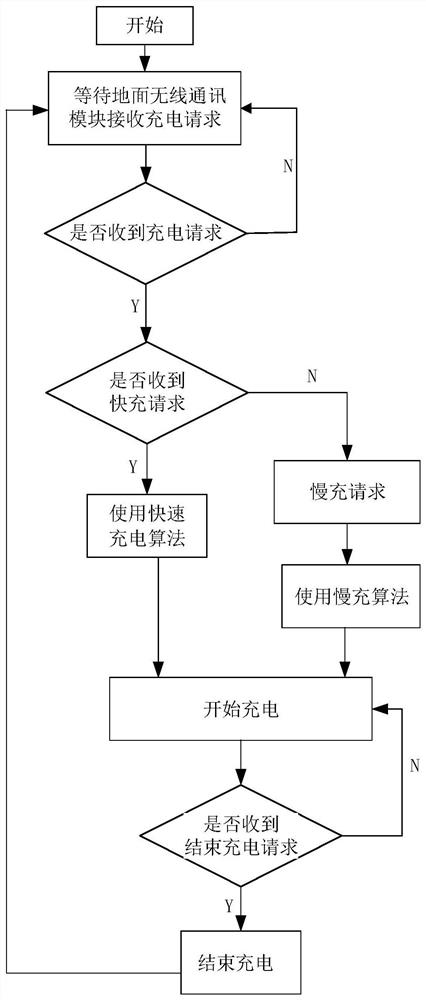

Wireless electric energy transmission system for AGVs and control method thereof

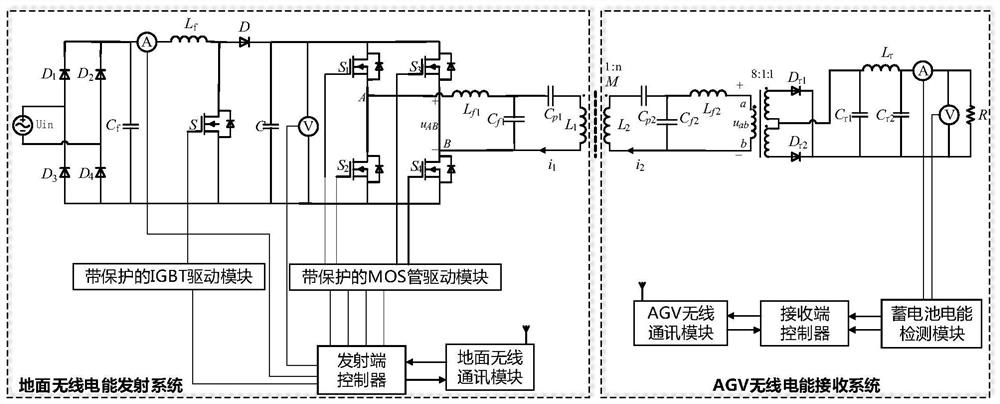

ActiveCN108448693AImprove securityImprove work efficiencyBatteries circuit arrangementsElectric powerResonanceTrickle charging

The invention discloses a wireless electric energy transmission system for AGVs and a control method thereof, and the system comprises a ground wireless electric energy transmission system and an AGVwireless electric energy receiving system. The system replaces wired charging with wireless charging to improve the safety of an AGV charging system. An electromagnetic resonance wireless electric energy transmission method is used to increase the transmission distance. A charging strategy combining quick charging and slow charging is used to improve the working efficiency of the AGV while ensuring the battery life, and to realize the automatic working of the AGV.

Owner:WUHAN UNIV OF TECH

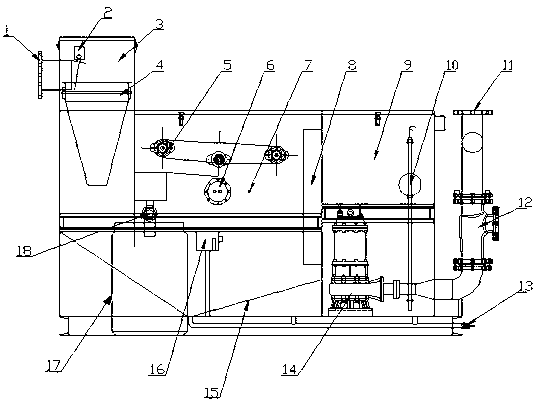

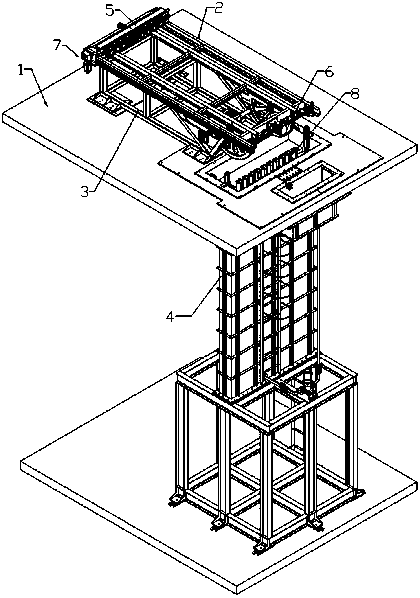

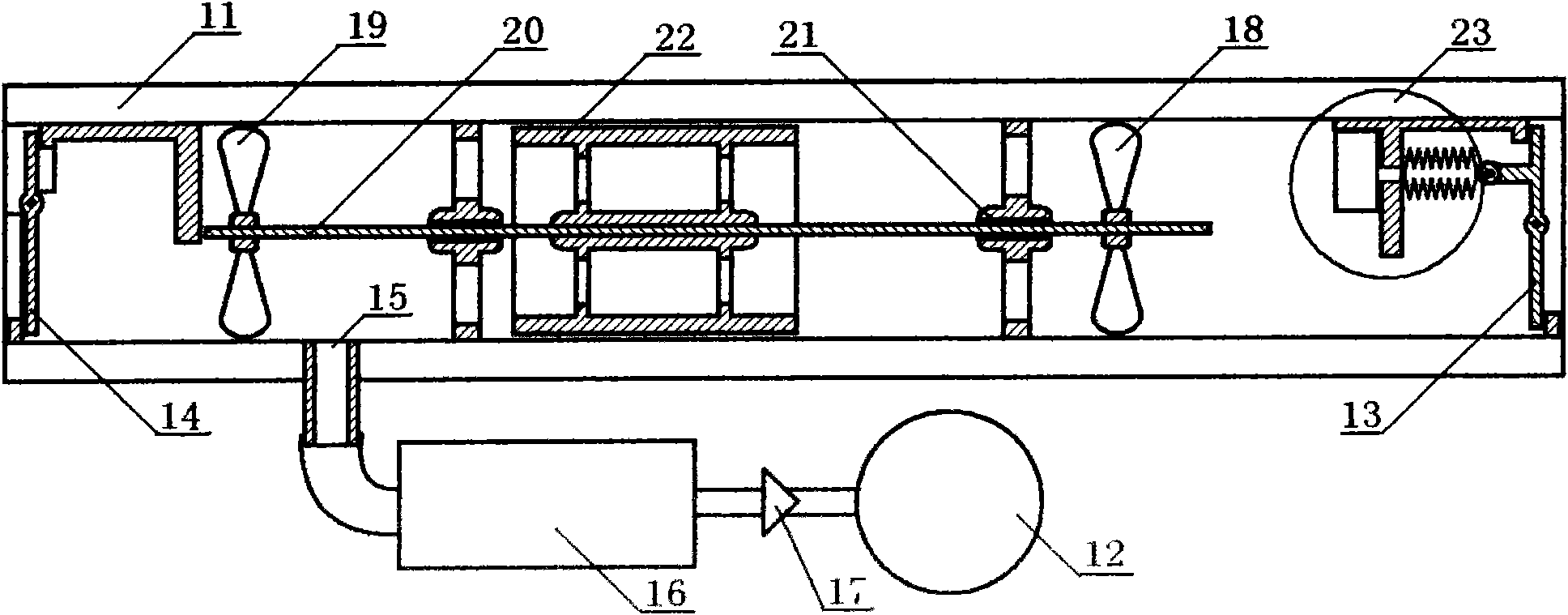

Full-automatic deslagging, oil separation and lifting integrated device

InactiveCN103058407AEasy to install and runReduce labor intensityFatty/oily/floating substances removal devicesMultistage water/sewage treatmentOil separationCell separation

The invention provides a full-automatic deslagging, oil separation and lifting integrated device. The integrated device comprises a solid-liquid separation tank, an oil separation and sludge discharge tank and a sewage lifting discharge tank, wherein the oil separation and sludge discharge tank is communicated with the sewage lifting discharge tank through a drainage and ventilation pipe, a solid-liquid separation apparatus is arranged at the lower end of a water inlet inside the solid-liquid separation tank, and the bottom of the solid-liquid separation tank is communicated with the bottom of the oil separation and sludge discharge tank; the bottom of the oil separation and sludge discharge tank is provided with a foaming apparatus and a sludge discharge pipe while the upper part thereof is provided with an oil scraping apparatus. The full-automatic deslagging, oil separation and lifting integrated device is designed in an integrative manner, is simple to mount and operate, and has the characteristics of preventing blockage, filtering, accelerating oil-water separation and being environment-friendly and sanitary; and the integrated device is controlled automatically and intelligently by a control cabinet, realizes full-automatic work, needs no special care and can reduce the labor intensity of people.

Owner:安徽特威达水电设备有限公司

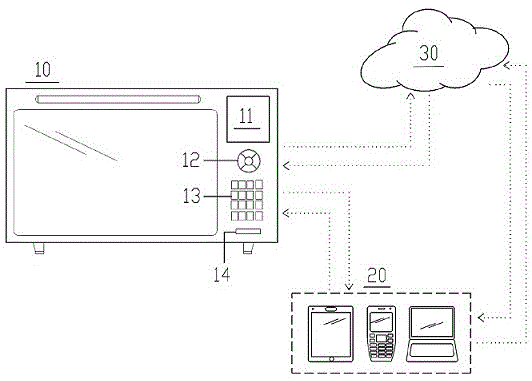

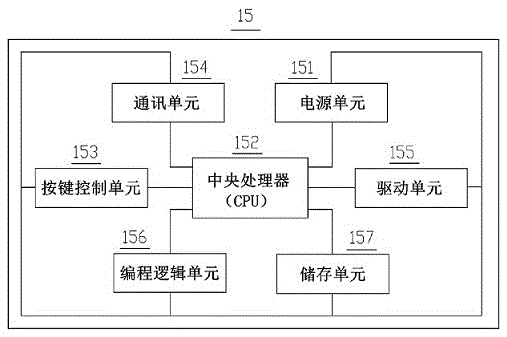

Intelligent electric oven with programmable cooking menu and using method thereof

InactiveCN105559624ARealize data sharingRealize offline independent workRoasters/grillsTransmissionEmbedded systemEngineering

The invention relates to the field of the mechanical and electrical technology, and provides an intelligent electric oven with a programmable cooking menu and a using method thereof. The intelligent electric oven comprises a display screen, functional keys, a numeric keyboard, a machine type bar code and a circuit control unit, wherein the display screen, the functional keys, the numeric keyboard and the machine type bar code are exposed out of the electric oven, and the circuit control unit is arranged in the electric oven; the circuit control unit comprises a communication unit connected with a cloud server and a mobile terminal and further comprises a programming logic unit and a storage unit which build connection with the communication unit through a central processing unit; the electric oven is supported by the programming logic unit to edit a new cooking menu matched with the machine type bar code; by means of the structure, the electric oven and the cloud server can build connection and share resources in the state that the electric oven disengages from the mobile terminal, a new application program matched with the machine type bar code is edited under supporting of the programming logic unit, and the good effects that the intelligent degree is high, operation is easy and convenient, the applicative functions of the electric oven are enhanced, and the applicable range of the electric oven is widened are achieved.

Owner:李文庆

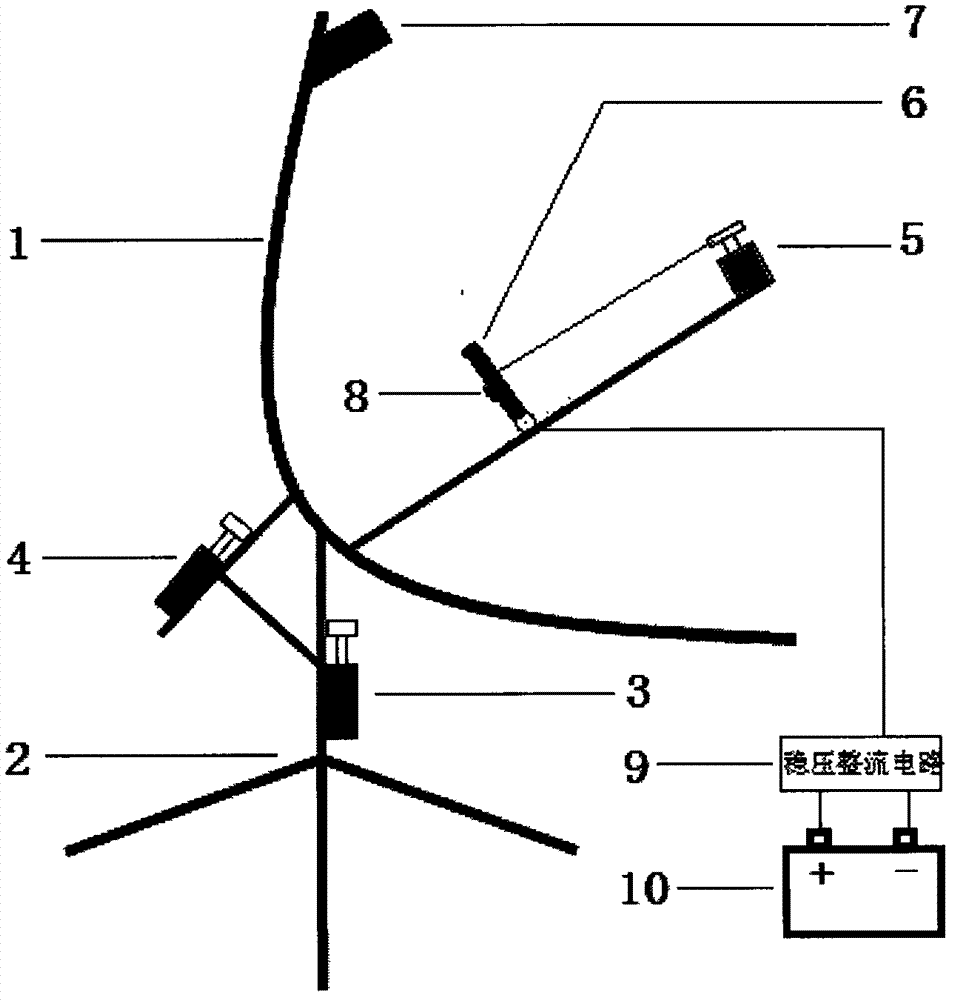

Intelligent tracking solar-powered semiconductor temperature difference generation device

InactiveCN103368464AReduce the power generation areaSmall footprintGenerators/motorsElectric machineryElectric energy

The invention provides an intelligent tracking solar-powered semiconductor temperature difference generation device. During working, a current light ray angle is detected via a light tracking module through an angle detection device; a reflecting plate is driven to rotate in a horizontal plane through a horizontal adjusting motor arranged on a device base and is driven to rotate in a vertical plane through a vertical adjusting motor; in three-dimensional adjustment, the reflecting plate is over against sunlight finally; a temperature probe in a mechanical control module is used for detecting the temperature at the hot end of a temperature difference generation sheet; the position of a generation module is adjusted by using a height adjusting motor to reach an optical generation temperature; at the moment, light rays are reflected and converged onto the hot end of the generation sheet by the reflecting plate; light energy is converted into heat energy which is further converted into electric energy through the generation sheet; and output direct current is stored in a storage battery after being subjected to voltage stabilization and rectification for users to use.

