Patents

Literature

44results about How to "Improve finishing accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

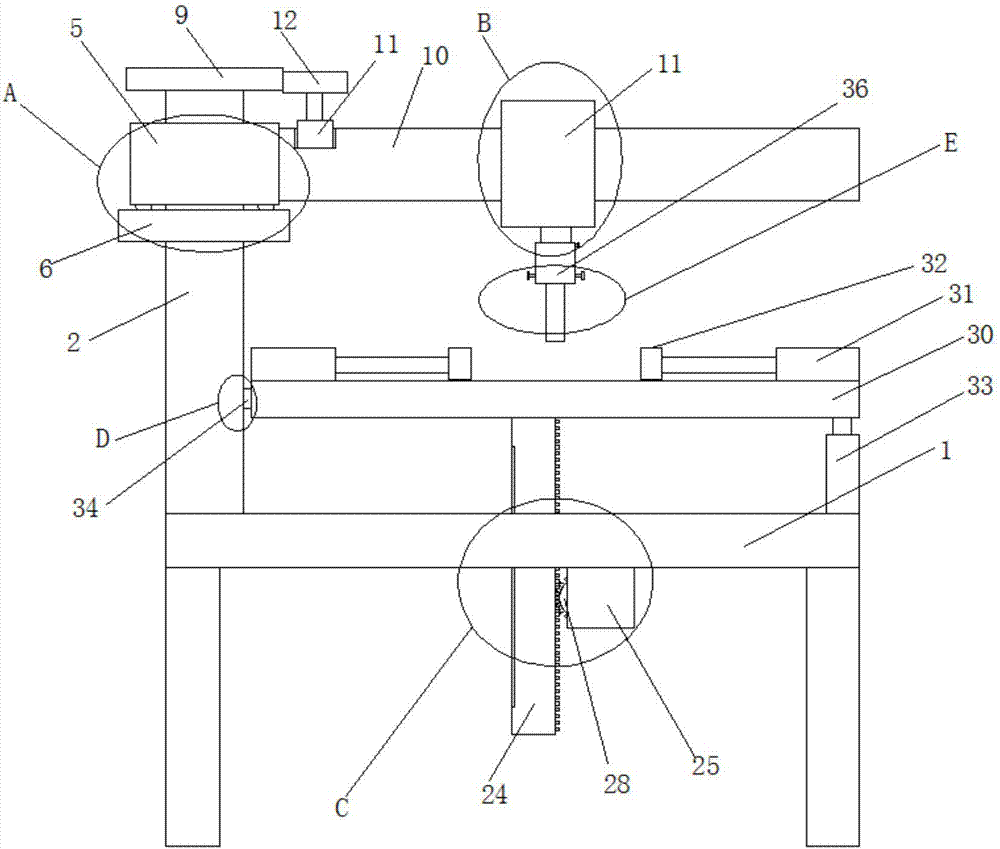

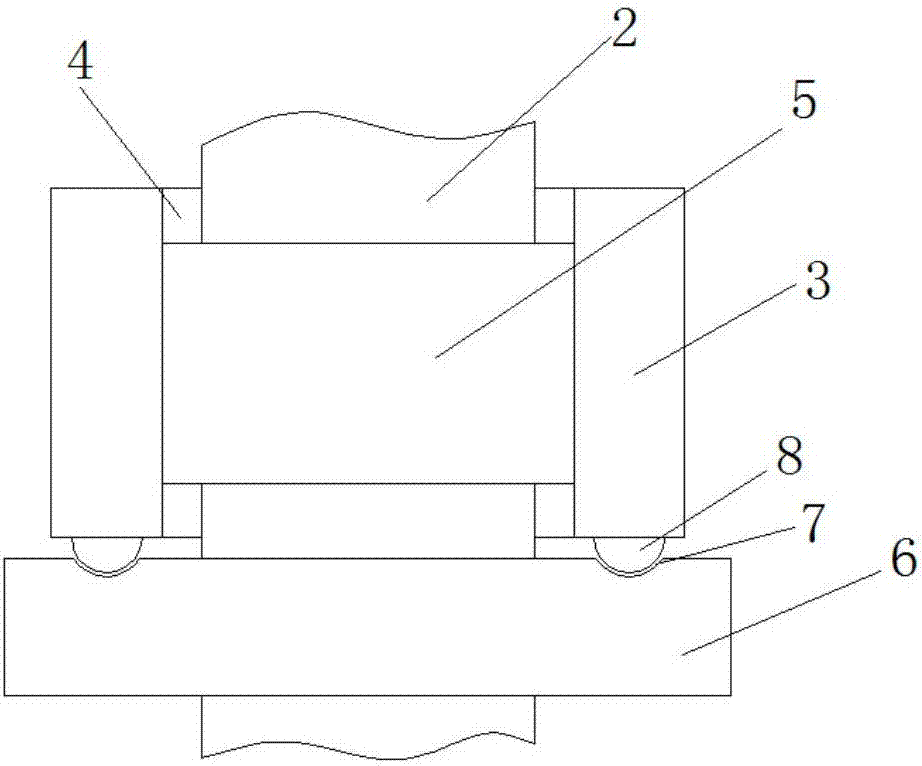

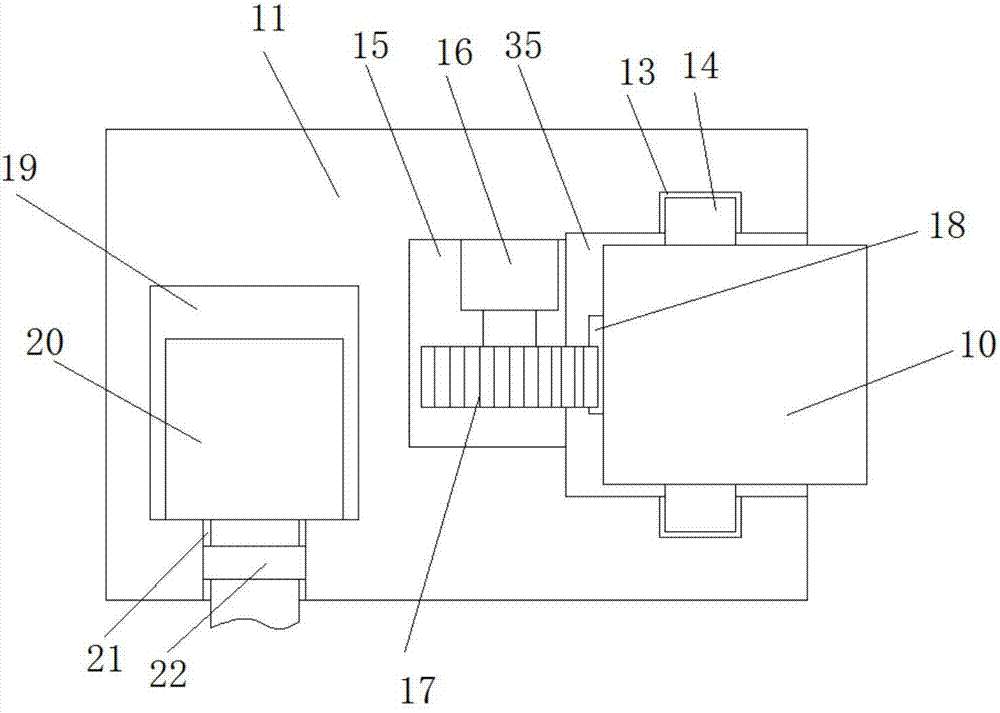

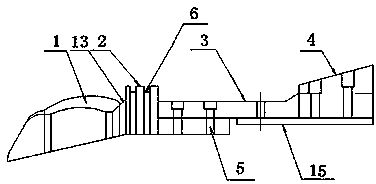

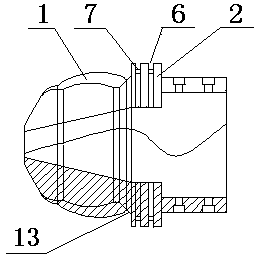

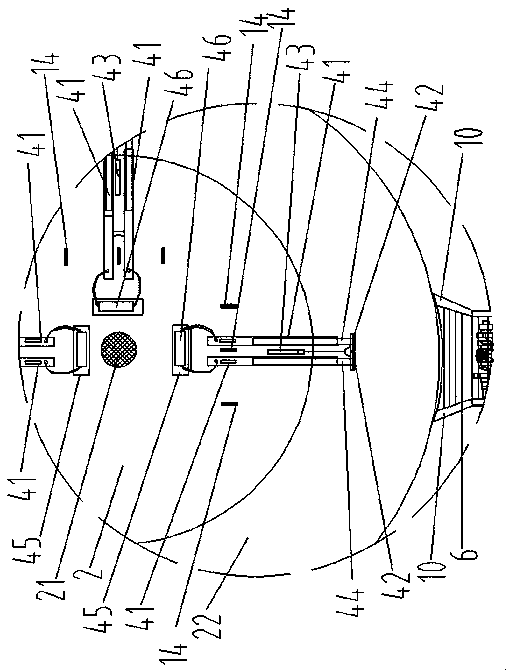

Radial drilling machine convenient to adjust

ActiveCN107378028AFast and smooth horizontal movementQuick changeFeeding apparatusLarge fixed membersEngineeringMachining

The invention discloses a radial drilling machine convenient to adjust. The radial drilling machine convenient to adjust comprises a base, a rotary device, a horizontal moving device, a drilling head fixing device, a lifting device and a working table. The rotary device is fixedly arranged at the top part of the base; the horizontal moving device is fixedly connected onto the rotary device; the rotary device drives the horizontal moving device to rotate; the drilling head fixing device is fixed onto the horizontal moving device; the horizontal moving device drives the drilling head fixing device to move in a horizontal direction; the lifting device is arranged on the base and controls the working table to move up and down; and the rotary device provides a support for moving the working table up and down. According to the radial drilling machine convenient to adjust provided by the invention, a drilling head in the radial drilling machine can be quickly and stably moved horizontally and rotated, and the height of the working table can be quickly adjusted, so that the radial drilling machine not only is convenient for operating personnel to use, but also can be beneficial for improving the finish machining accuracy.

Owner:广州市鹏骏机床有限公司

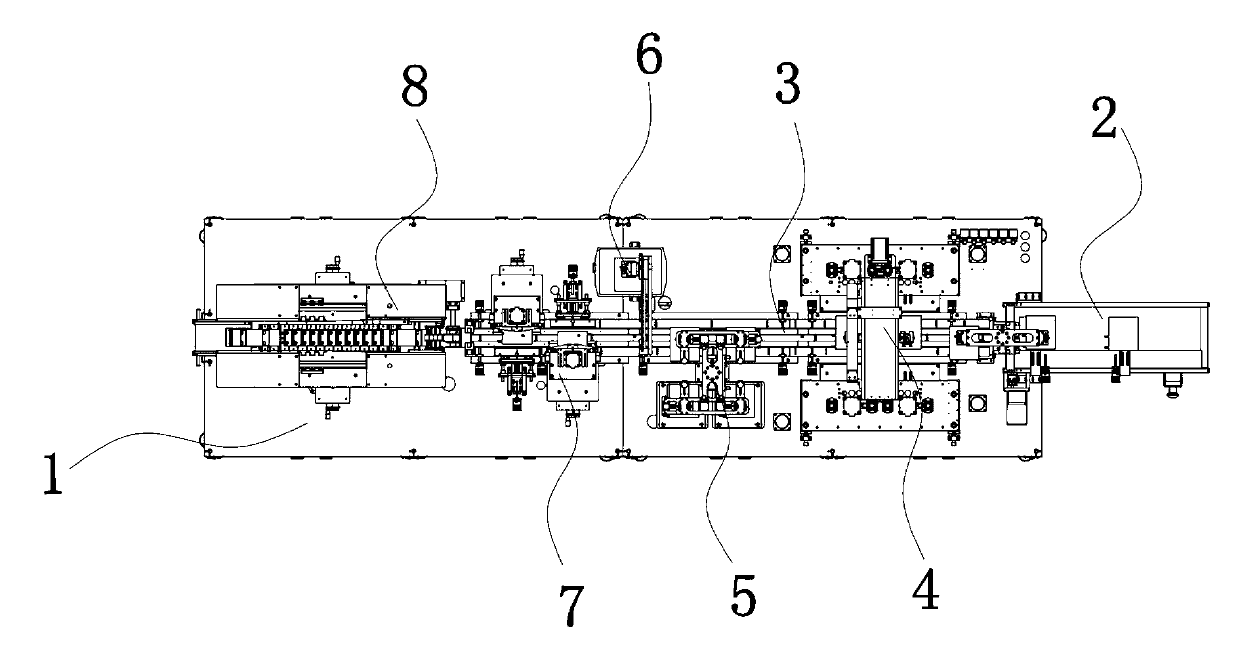

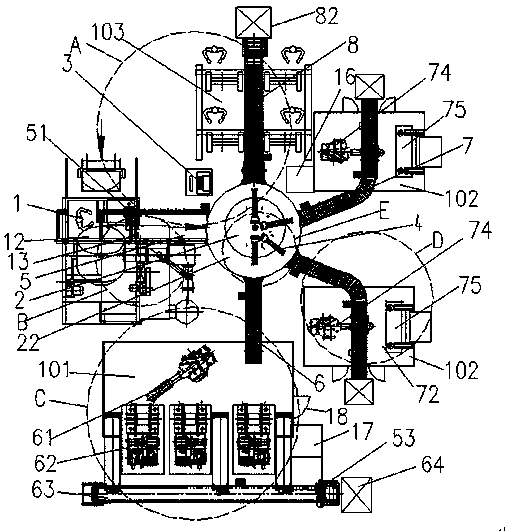

Automatic five-in-one lithium battery forming machine

InactiveCN103123982AIncrease productivityImprove finishing accuracyFinal product manufactureElectrolyte accumulators manufactureControl systemButt joint

The invention provides an automatic five-in-one lithium battery forming machine which belongs to the field of lithium battery manufacturing equipment. The automatic five-in-one lithium battery forming machine comprises a worktable, wherein the worktable comprises a feeding mechanism, the feeding mechanism is connected with a material delivering mechanism, a fine sealing mechanism, a test mechanism, an unqualified product removal mechanism and a single trimming mechanism are respectively arranged above the material delivering mechanism, the tail end of the material delivering mechanism is also connected with a flanging ironing mechanism, the worktable is also provided with a framework consisting of a plurality of stand columns, and the framework is also connected with a control system. The automatic five-in-one lithium battery forming machine is has the advantages that the structure is compact, the appearance is attractive, a previous procedure and devices of a subsequent procedure can be conveniently in butt joint by linearly arranging all procedures, and the production efficiency of products can be improved.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

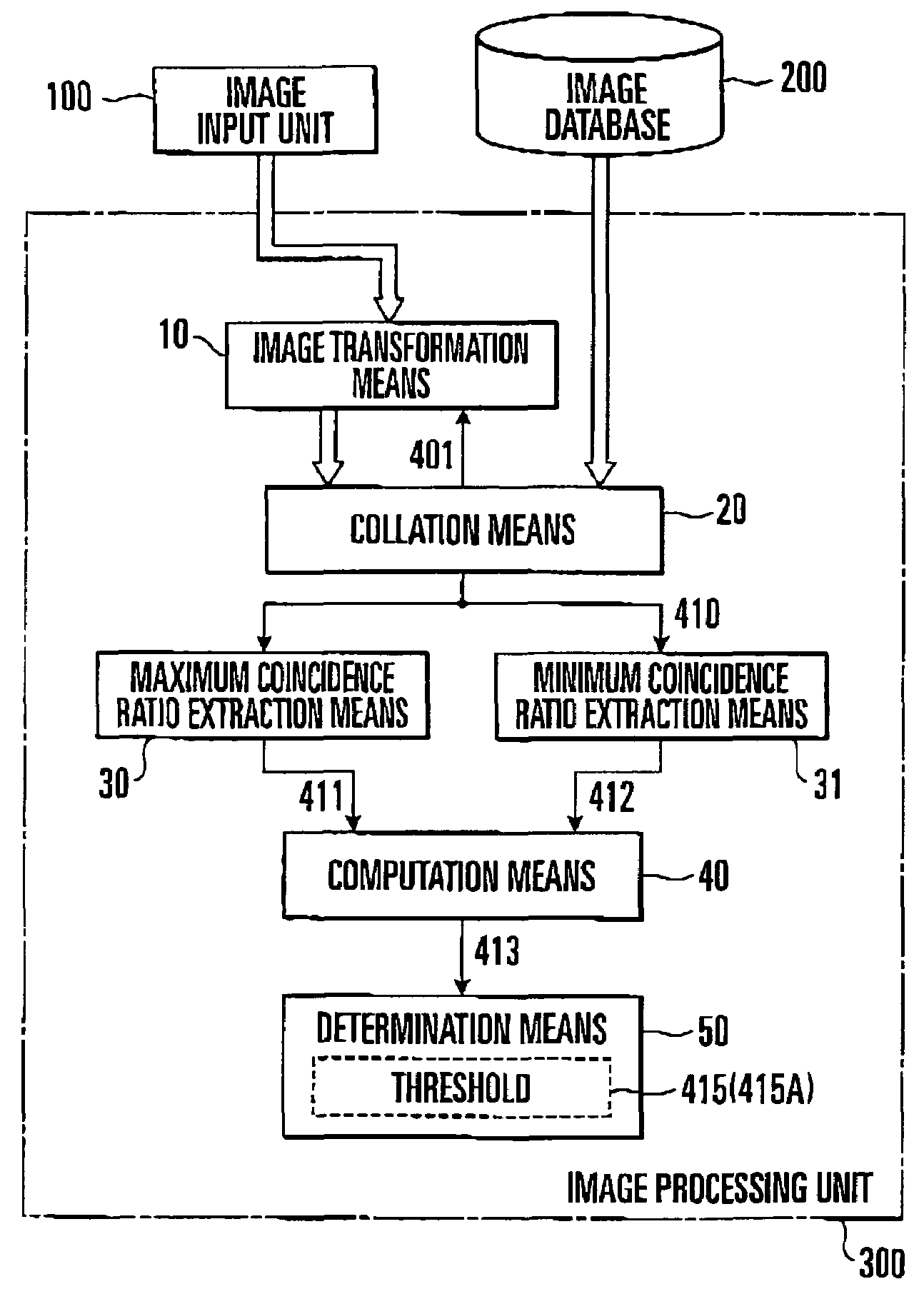

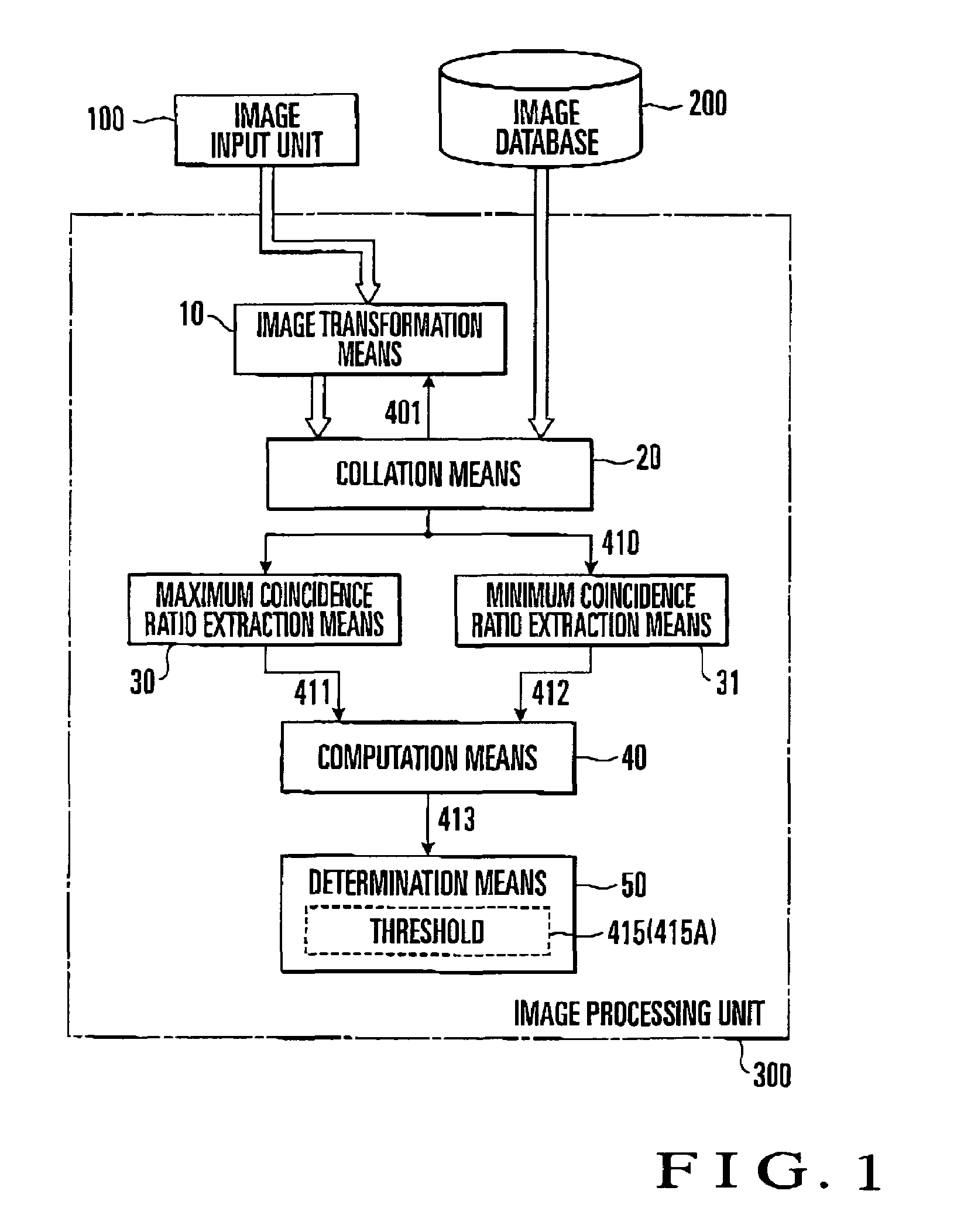

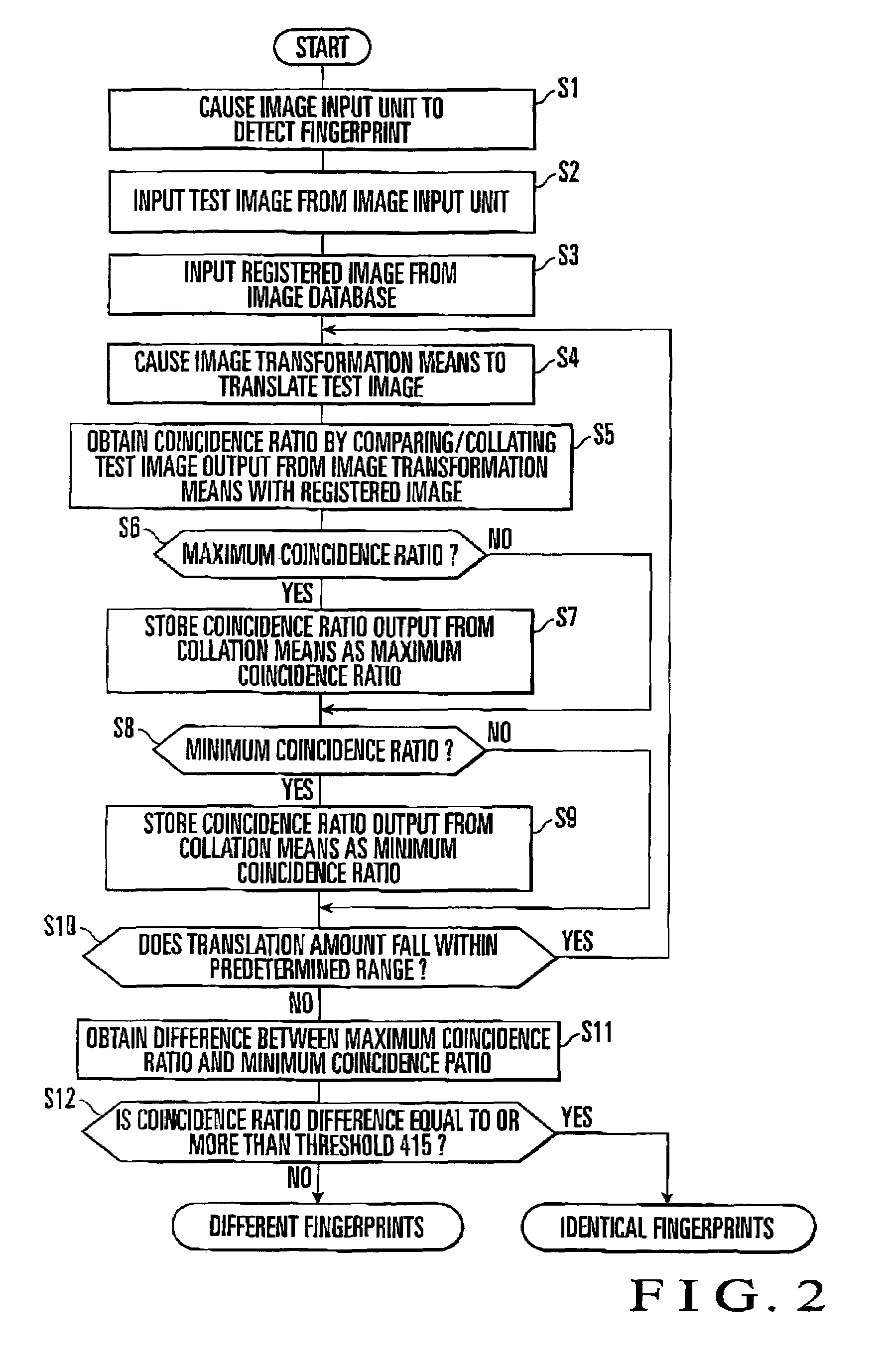

Image collation method and apparatus and recording medium storing image collation program

InactiveUS7031501B2Improve finishing accuracyHigh precisionImage analysisPerson identificationCollationComputer science

An image collation apparatus includes a collation unit, minimum coincidence ratio extraction unit, and determination unit. The collation unit obtains a coincidence ratio between first and second images within a printing element range for each collation unit by collating the first and second images with each other. The minimum coincidence ratio extraction unit obtains a minimum coincidence ratio from coincidence ratios obtained from the collation unit. The determination unit determines that the first and second images are identical, if the extracted minimum coincidence ratio is smaller than a predetermined threshold. An image collation method is also disclosed.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

