Phenylhydrazine measuring tank automatic control feeding device

A technology of feeding device and metering tank, which is applied in the direction of measuring device, distribution device, special distribution device, etc., can solve the problems of lower production efficiency, excessive feeding, operation errors, etc., and achieve the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

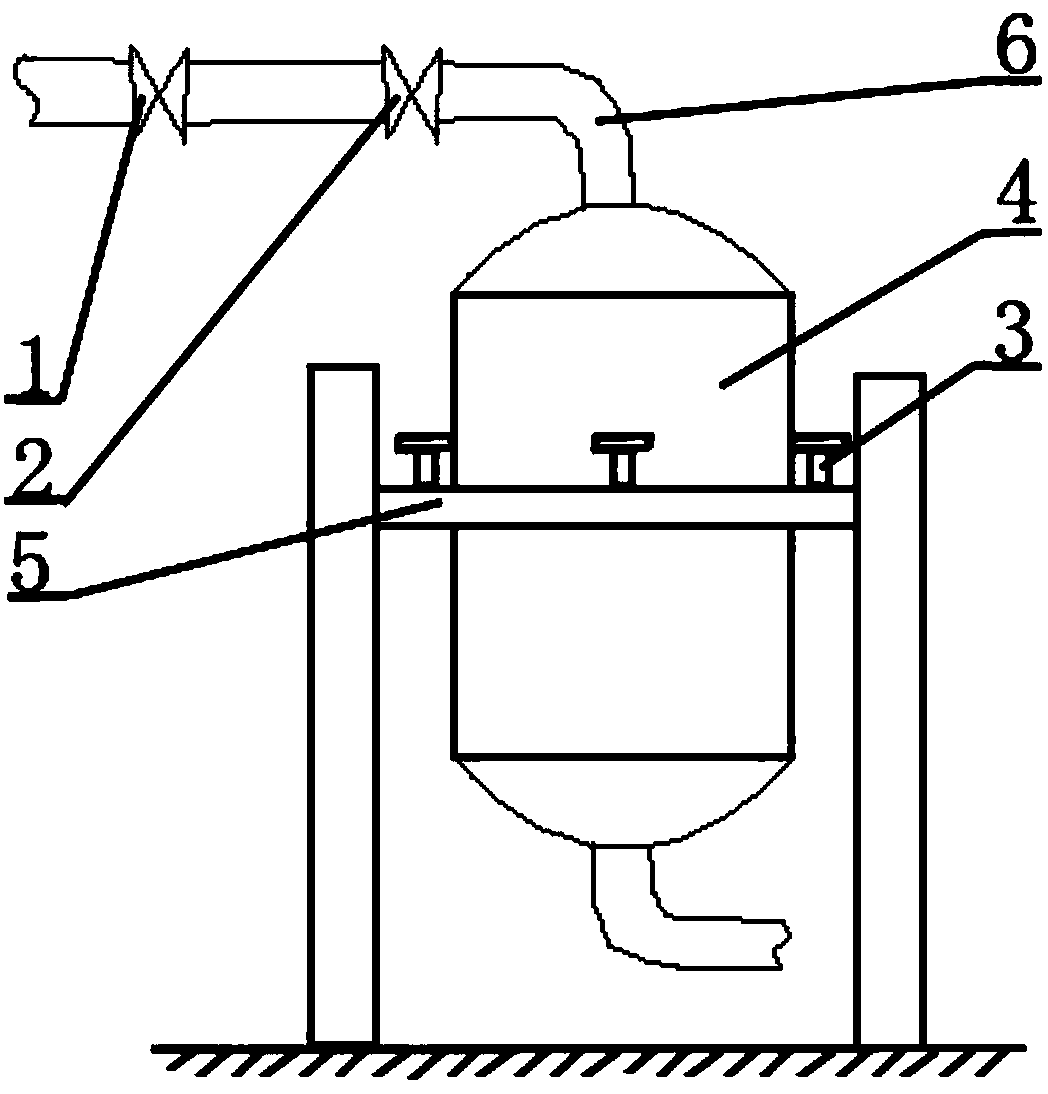

[0011] Example: see attached figure 1 , the phenylhydrazine metering tank automatically controls the feeding device, which includes a feeding control valve 1, a shut-off valve 2, a pressure sensor 3 and a phenylhydrazine metering tank 4. The phenylhydrazine metering tank 4 is installed in the middle of the bracket 5, and the phenylhydrazine metering tank 4 There are pressure sensors 3 installed in four directions around, the lower end of the pressure sensor 3 is installed on the bracket 5, the cut-off valve 2 is installed on the feeding pipe 6 at the upper end of the phenylhydrazine metering tank 4, and the feeding control valve 1 is installed on the outer pipe of the cut-off valve 2. On the road; the automatic control feeding device of the phenylhydrazine metering tank is controlled and operated through a program control box.

[0012] The pressure sensor 3 is installed between the phenylhydrazine metering tank 4 and the bracket 5 , and the phenylhydrazine metering tank 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com