Owner:赵吉庆

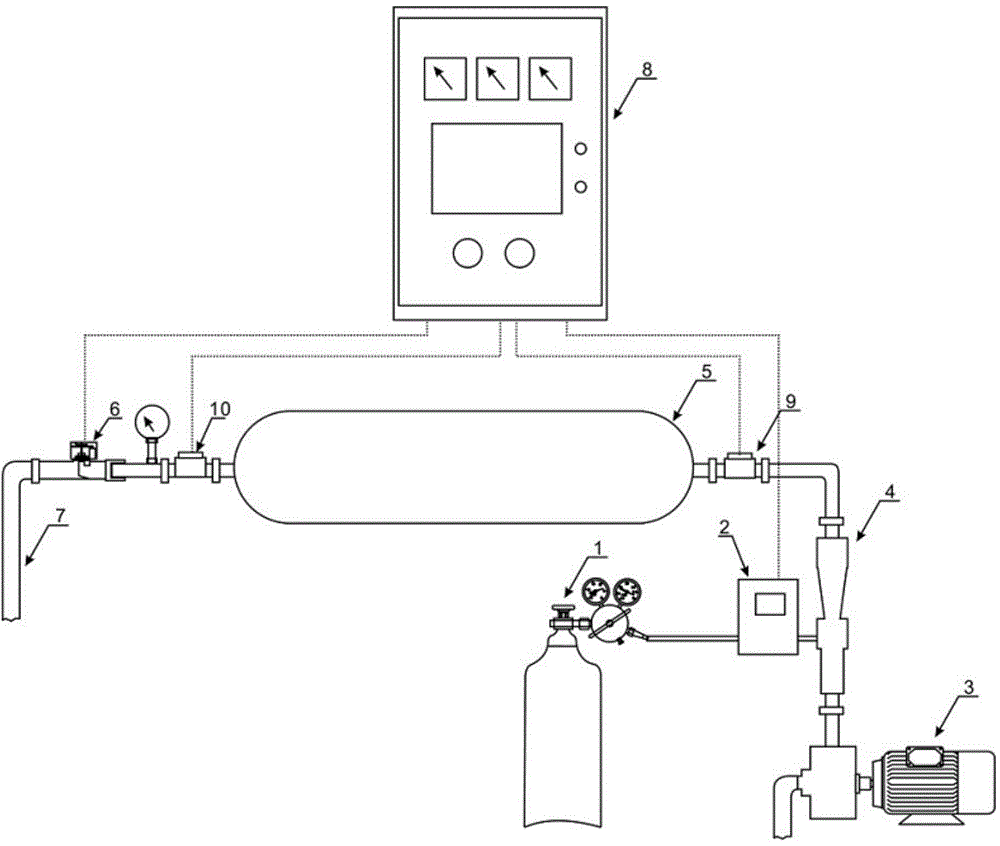

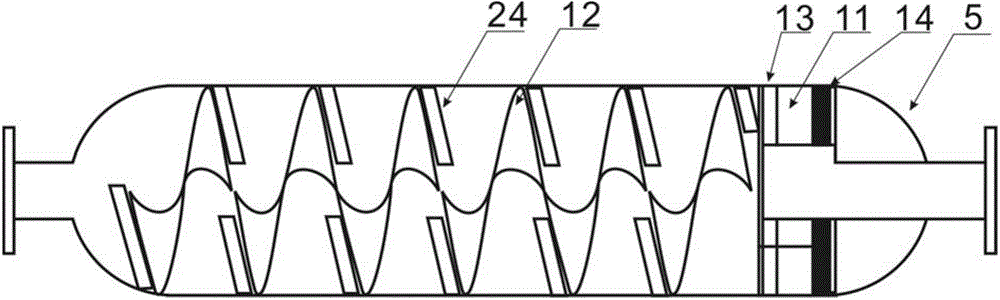

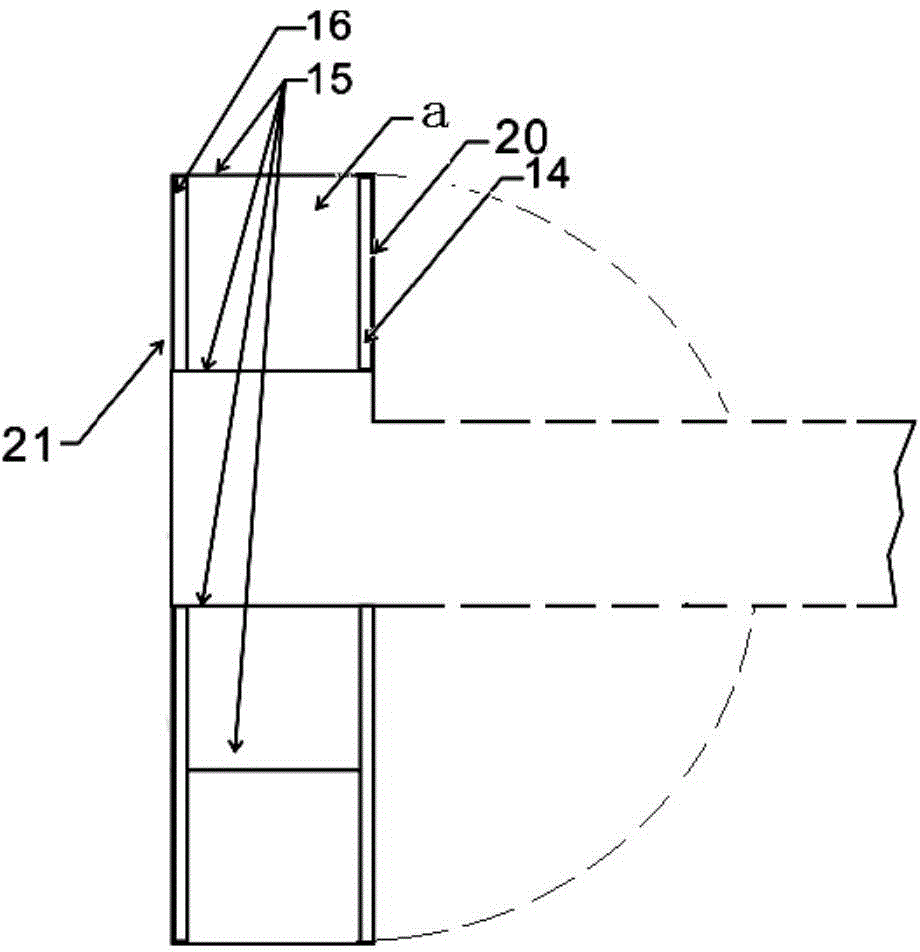

High-magnetism vortex-type ultrafine bubble generation cavity and aerator thereof

InactiveCN104163511AIncrease profitImprove solubilityMixing methodsWater aerationCavitationSmall footprint

The invention relates to a high-magnetism vortex-type ultrafine bubble generation cavity and an aerator thereof, belonging to the technical field of water treatment. The aerator comprises a high-magnetism vortex-type ultrafine bubble generation cavity, a Venturi pipe, a controller, an oxygen gas source with a flow regulating valve, and a self-priming water pump, wherein the high-magnetism vortex-type ultrafine bubble generation cavity, Venturi pipe and controller are respectively electrically connected with the oxygen gas source; the input end of the Venturi pipe is respectively connected with the oxygen gas source and the self-priming water pump; and the output end of the Venturi pipe is connected with the water inlet of the high-magnetism vortex-type ultrafine bubble generation cavity. The aerator has the characteristics of compact structure, small occupied area, low energy consumption, high oxygen utilization, low cavitation corrosion, no blockage and the like, and can generate an N5 neodymium-iron-boron high-magnetism material with the magnetic field intensity of higher than 14500GS; and the volume of the output bubbles is lower than 10 mu m. The aerator is applicable to the field of in-water aeration, can be used instead of the traditional dissolved gas tank, and is suitable for sewage treatment, aquiculture and other water body oxygenation aeration or floatation separation and other water treatment techniques.

Owner:上海佛欣流域环境治理有限公司

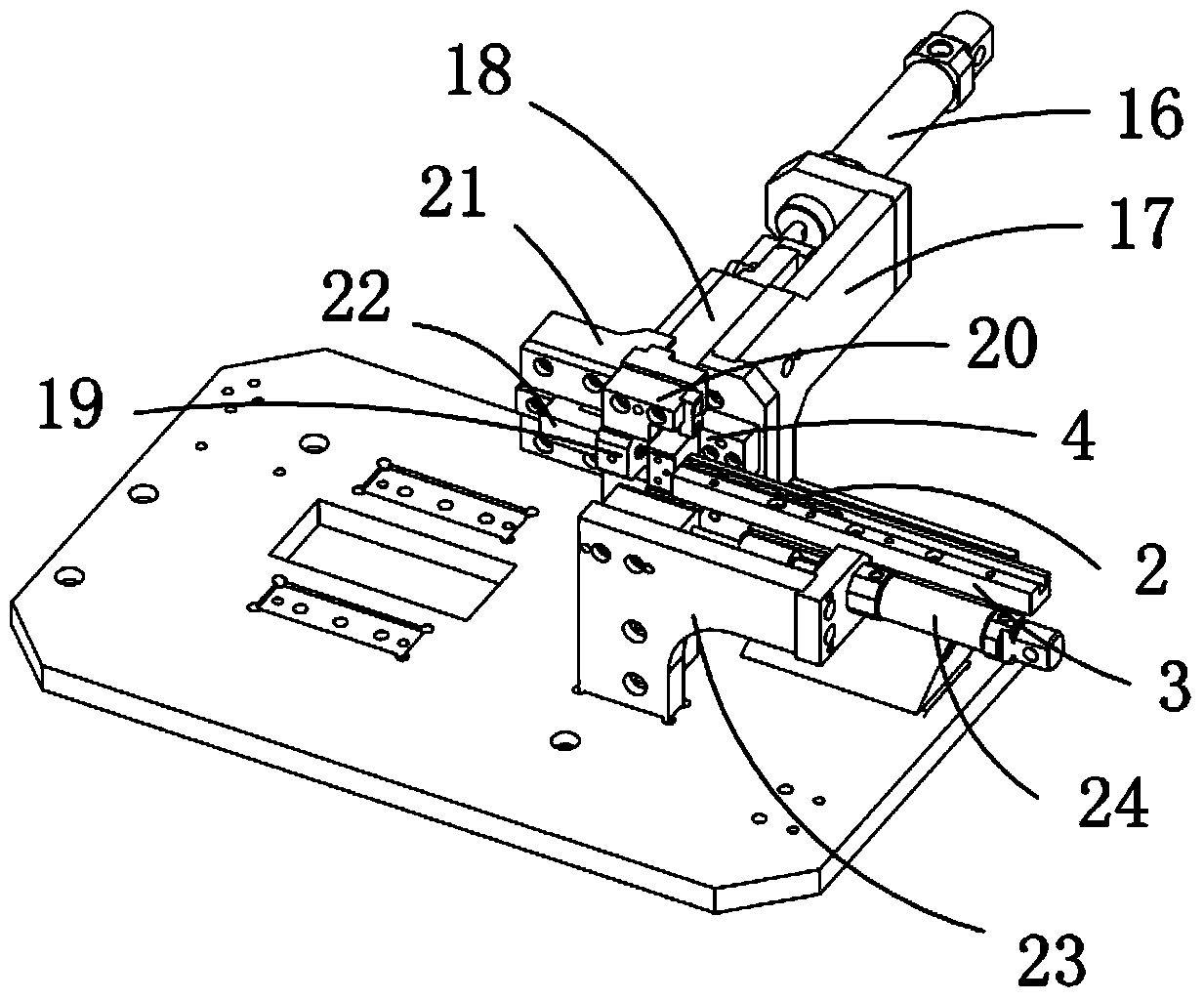

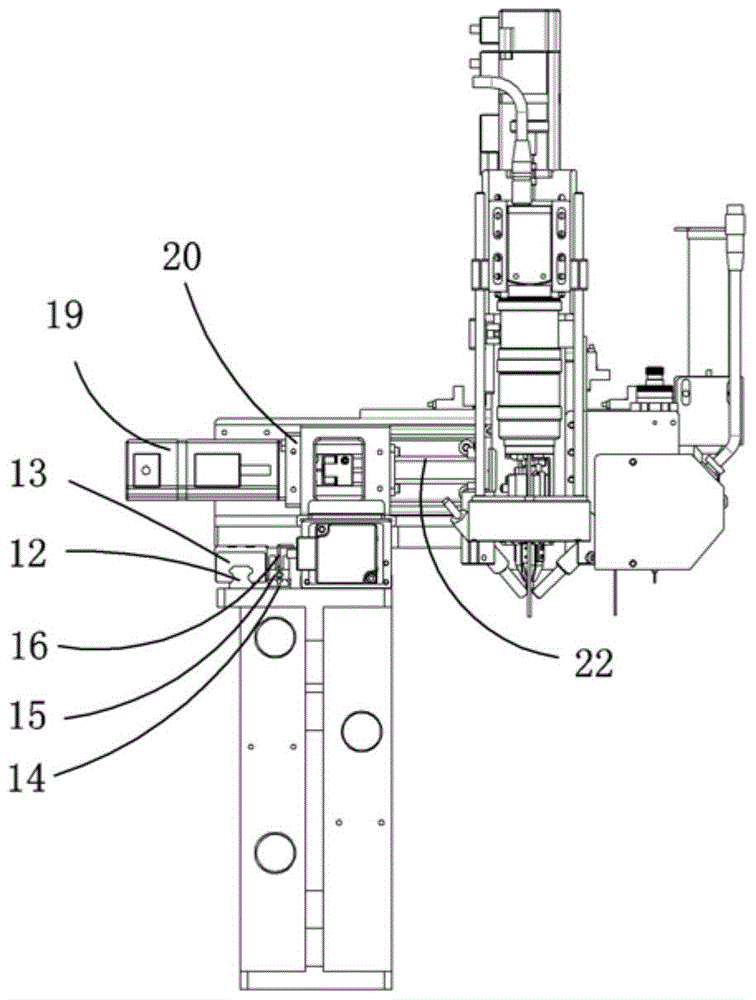

Material conveying mechanism

ActiveCN103640871AAffect feedLow costControl devices for conveyorsRotary conveyorsEngineeringInductor

The invention relates to a material conveying mechanism. Materials are fed from a material groove, then reach the position of a feeding guide rail connecting block and enter a receiving block, an inductor induces whether the materials exit or not, after the materials enter the receiving block, a material pushing air cylinder drives a sliding block to forwards move to push the connecting block to enable the receiving block to forwards move with the materials, the materials are moved to the position aligned with a product fixing base, and then the material feeding air cylinder drives a feeding rod to push the materials to the product fixing base from the receiving block; a rotary disc driving air cylinder drives a rotary disc to rotate to drive a disc to rotate, the disc can only perform one-way rotation under the effect of a one-way swinging block, the product fixing base can be aligned with the receiving block one time when the disc rotates once, and therefore continuous material feeding is achieved; when the materials rotate in the product fixing base to be at the vertical position, the tapping process is carried out, after tapping is finished, the disc continuously rotates, when the materials are aligned with a material outlet pipe, a material ejecting air cylinder in a material ejecting mechanism drives a brake block to push an ejecting block to eject out the completely-machined materials from the product fixing base, and the completely-machined materials are taken out form the material outlet pipe.

Owner:BOZHON PRECISION IND TECH CO LTD

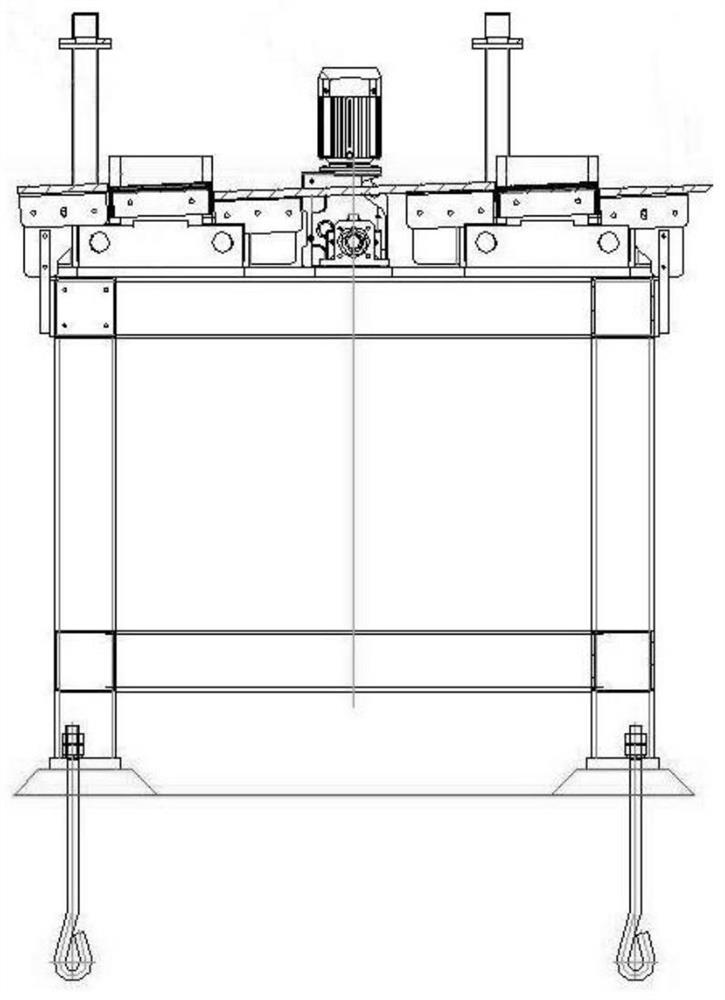

Glass tube coating device

ActiveCN104069980ARealize fully automatic workRealize large-scale automated productionLiquid surface applicatorsCoatingsAutomatic controlLocking mechanism

The invention relates to a glass tube coating device which comprises a rack, wherein a glass holding frame, a locking mechanism, a turnover mechanism and a lifting mechanism are arranged on the rack; the turnover mechanism comprises a support, a turnover motor, a driving gear and a driven gear; the driving gear is meshed with the driven gear, and the driven gear is a semicircular gear; the circle center of the semicircular gear is articulated with the support, and the right-angle side of the semicircular gear is fixed to the glass holding frame; the turnover motor is fixed on the support, drives the driving gear to rotate, further drives the driven gear to rotate, and further drives the glass holding frame to rotate. Through the transition between the horizontal state and the vertical state of a glass tube and match with the longitudinal movement, the glass tube coating device with a novel structure realizes fully-automatic operation of feeding, rotating, decreasing infiltration coating, lifting, rotating and discharging and completely automated control, can realize large-scale automated production, and greatly improves the production efficiency.