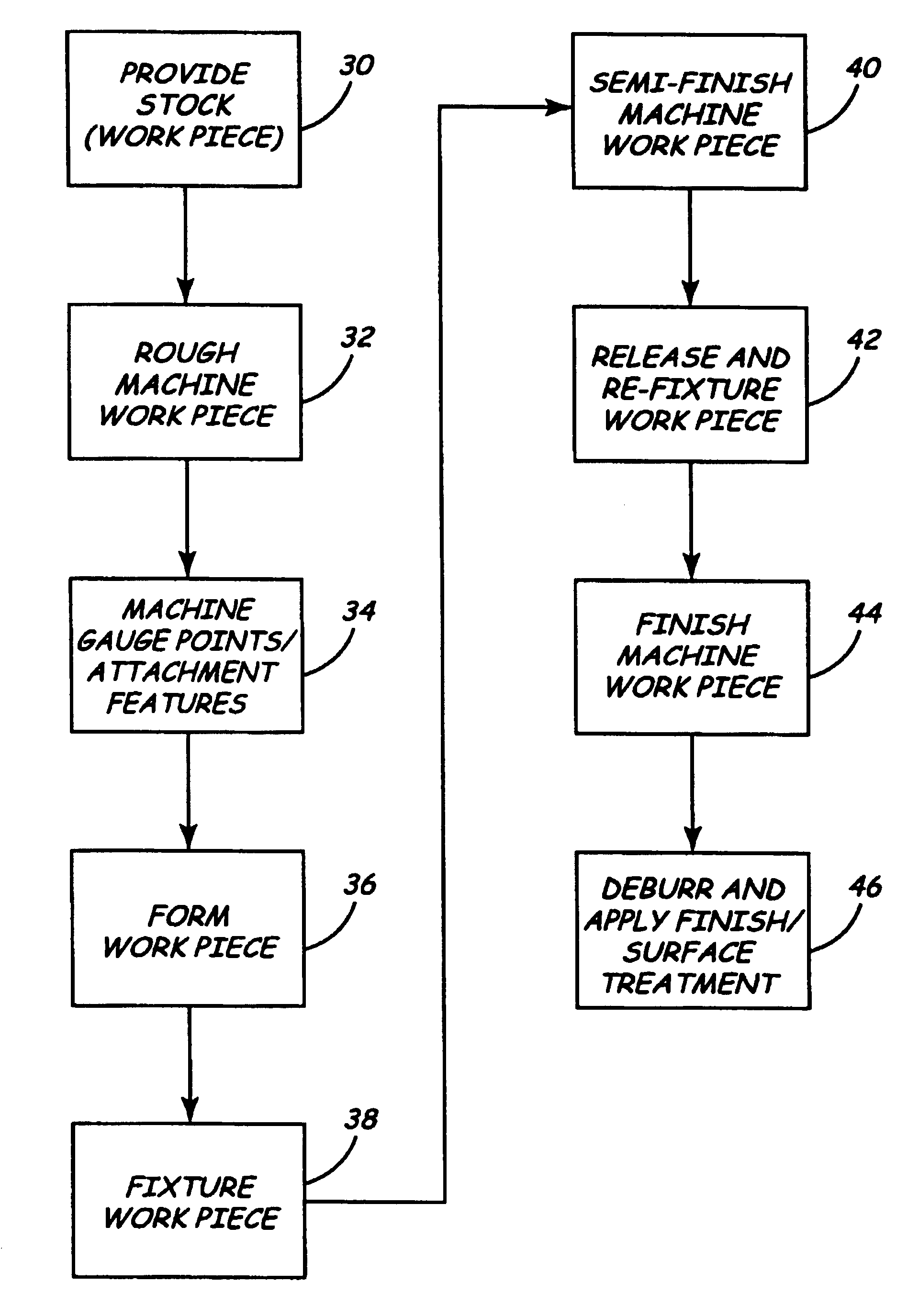

Monolithic part and process for making the same

Owner:REMMELE ENG

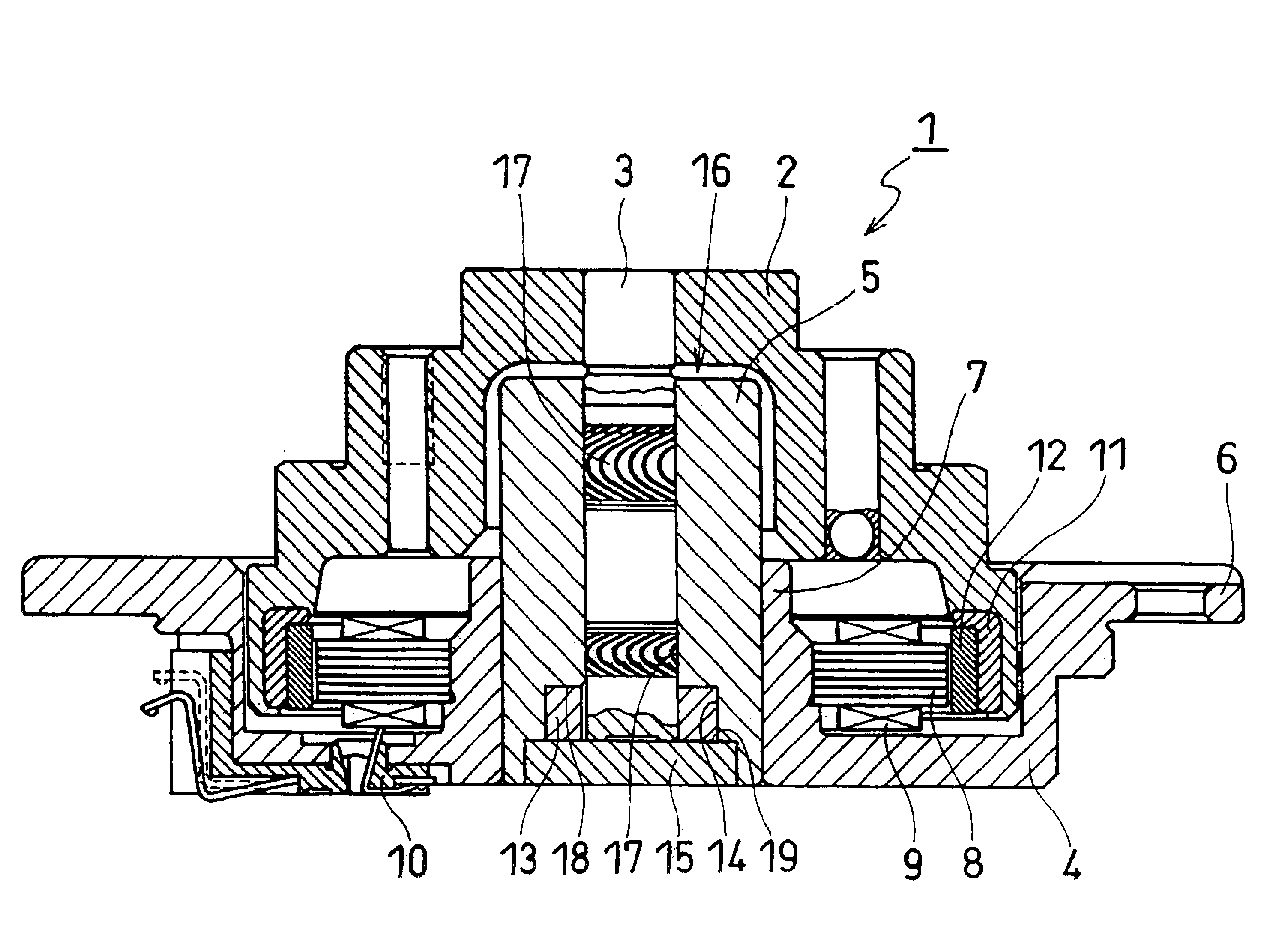

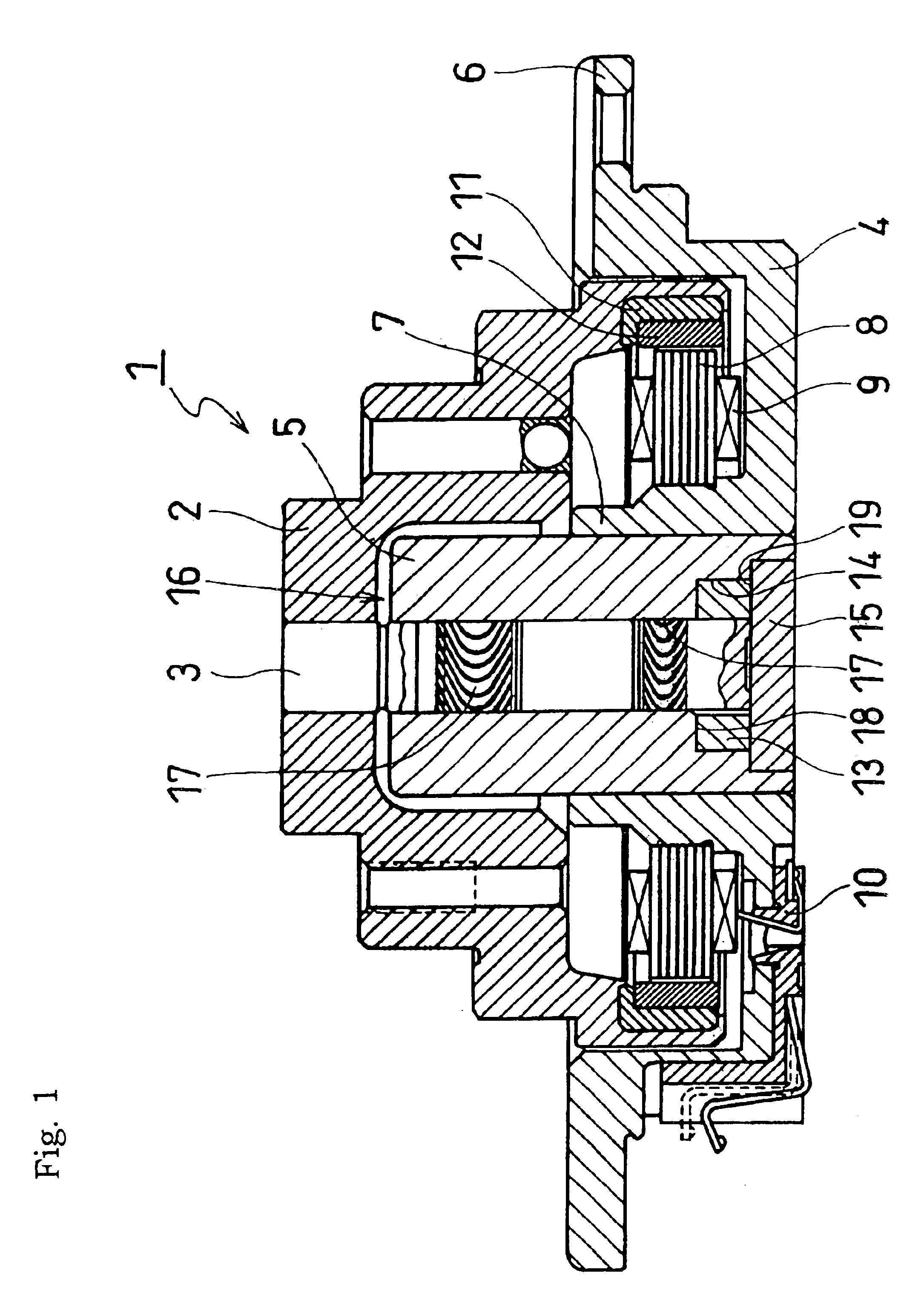

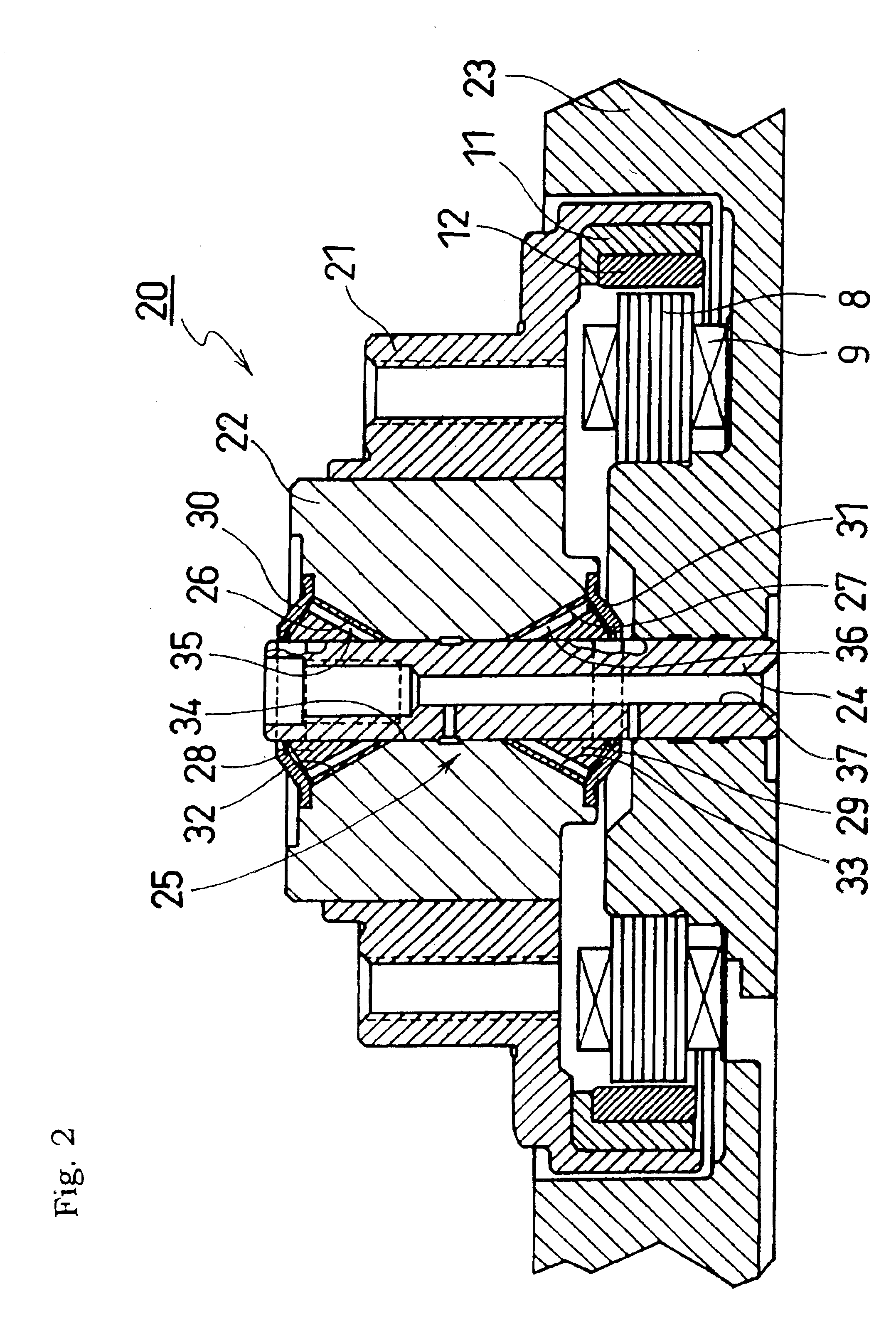

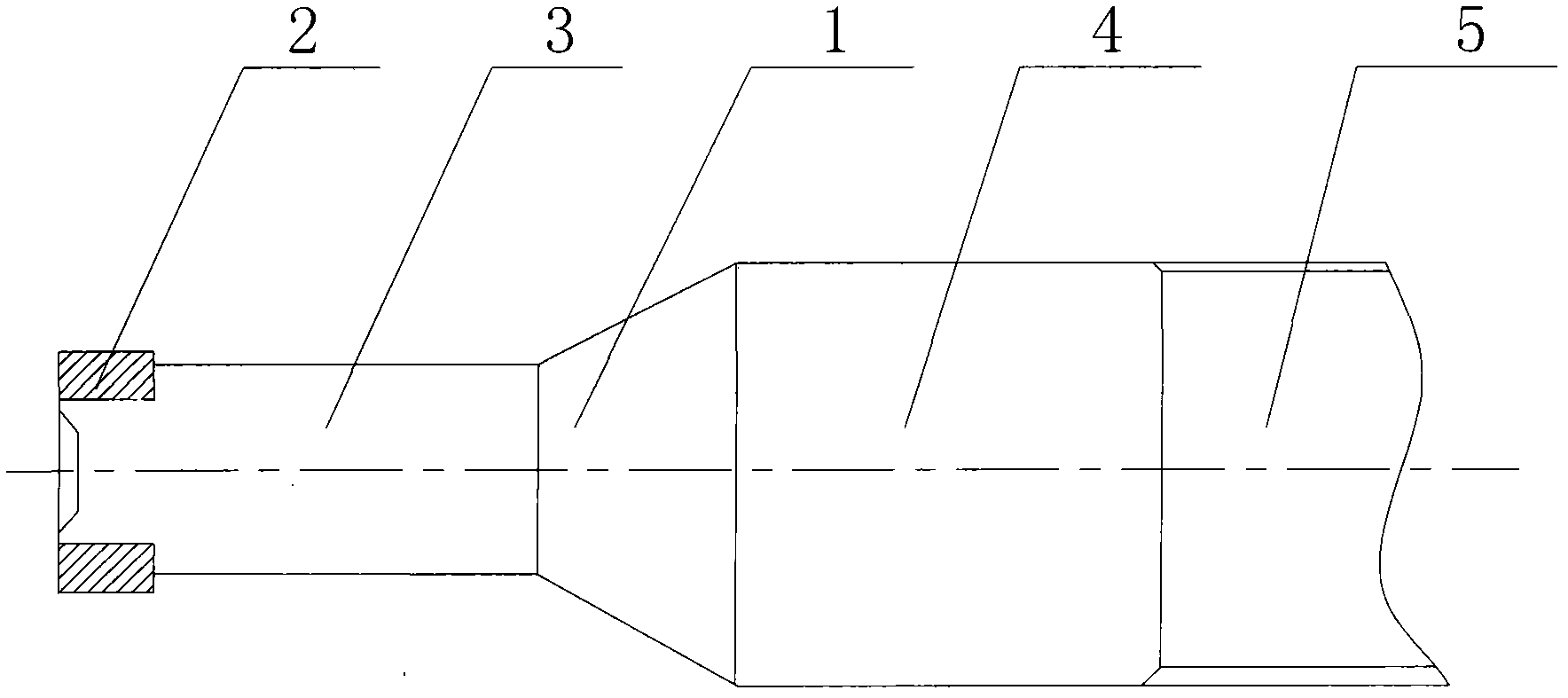

Hydrodynamic pressure bearing system and spindle motor using the same

InactiveUS6965493B2Reduce variationImprove finishing accuracyRecord information storageBearing componentsThermal expansionBearing surface

A shaft secured to a hub is inserted and rotatably supported in a sleeve secured to a base. A dynamic pressure groove is formed in the inner peripheral surface of the sleeve, and lubricant is sealed between the shaft and the sleeve. The rotation of the shaft causes dynamic pressure to generate in the lubricant due to the dynamic pressure groove, supporting the shaft floatingly. The crystallized-glass sleeve allows heat generated in a coil to be hardly transferred to the shaft, thereby reducing the variations in the clearance between the shaft and the sleeve due to temperature changes to a minimum in cooperation with the crystallized-glass sleeve with a low thermal expansion coefficient. Finishing accuracy of the bearing surface can be improved by chemical polishing. Consequently, the rotation accuracy can be improved and the leakage of lubricant due to the variations in the clearance can be prevented.

Owner:MINEBEA CO LTD

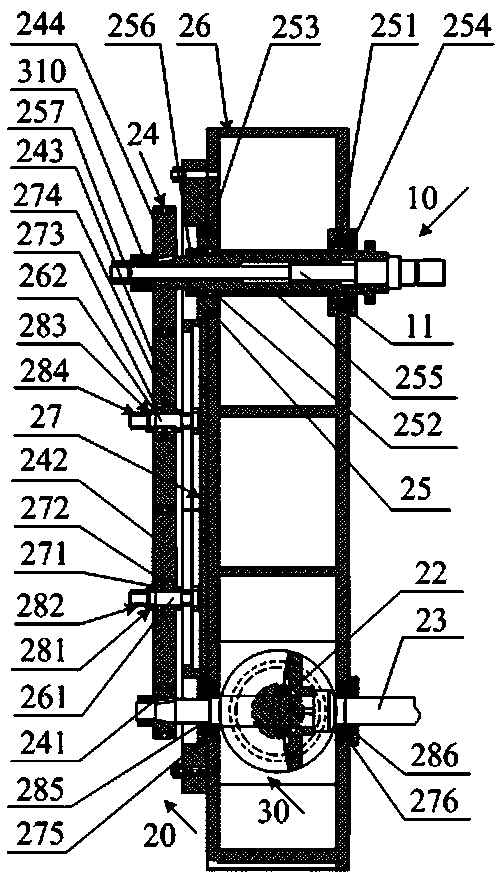

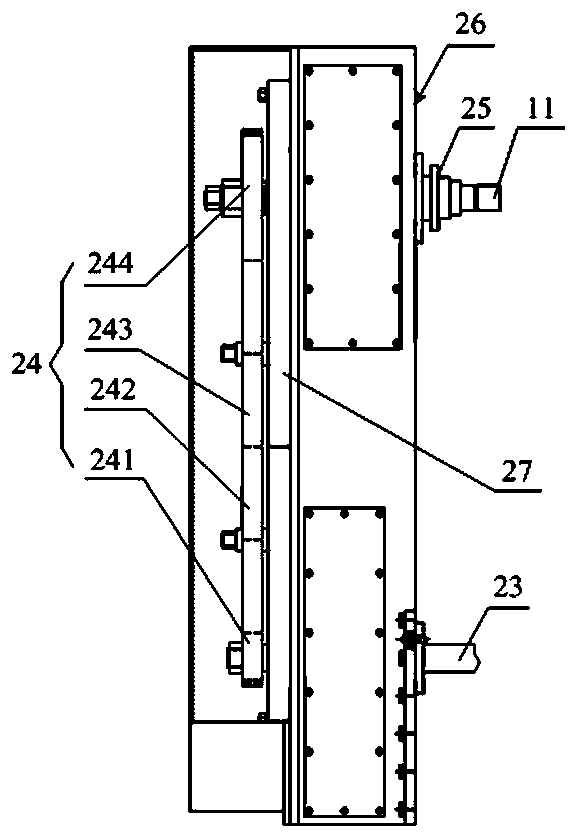

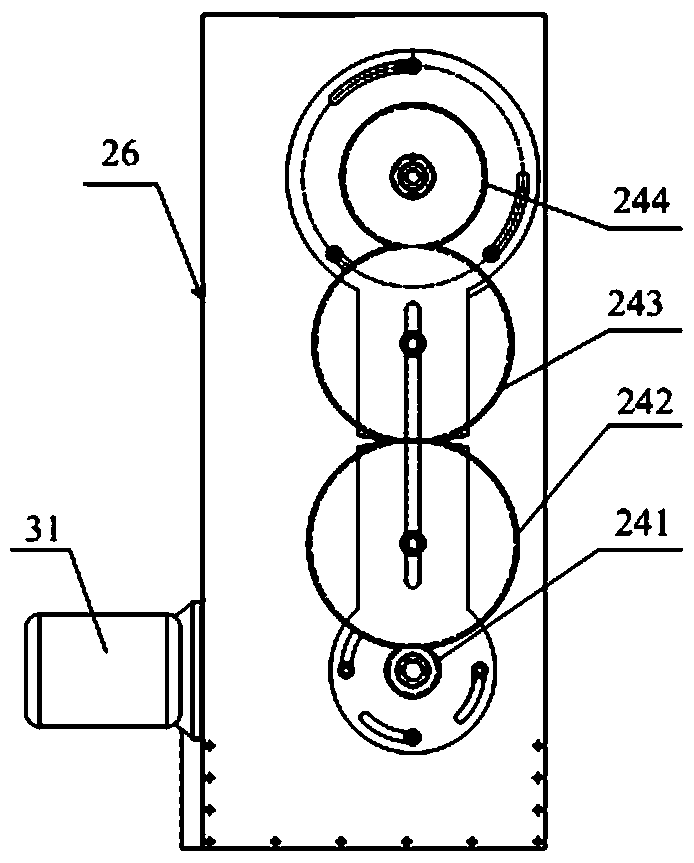

Continuous hinge circle-rolling device

InactiveCN104338853AImprove finishing accuracyIncrease productivityShaping toolsMetal-working feeding devicesMechanical engineeringHinge angle

Owner:重庆市大足区君帅五金加工厂

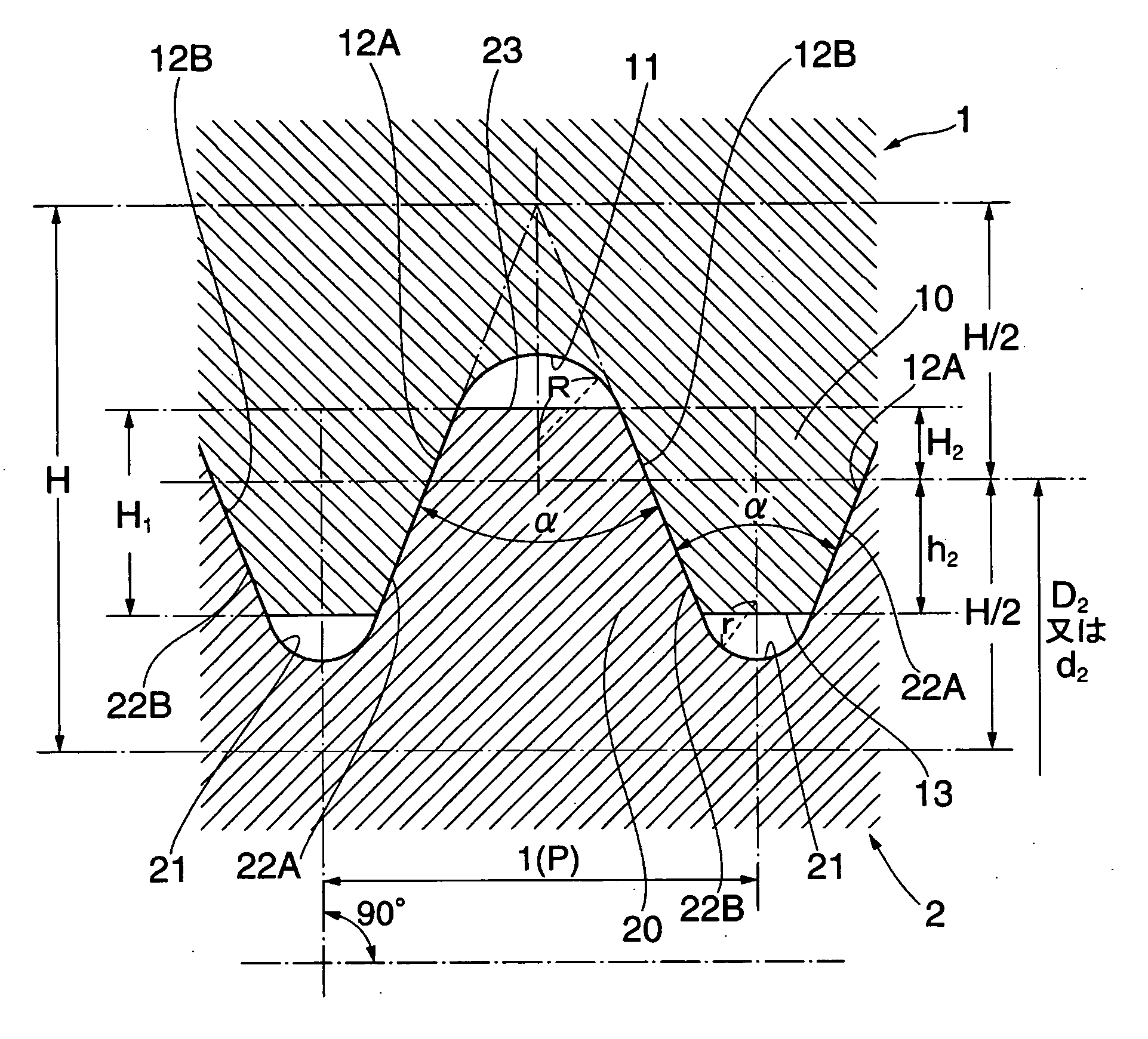

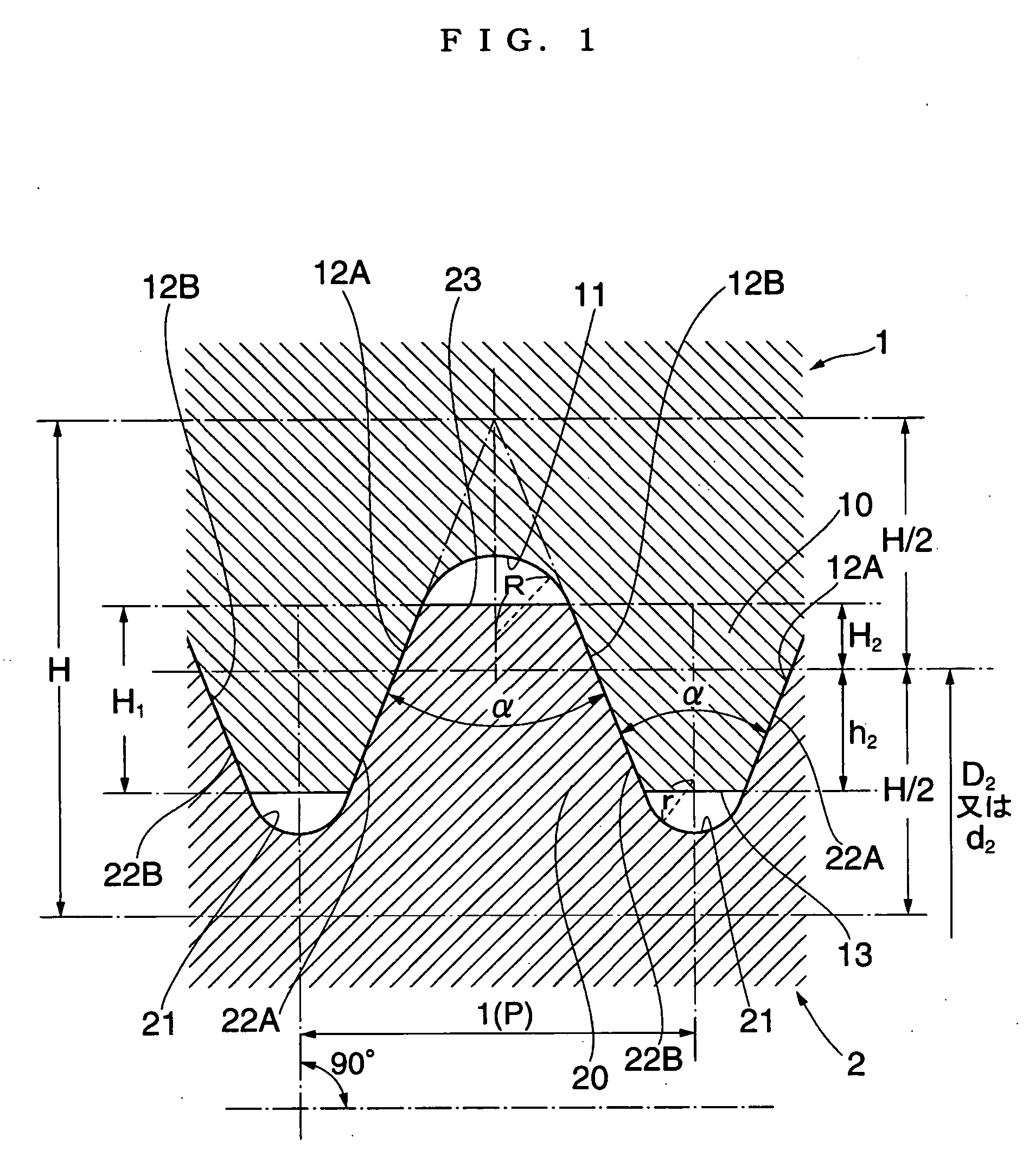

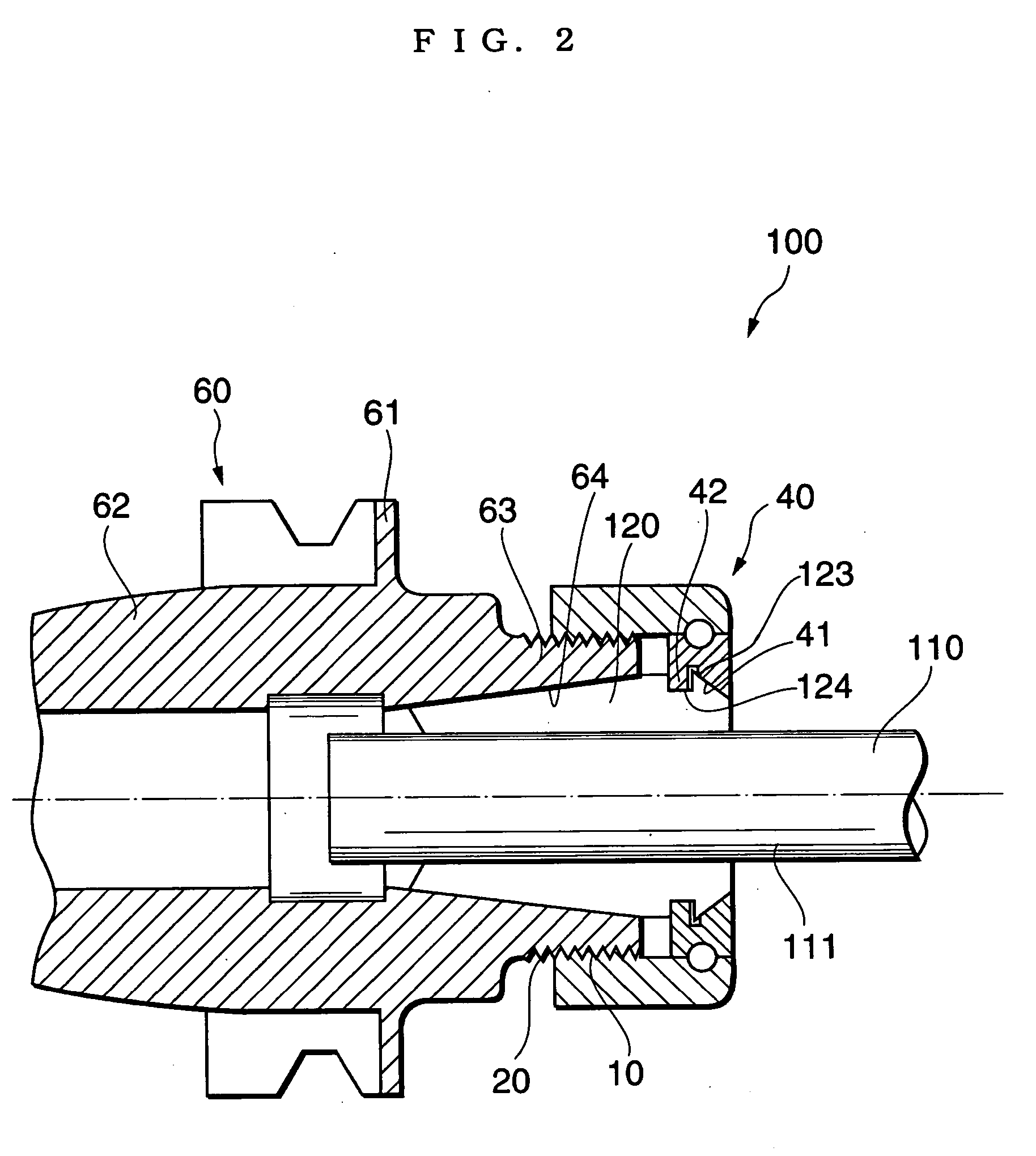

Internal thread member, external thread member, and cutter for internal thread

ActiveUS20060140739A1High degree of completionReduced internal diameterThread cutting toolsNutsBreaking strengthPullout strength

The present invention provides an internal thread member and an external thread member that can achieve stable finishing accuracy, can assure a desirable thread overlap, and have sufficient breaking strength and pullout strength. This invention also provides a cutter which can machine internal threads with stable finishing accuracy and can assure improved durability.