Owner:北京天瑞星光热技术有限公司

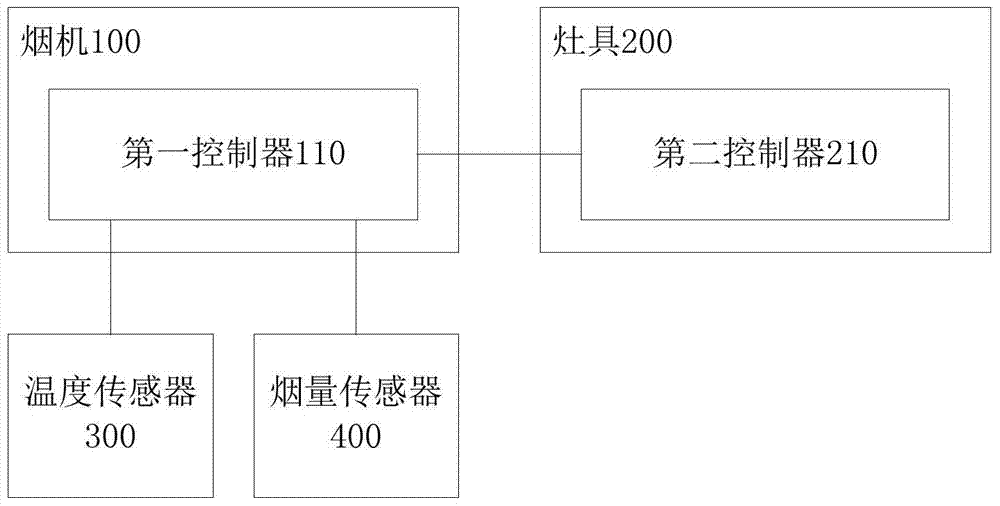

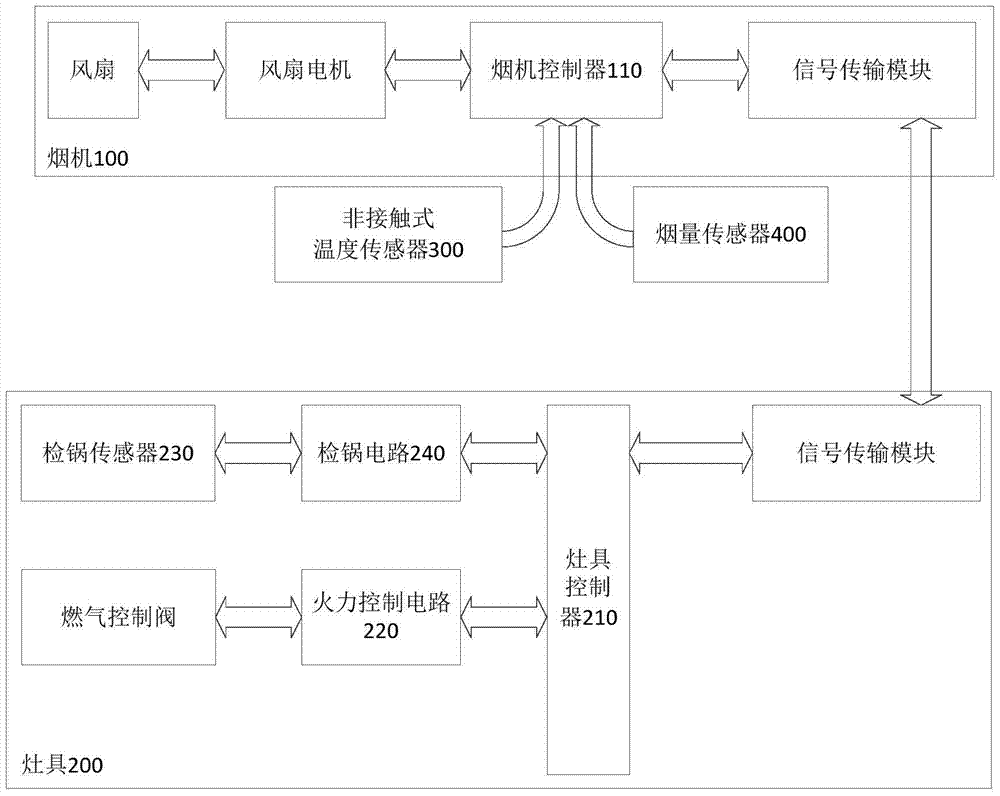

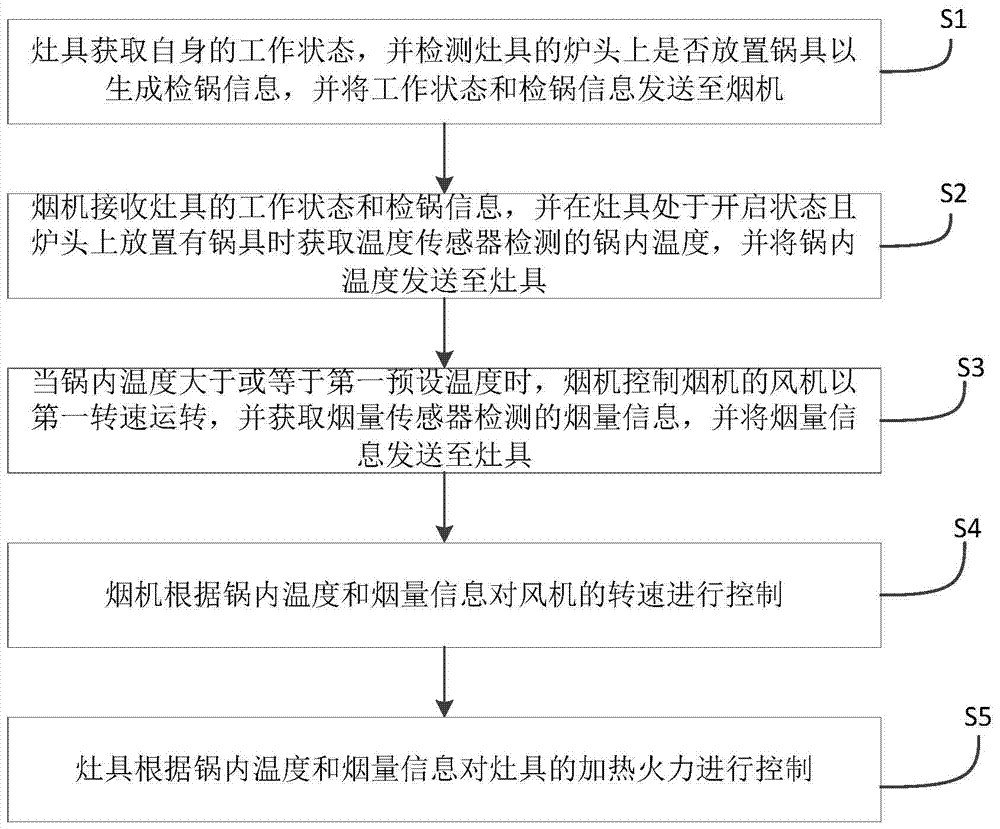

Smoke cooker linkage control system and method

ActiveCN105333477BRealize intelligent controlRealize energy savingDomestic stoves or rangesLighting and heating apparatusControl systemEngineering

The invention discloses a smoke range linkage control system and method. The system includes: a range hood (including a first controller), a cooker (including a second controller), a temperature sensor and a smoke sensor, and the second controller acquires The working status of the cooker, and detect whether a pot is placed on the burner of the cooker to generate the pot inspection information, and send the working status of the cooker and the pot inspection information to the first controller; the first controller receives the work status of the cooker and the pot check information information, and when the stove is turned on and a pot is placed on the burner, the temperature in the pot is obtained, and the temperature in the pot is sent to the stove. When the temperature in the pot is greater than or equal to the first preset temperature, the fan runs at the first speed. The smoke volume information is obtained and sent to the cooker. The first controller controls the speed of the fan according to the temperature in the pot and the smoke volume information; the second controller also controls the heating power according to the temperature in the pot and the smoke volume information. This system enables the hood and cooker to work fully automatically, improving the user experience.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

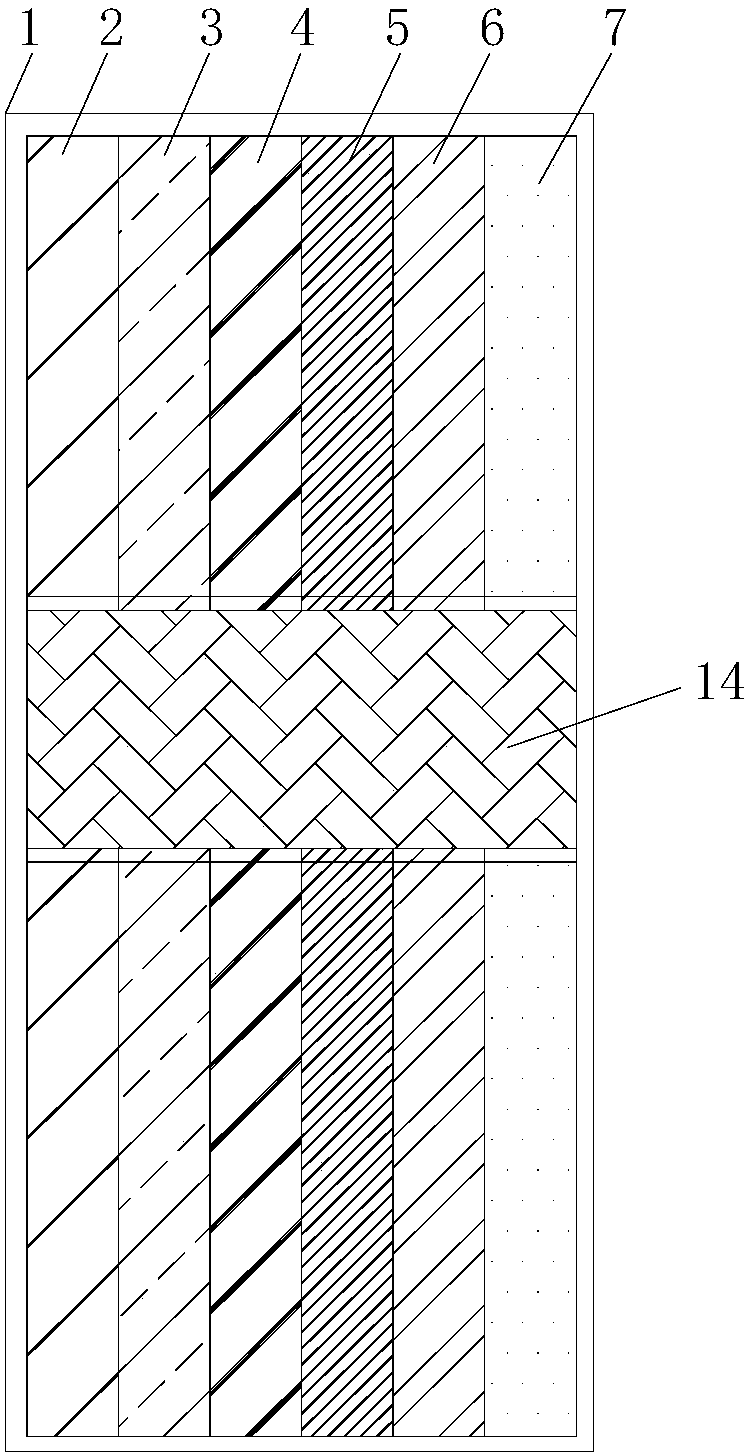

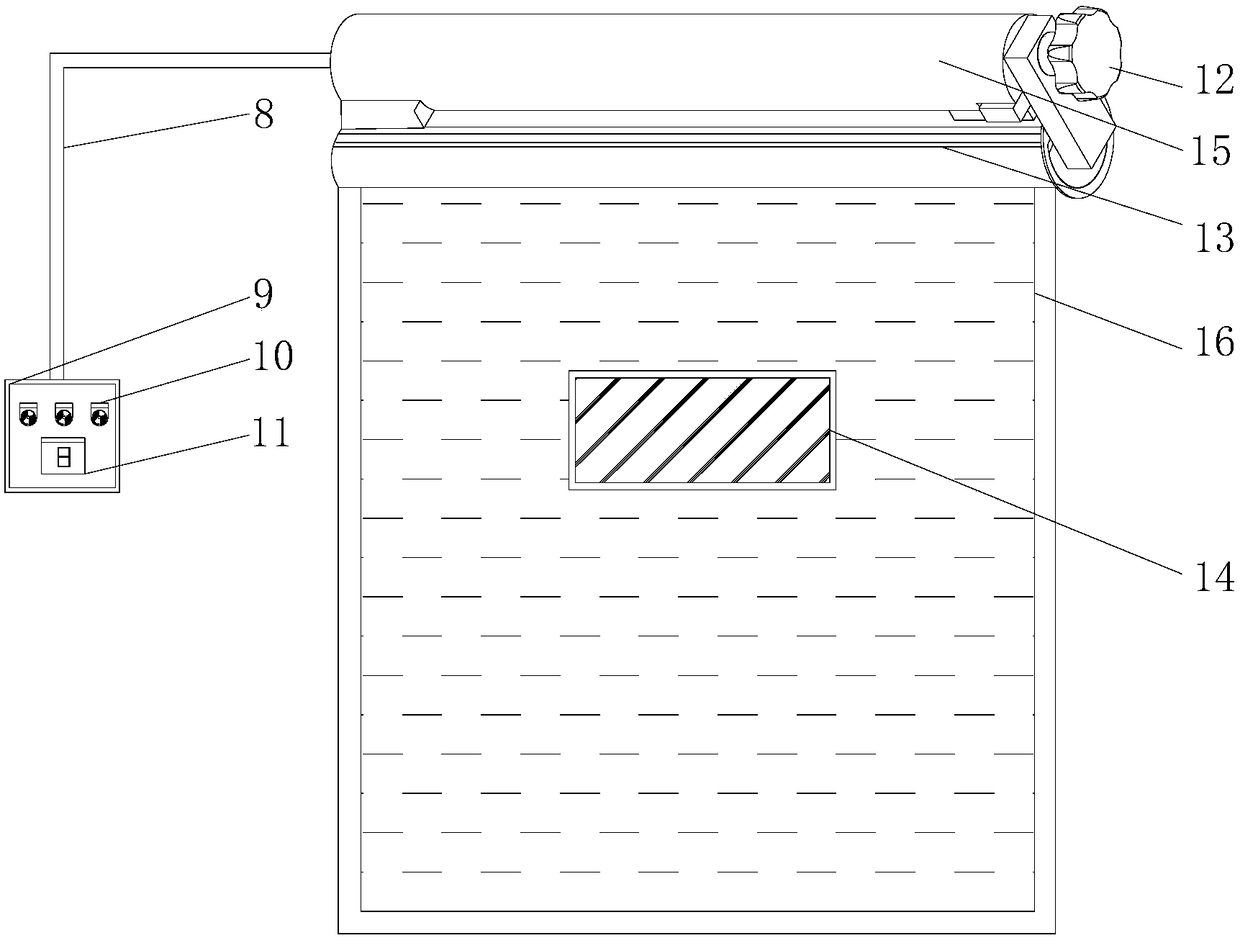

Colored steel rolling device for visual rolling door

InactiveCN108301751AImprove sound absorptionImprove corrosion resistanceShutters/ movable grillesFireproof doorsFire protectionInsulation layer

The invention discloses a colored steel rolling device for a visual rolling door. The colored steel rolling device comprises a rolling shutter contraction box and a rolling shutter plate. A loading shaft arranged in the rolling shutter contraction box and a turning and rotating button arranged on the right side of the rolling shutter contraction box are connected with each other. A roller is arranged at the lower side of the rolling shutter contraction box which is in contraction connection with the rolling shutter plate. The rolling shutter plate is provided with a transparent plastic pad, agalvanized iron plate, a fire protection layer, a sound insulation layer, a foaming layer and a stainless steel plate from outside to inside successively. An observation window penetrates through theinside of the rolling shutter plate. The rolling shutter contraction box is electrically connected with a control panel by conducting wires. A control button and a rotary switch are arranged on the surface of the control panel. The observation window is made of tempered glass. The inside situation is observed by the observation window and the observation window is made of the tempered glass whichis high in hardness, so that stealing is avoided and safety is strengthened. The rolling shutter plate is electrically connected with the control panel, so that fully automatic working is realized, both time and labour are saved, and work efficiency is improved.

Owner:盐城市盐阜板业有限公司

Glass tube coating device

ActiveCN104069980BRealize fully automatic workRealize large-scale automated productionLiquid surface applicatorsCoatingsGear driveMotor drive

A glass tube coating device, comprising a frame, the frame is provided with a glass placement frame, a locking mechanism, an overturning mechanism and a lifting mechanism, and the overturning mechanism includes a bracket, an overturning motor, a driving gear and a driven gear. The driving gear and the driven gear mesh with each other. The driven gear is a semicircular gear. The gear rotation further drives the driven gear to rotate, and further drives the glass placement rack to rotate. The glass tube coating mechanism with a new structure realizes the transformation from the horizontal state to the vertical state of the glass tube, and then cooperates with the vertical movement to realize the automatic feeding , Rotation, descent dipping coating, lifting, rotation, unloading fully automatic work, complete automatic control, can realize large-scale automatic production and greatly improve production efficiency.

Owner:北京天瑞星光热技术有限公司

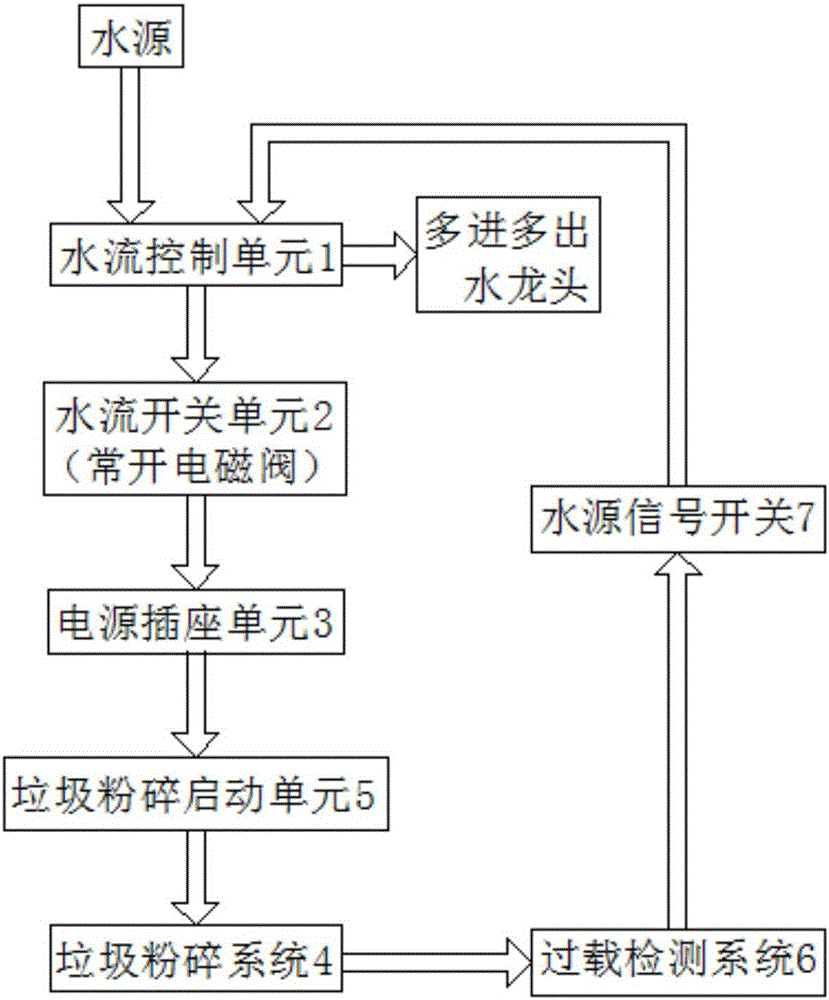

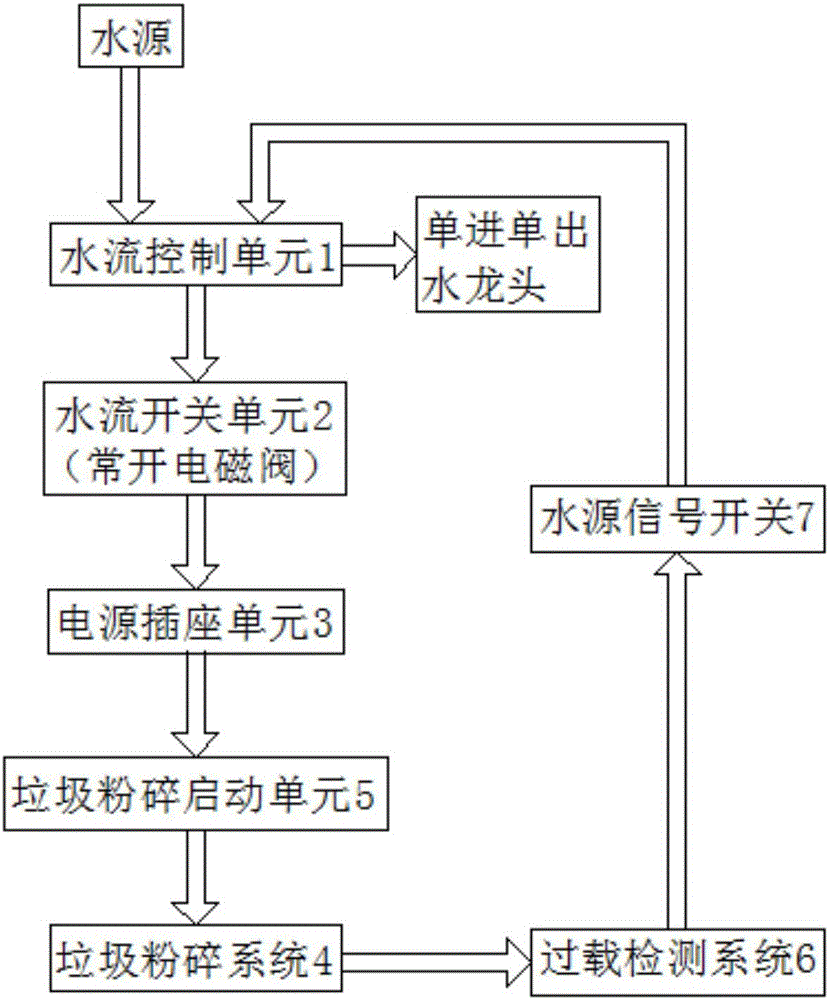

Water flow control system

InactiveCN106647357ARealize automatic power onAchieve closureProgramme control in sequence/logic controllersElectrical conductorControl system

The invention discloses a water flow control system, comprising a water flow control unit; the control system further comprises a water flow switch unit, a power socket unit and a garbage crushing system, wherein the water flow switch unit controls on and off of the power socket unit and a main power supply, the power socket unit controls the working states of connection and disconnection of a power socket unit body, and the garbage crushing system is used for crushing garbage; the water flow control unit is opened to urge power-on start of the water flow switch unit so that the power socket unit is connected to the main power supply, passing water flow serving as a conductor is connected to the power socket unit body, the power socket unit is in a turn-on working state, and then the garbage crushing system is started. The control system can realize full-automatic operation from starting a water source, connecting to power and starting a garbage crusher, the power-on safety is further ensured via an overload detection system, and the control system is energy-saving, environment-friendly and simple in operation, guarantees the safety and prolongs the service life of the garbage crusher.

Owner:张广威

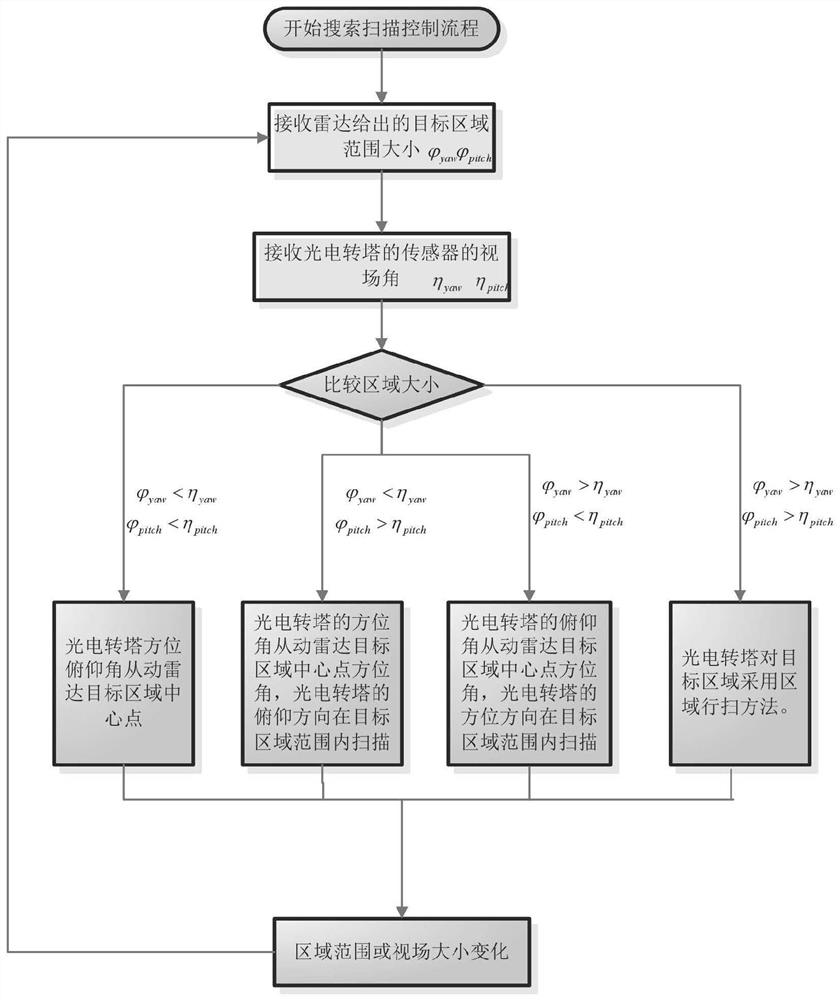

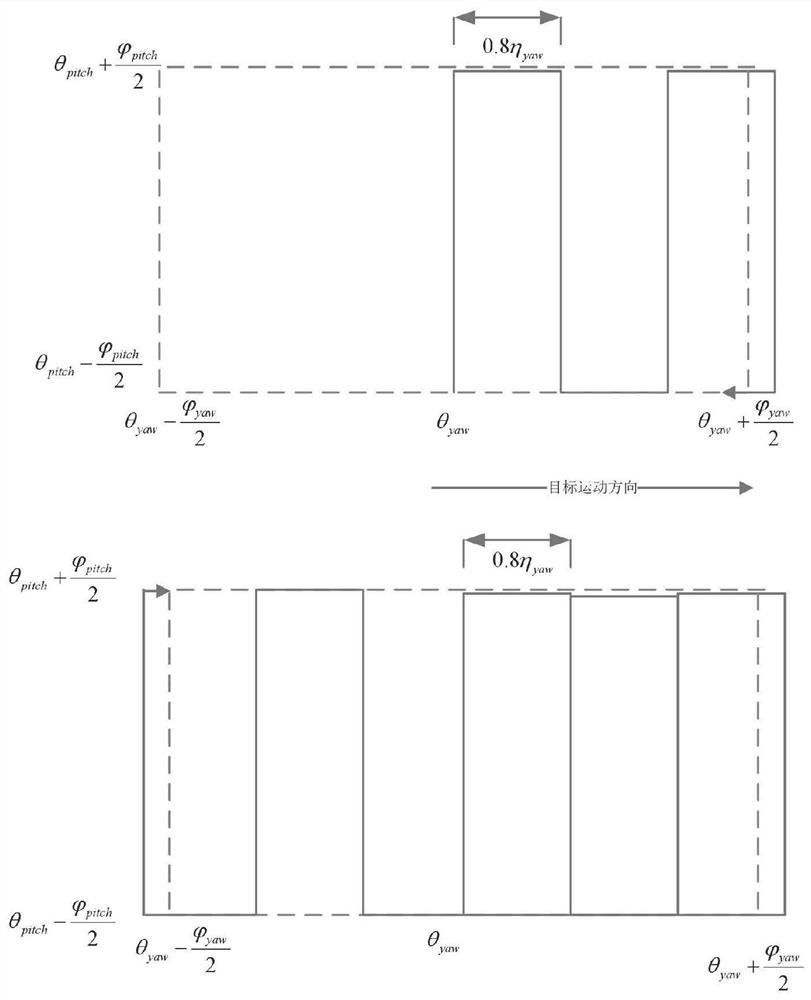

Searching and scanning control method of photoelectric turret for radar identification target area

PendingCN114114206ARealize fully automatic workImprove search speedWave based measurement systemsControl using feedbackAutomatic controlRadar

The invention discloses a searching and scanning control method of a photoelectric turret for a radar identification target area, and belongs to an automatic control technology. The scanning search mode and the search range are automatically calculated according to the view field size of the turret sensor and the target possible range given by the radar, and full-automatic search scanning is achieved. In the area searching and scanning process, the photoelectric turret can switch searching and scanning modes according to the target area range given by the radar and the field angle information range of the current sensor, an appropriate scanning mode is selected from the four scanning modes according to the size of the target area range and the field angle range, and scanning parameters are calculated. Therefore, the whole target area range can be scanned under the condition that the target area changes continuously. Practical tests prove that the searching and scanning control method realizes full-automatic searching and scanning, human intervention is not needed, the target can be found when the range given by the radar is not accurate enough, the efficiency is greatly improved, and the probability of missing the target is reduced.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Gas compressor and overpressure controller

InactiveCN101963099ASimple structureSave raw materialsPumpsPositive-displacement liquid enginesGas compressorFuel tank

The invention discloses a gas compressor and an overpressure controller. The invention provides two types of equipment for manufacturing compressed gas, which can reduce the manufacturing cost and use cost of a booster engine system and is favorable for wide use. A full-automatic overpressure switch is designed for a solar air compressor. An inner fuel tank comprises a gas storage tank, a gas inlet pipe and an igniter and is characterized in that liquid is contained in the gas storage tank; a floating plate is arranged on the liquid surface; the gas inlet pipe is connected to the floating plate; the igniter is arranged on the floating plate; and the outlet of the gas inlet pipe is below the liquid surface. In the inner fuel tank, an engine is embedded in a gas tank and bubbles are utilized to isolate gases before and after burning, therefore the engine structure is simplified, the raw materials are saved and the manufacturing cost is reduced. The solar air compressor compresses air into the gas storage tank by using the principle that gas expands when being heated; and as the air is not mechanically compressed, the solar air compressor has the advantages of simple structure, low cost and low price of manufactured compressed air, and facilitates the popularization of machinery powered by compressed gas.