Owner:BIG ALPHA CO LTD

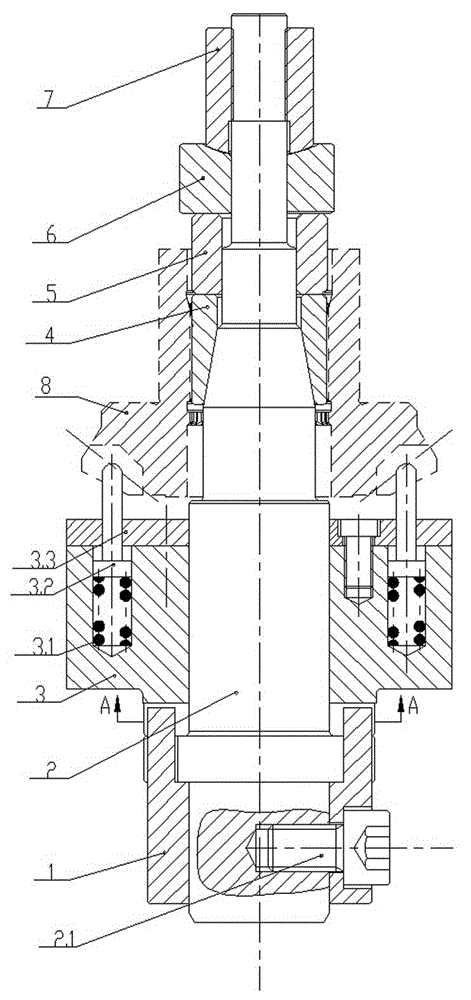

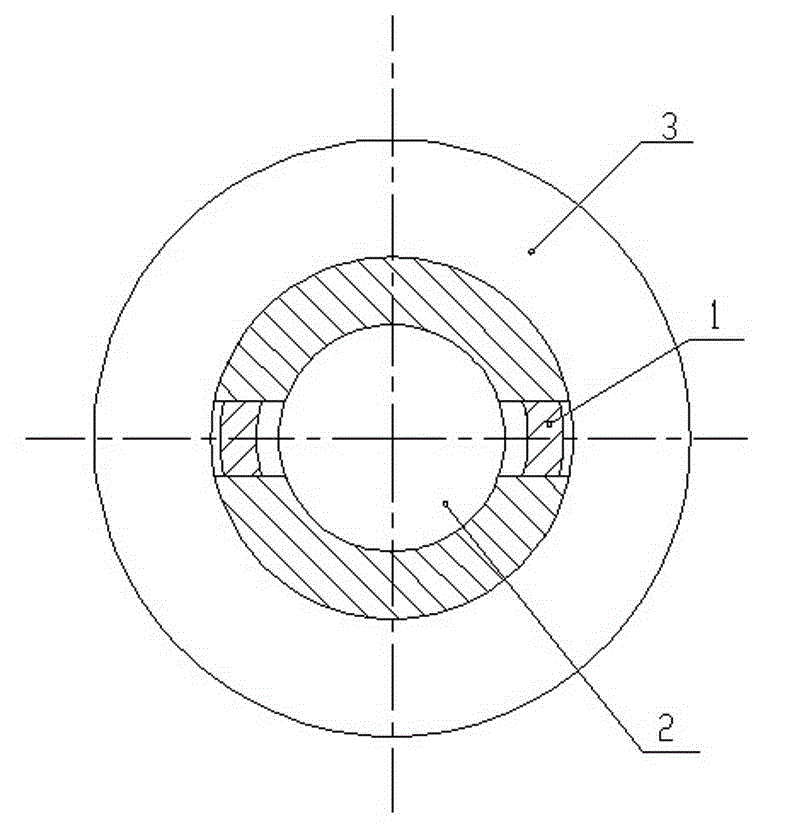

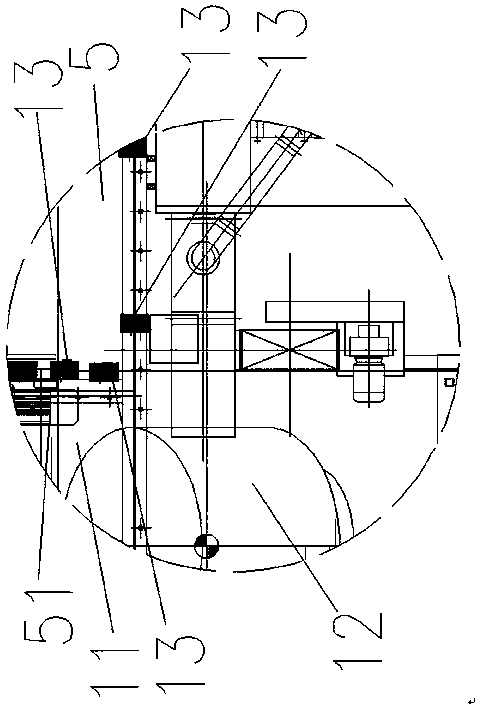

Axial floating positioning mandrel clamp

InactiveCN104439546ASimple floating positioning structureEasy to manufactureGear-cutting machinesGear teethEngineeringDegrees of freedom

The invention discloses an axial floating positioning mandrel clamp. The axial floating positioning mandrel clamp is composed of a round sleeve, a mandrel, a base, an expansion sleeve, a ring sleeve, a gasket and a nut, wherein the ring sleeve arranged outside the large diameter end of the mandrel in a sleeving mode is locked through a bolt, the small diameter end of the mandrel is provided with an outer thread matched with the nut, and a section of the expansion sleeve matched with a conical shaft is arranged at the middle section of the mandrel and is of an axial spiral expansion structure composed of the ring sleeve, the gasket and the nut. A matched linkage structure composed of an outer protruding tooth and a groove is arranged on the combination surface of the ring sleeve and the base. Counter bores are evenly distributed in the end surface, facing a tooth part of a bevel gear of a workpiece, of the base, piles supported by springs axially are arranged in the counter bores, and the outwards extending piles are sealed by covering plates to form elastic telescopic structures. By means of the axial floating positioning mandrel clamp, the degree of freedom of rotation of the workpiece in the radial direction and axial direction and around the axis of the mandrel is limited, the workpiece is positioned accurately and reliability, and the fine machining accuracy is improved. In addition, the inner expansion structure is not provided with external objects, and efficient grinding machining on an outer ledge of the workpiece is facilitated.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

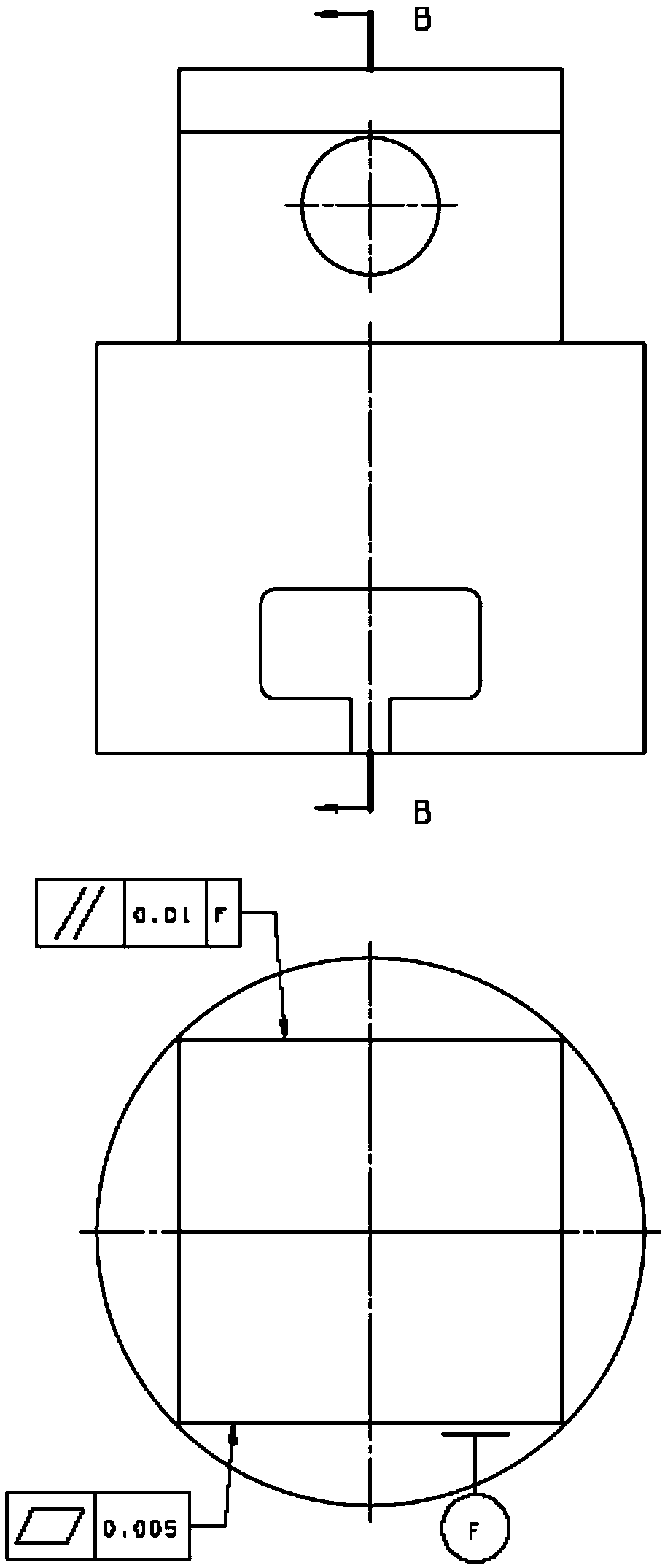

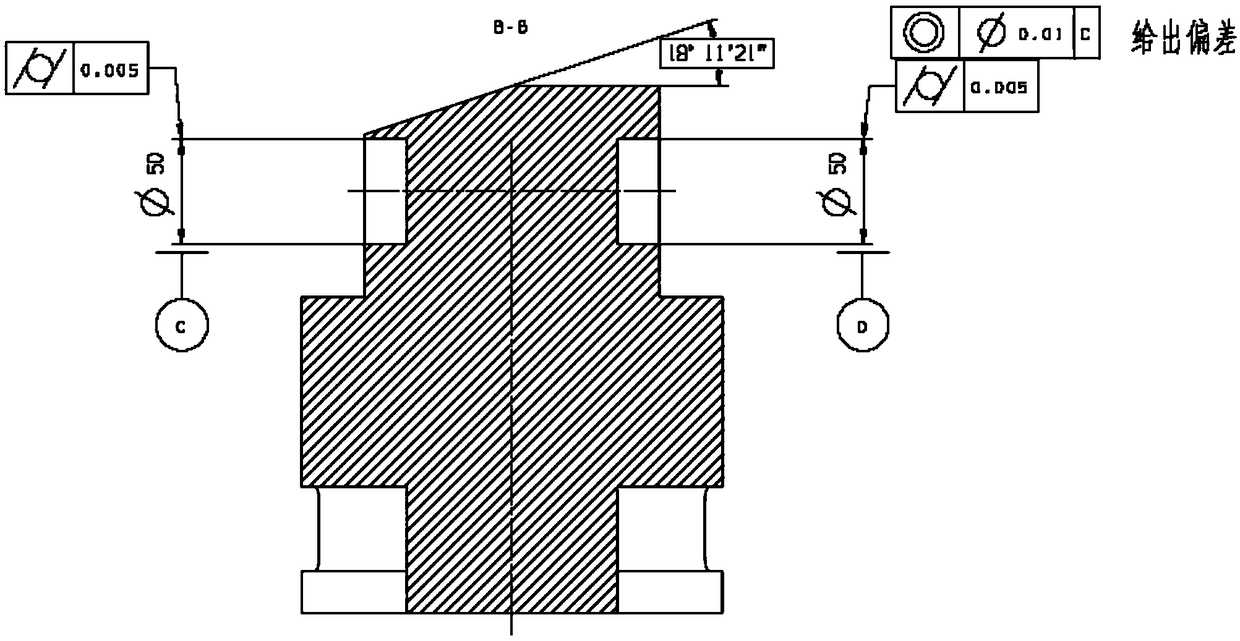

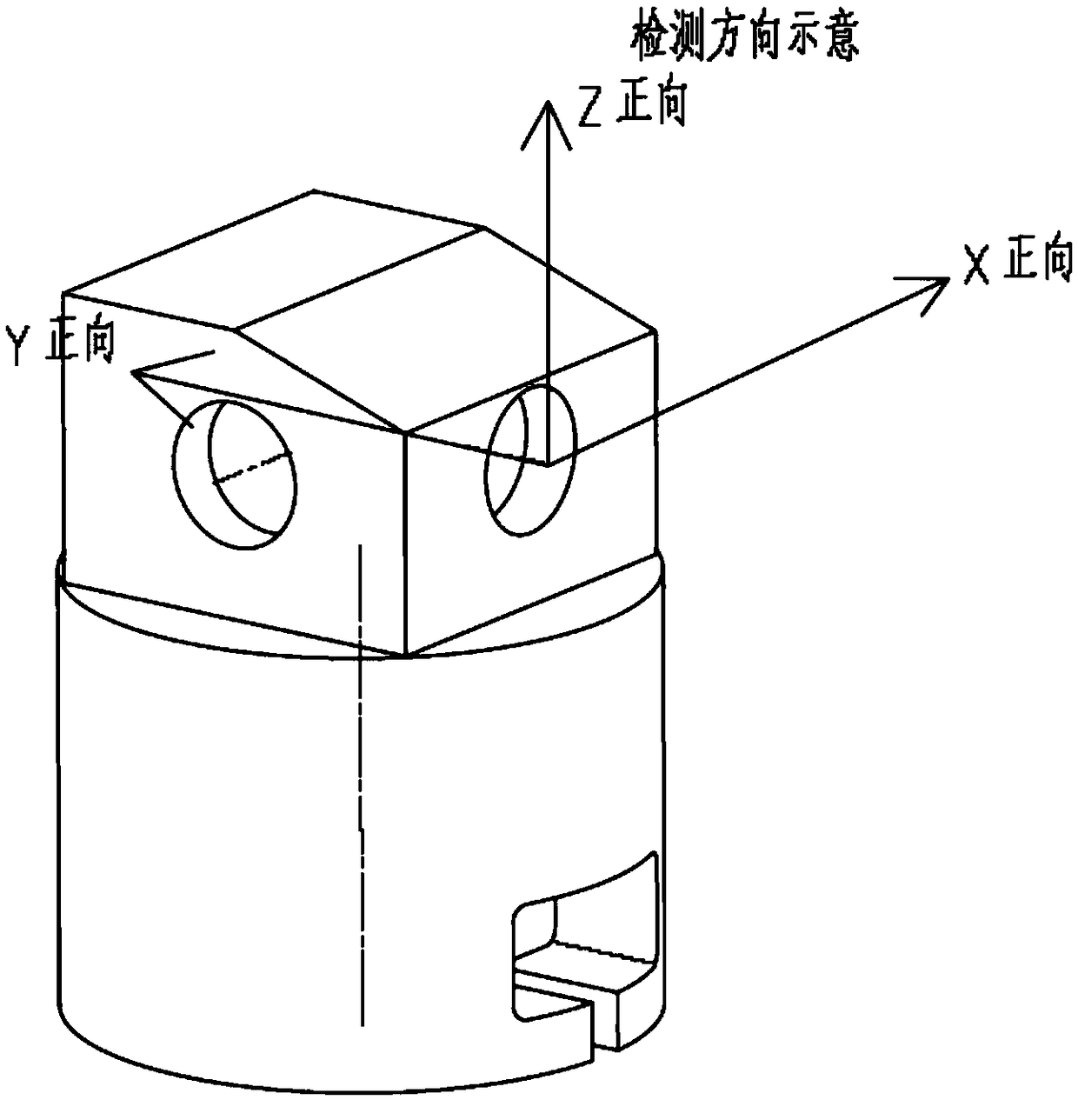

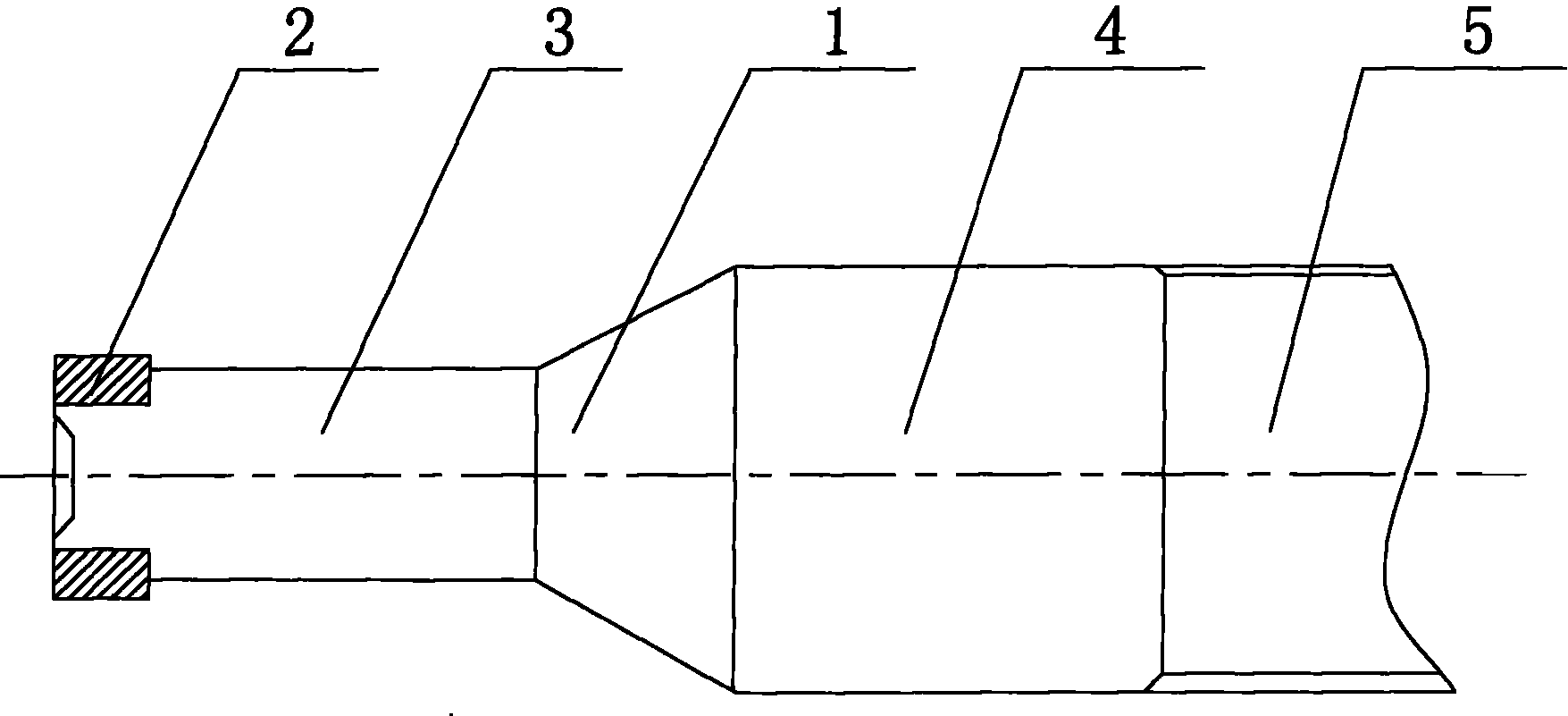

Method for detecting precision of numerical control machine tool by special tool

ActiveCN109396952AConvenient accuracy detectionImprove processing efficiencyMeasurement/indication equipmentsEngineeringMachine tool

The invention provides a method for detecting precision of numerical control machine tool by special tool so as to solve the problem that when the numerical control machine tool runs for a long time,the precision is reduced. According to the method, the special tool is designed, wherein the special tool is composed of a cylinder and a cube located on the cylinder, a groove used for allowing a screw to be installed is formed in the lower end of the cylinder, an oblique angle with any angle is chamfered in one side of the top of the cube, and a concentric circular hole is formed in each of anytwo corresponding surfaces of the cube. All the parameters of the special tool are detected in a three-coordinate mode and then are compensated into actual machining so as to ensure the precision.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