Owner:张金铭

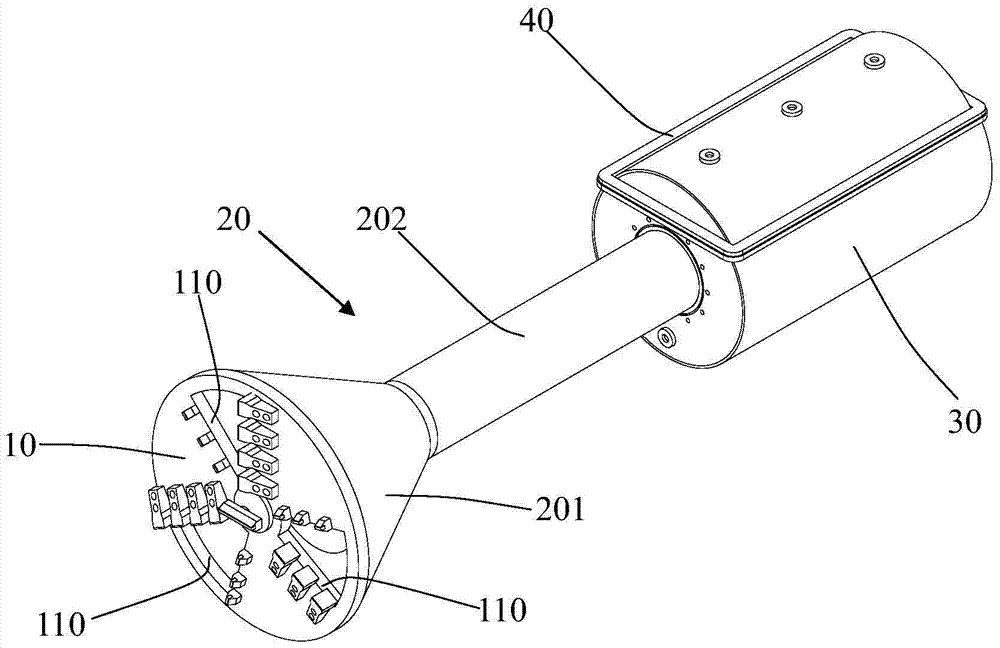

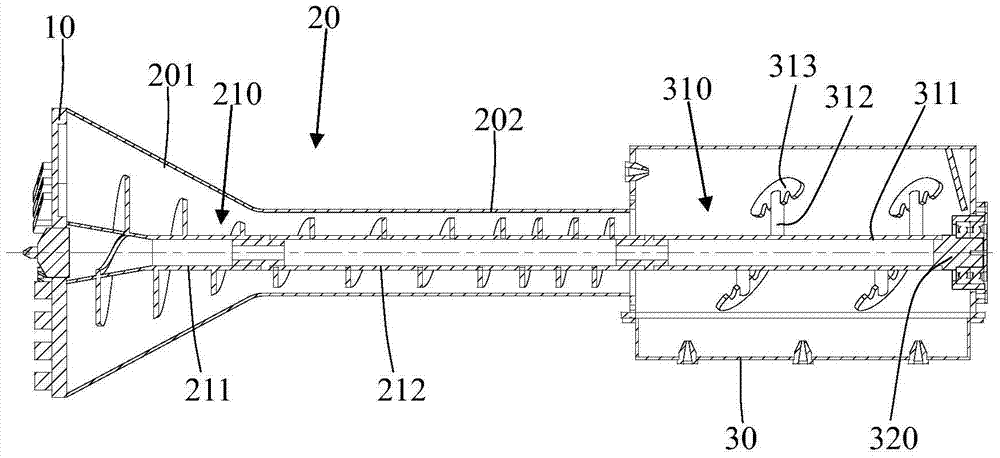

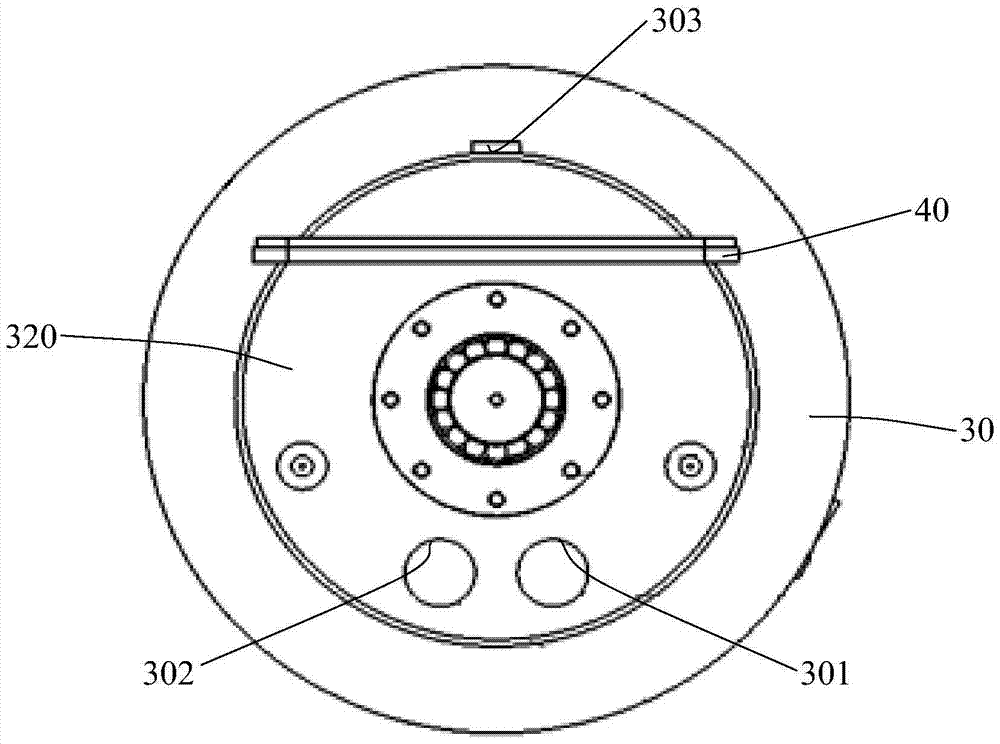

Cutting device of earth pressure balance pipe jacking machine

ActiveCN105298508BReduce or even avoid the problem of deep in-pipe constructionAvoid the problem of deep in-pipe constructionTunnelsSludgeEngineering

The invention discloses a cutting device of an earth pressure balance pipe jacking machine, comprising: a cutting cutter head, which is provided with a cutting tool and a soil conveying port; The soil conveying bin connected with the mouth, and the inside of the soil conveying bin is provided with a screw rod; the mixing bin which is fixedly connected to the soil conveying bin and communicated with the soil conveying bin, and the mixing bin is provided with a The water injection hole and the mud outlet, the inside of the mixing chamber are equipped with a stirring mechanism connected to the screw rod by transmission and a mud discharge mechanism arranged at the mud outlet. The soil cut by the cutting cutter head enters the soil conveying chamber through the soil conveying port, and then the soil is conveyed to the mixing chamber through the screw rod, and then water is injected into the mixing chamber from the water injection hole, and the soil and water are stirred by the stirring mechanism at the same time. into muddy water, and finally the muddy water is discharged from the mud outlet through the mud discharge mechanism. Utilizing the characteristics of stable earth pressure balance and good mud-water balance, it avoids the problem of workers going deep into the pipeline for construction.

Owner:SHANGHAI TUNNEL ENG CO LTD

Serious disease monitoring and early warning device for livestock aquatic products

InactiveCN108377942ASpray evenlyStir wellTransportation and packagingClimate change adaptationDisease monitoringAquatic product

The invention discloses a serious disease monitoring and early warning device for livestock aquatic products. The device comprises an engine base, a rotor wing mechanism rotationally arranged on the top of the engine base and supporting feet fixedly arranged at the four corners of the bottom of the engine base. Medicament stirring bins are bilaterally symmetrically arranged in the engine base, anda transmission cavity extending left and right is formed in the portion, above the medicament stirring bins, of the engine base; Due to one motor, medicament stirring work and flight work of the engine base can be achieved, medicaments can be controlled to be sprayed out quantitatively on time by partitioning closed sliding blocks, the equipment manufacturing cost is greatly lowered, full-automatic work of the device is achieved, the working efficiency and safety of medicament spraying are greatly improved, artificial input is lowered, and the device is simple in structure, convenient and rapid to operate and capable of effectively preventing livestock aquatic product serious diseases.

Owner:YICHANG HUIYIXING NEW ENERGY TECH CO LTD

Wireless power transmission system for AGV and control method thereof

ActiveCN108448693BImprove securityImprove work efficiencyBatteries circuit arrangementsElectric powerFast chargingBattery cell

The invention discloses a wireless power transmission system for AGV and a control method thereof. The system includes a ground wireless power transmission system and an AGV wireless power receiving system. The invention adopts wireless charging instead of wired charging to improve the safety of the AGV charging system ; Adopt the electromagnetic resonance wireless power transmission method to increase the transmission distance; adopt the charging strategy combining fast charging and slow charging, while ensuring the service life of the battery, it improves the working efficiency of the AGV and realizes the automatic operation of the AGV.

Owner:WUHAN UNIV OF TECH

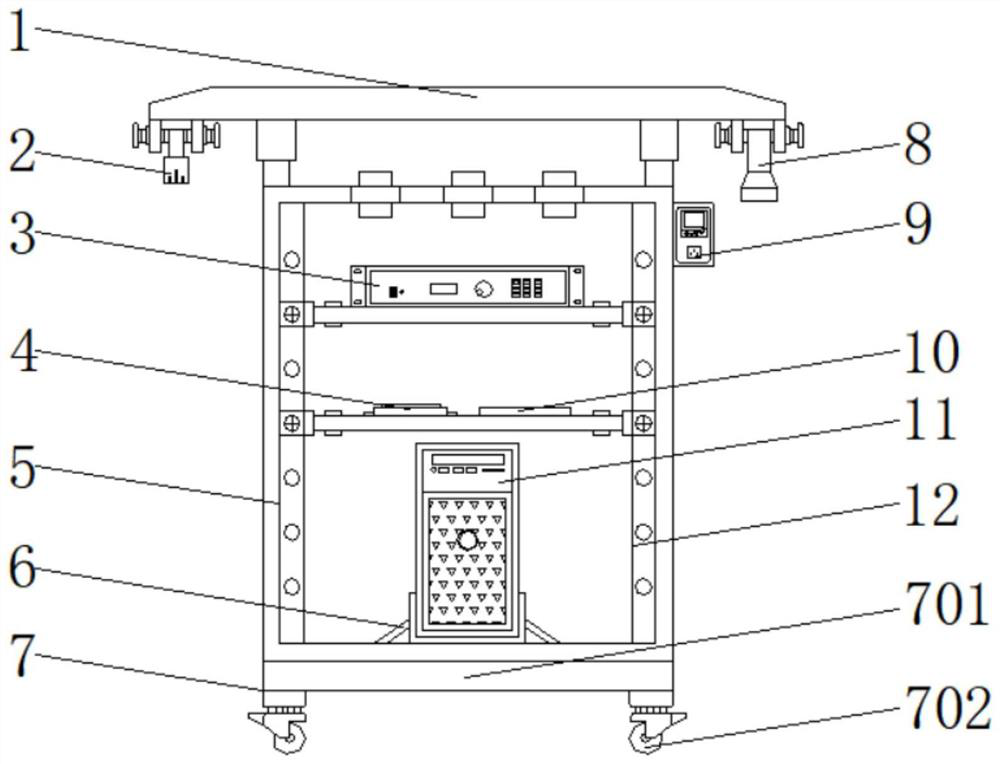

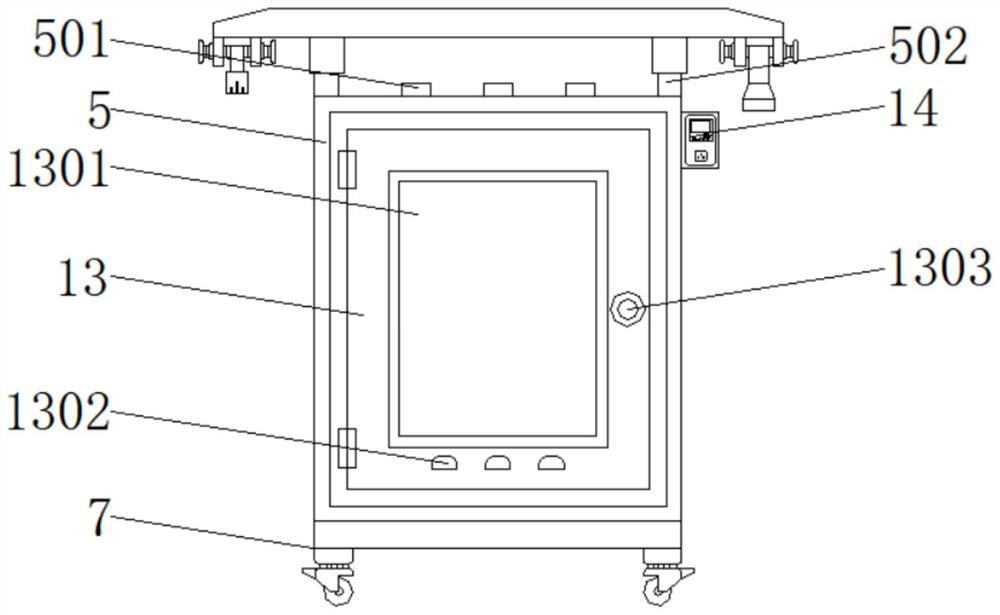

Ccd-based image capture and contact identification acquisition device

PendingCN112834513AHigh precisionEasy to operateTelevision system detailsElectrets selectrostatic transducerEmbedded systemFrame grabber

The invention discloses a ccd-based image capture and contact identification acquisition device, which comprises a mounting assembly, a shell and a moving assembly, and is characterized in that a supporting frame is fixedly mounted at the bottom end in the shell. The supporting assembly is fixedly mounted at the top of the PC host, the PC host can be supported by a supporting frame, then a supporting plate is fixed by matching a through hole with a fastening bolt, and then a wire penetrates through a second wire conduit, so that a worker can perform laying work conveniently; then, a system timer, a single chip microcomputer and an image acquisition card are stored through a supporting plate, and then the time precision is controlled through the system timer; and the ccd-based image capture and contact identification acquisition device is high in precision, simple to operate, high in interpretation speed, high in automation degree, few in peripheral equipment and capable of sharing data in all links in time, personal error factors of traditional contact recognition are reduced, and the system has very important use value.

Owner:内蒙古科技大学包头师范学院

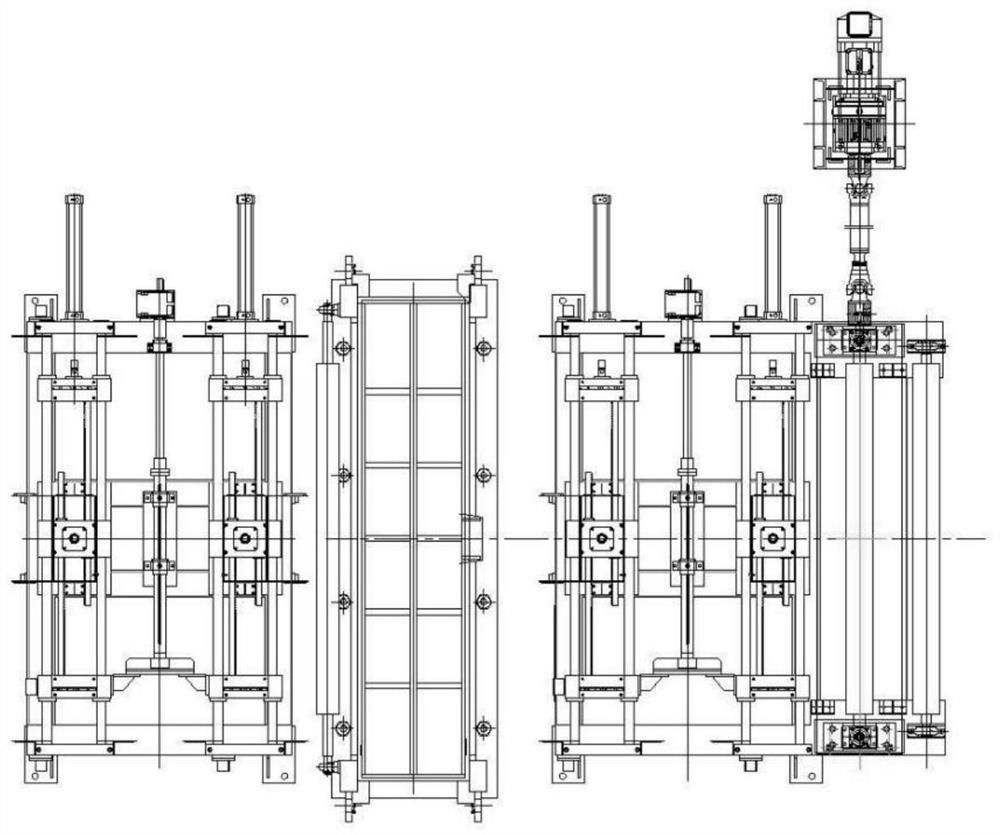

Full-automatic sheet strip sewing machine and control method

PendingCN113070410ARealize fully automatic workEasy to operateMetal-working feeding devicesPositioning devicesTransmission beltEngineering

The invention discloses a full-automatic sheet strip sewing machine and a control method, and belongs to the field of sheet strip processing. The sewing machine is provided with a sewing machine body, and a centering platform a and a centering platform b are arranged on the two sides of the sewing machine body respectively. A sewing method is further included. The sewing method comprises the following steps of determining a strip tail stopping position, centering the strip tail, determining a strip tail sewing position, opening a backup plate of the centering platform a, determining a strip head stopping space, centering the strip head, sewing and connecting, tensioning an uncoiling section, and performing speed-up operation. The centering platform is matched with the sewing machine body to achieve sewing operation of a sheet strip, the centering platform is provided with a transmission mechanism, the sheet strip is moved to a proper position through a transmission belt during sewing, sewing is achieved in cooperation with the sewing machine body, operation is easy and convenient, regulation and control are achieved through an encoder, full-automatic work is achieved, manual carrying is not needed, the labor cost is saved, and the yield is high.