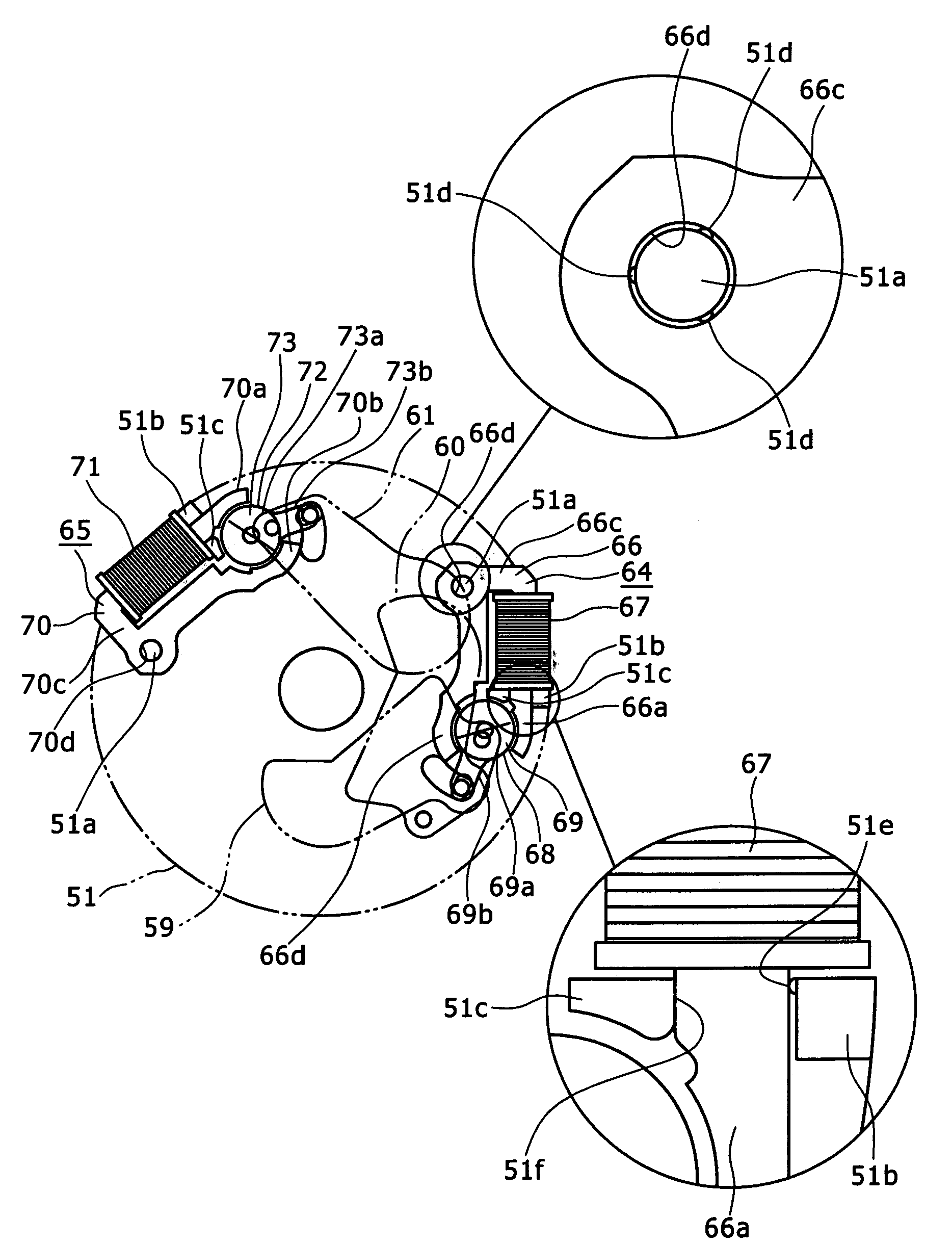

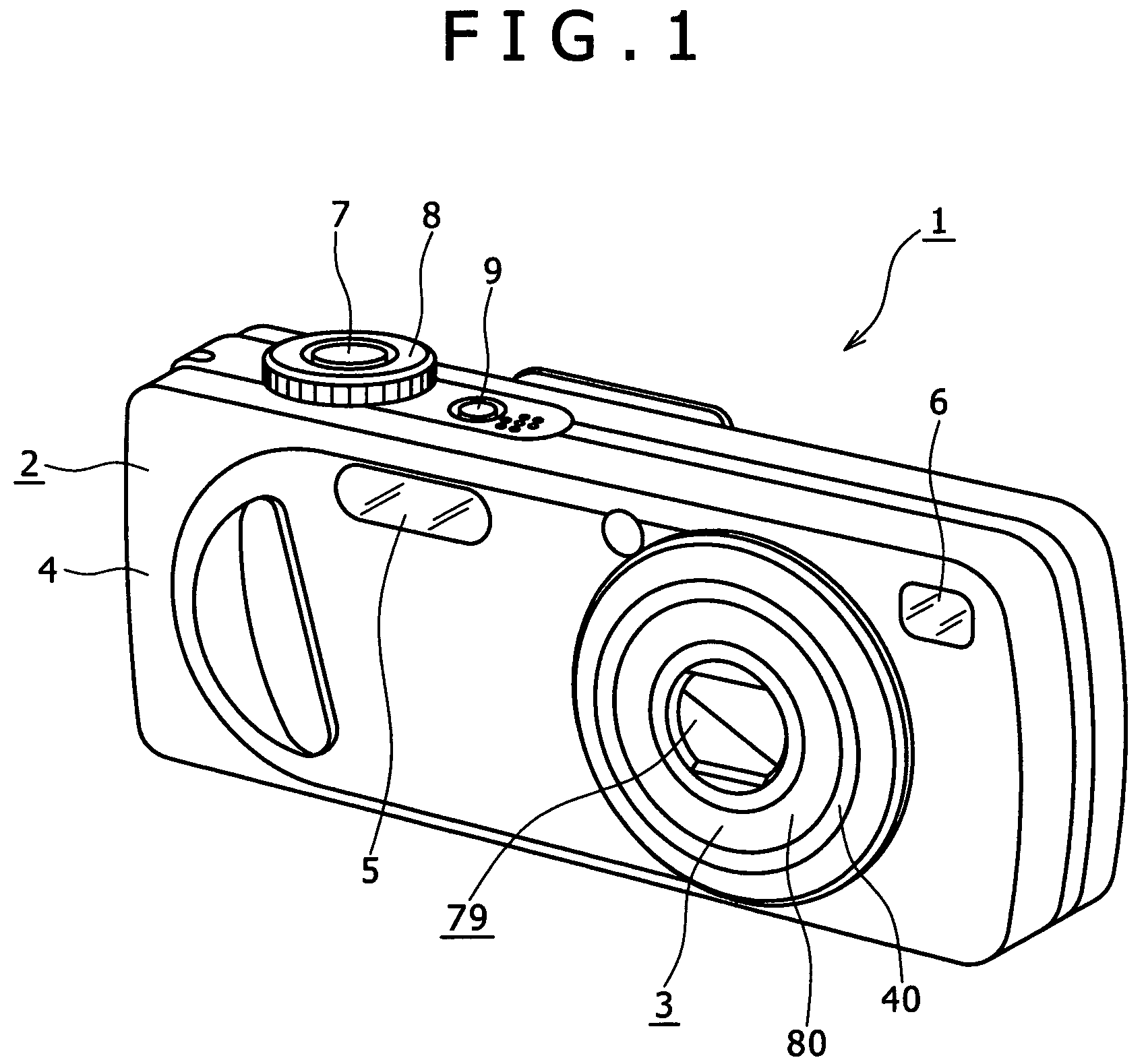

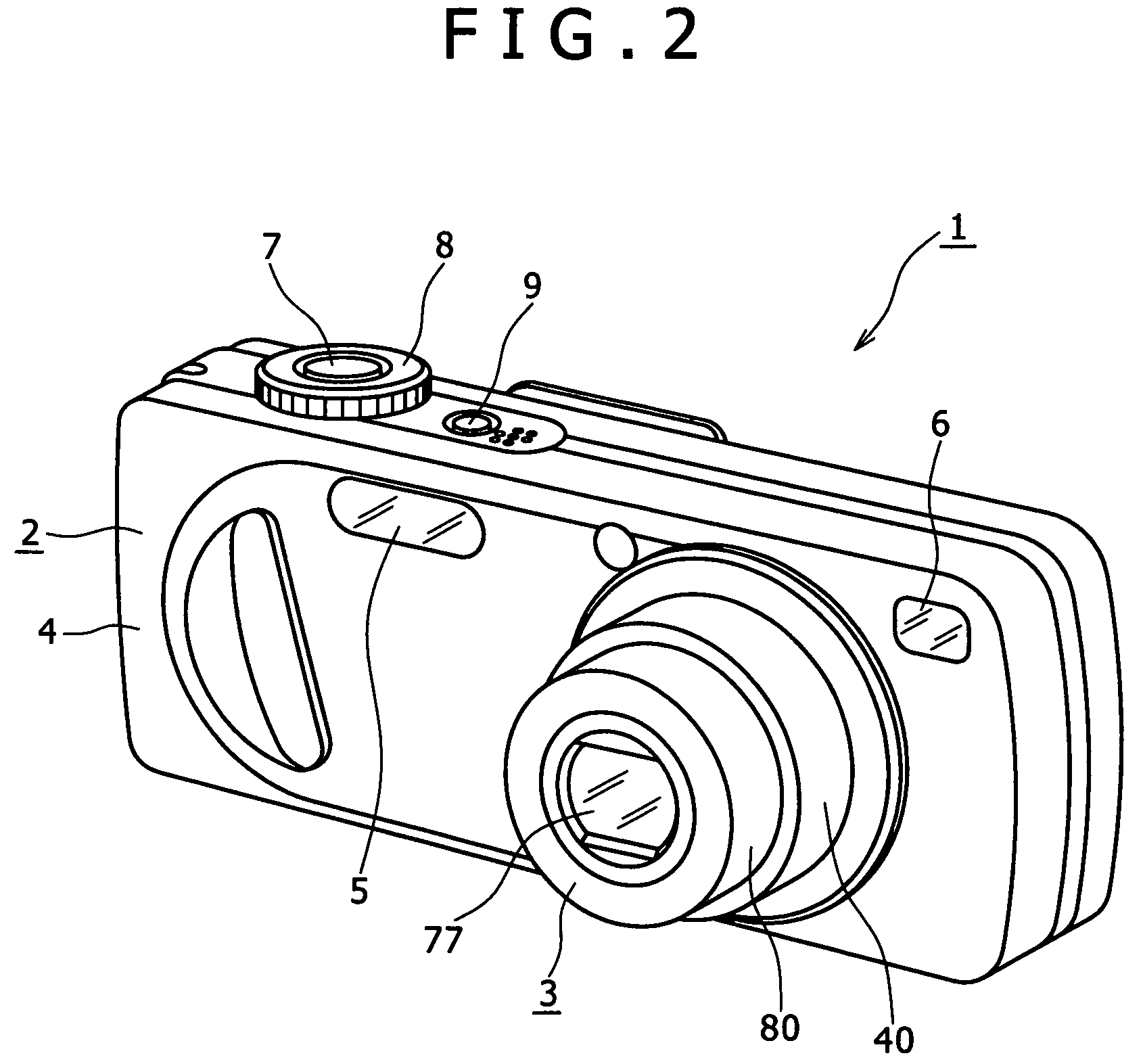

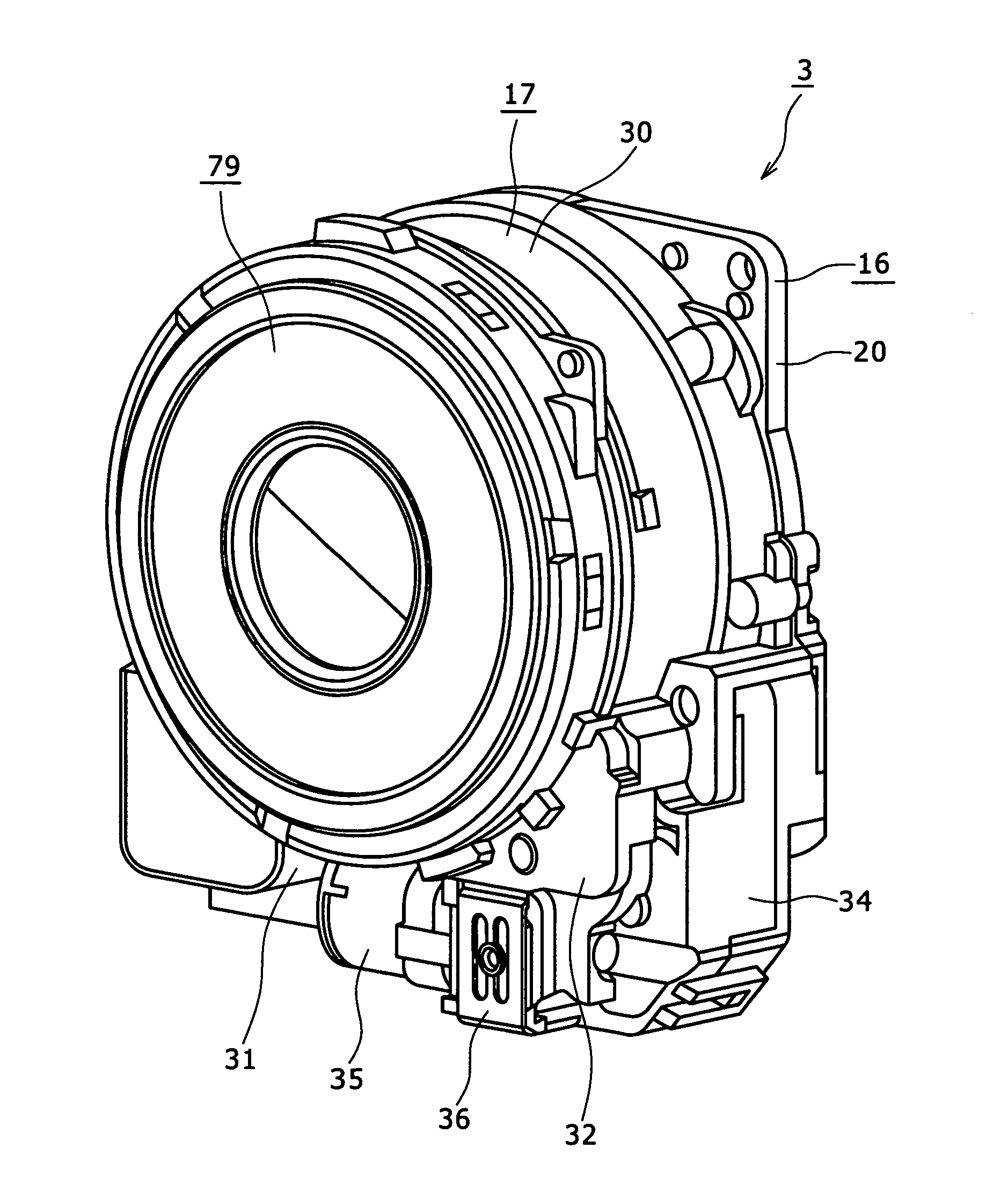

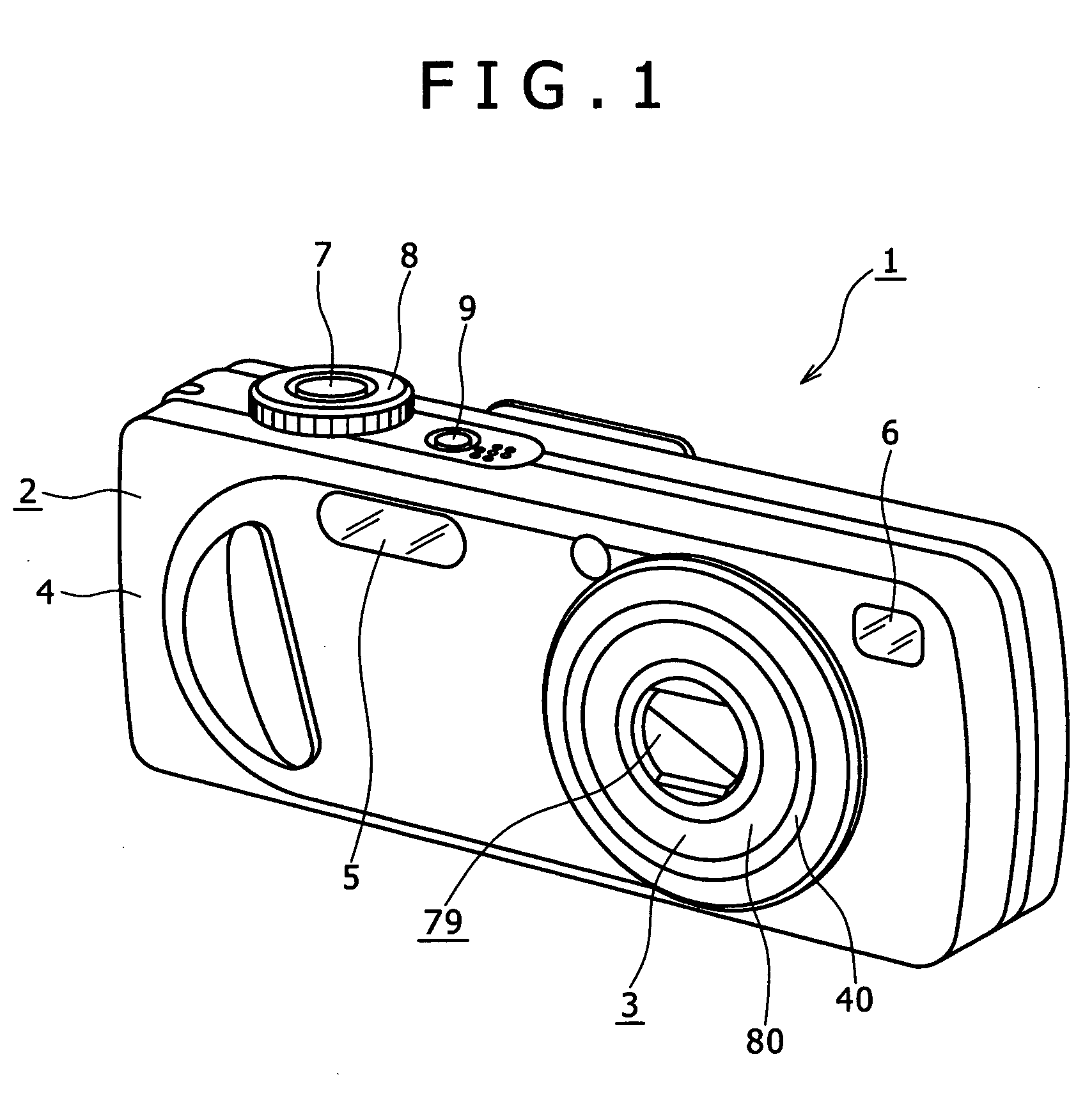

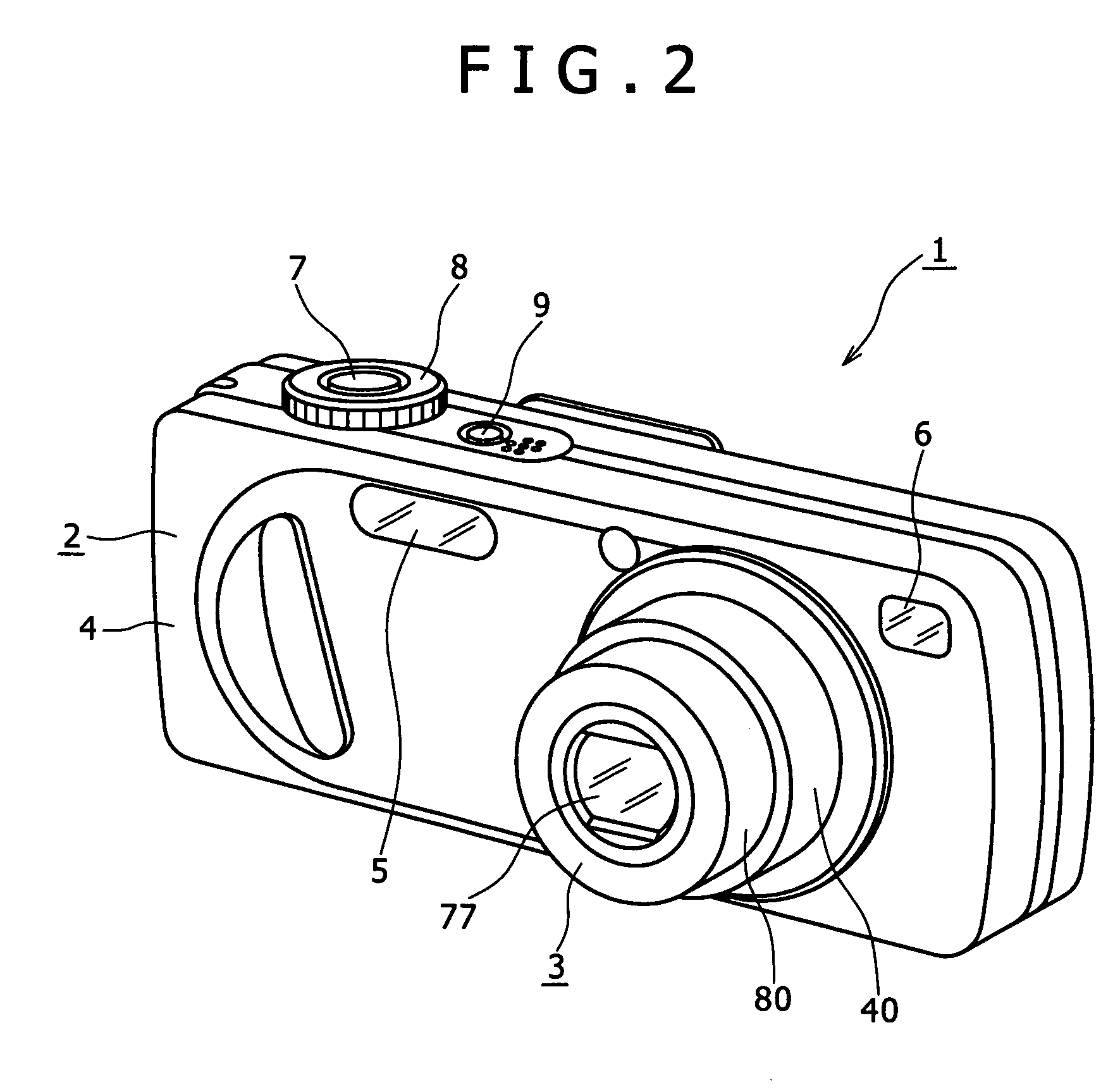

Light amount adjustment apparatus and image pickup apparatus

InactiveUS7758261B2Improve finishing accuracyAvoid playingMagnetic circuit rotating partsMaster clocksCircular discMagnet

Disclosed herein is a light amount adjustment apparatus, including: a light amount adjustment member; a rotatable magnet formed in a disk shape; a driving arm configured to be pivoted by rotation of the magnet to operate the light amount adjustment member; a core having a pair of confronting portions positioned so as to sandwich the magnet from an outer circumference side and a connecting portion configured to connect end portions of the confronting portions to each other; a coil through which one of the portions of the core extends; and a base member having the core attached to the base member and supporting the magnet for rotation on the base member. The base member has a plurality of attaching projections provided at least at two places of the base member for attaching the core to the base member. The attaching projections have a small projection for fitting with the core.