Owner:DALIAN CHENGTONG ENG TECH CO LTD

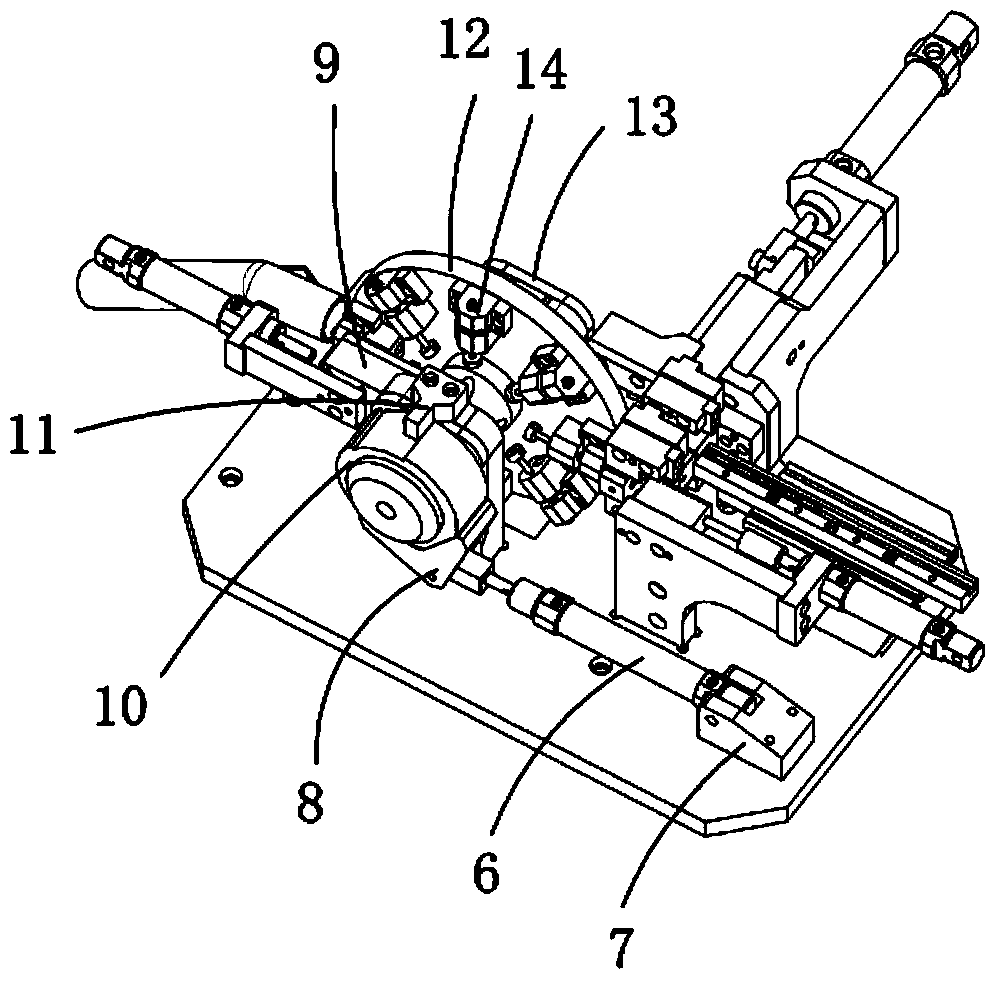

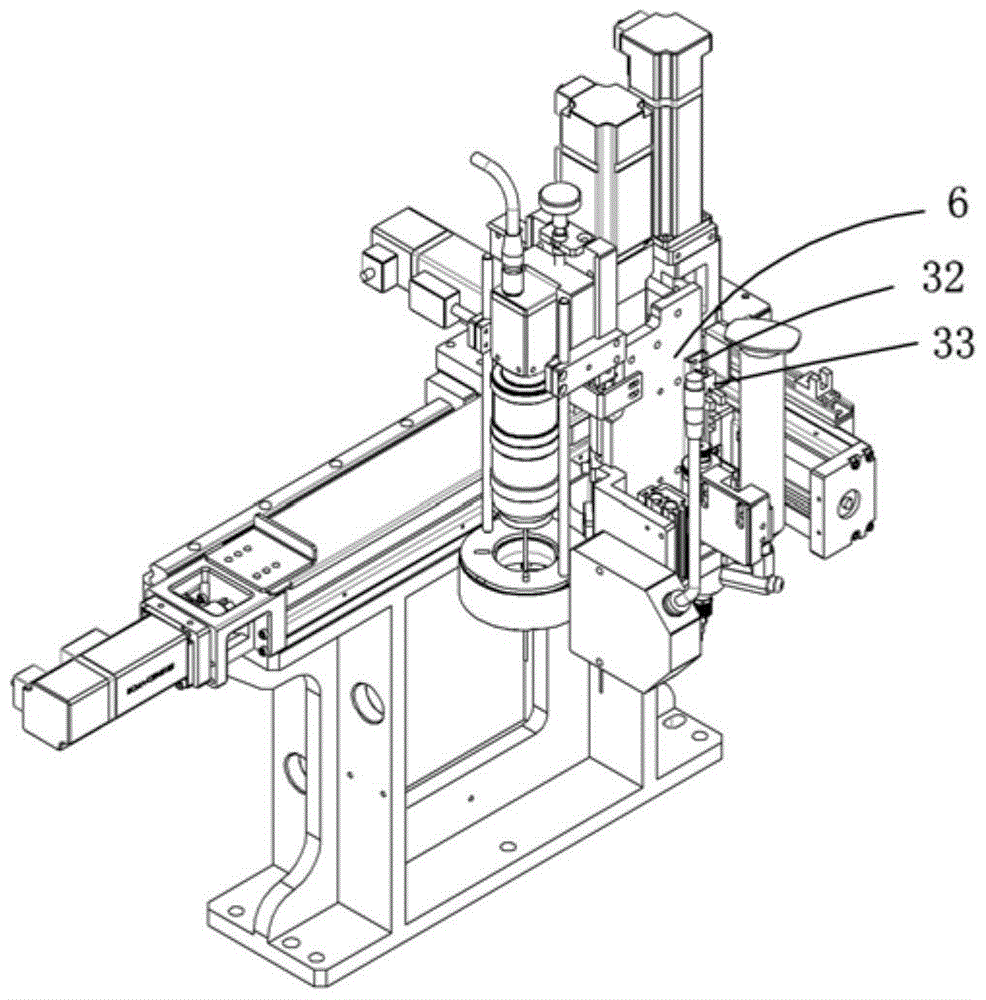

A dispensing and curing mechanism for assembling small parts of electronic products

ActiveCN104549892BEasy to replaceEasy to adjust up and down positionPretreated surfacesCoatingsEngineeringMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

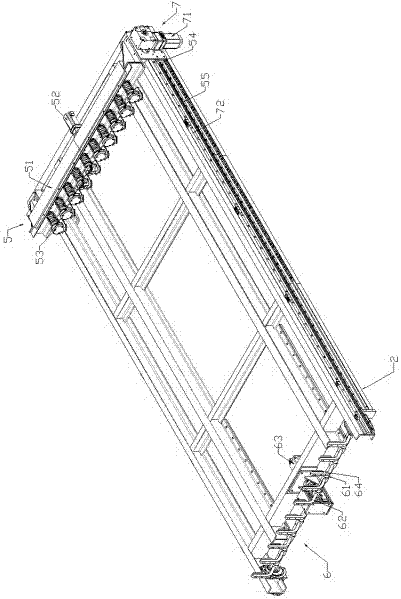

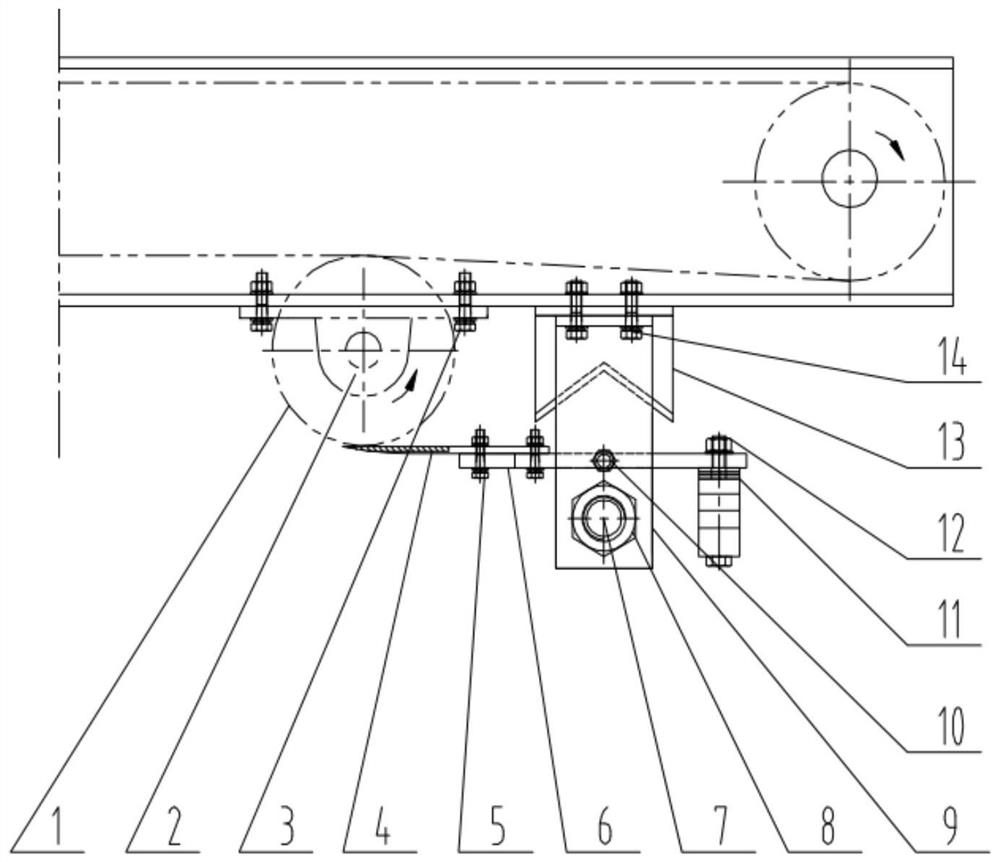

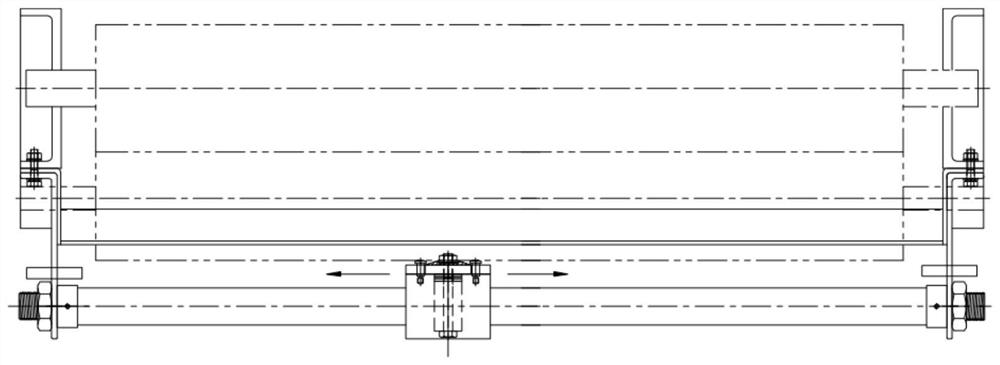

Carrier roller pneumatic rubber scraping device of belt conveyor

PendingCN114030847ARealize fully automatic workRealize reciprocating motionCleaningReciprocating motionEngineering

The invention relates to a carrier roller pneumatic rubber scraping device of a belt conveyor. The carrier roller pneumatic rubber scraping device comprises a carrier roller, a mounted bearing, a scraper, a scraper seat, a rodless cylinder, a cylinder support, a proximity switch, a balancing weight, a glue blocking plate and the like, wherein the carrier roller is fixed to a machine frame of the conveyor through the mounted bearing, the rodless cylinder is fixed to the machine frame of the conveyor through the cylinder support and the rubber blocking plate, the axis of the carrier roller is parallel to the axis of the rodless air cylinder, the middle of the scraper seat is fixed to a sliding block of the rodless cylinder, the scraper and the balancing weight are installed at the two ends of the scraper seat, the scraper makes contact with the outer circle of the carrier roller, the contact pressure can be adjusted by increasing or decreasing the balancing weight, when the belt conveyor runs, the scraper can continuously remove rubber covering the carrier roller along with axial reciprocating motion of a sliding block on the rodless cylinder, the rubber blocking plate with the inverted-V-shaped cross section is installed above the rodless cylinder, and normal work of the rodless cylinder can be guaranteed, so that heavy physical labor of workers is relieved, the operation cost is reduced, and the production efficiency is improved.

Owner:青岛众屹科锐工程技术有限公司

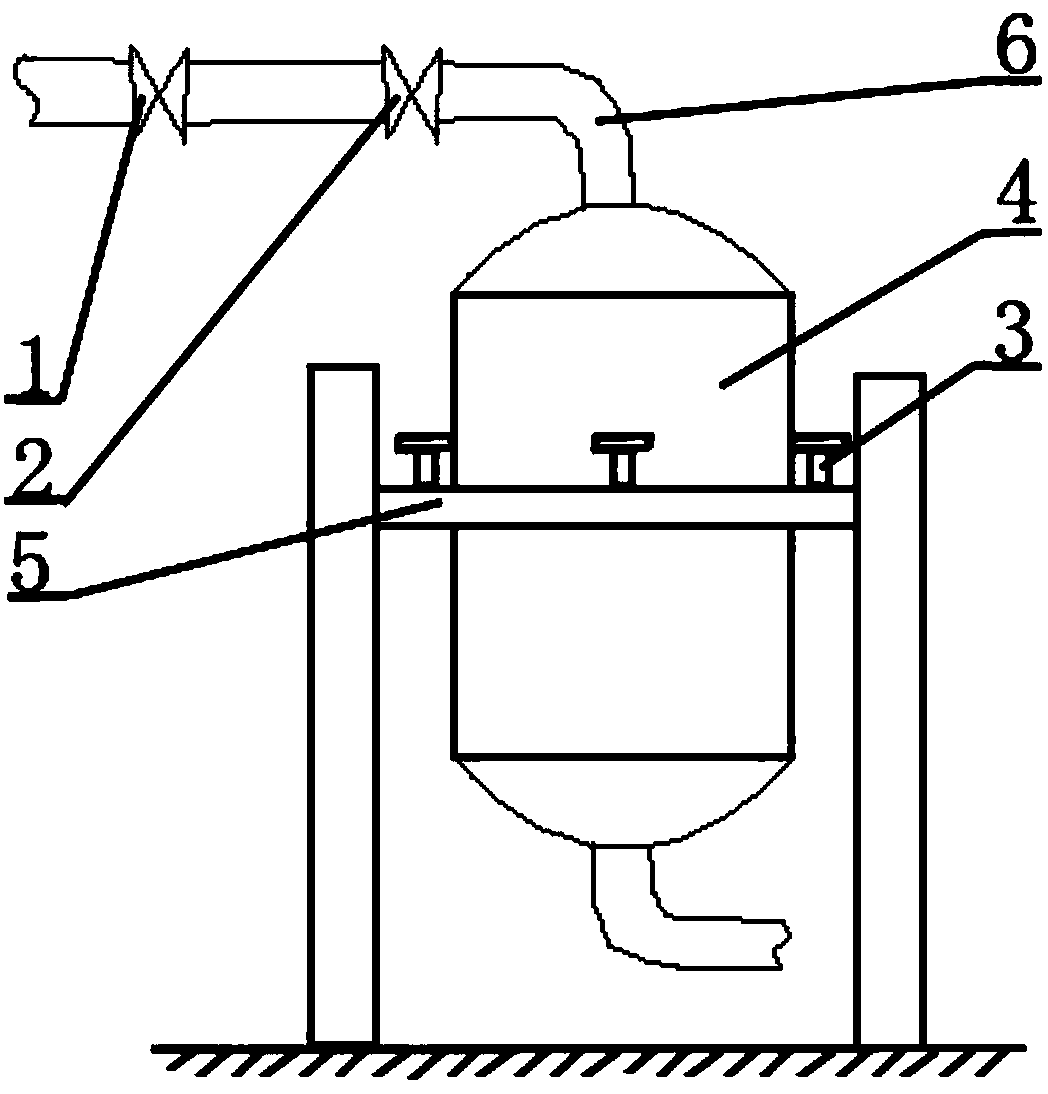

Phenylhydrazine measuring tank automatic control feeding device

InactiveCN108069384ARealize fully automatic workNo manualLiquid transferring devicesWeighing apparatus for materials with special property/formAutomatic controlEngineering

The invention discloses a phenylhydrazine measuring tank automatic control feeding device which comprises a feeding control valve, a cut-off valve, pressure sensors and a phenylhydrazine measuring tank. The device is characterized in that the phenylhydrazine measuring tank is installed on a support, the pressure sensors are installed on the periphery of the phenylhydrazine measuring tank in four directions, the lower ends of the pressure sensors are installed on the support, the cut-off valve is installed on a feeding pipe at the upper end of the phenylhydrazine measuring tank, and the feedingcontrol valve is installed on a pipeline at the outer end of the cut-off valve. The phenylhydrazine measuring tank automatic control feeding device is controlled by a program control box to operate.The device has the advantages that the pressure sensors are designed so as to automatically weigh the phenylhydrazine measuring tank at any time, the feeding amount of the feeding control valve and on-off of the cut-off valve are automatically controlled through the program control box, full-automatic work is achieved, manual work is not needed, operation is safe and reliable, and production efficiency is greatly improved.