Owner:SONY CORP

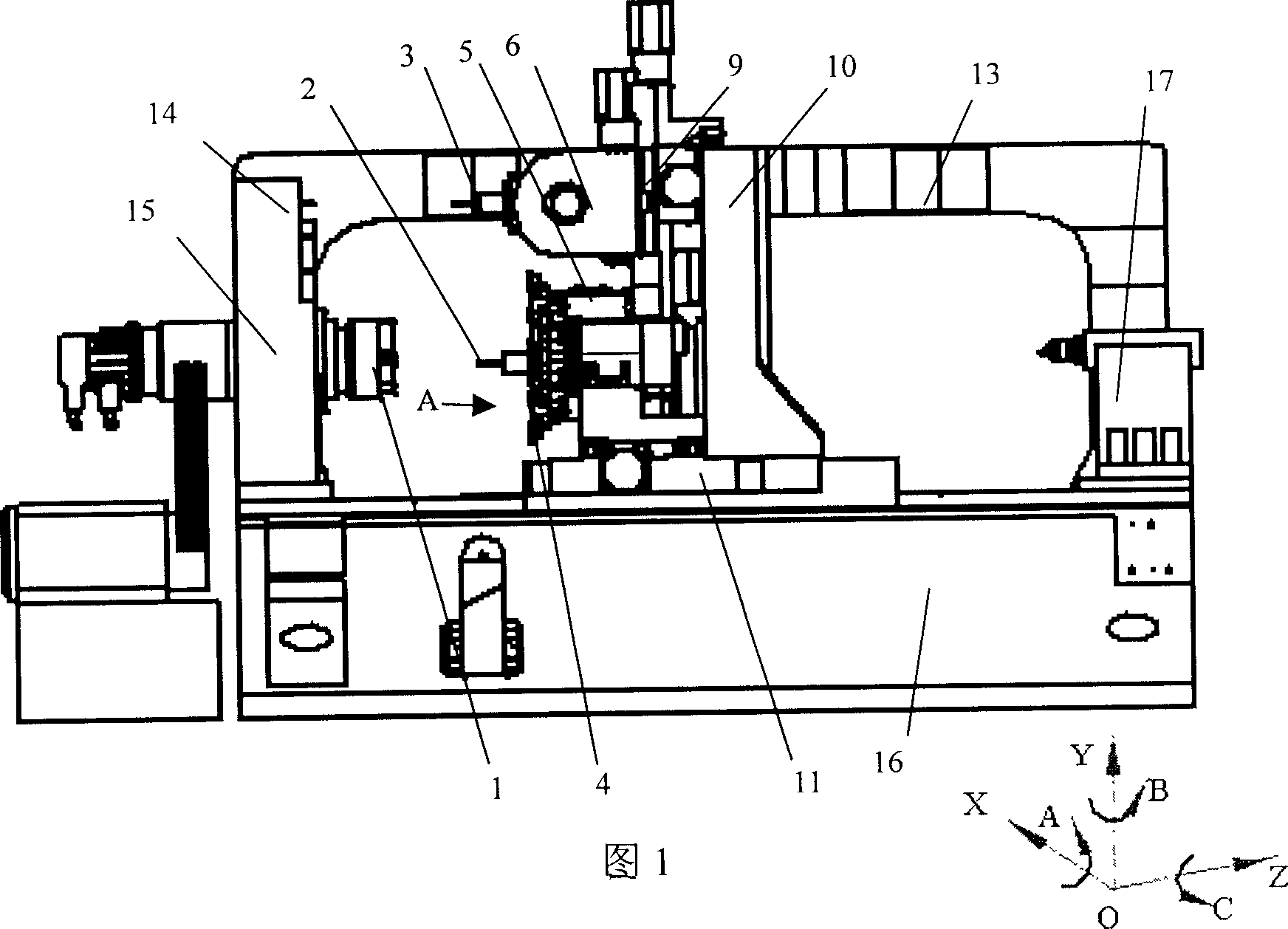

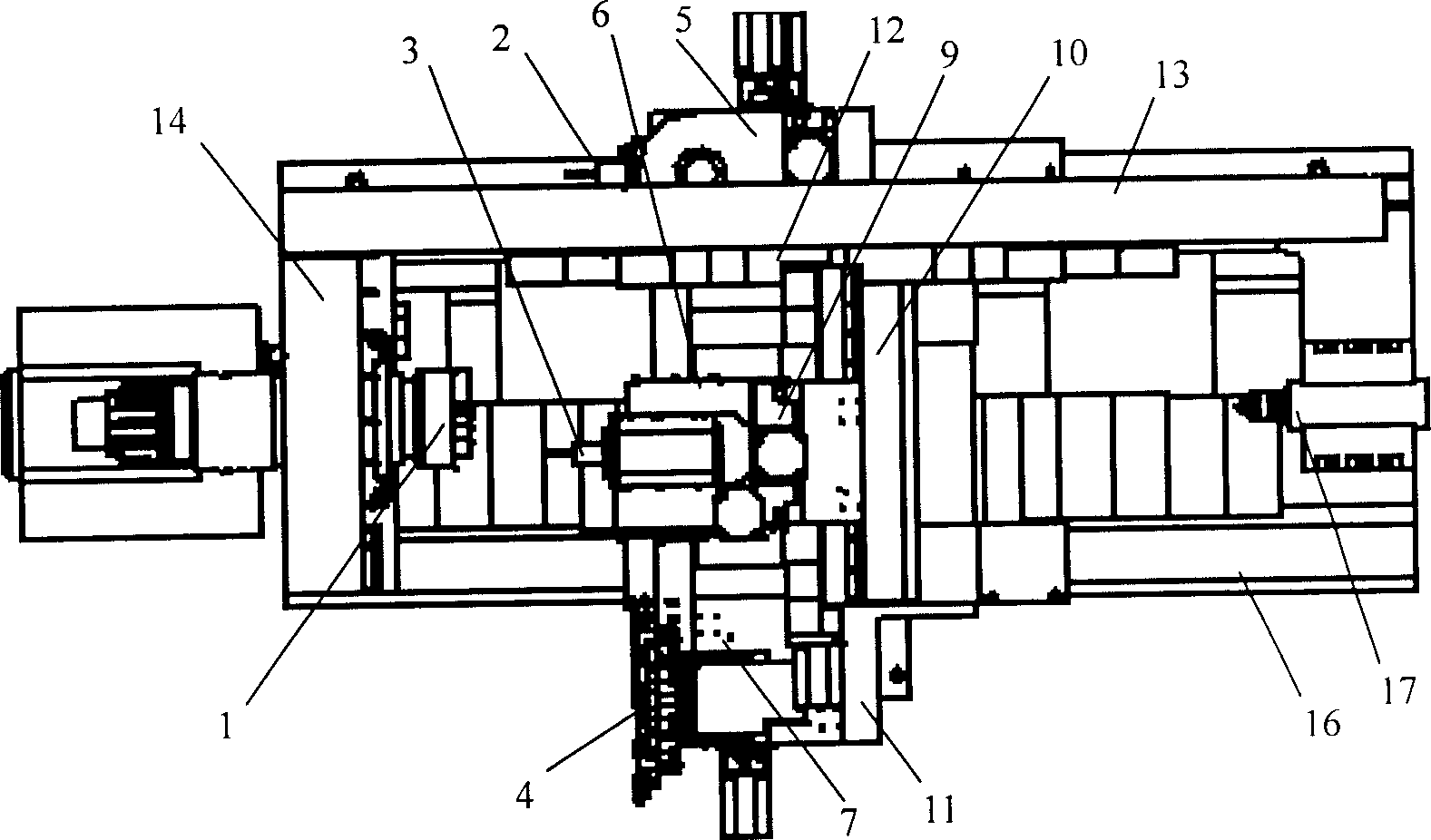

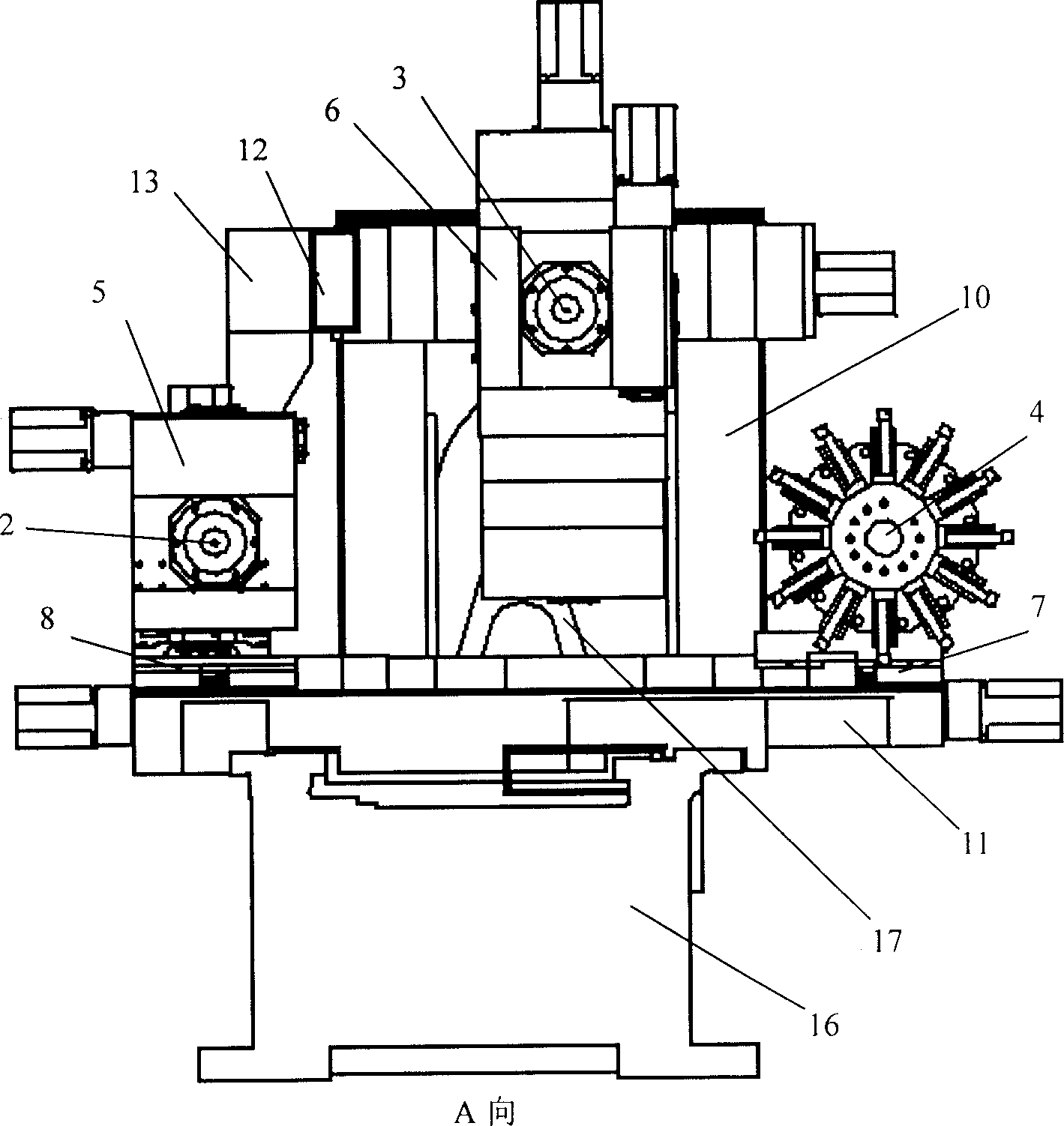

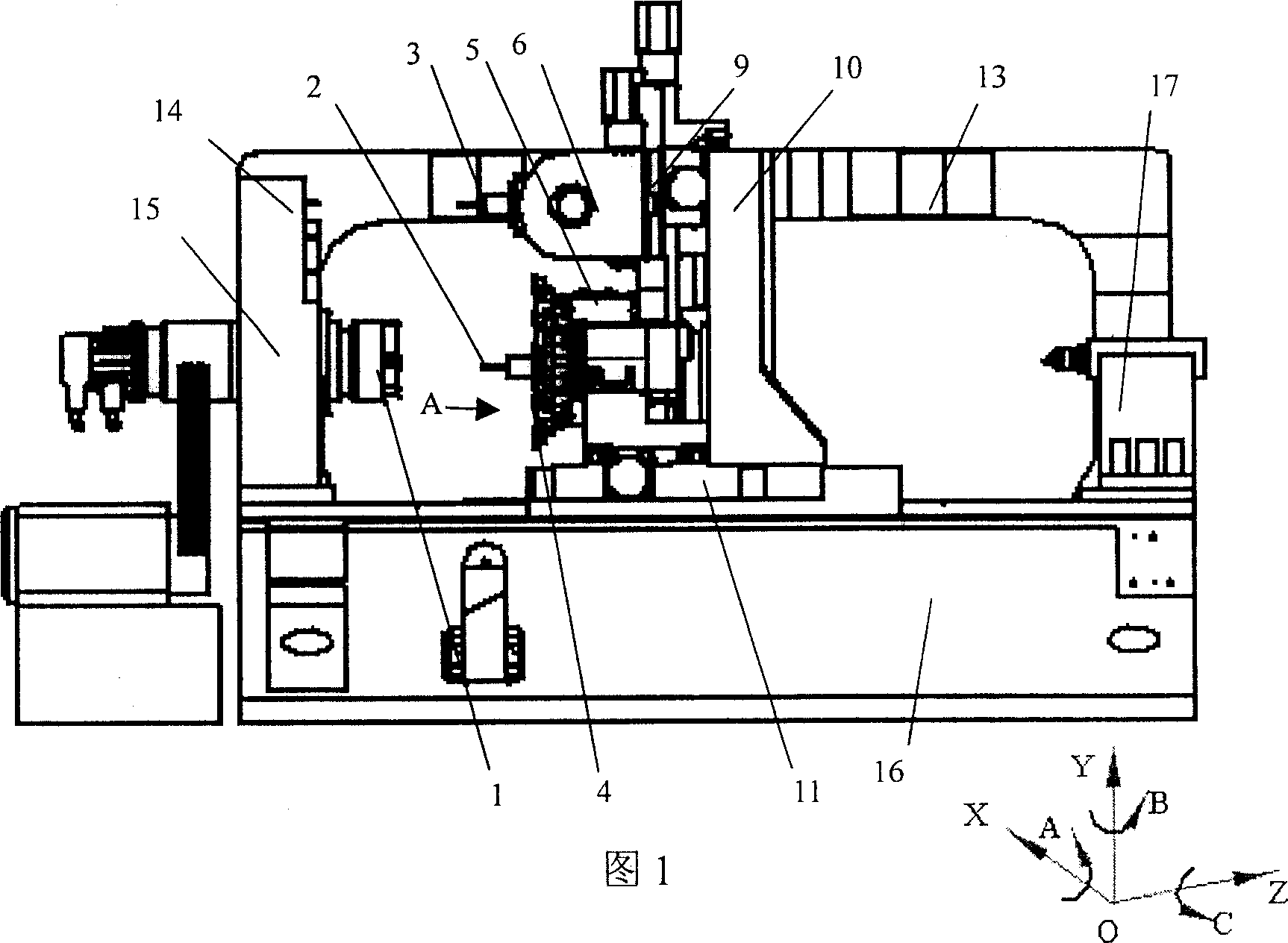

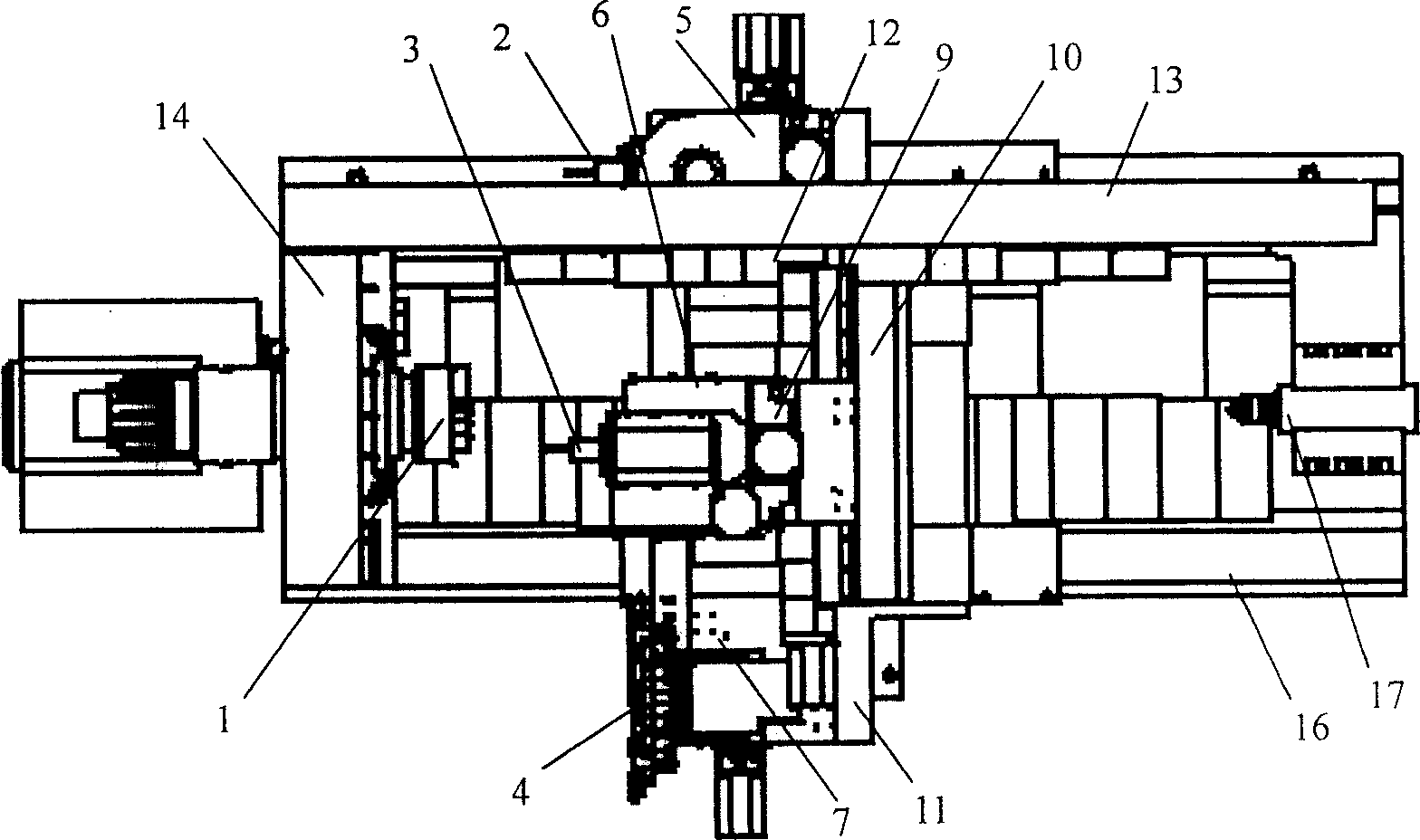

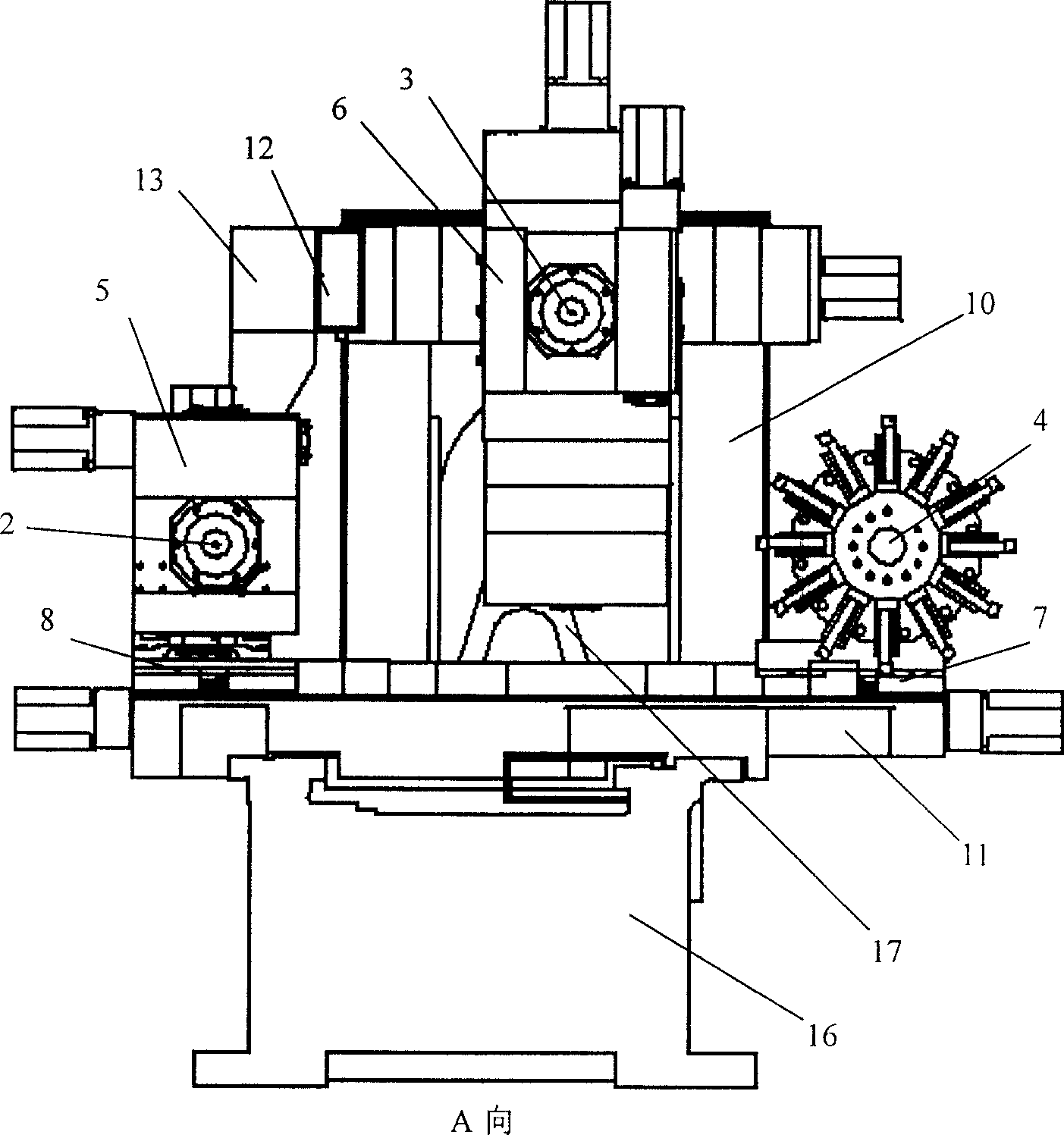

Three-axis double door frame double drive five linkage combination production center

InactiveCN1546278AImprove accuracy retentionAccuracy Retention GuaranteeOther manufacturing equipments/toolsDigital controlMachine tool

The invention discloses a kind of digital control compound processing centre which has three primary axis heads and three blade brackets to provide double drives, it is made up of turning primary axis head, milling axis head, fine machining primary head, turning blade bracket, milling blade bracket components, straight lade bracket component, saddle, transverse sliding boards, small door bracket component, a bed, the side door bracket component, tail bracket component and blade bank. The fine machining primary head can be changed, it can assemble high speed milling head, grinding head; the primary axis has servo axis function, the other two primary axes is servo axis. The bathe has at least nine servo axes, it can have twenty servo axes at most, it can realize five-axes linked control; the piece can realize turning, milling, boring, drilling and screwing, and high speed milling and so on. The raw and fine process can be separated, in order to upgrades the precise maintaining of bathe.

Owner:XIAN UNIV OF TECH

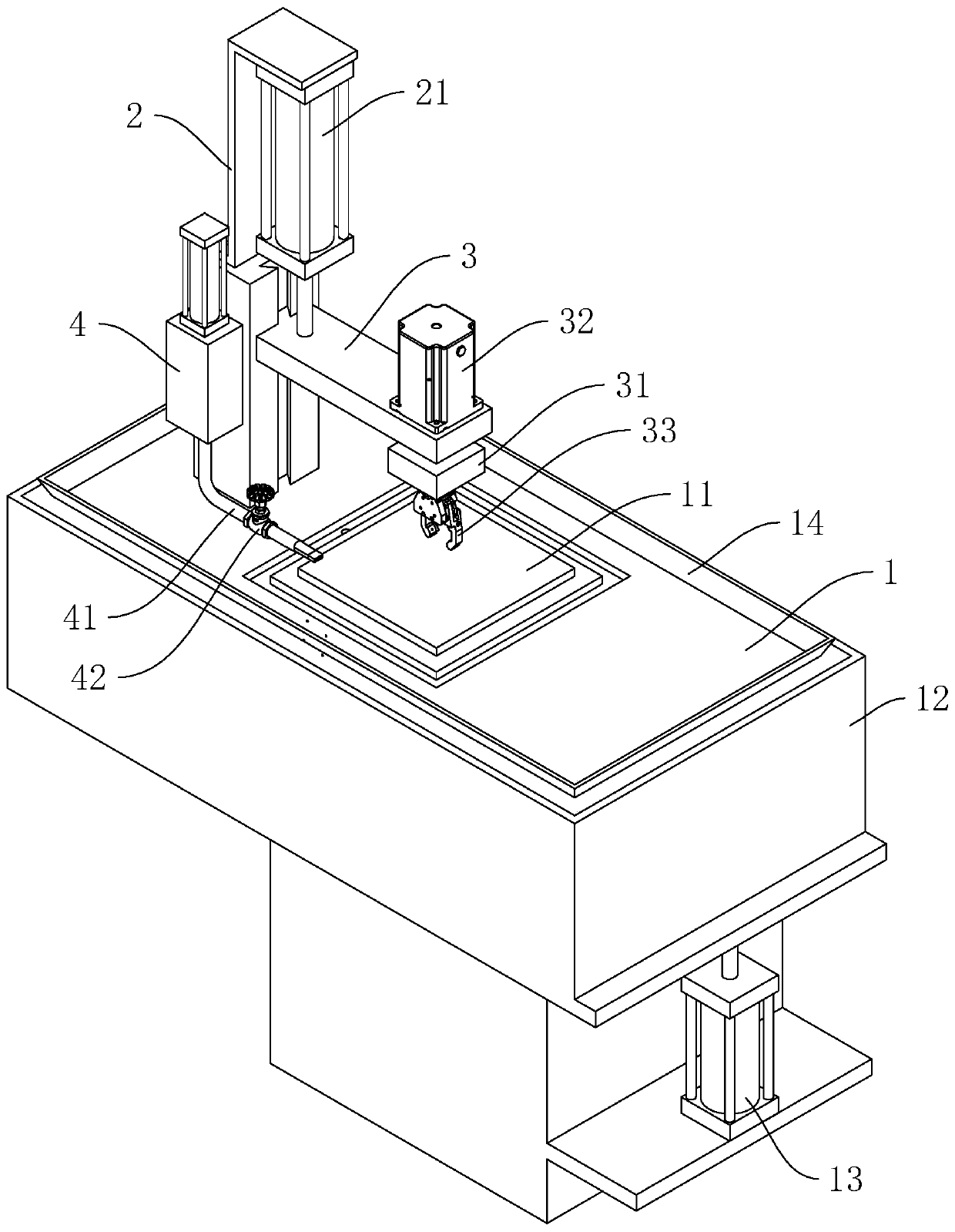

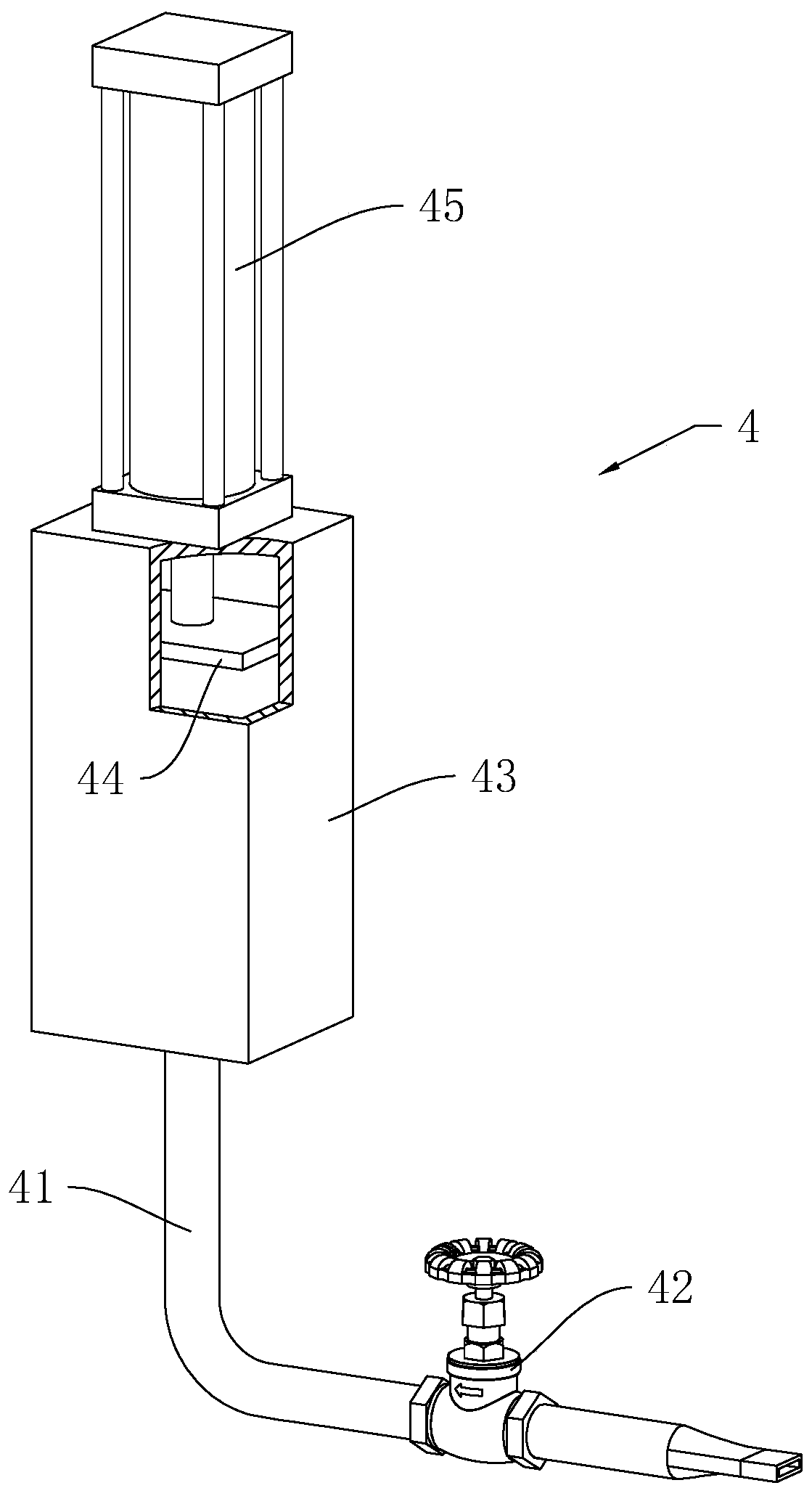

Fine machining device and technology of surface of die steel

InactiveCN110509172AImprove finishing accuracySimple structurePolishing machinesGrinding drivesChemical reactionEngineering

The invention discloses a fine machining device and technology of the surface of die steel, and relates to the field of die production and manufacturing. The fine machining device comprises a workingtable, the working table is vertically provided a support seat, and the support seat is vertically and slidably connected with a sliding seat; the lower end surface of the sliding seat is rotatably connected with a rotating seat, and a pneumatic clamping jaw is arranged on the lower end surface of the rotating seat; a polishing pad is arranged on the upper end surface of the working table, a liquid supply mechanism is arranged on the side wall of the support seat, the liquid supply mechanism is provided with a liquid discharging pipe, the liquid discharging pipe is provided with a valve, and the pipe opening of the liquid discharging pipe aligns with the surface of the polishing pad. The fine machining device and technology have the advantages and effects that through matching of polishingliquid and the polishing pad, ultra-precision fine machining of the die steel is achieved in the alternating process of the chemical reaction and mechanical action, and thus the fine machining accuracy of the die steel is improved; and meanwhile the steps are set to be simple, the fine machining technology with high automation is achieved, the accurate machining of the die steel is achieved, andthe fine machining accuracy of the die steel is improved.

Owner:浙江日成模具有限公司

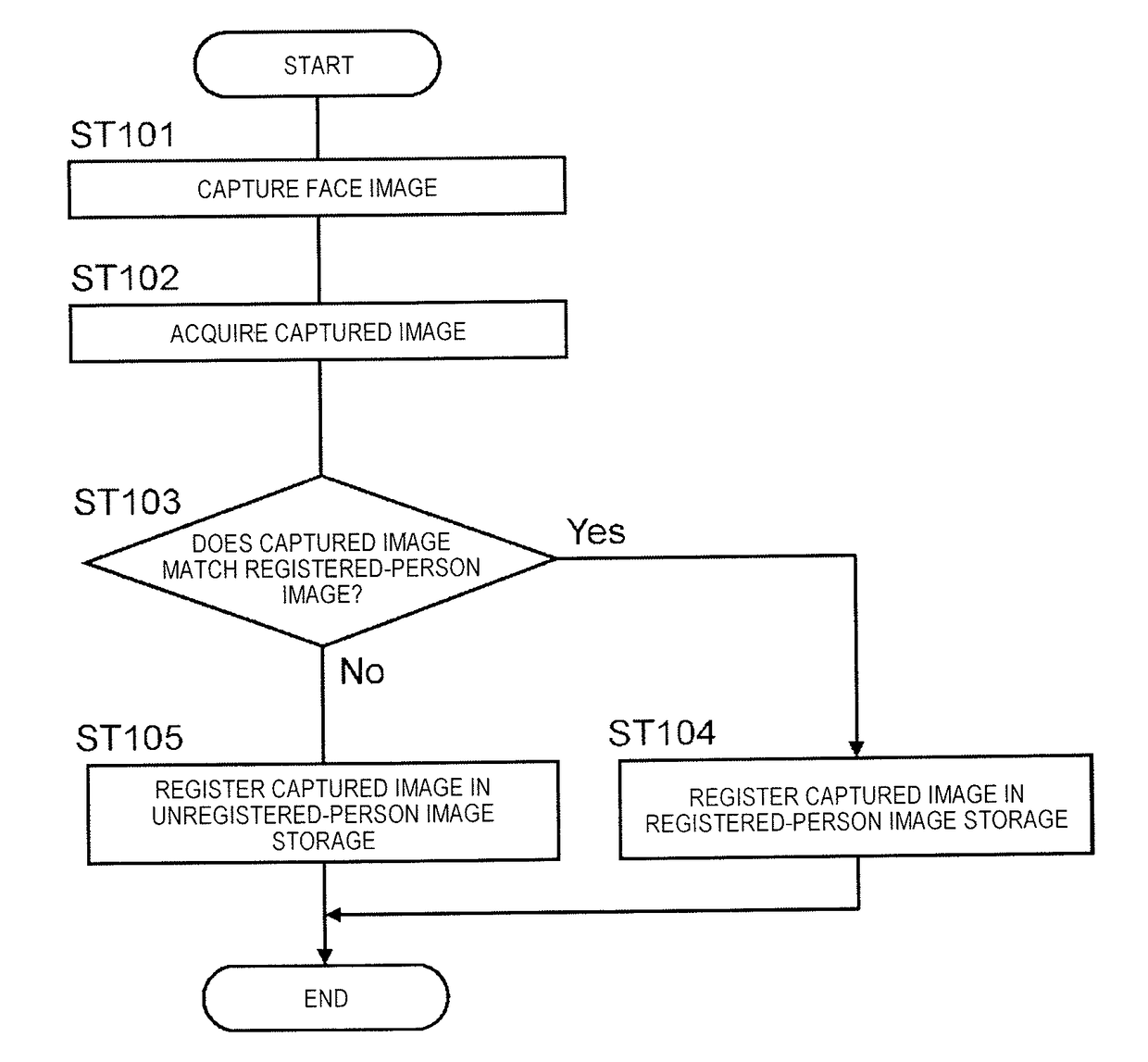

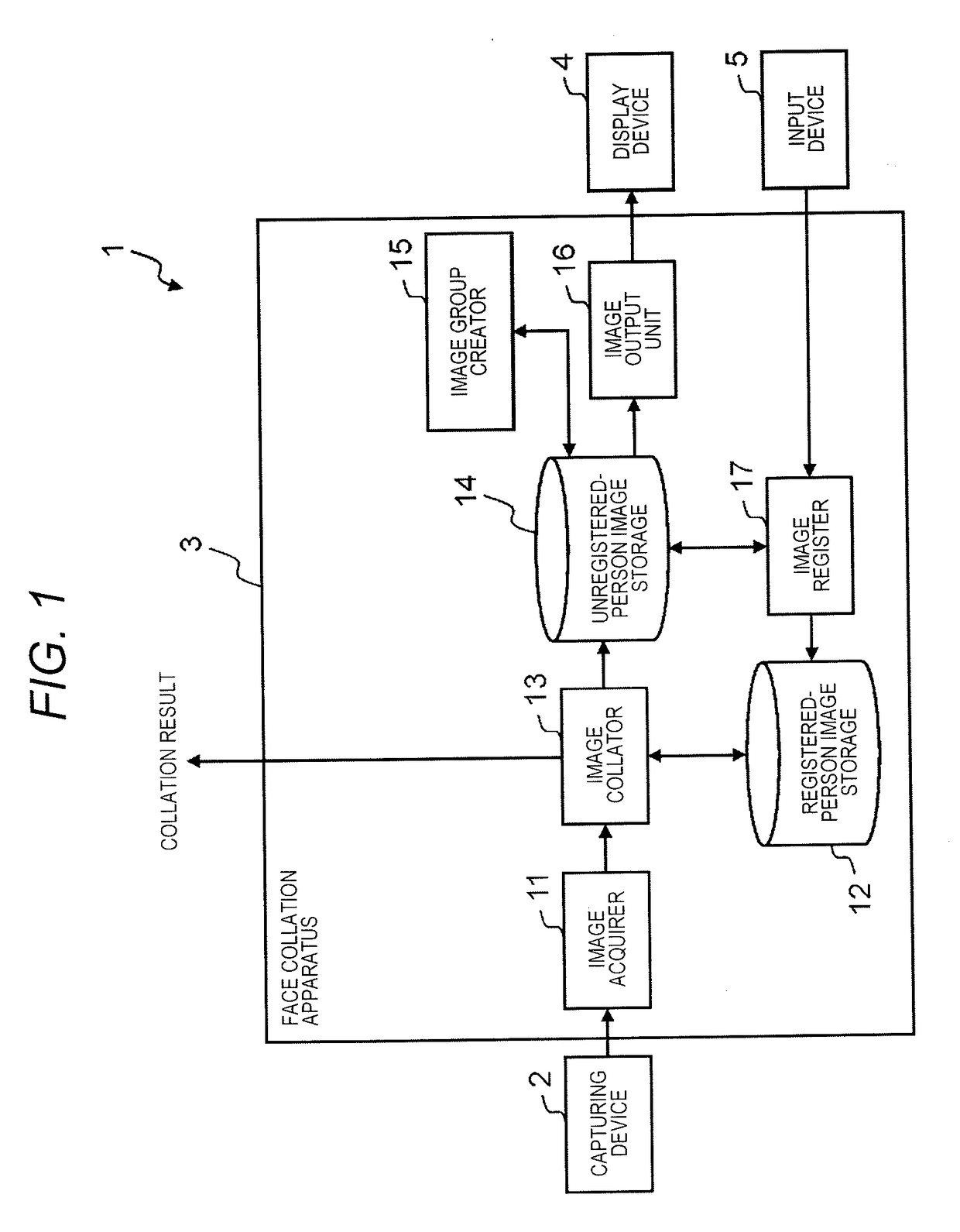

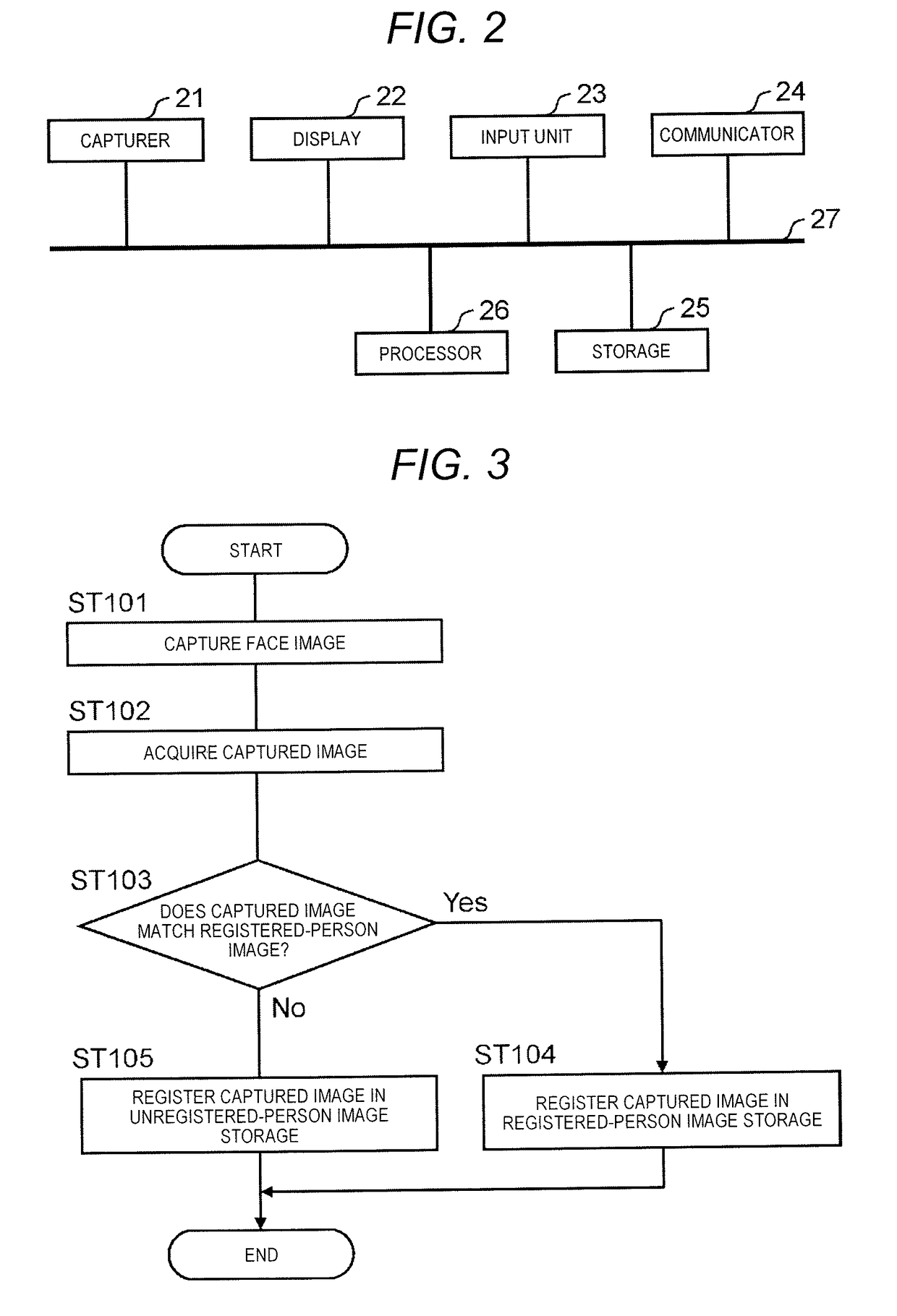

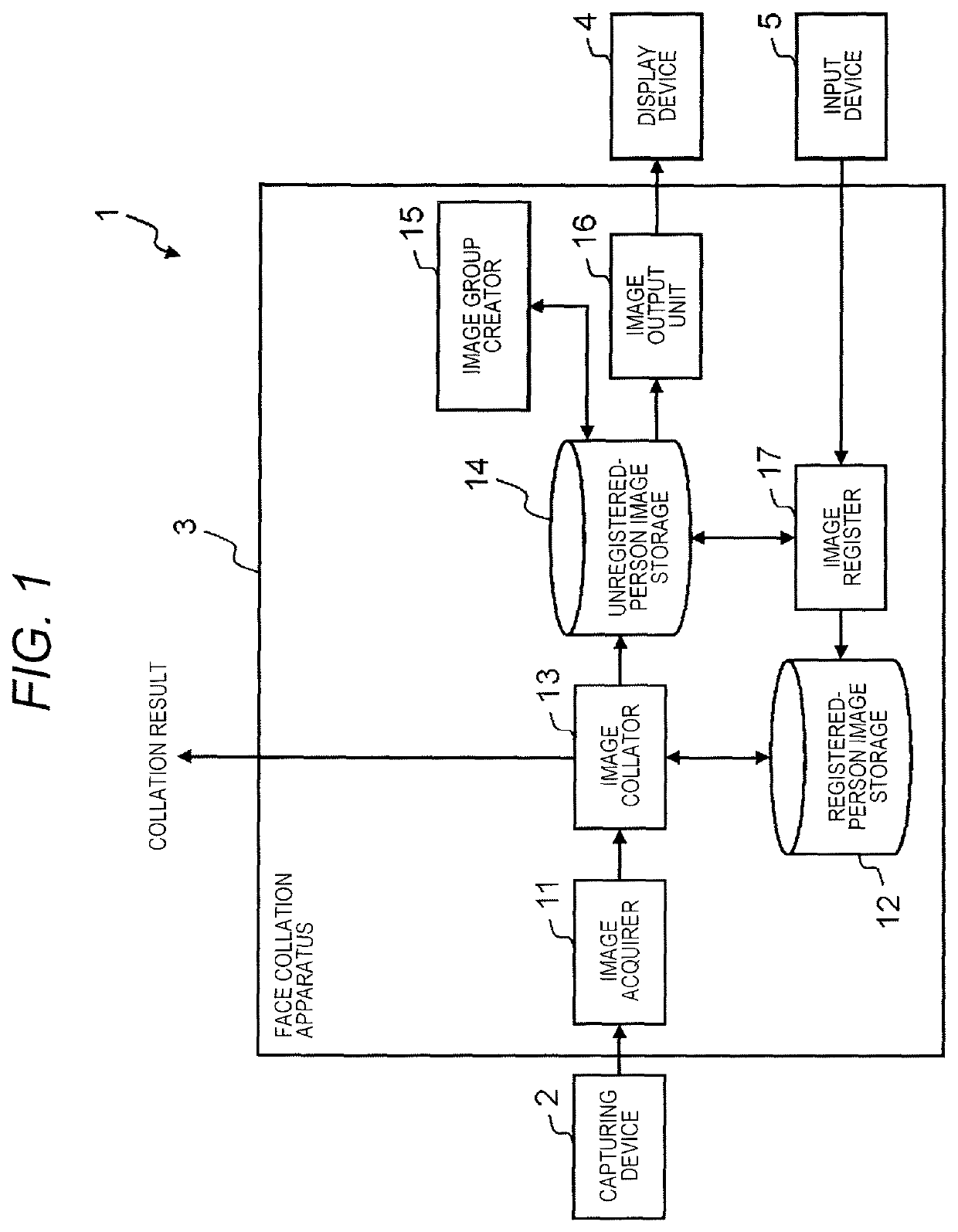

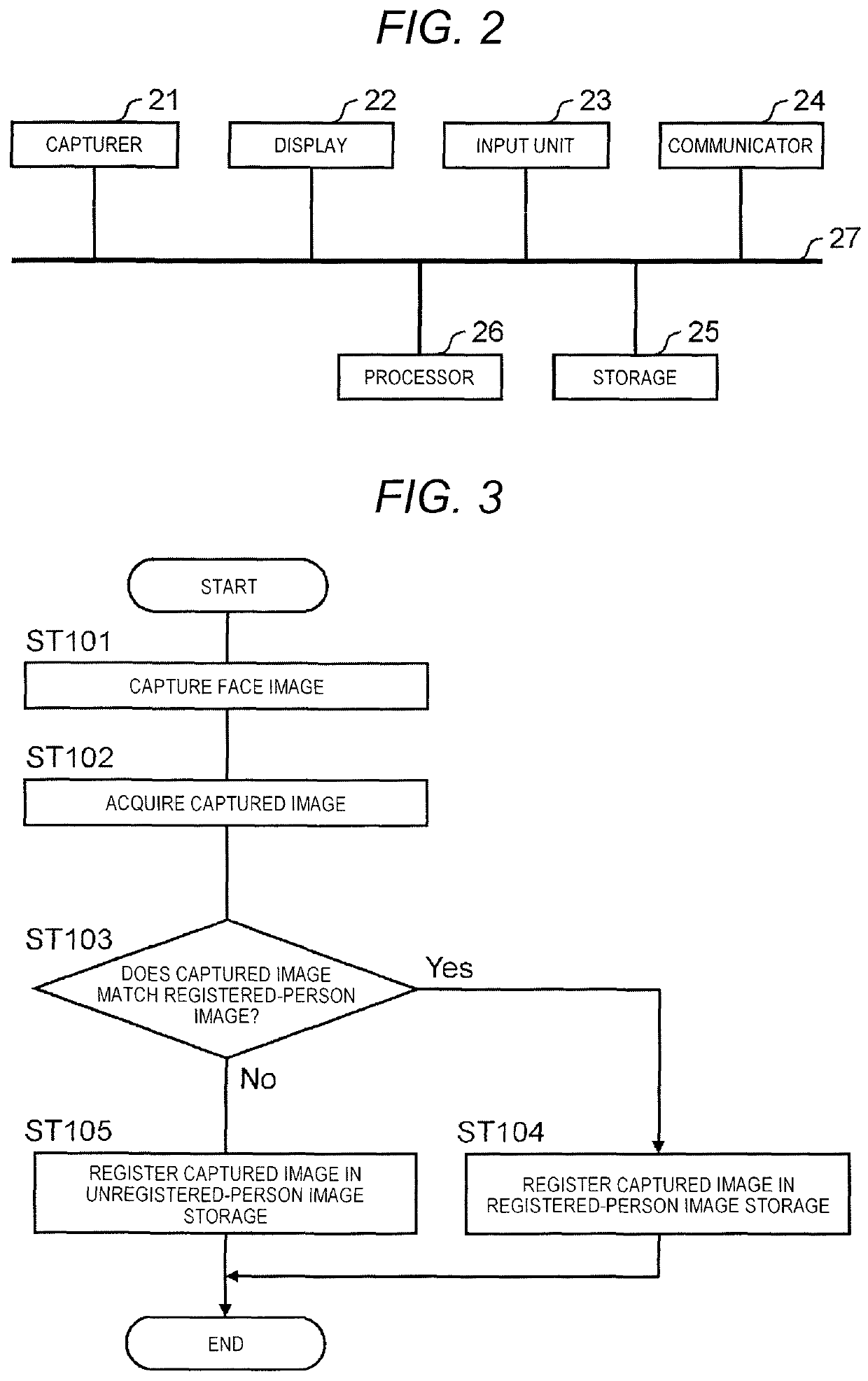

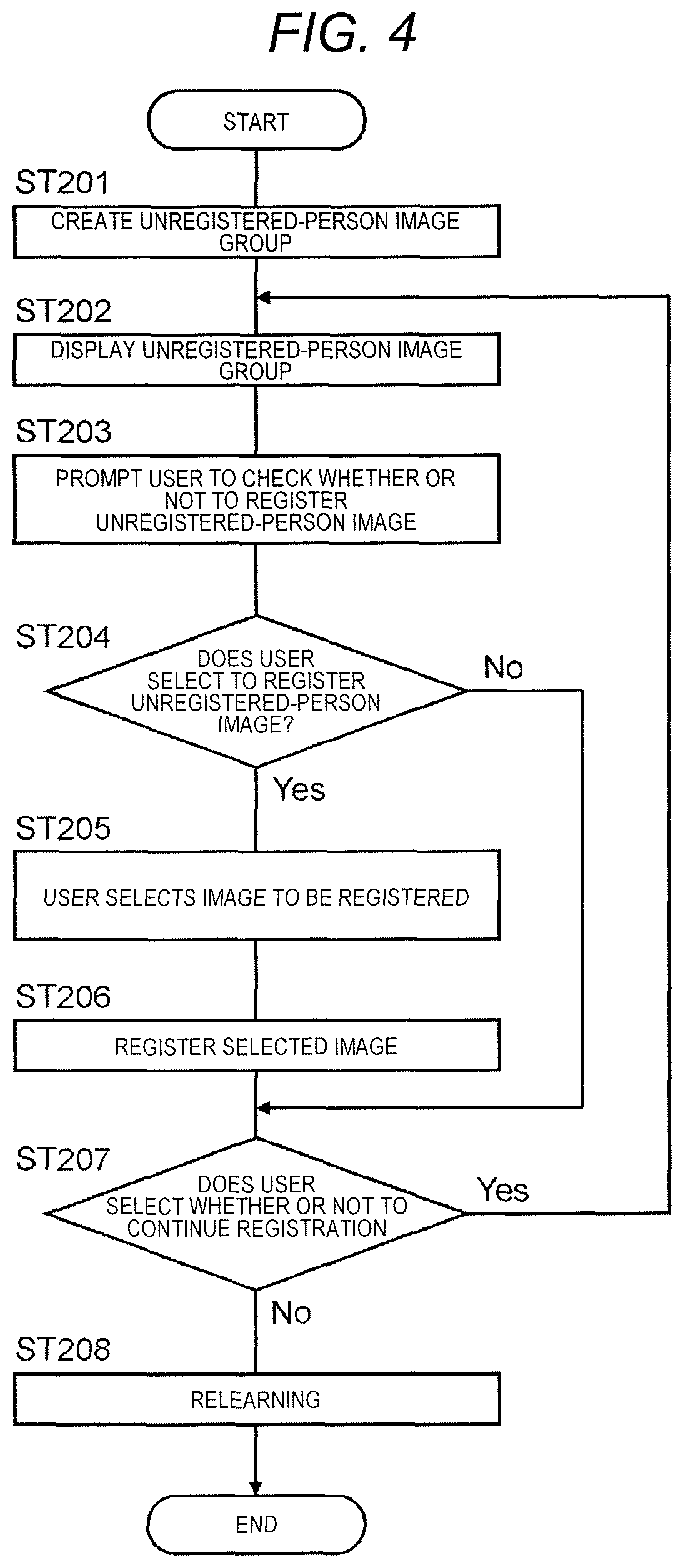

Face collation device, face collation system comprising same, and face collation method

ActiveUS20170357845A1High precisionImprove finishing accuracyStill image data retrievalImage enhancementDisplay deviceComputer science

To improve precision in collation processes or create a database of collation images by registering at least a part of captured images not matching a previously registered face image, as a collation face image, a face collation apparatus includes an image acquirer that acquires captured face images captured by a capturing device, a registered-person image storage that stores registered-person images that are previously registered face images, an image collator that collates the captured images with the registered-person images, an unregistered-person image storage that stores the captured images that do not match the registered-person images, an image output that outputs at least one of the unregistered-person images stored in the unregistered-person image storage to a display device, and an image register, selected to be registered by a user, that registers the unregistered-person image, among the unregistered-person images output to the display device, as a registered-person image in the registered-person image storage.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Polishing apparatus

InactiveUS20050227592A1Easy to replaceThe curvature of a lens more accuratelyOptical surface grinding machinesGrinding feed controlEngineeringFluid supply

A polishing apparatus includes a polishing jig. The polishing jig includes an elastic balloon member, a fixture, and a fluid supply portion. The fixture airtightly closes the rear opening portion of the balloon member. The fluid supply portion supplies a fluid into a space formed by the fixture and balloon member. The balloon member has a cup shape constructed by a dome portion and a cylinder portion extending backward from the outer periphery of the dome portion. The fixture fixes the opening portion of the cylinder portion of the balloon member.

Owner:HOYA CORP

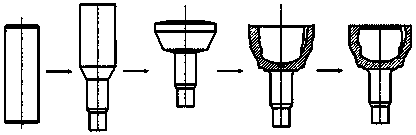

Cold forging finishing punch for inner cavities of finish-forge pieces of outer spherical cages

InactiveCN103447445AImprove pass rateSimple structureForging/hammering/pressing machinesRubber ringForge

The invention discloses a cold forging finishing punch for inner cavities of finish-forge pieces of outer spherical cages. The cold forging finishing punch comprises at least three split punches and a middle core rod. Each single split punch comprises a punch squeezing portion, a punch base, a punch rod and a punch guide block from top to bottom, the shape of each punch squeezing portion is matched with that of a cavity of a spherical channel, a combination of the punch bases is cylindrical after all the split punches are combined with one another, at least one annular groove is formed in the cylindrical combination of the punch bases, a rubber ring is arranged in each annular groove, a cylindrical packing block is arranged on the lower portion of the middle core rod, a high-performance spring ring is arranged on the periphery of the pressure packing block and is positioned on the lower portions of the punch guide blocks, a transition portion which is in the shape of a circular truncated cone is arranged between each punch squeezing portion and the corresponding punch base, and the head of the middle core rod is tapered. The cold forging finishing punch has the advantages of simple structure, simplicity in operation and high finishing precision, qualified rate of finished products and production efficiency.

Owner:JIANGSU HAIYU MACHINERY

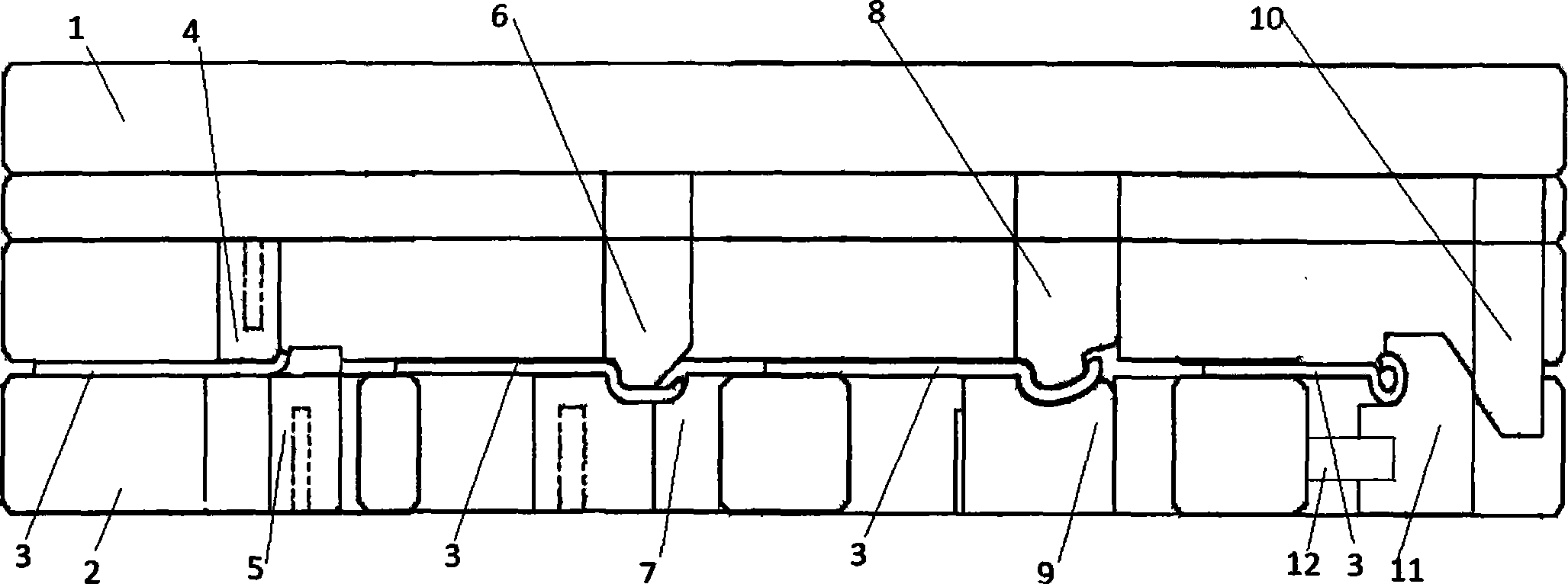

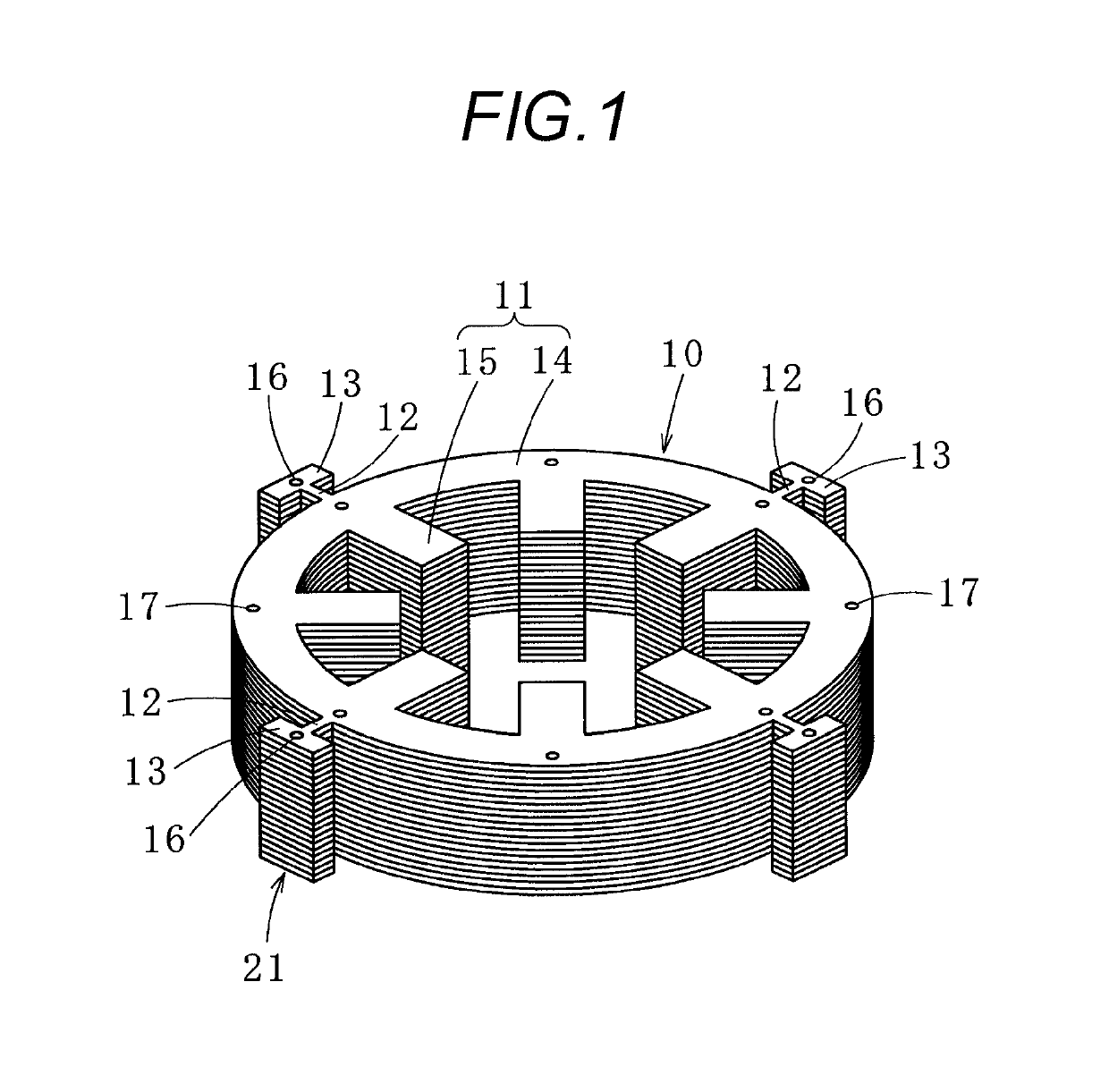

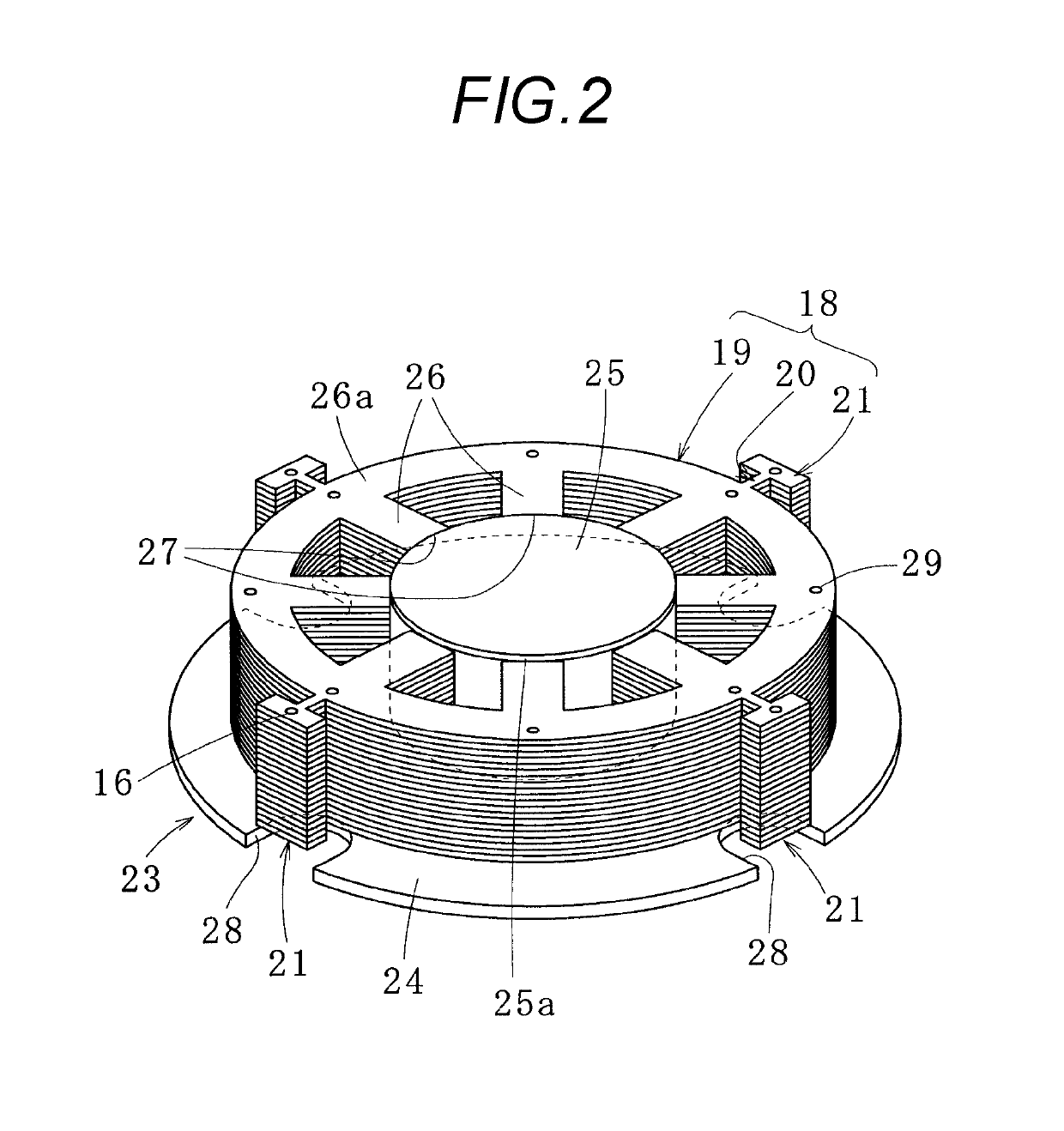

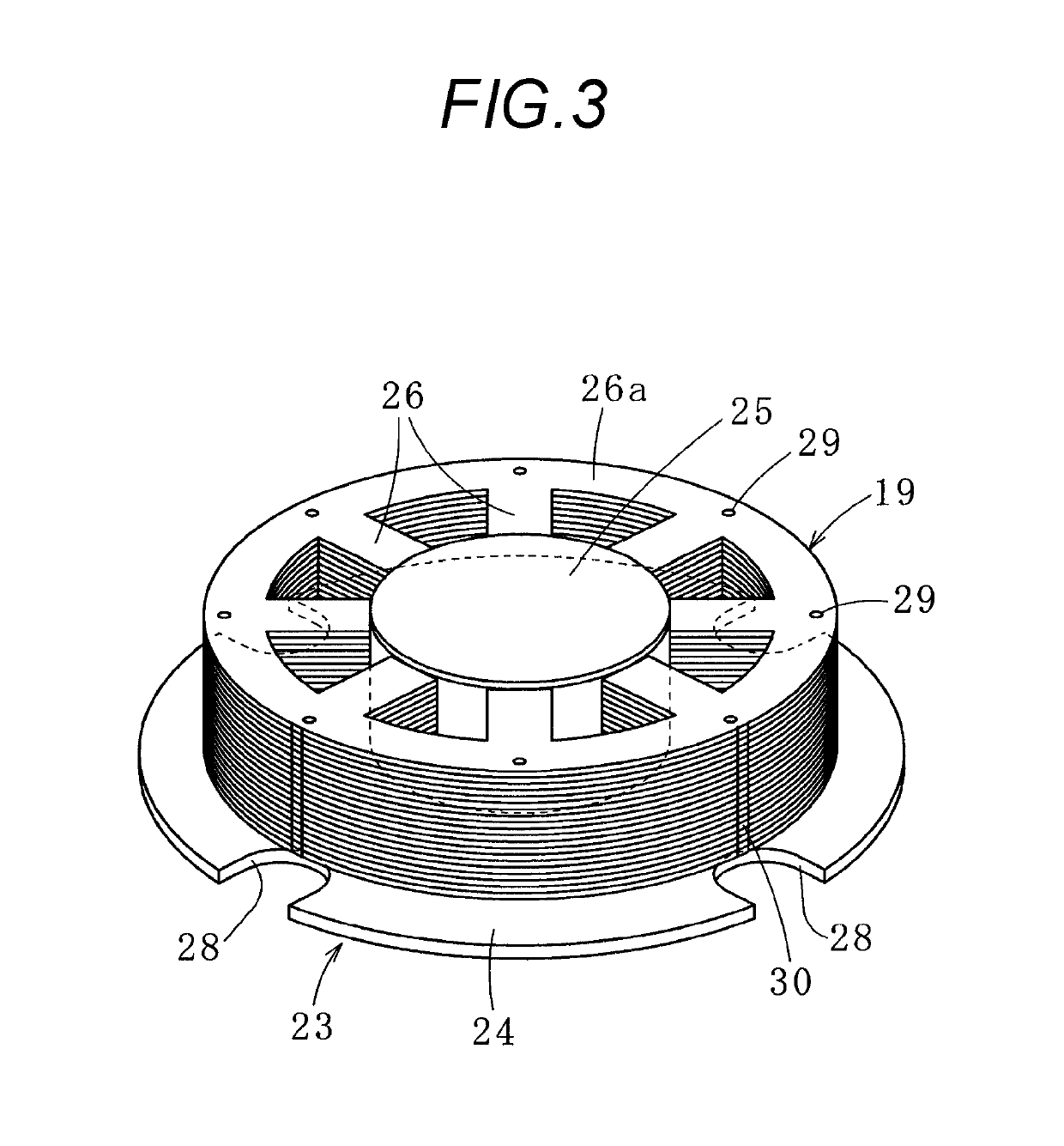

Method for manufacturing laminated core

ActiveUS10418886B2Avoid deformationEasy to handleManufacturing stator/rotor bodiesEngineeringMechanical engineering

Owner:MITSUI HIGH TEC INC

Light amount adjustment apparatus and image pickup apparatus

InactiveUS20080175585A1Avoid playingStabilization of attaching stateMagnetic circuit rotating partsShuttersCircular discEngineering

Disclosed herein is a light amount adjustment apparatus, including: a light amount adjustment member; a rotatable magnet formed in a disk shape; a driving arm configured to be pivoted by rotation of the magnet to operate the light amount adjustment member; a core having a pair of confronting portions positioned so as to sandwich the magnet from an outer circumference side and a connecting portion configured to connect end portions of the confronting portions to each other; a coil through which one of the portions of the core extends; and a base member having the core attached to the base member and supporting the magnet for rotation on the base member. The base member has a plurality of attaching projections provided at least at two places of the base member for attaching the core to the base member. The attaching projections have a small projection for fitting with the core.