Owner:RUGAO OUTONG MACHINERY FITTINGS

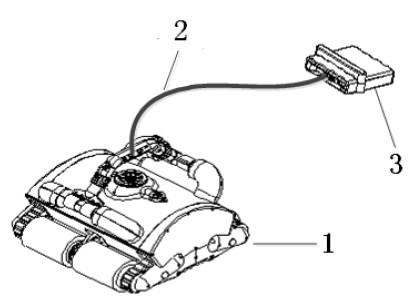

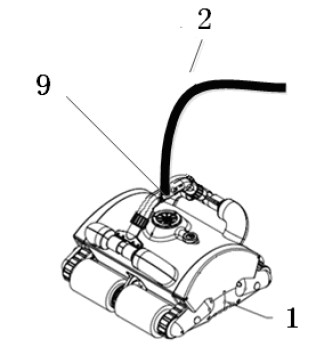

Method for preventing and detecting winding of buoyant cable

ActiveCN102691427ASave the trouble of repeatedly charging and discharging manuallyAvoid tanglesGymnasiumConverting sensor output electrically/magneticallyEngineeringMotor controller

The invention discloses a method for preventing and detecting the winding of a buoyant cable, comprising the following steps of: 1) a step of preventing the buoyant cable from being wound and knotted and 2) a step of detecting the winding and the knotting of the buoyant cable, wherein the step of preventing the buoyant cable from being wound and knotted comprises the following steps that when an automatic washing robot sends a forward or backward signal to a motor controller of a cable drum device arranged on the automatic washing robot, the cable drum device arranged on the automatic washing robot receives a corresponding signal and then controls a direct-current motor of the cable drum device to rotate, so as to keep the same unreeling / reeling of the buoyant cable as the automatic washing robot. According to the method disclosed by the invention, a bank-side power supply box supplies power and the working time and a power supply capacity of the automatic washing robot are not limited, so that a trouble of repeatedly and manually charging and discharging a buoyant power supply for a plurality of times is saved, and the buoyant cable is prevented from being wound and knotted and the winding and the knotting of the buoyant cable are detected.

Owner:HANGZHOU GAOYUE TECH

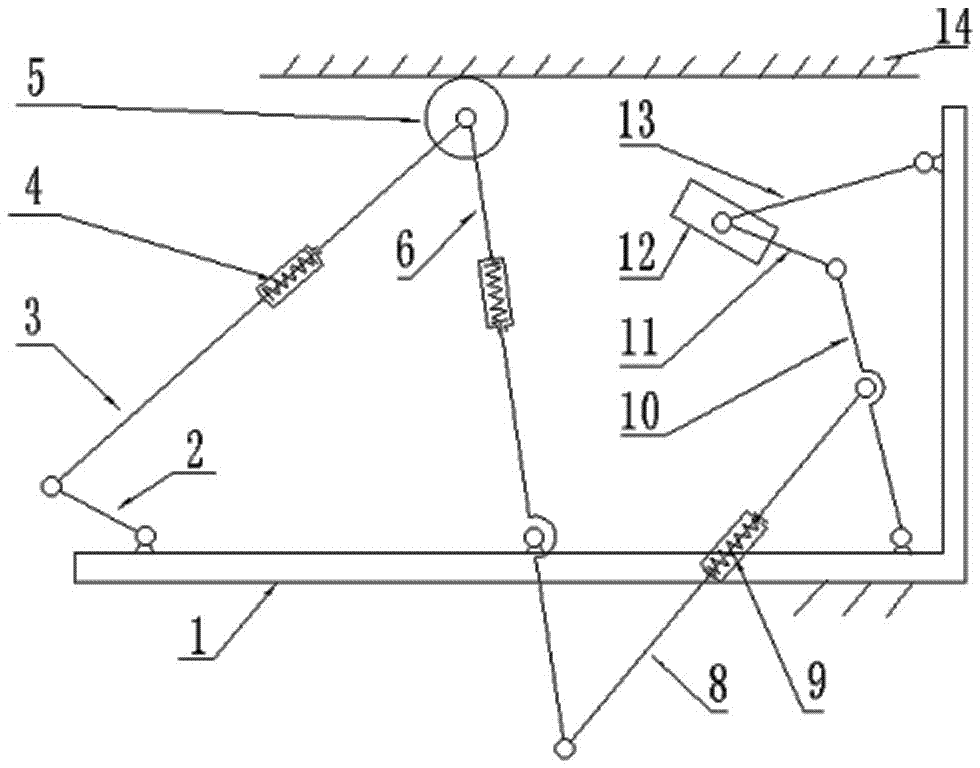

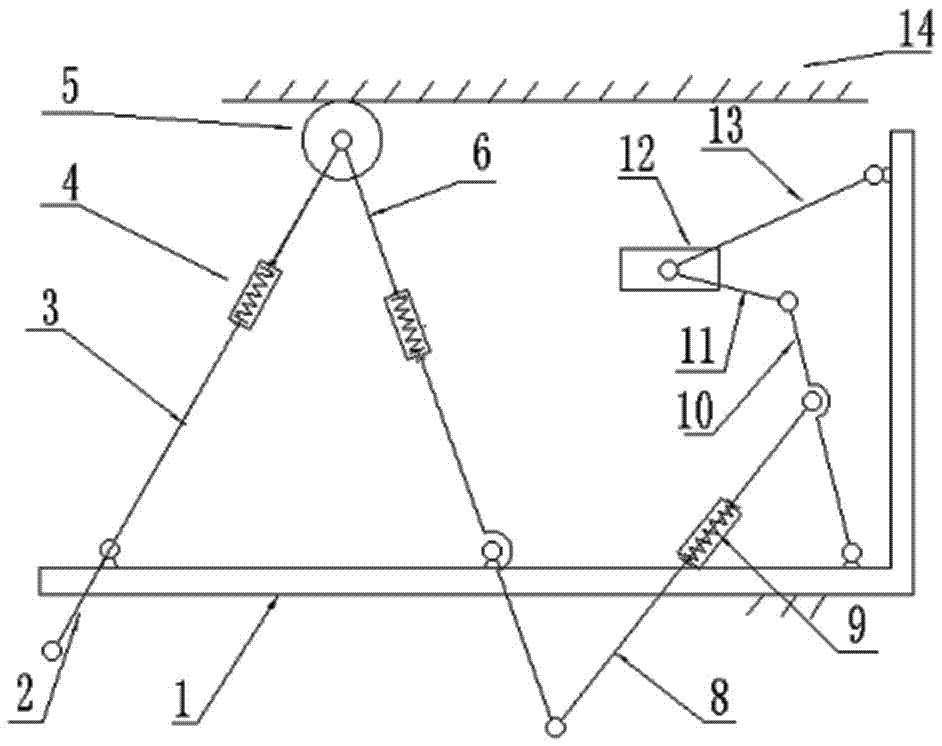

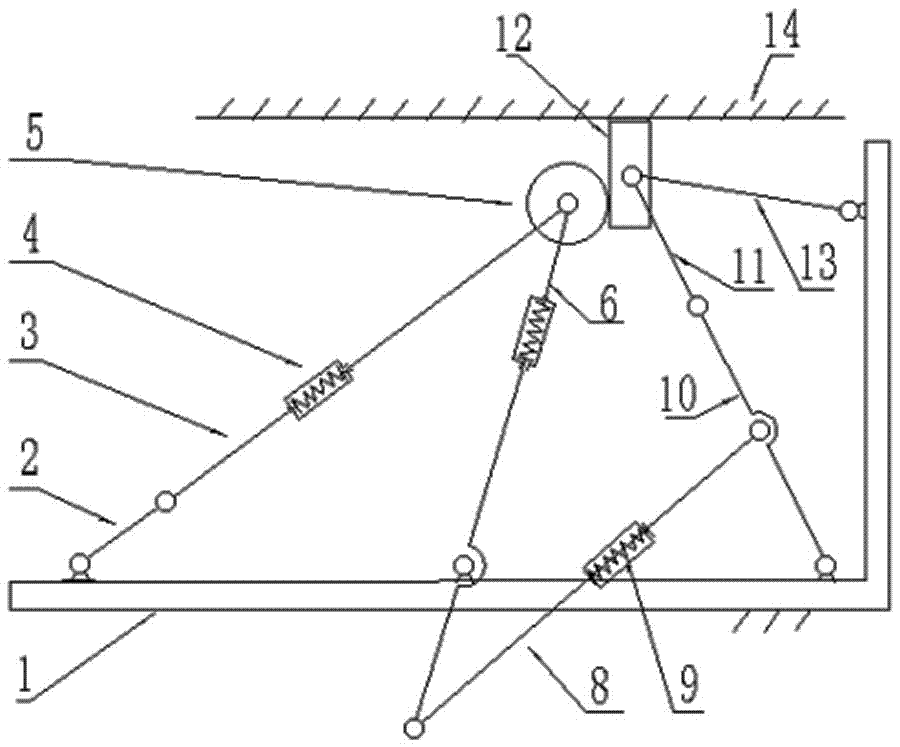

A wall painting machine based on a single-degree-of-freedom seven-bar mechanism

InactiveCN105569323BWith local degrees of freedomAbsorb evenlyBuilding constructionsSingle degree of freedomElastic compression

The invention relates to a wall painting machine based on a single-degree-of-freedom seven-rod mechanism. The wall painting machine comprises a motor, a rack, a rolling brush, an absorption cotton pad, two elastic compression parts, an elastic extension part and seven rods, wherein the motor is arranged on the rack; the seven rods comprise a first rod, a second rod, a third rod, a fourth rod, a fifth rod, a sixth rod and a seventh rod, and the third rod and the fifth rod are levers. The wall painting machine can paint higher planes such as roofs and the like and can realize automatic feeding during painting to finish painting. The single-degree-of-freedom seven-rod mechanism is adopted, the mechanical structure is simplified, the cost is saved, and the cycle operation of painting and feeding can be realized under the drive of one motor. Besides, during work, through painting with the slow working stroke and the quick working return stroke, painting is more careful, paint is more uniform, working time is saved, and the working efficiency is improved.

Owner:HEFEI UNIV OF TECH

Full-automatic sewage treatment and purification device

InactiveCN106946386AImprove versatilityLow costTreatment involving filtrationMultistage water/sewage treatmentWater qualityTransmitter

The invention discloses a fully automatic sewage treatment and purification device, which comprises a device body, a purification tank body, a water quality detection device and a built-in circuit. The device body is provided with a conveying pipeline, and the purification tank body is provided with a pool bottom absorber. , descaling layer, the interior of the purification pool body is provided with a water quality detection device, the interior of the water quality detection device is provided with a built-in circuit, a water inlet hole, and a water outlet hole, the built-in circuit is provided with a power module, and one end of the power module Equipped with a microprocessor, a main control circuit, a storage module, a wireless signal transmission module, a metal component analysis module, a biological detection module, a drive signal transmission module, a data analysis module, and a valve control module, the present invention is suitable for purifying domestic sewage and industrial production For sewage, the purification process and the detection process of purified water quality are fully automated.

Owner:湖州梦源环保科技有限公司

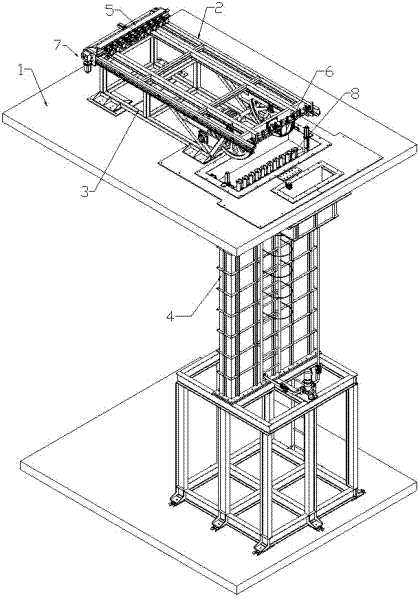

A fully automatic parts assembly machine

ActiveCN104551660BPrevent camera alignment and other workQuick and accurate assemblyAssembly machinesWorkstationFully automatic

The invention relates to a full-automatic part assembly machine. A rotary plate mechanism is mounted at the center of the bottom plate, a first part assembly workstation and a second part assembly workstation are identical in structure and mounted on the left rear portion and the right rear portion of the bottom plate respectively, and a detecting workstation is mounted on the front portion of the right side of the bottom plate. An operator places a workpiece on a carrier, a rotary motor rotates the carrier on a rotary plate to the first part assembly workstation, and a small part a is assembled onto the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the second part assembly workstation, and a small part b is assembled on the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the detecting workstation, a CCD on the detecting workstation takes pictures and detects whether the assembled workpiece is qualified or not; after detection, the rotary motor rotates the rotary plate to the initial position. The full-automatic part assembly machine is simple to operate, the small parts can be quickly and accurately assembled to the workpiece, labor is saved, production efficiency is improved, and production cost of enterprises is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