Owner:SONY CORP

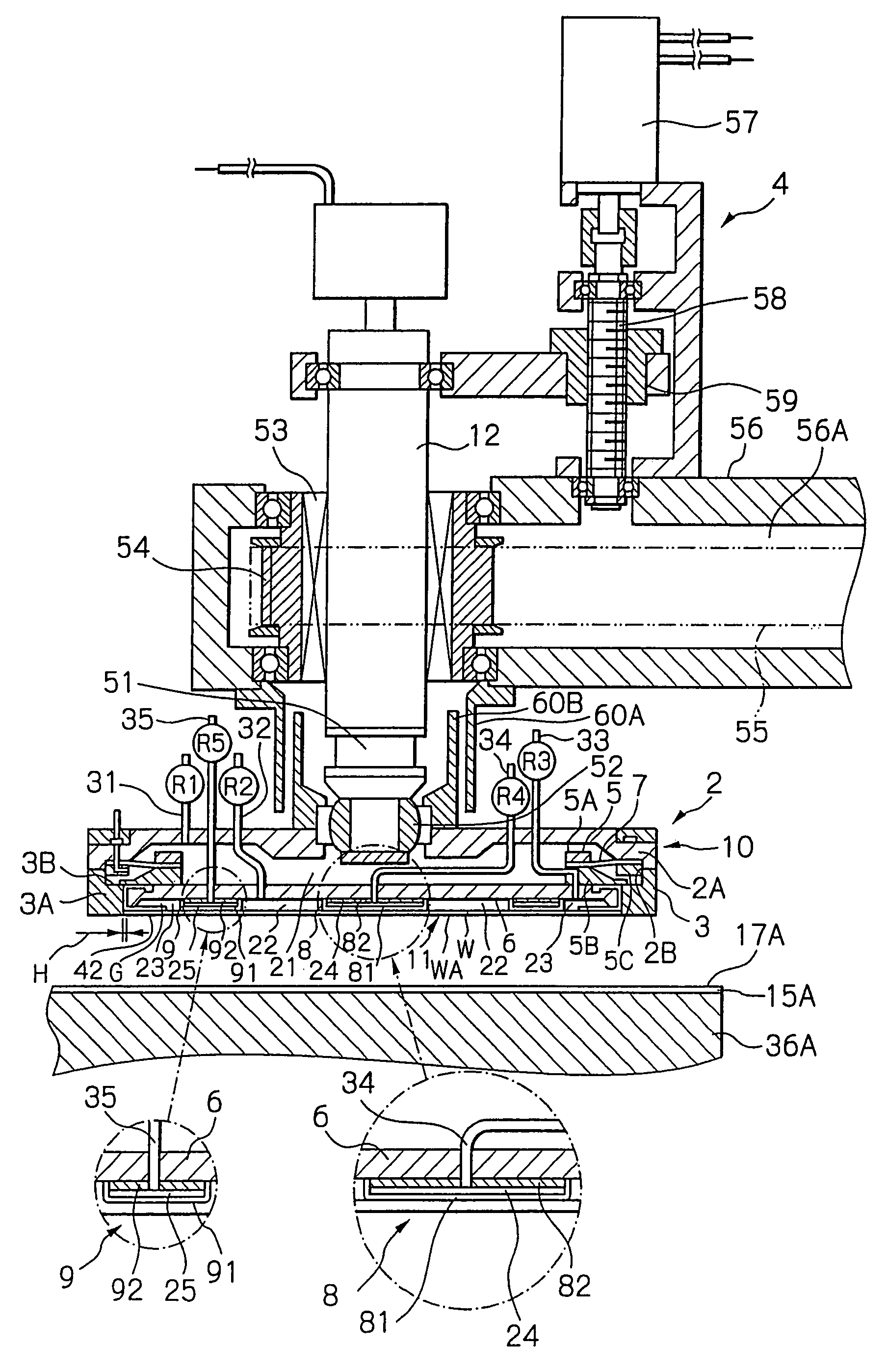

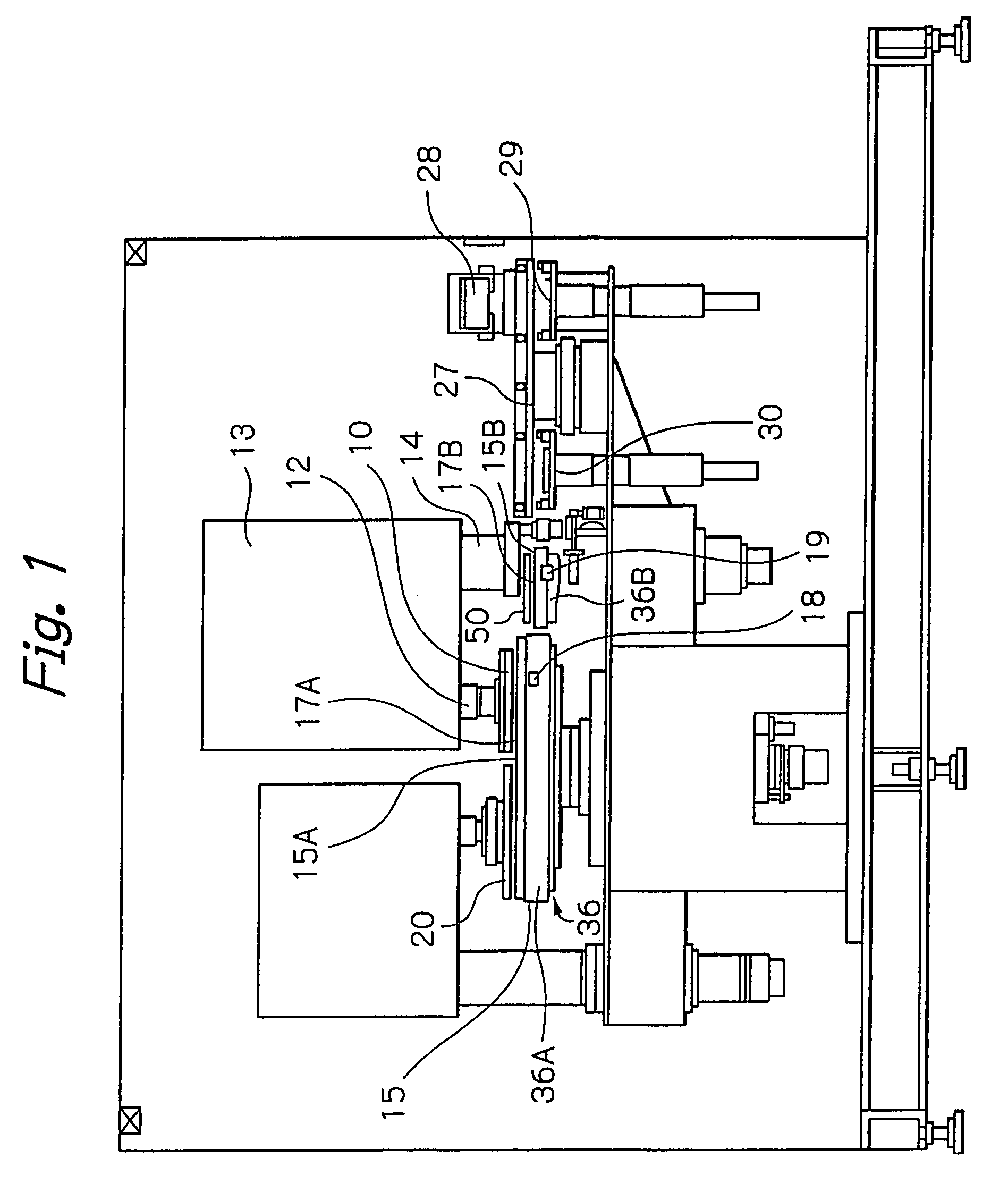

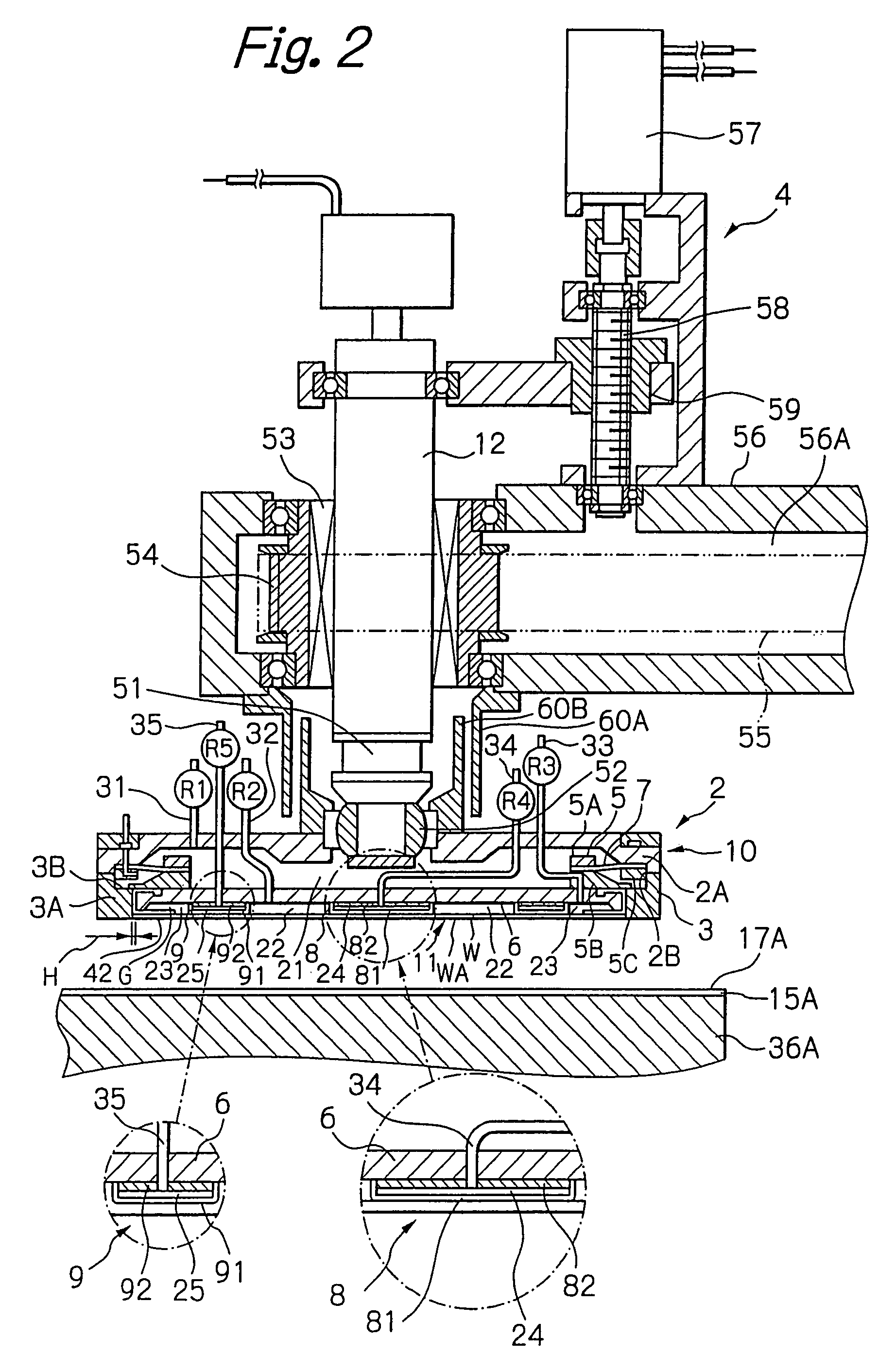

Polishing apparatus and polishing method

InactiveUS7448940B2Improve finishing accuracyIncrease polishing speedSemiconductor/solid-state device manufacturingLapping machinesEngineeringElectrical and Electronics engineering

A polishing apparatus comprises a first polishing table having a first polishing surface, a substrate carrier for holding a substrate and positioning the substrate so as to bring a surface of the substrate into contact with the first polishing surface, a pressing mechanism for pressing, against the first polishing surface, the surface of the substrate which has been brought into contact with the first polishing surface by the substrate carrier, a retainer ring mounted on the substrate carrier so as to surround the substrate which has been pressed against the first polishing surface by the pressing mechanism, and a retainer-ring-position-adjustment mechanism for adjustably positioning the retainer ring relative to the substrate, which has been pressed against the first polishing surface, in directions toward and away from the first polishing surface.

Owner:EBARA CORP

Grinding wheel for casting finish

InactiveCN102463509AReduce volumeFlexible operationEdge grinding machinesGrinding machine componentsEngineeringGrinding wheel

The invention relates to a grinding wheel for casting finish. The grinding wheel comprises a grinding wheel rod and a grinding wheel sheet, and is characterized in that: the grinding wheel rod has a step rod structure; the grinding wheel sheet is fixed to the small head end of the grinding wheel rod; and the large head end of the grinding wheel rod is connected with a motor. The grinding wheel has the advantages of small volume, flexible operation, convenience for use and high finishing accuracy.

Owner:朱菊香

Finish machining auxiliary device suitable for concave-convex lens and uniform in cutting component force

InactiveCN111906587AReduce deformationImprove finishing accuracyAutomatic control devicesFeeding apparatusPhysicsGrinding

The invention discloses a finish machining auxiliary device suitable for a concave-convex lens and uniform in cutting component force. The finish machining auxiliary device comprises a main box body,wherein a speed change cavity is arranged in the main box body; a right belt cavity extending upwards is arranged in the right side of the speed change cavity; a right screw extending rightwards intothe right belt cavity and extending leftwards into the speed change cavity is connected into the left end wall of the right belt cavity in a running fit mode; a right transmission bevel tooth cavity located in left side of right belt cavity is arranged in upper side of speed change cavity; and when the concave surface of the lens needs to be machined, the left speed change wheel just abuts againstthe speed change gear, so that the uniformity of the vertical component force during machining of the concave surface of the lens is realized, and the finish machining precision is improved. when theconvex surface of the lens needs to be machined, the change gear moves downwards, so that the rotating speed of the grinding rod is increased, the cutting force in the vertical direction is reduced,the vertical cutting component force generated on the arc-shaped lens in the machining process is uniform, and therefore deformation caused by uneven stress is reduced;.

Owner:缙云唐纳机械科技有限公司

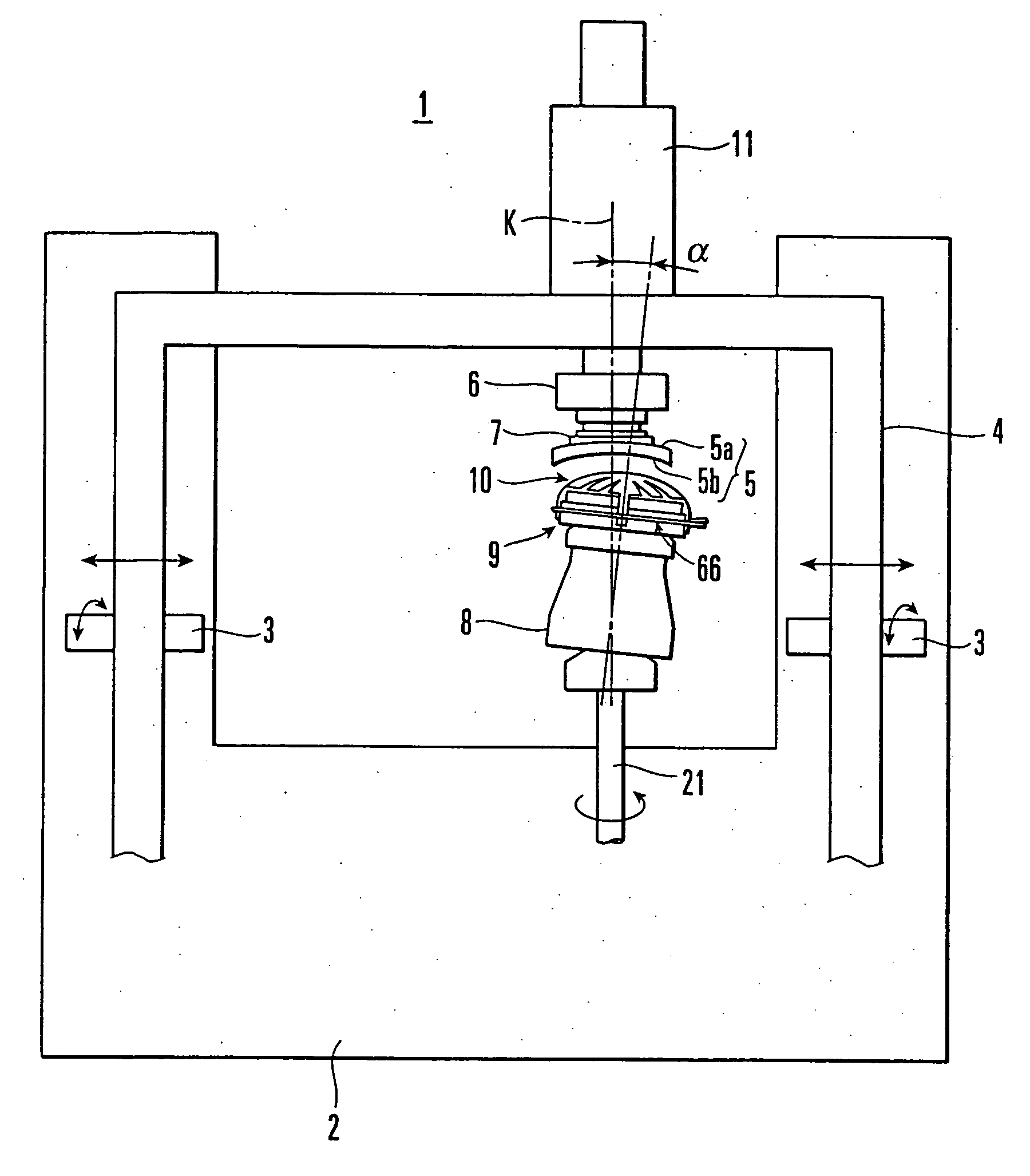

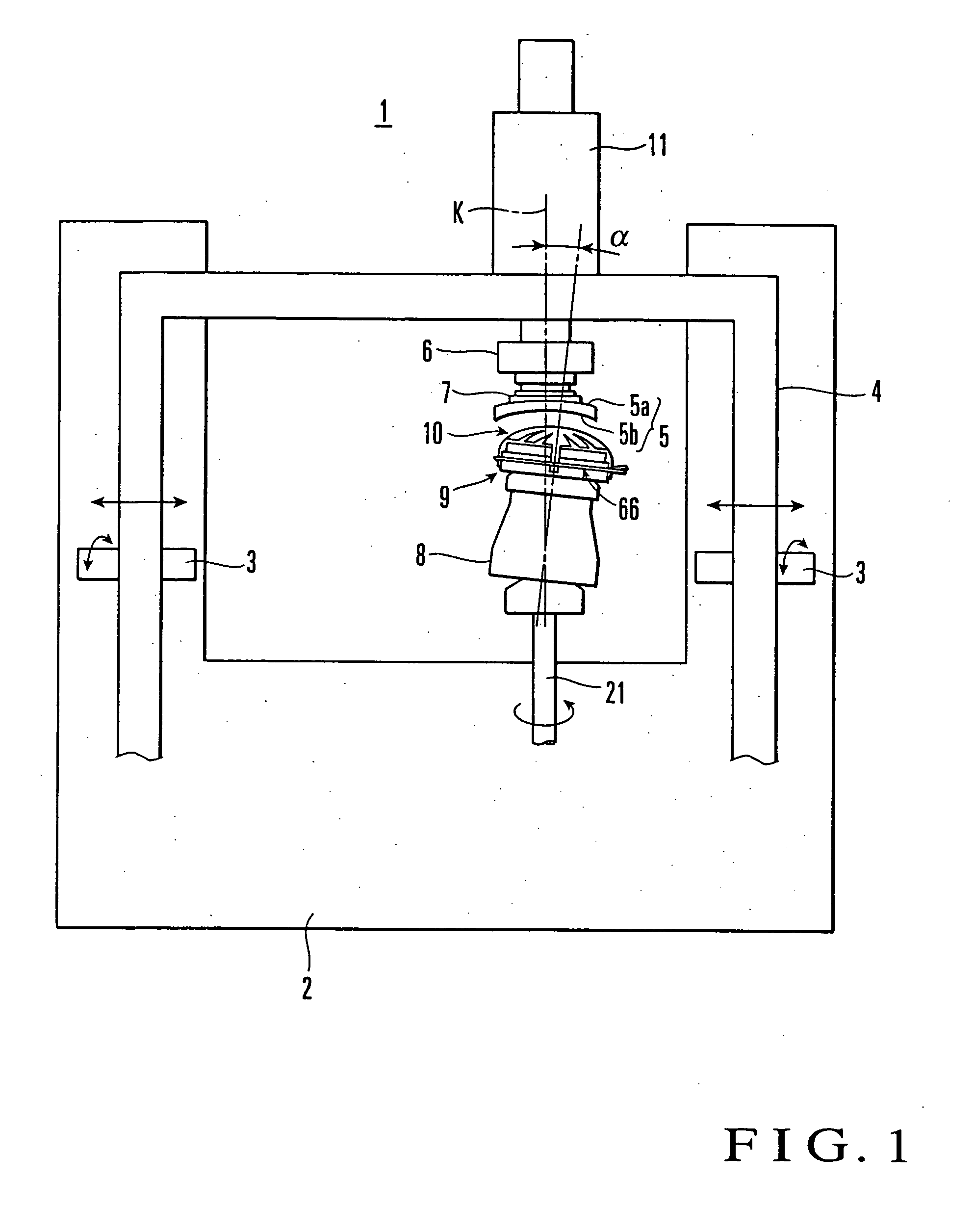

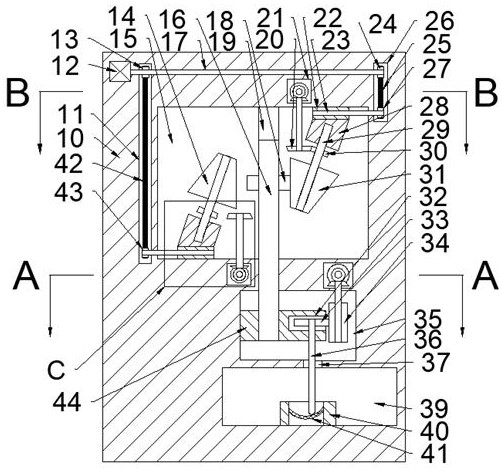

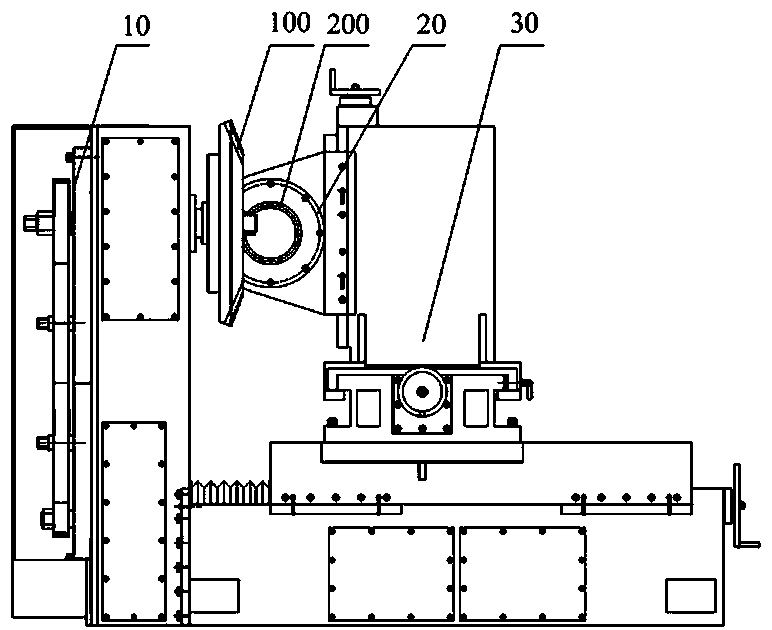

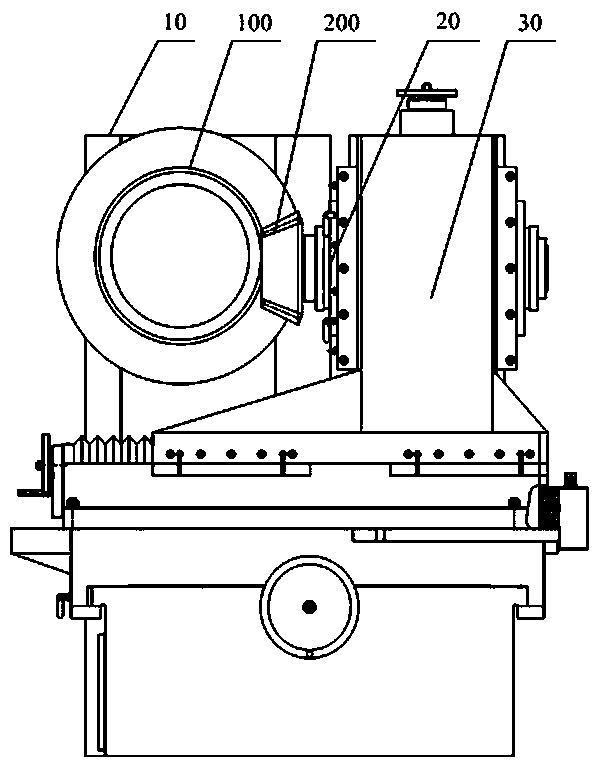

Forced kinematic chain bevel gear variable intersection angle offset roller mill

PendingCN109865900AImprove finishing accuracyImprove machining accuracyGear-cutting machinesGear teethGear wheelEngineering

The invention discloses a forced kinematic chain bevel gear variable intersection angle offset roller mill. The forced kinematic chain bevel gear variable intersection angle offset roller mill is usedfor finishing quenched machined spiral umbrellas and comprises a reduction hanging wheel device used for installing and driving the machined spiral umbrellas, a roller mill head used for installing roller-milled spiral bevel gears and an offset adjusting transmission device, wherein the offset adjusting transmission device is connected with the roller mill head and used for adjusting the roller-milled spiral bevel gears installed by the roller mill head in the horizontal direction and the vertical direction so as to enable the roller-milled spiral bevel gears to mesh with the machined spiralumbrellas and to enable the machined spiral bevel gears installed on the roller mill head and the machined spiral umbrellas installed on the reduction hanging wheel device to be mutually roller-milledunder the drive of a forced kinematic chain. According to the forced kinematic chain bevel gear variable intersection angle offset roller mill, the machining precision of the tooth-shaped tooth surface of a quenched gear is high, and the forced kinematic chain bevel gear variable intersection angle offset roller mill can be suitable for machining various bevel gears and is high in universality.