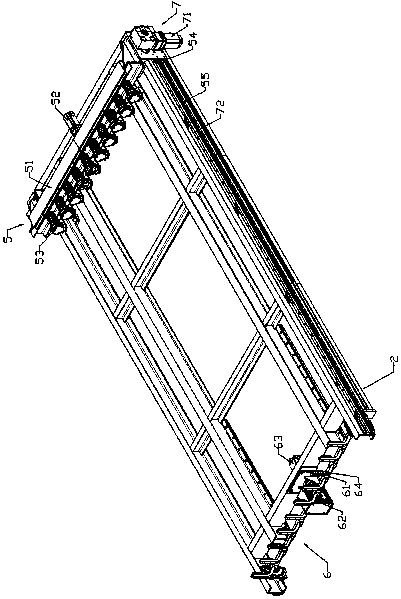

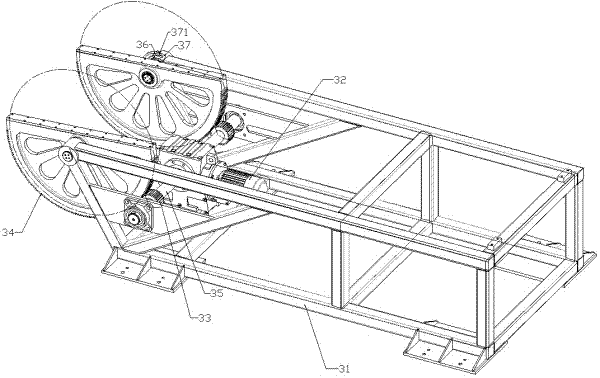

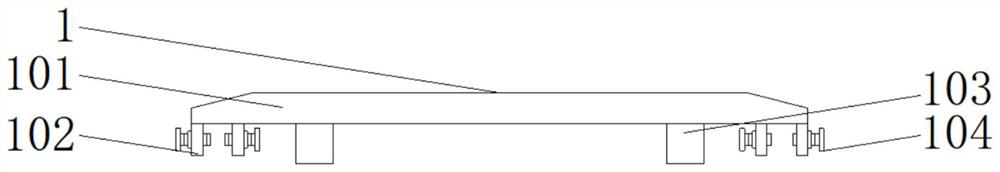

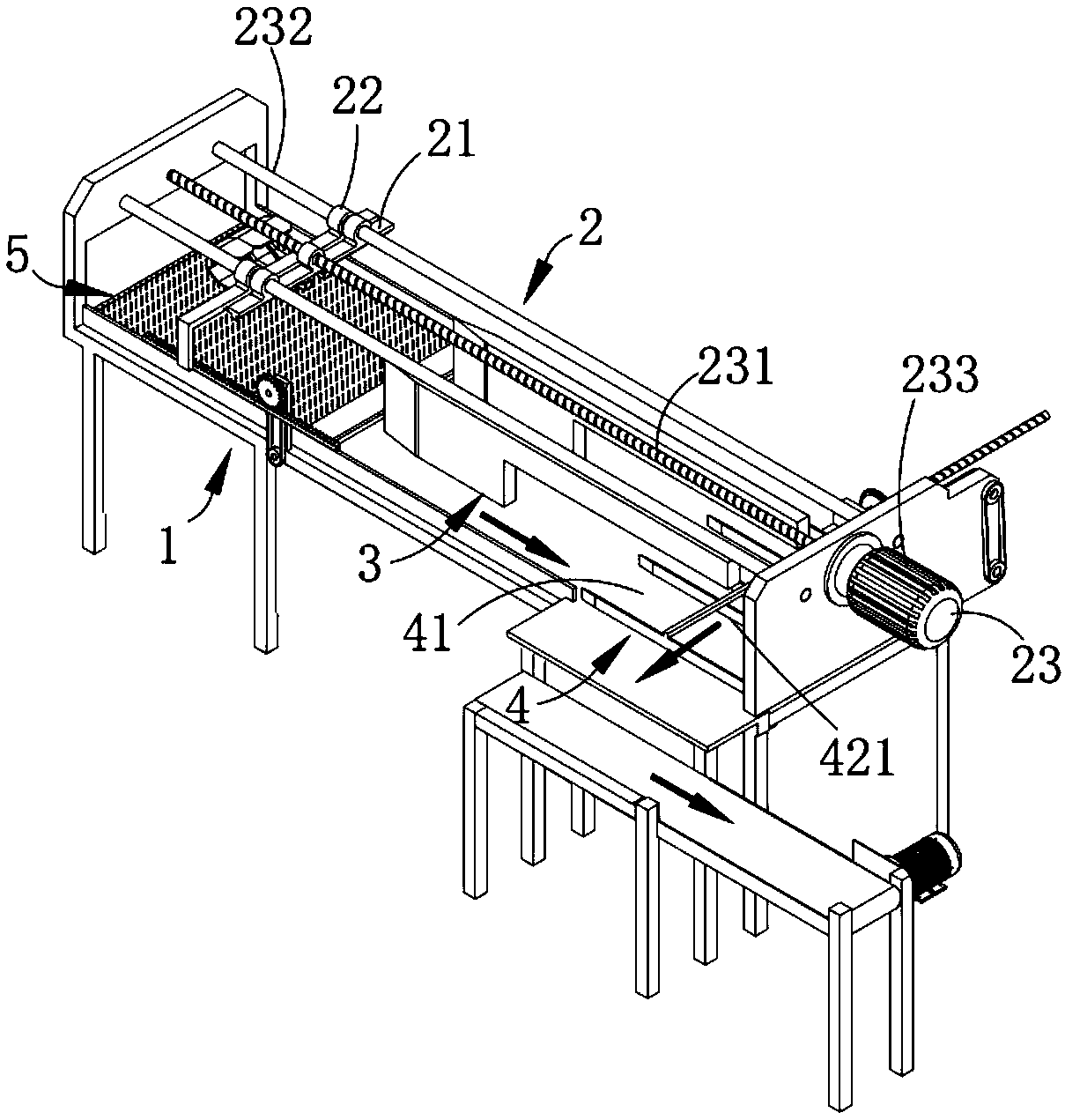

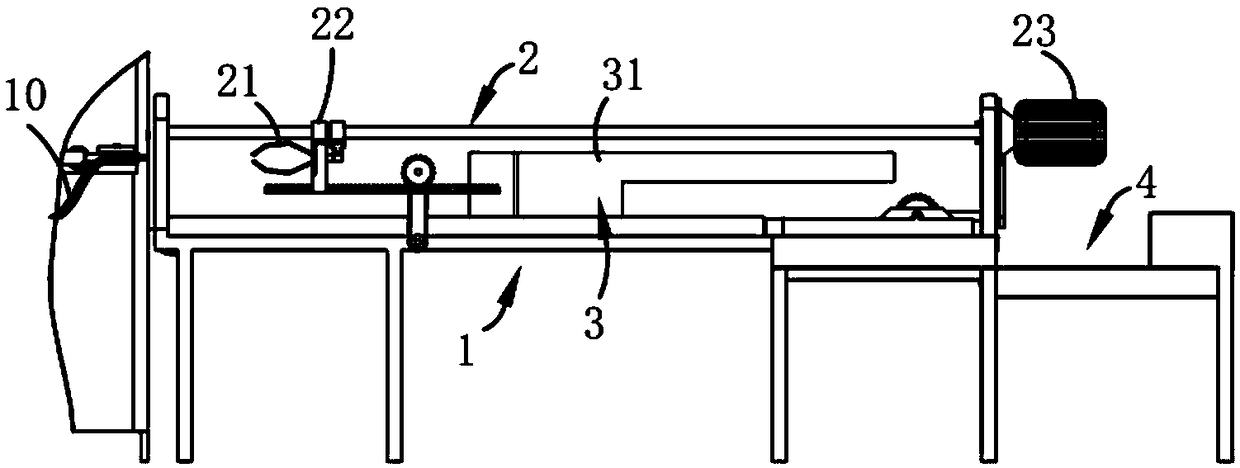

Automatic beam splitting equipment for linen yarn production

InactiveCN109023542ARealize fully automatic workSolve the technical problems of low production efficiency in manual operationHackling machinesYarnFiber bundle

The invention relates to the technical field of linen yarn production, in particular to automatic beam splitting equipment for linen yarn production. The equipment comprises a rack, a traction mechanism, a beam splitting mechanism and an output mechanism, wherein the traction mechanism comprises clamping assemblies, a fastening assembly and a driving assembly, and continuous fibers carded by a heckling machine are transferred through the clamping mechanisms; two adjacent clamping mechanisms are separated through the beam splitting mechanism to form fiber bundles; the output mechanism is arranged at the rear section of the beam splitting mechanism, and driven by the driving assembly to output the fiber bundles formed after beam splitting; automatic beam splitting and automatic output are performed on the long fibers through the traction mechanism when the long fibers are indirectly transferred, and the arrangement of a special mechanism of a carding mechanism is combined, so that automatic removing and output are performed on short fibers before beam splitting is performed on the long fibers, the automatic production of beam splitting the long fibers is achieved, and the technical problem of low production efficiency of manual operation in the prior art is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

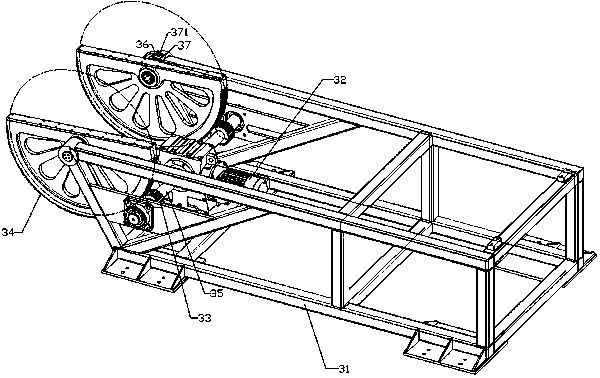

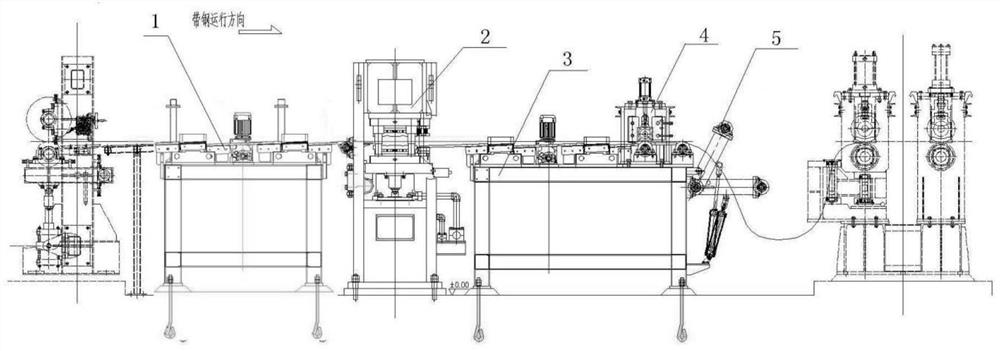

Fully automatic five-in-one lithium battery forming machine

InactiveCN103123982BIncrease productivityImprove finishing accuracyFinal product manufactureElectrolyte accumulators manufactureProcess equipmentControl system

The invention provides a fully automatic five-in-one lithium battery forming machine, which belongs to the field of lithium battery manufacturing equipment. The present invention includes a workbench, the workbench includes a material feeding mechanism, the material feeding mechanism is connected to a material transfer mechanism, and above the material transfer mechanism are respectively equipped with a fine packaging mechanism, a testing mechanism, a defective product rejecting mechanism, Single edge trimming mechanism, the end of the material conveying mechanism is also connected with an edge folding and ironing mechanism, the workbench is also equipped with a frame composed of several columns, and the equipment frame is also connected with a control system. It has a compact structure, beautiful appearance, and each process is arranged in a straight line, which is convenient for docking with front and rear process equipment, and improves the production efficiency of the product.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

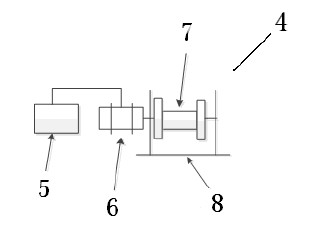

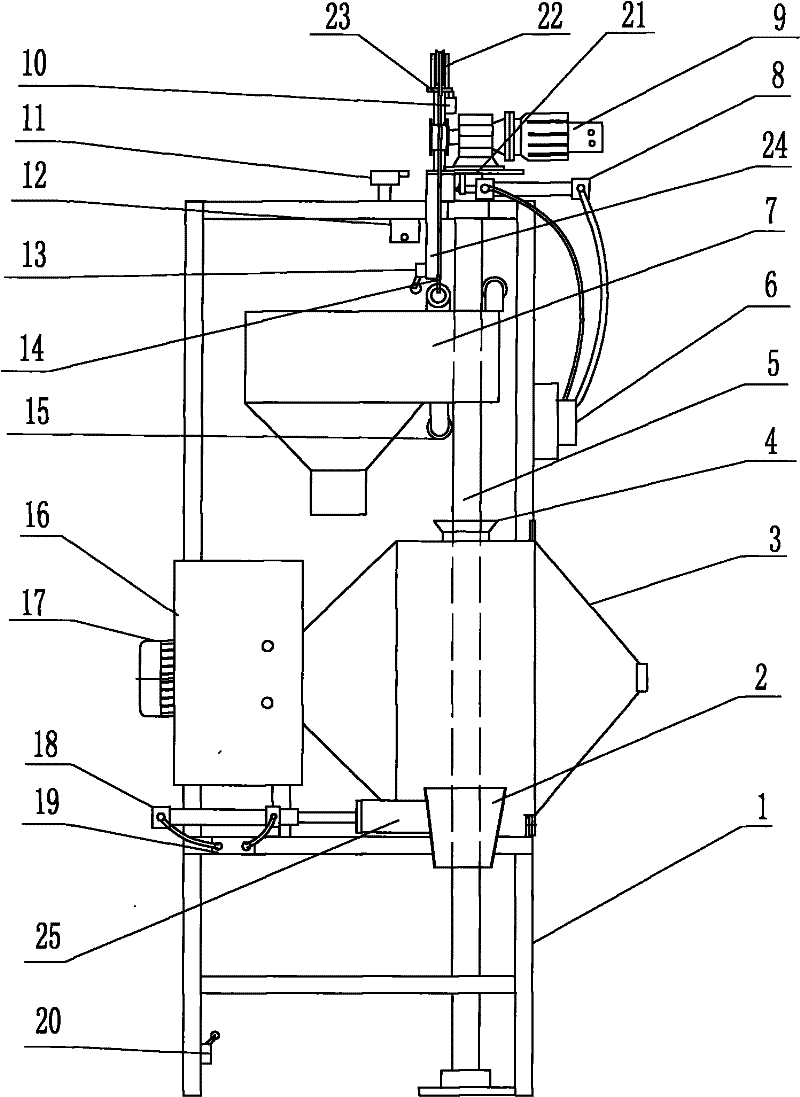

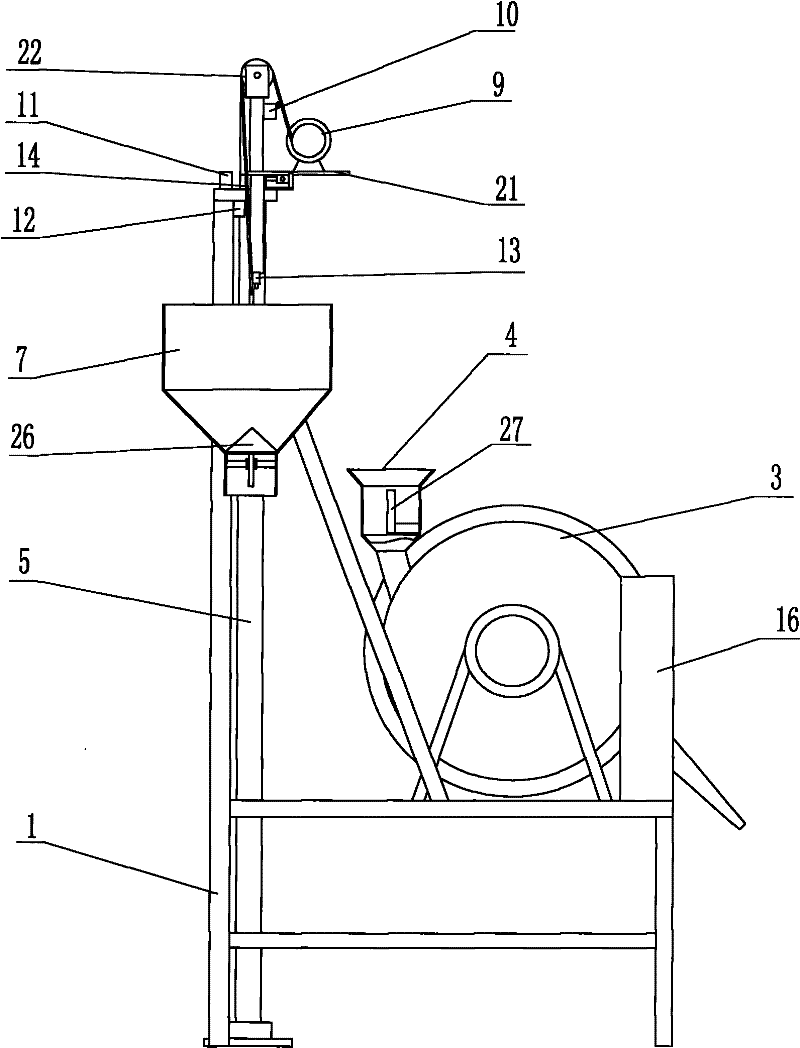

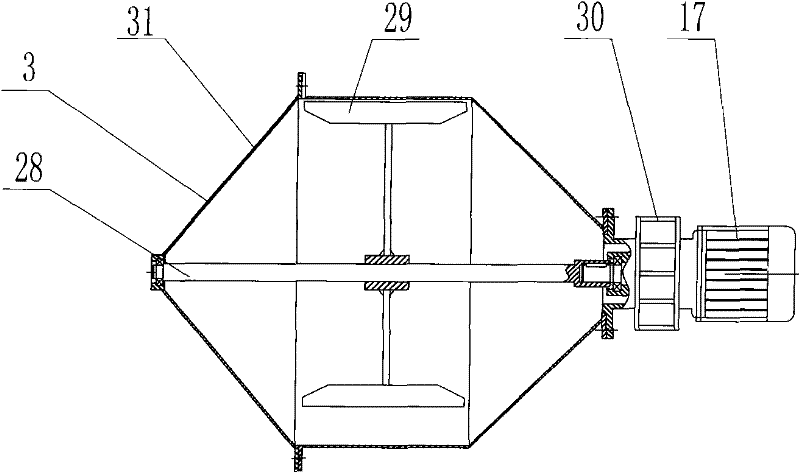

Automatic Plastic Mixer

A full-automatic plastic mixer, which adopts a fixed mixing device, an electric control cabinet, a pneumatic solenoid valve I and a cylinder I on the lower platform of the frame, the pneumatic solenoid valve I is connected to the cylinder I through the air pipe, and the pneumatic solenoid valve is installed on the right vertical beam of the frame. Valve II, pneumatic solenoid valve II is connected to cylinder II through the air pipe, cylinder II, left stroke switch and right stroke switch are installed on the upper beam, floor stroke switch is installed on the left lower part of the frame; the lower end of the rotating slide rod is fixed on the foundation through the bearing seat, The upper part is connected to the upper beam of the frame through the bearing seat. Two rollers are installed on the feeding hopper to connect with the rotating slide bar. The feeding hopper is connected to the hoist through the wire rope around the pulley. Fixed on the support plate, the support plate is fixed on the top of the rotating slide bar, the winch travel switch is installed on the pulley frame, and the upper travel switch is installed at the lower part of the limit plate, which overcomes the defect of uneven mixing of various mixers. It is suitable for mixing plastics and other materials with various formulations.

Owner:HUNAN ZHENHUI PIPE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com