Owner:YIYANG KANGYI MACHINERY DEV

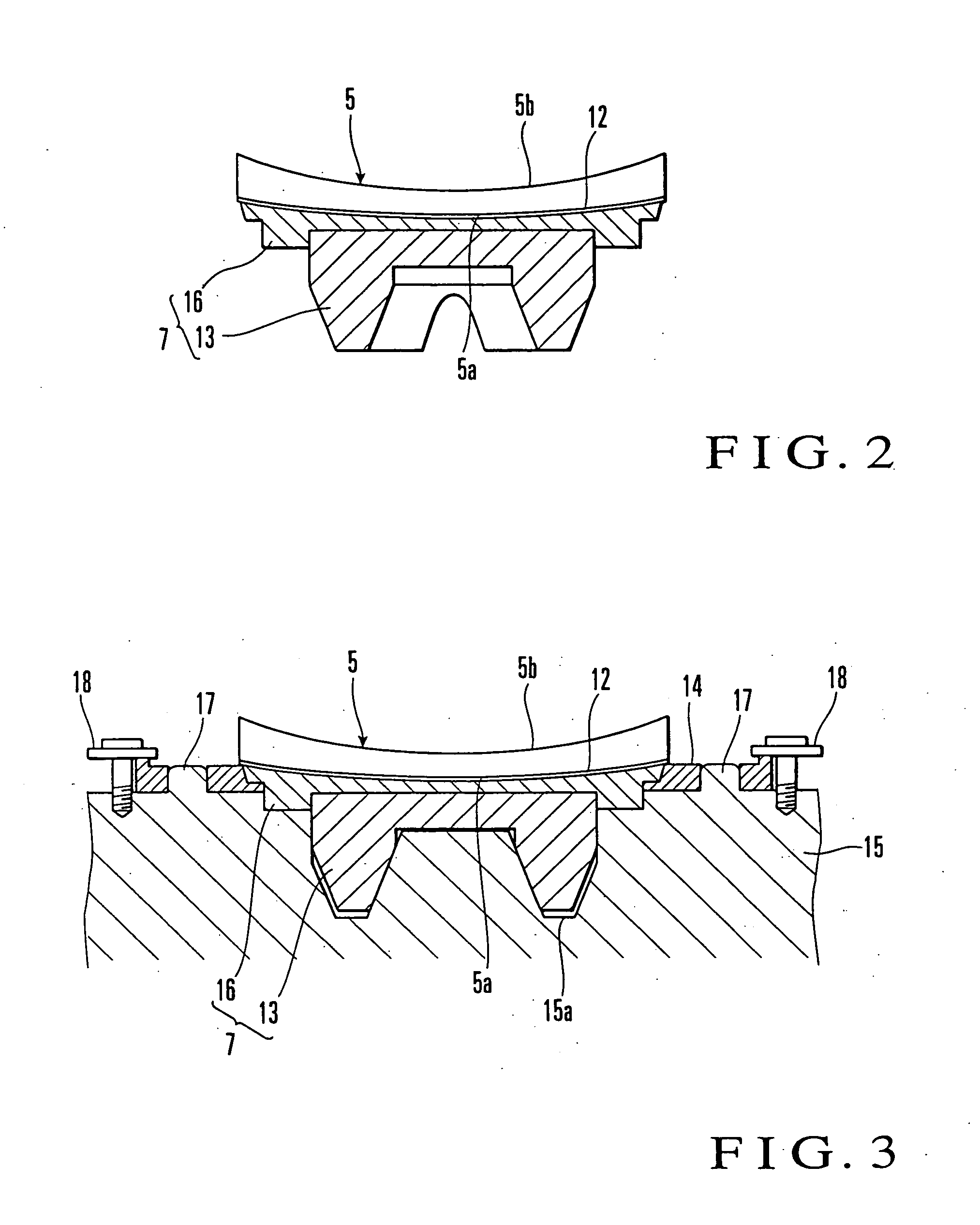

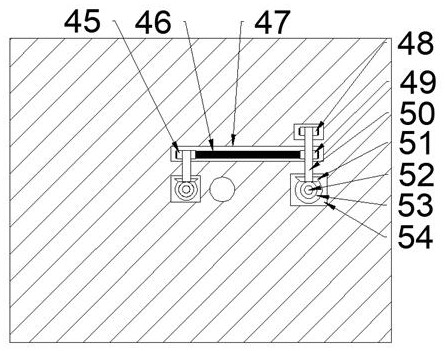

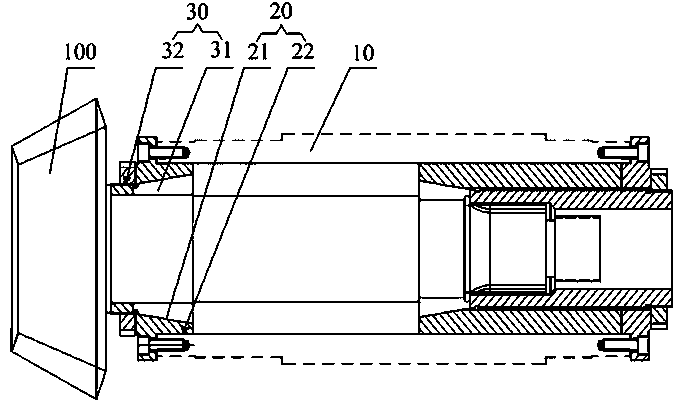

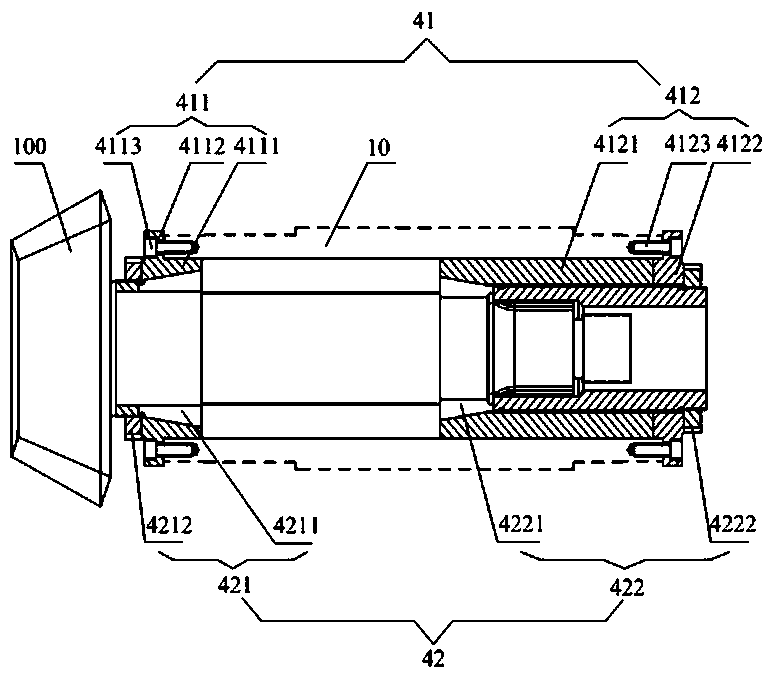

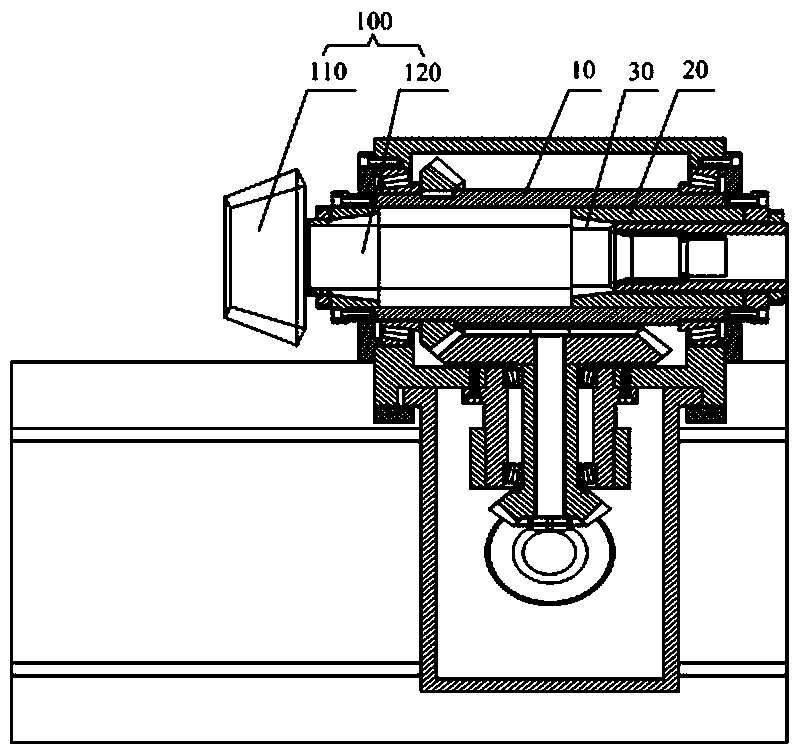

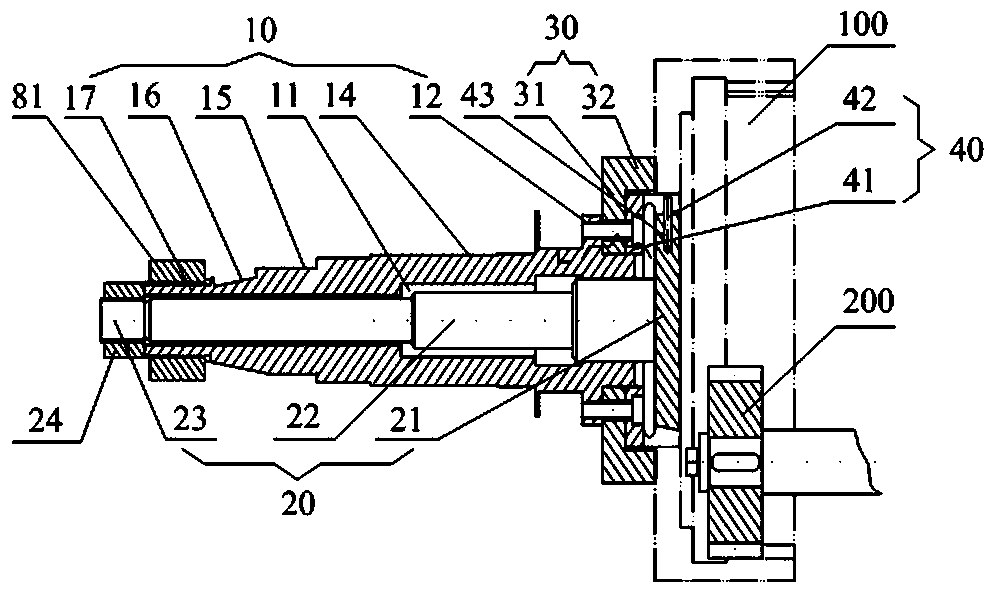

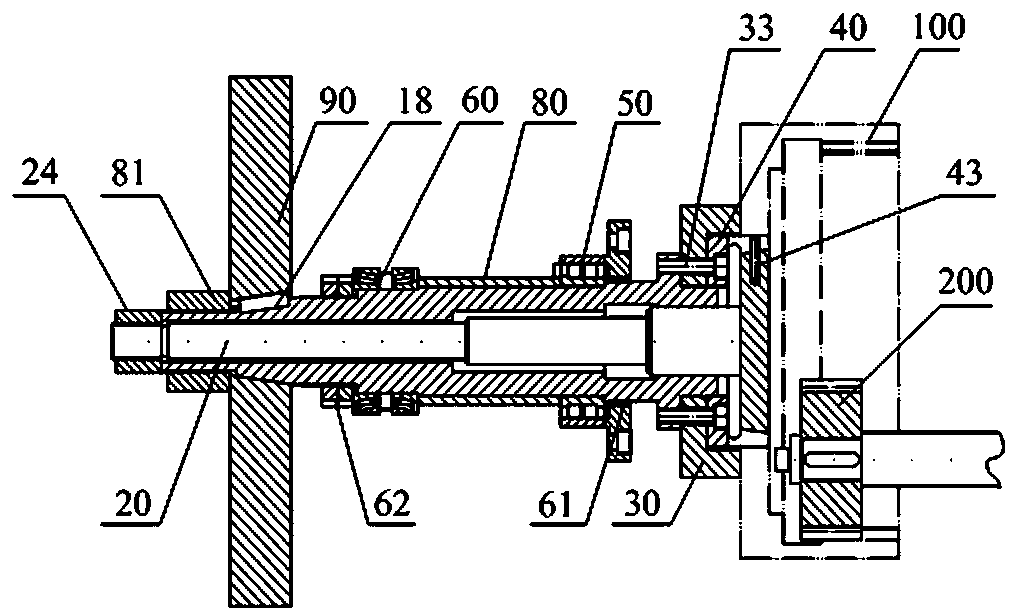

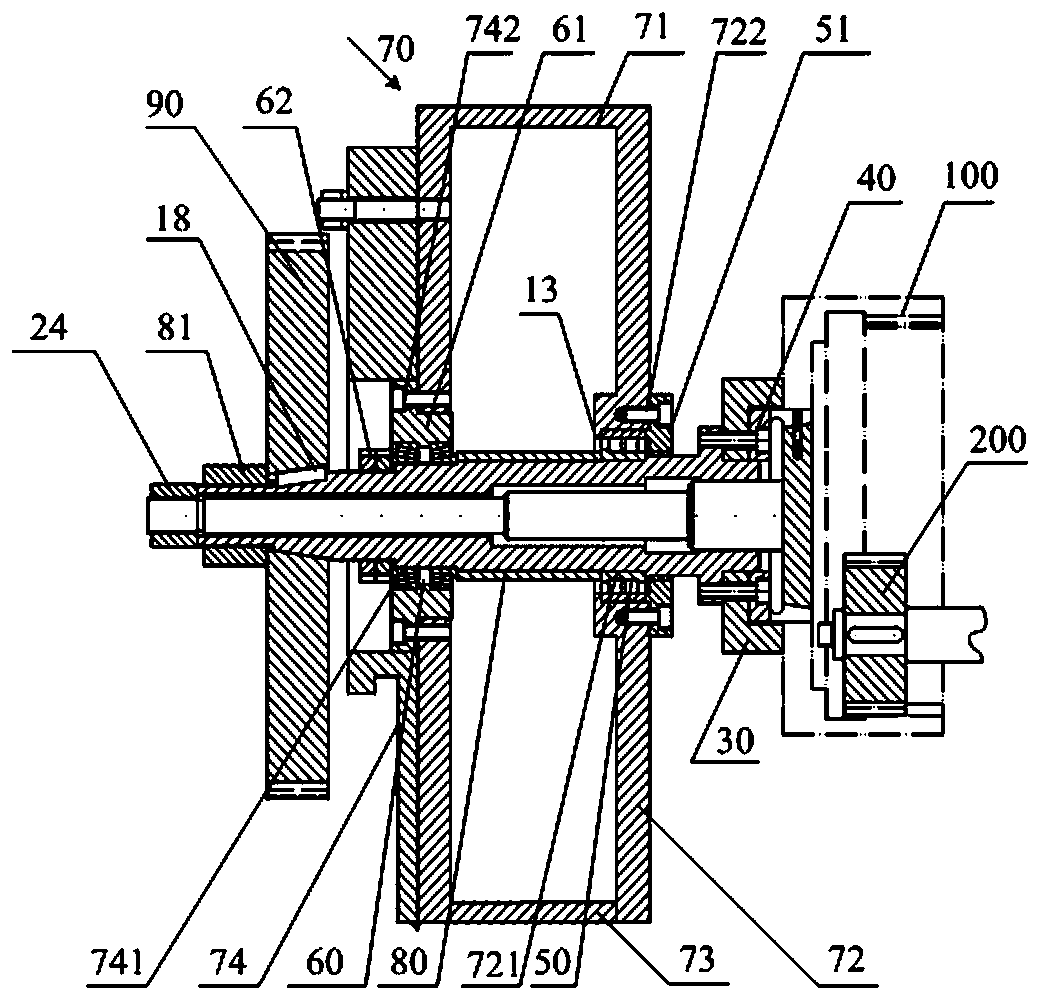

Forced kinematic chain bevel gear variable-intersection-angle offset barreling machine barreling wheel clamp

PendingCN109834342AImprove machining accuracyImprove general performanceGear-cutting machinesGear teethLocking mechanismKinematic chain

The invention discloses a forced kinematic chain bevel gear variable-intersection-angle offset barreling machine barreling wheel clamp, which is used for mounting a barreling wheel and driving the mounted barreling wheel to prompt the mounted barreling wheel to conduct barreling together with a machined spiral bevel engaged with the barreling wheel. The forced kinematic chain bevel gear variable-intersection-angle offset barreling machine barreling wheel clamp comprises a transmission sleeve, a taper sleeve, an elastic sleeve and axial movement locking mechanisms, wherein the two ends of the transmission sleeve are open, the transmission sleeve is in a hollow cylinder shape and is used for mounting a transmission gear, the transmission sleeve sleeves the taper sleeve, the elastic sleeve isarranged between the taper sleeve and a mounting handle part and used for radially expanding the barreling wheel, and the axial movement locking mechanisms are arranged at the two ends of the transmission sleeve and used for tensioning and centering the elastic sleeve to limit axial movement of the barreling wheel. The forced kinematic chain bevel gear variable-intersection-angle offset barrelingmachine barreling wheel clamp has the high precision of machining tooth profiles and tooth surfaces of quenched gears, can adapt to machining of the various bevel gears, and is high in universality.

Owner:YIYANG KANGYI MACHINERY DEV

Face collation device, face collation system comprising same, and face collation method

ActiveUS10558846B2High precisionImprove finishing accuracyStill image data retrievalImage enhancementPattern recognitionComputer graphics (images)

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

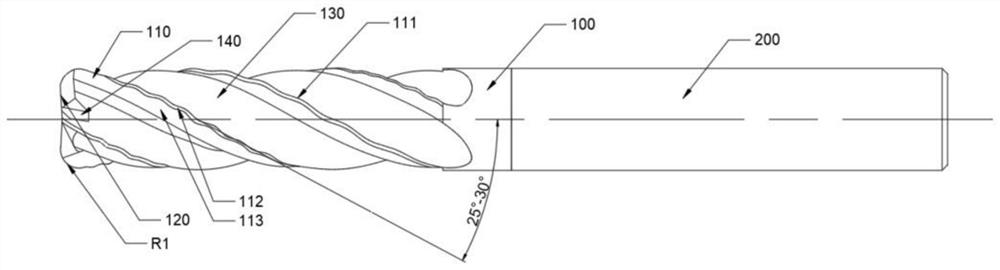

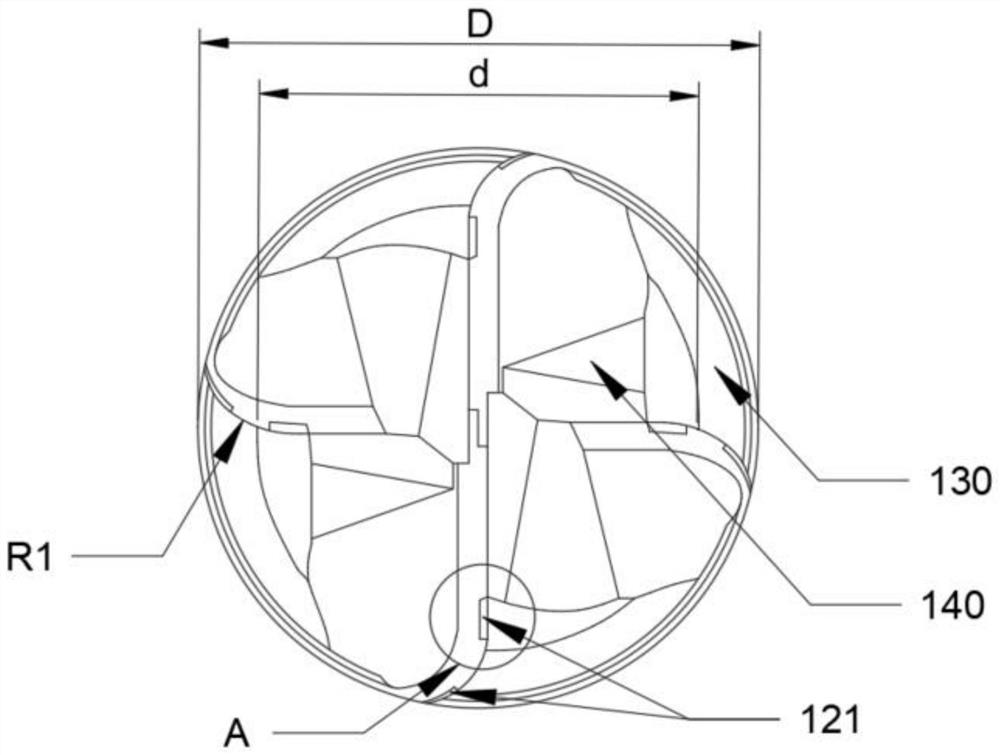

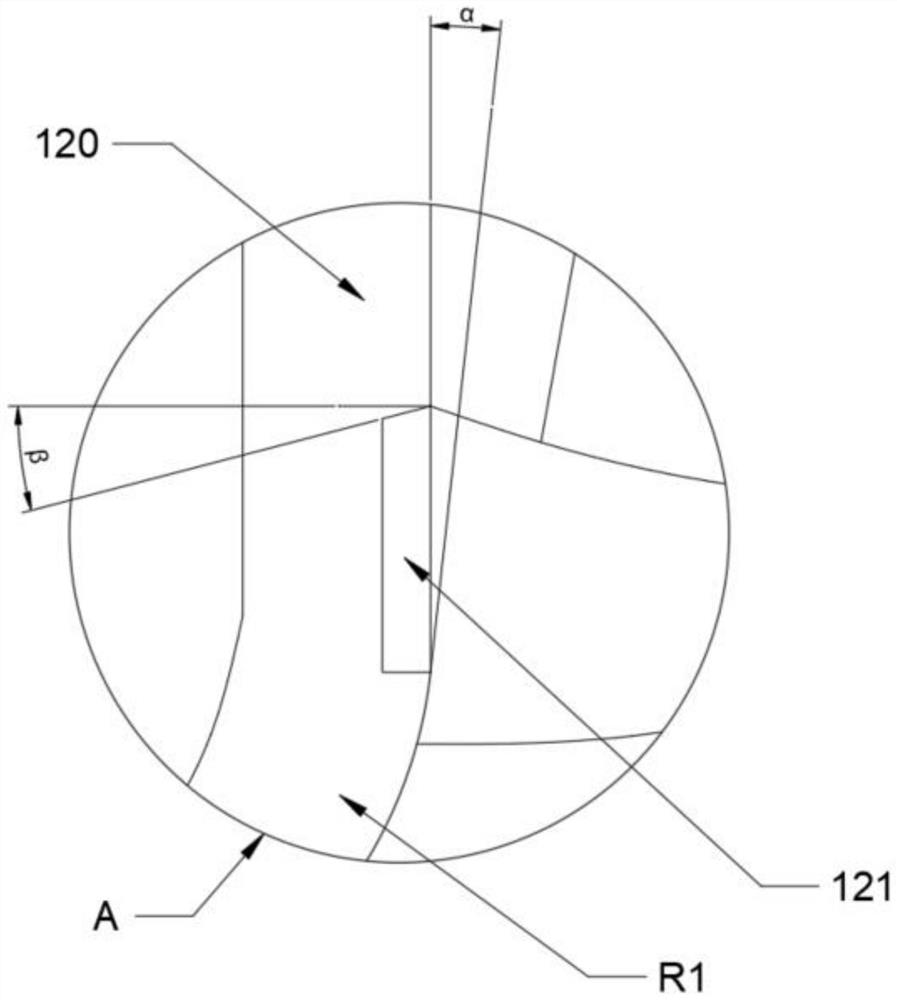

Corrugated spiral milling cutter for precise machining of aerospace material

PendingCN113649633AIncrease contact areaImprove surface roughnessMilling cuttersWorkpiecesFiberCarbon fibers

The invention provides a corrugated spiral milling cutter for precise machining of an aerospace material, which comprises a blade part for cutting and a handle part for clamping, wherein the blade part comprises peripheral blades and end blades, chip discharging grooves are uniformly distributed between the peripheral blades, chip containing grooves are uniformly distributed between the end blades, each chip containing groove is communicated with one chip discharging groove, and the cutting edge of each peripheral blade is in an circular arc wave shape. The corrugated spiral milling cutter for precise machining of the aerospace material has the following beneficial effects that through the circular-arc-wave-shaped cutting edges of the peripheral edges, the technical problem that when an existing cutter is used for precise machining of the aerospace materials, the roughness and the machining precision are poor is solved; and the corrugated spiral milling cutter for precise machining of the aerospace material can achieve precise machining of materials such as aerospace composite materials, carbon fiber materials, titanium alloys and nickel-based alloys.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

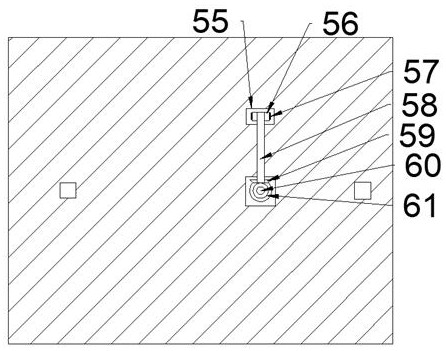

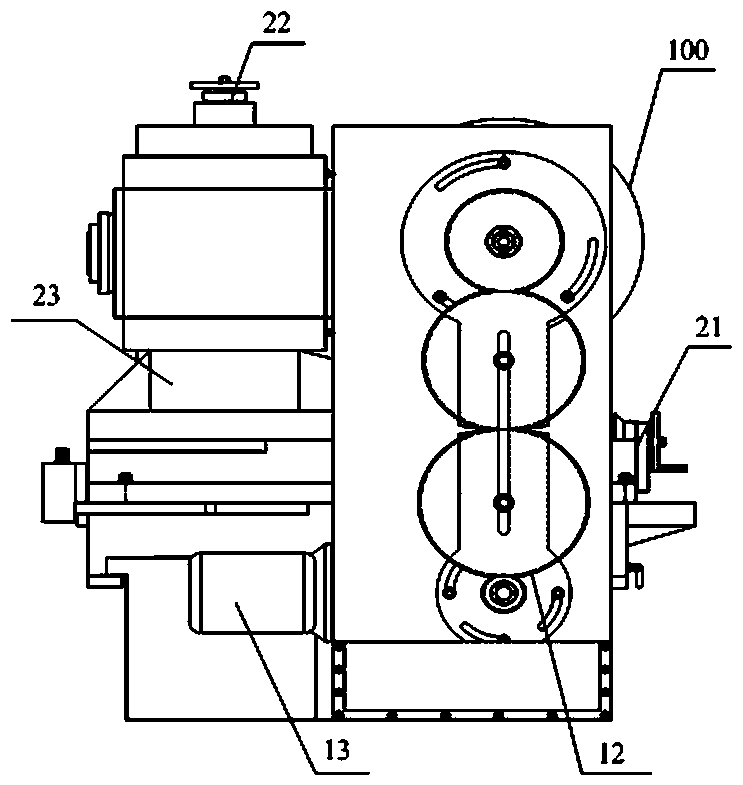

Deceleration change gear mechanism of forced motion chain bevel gear variable-angle offset roller mill

PendingCN109807406AImprove machining accuracyVersatileToothed gearingsGearing detailsKinematic chainEngineering

The invention discloses a deceleration change gear mechanism of a forced motion chain bevel gear variable-angle offset roller mill. The deceleration change gear mechanism of the forced motion chain bevel gear variable-angle offset roller mill comprises a workpiece clamp for installing a processed spiral umbrella, a transmission device connected with the workpiece clamp for transmitting torque to the processed spiral umbrella installed by the workpiece clamp, and a power output device connected with the transmission device for providing torque to the transmission device; and the transmission device comprises a spiral bevel gear shaft, a spiral bevel gear meshed with the spiral bevel gear shaft, a transmission shaft sleeved in the spiral bevel gear, a straight tooth transmission component connected with the transmission shaft, and a main shaft connected with the straight tooth transmission component for installing the workpiece clamp. The deceleration change gear mechanism of the forcedmotion chain bevel gear variable-angle offset roller mill provided by the invention has high processing precision on the tooth profile tooth surface of the quenched gear, is suitable for processing various processed spiral umbrellas, and has strong universality.

Owner:YIYANG KANGYI MACHINERY DEV

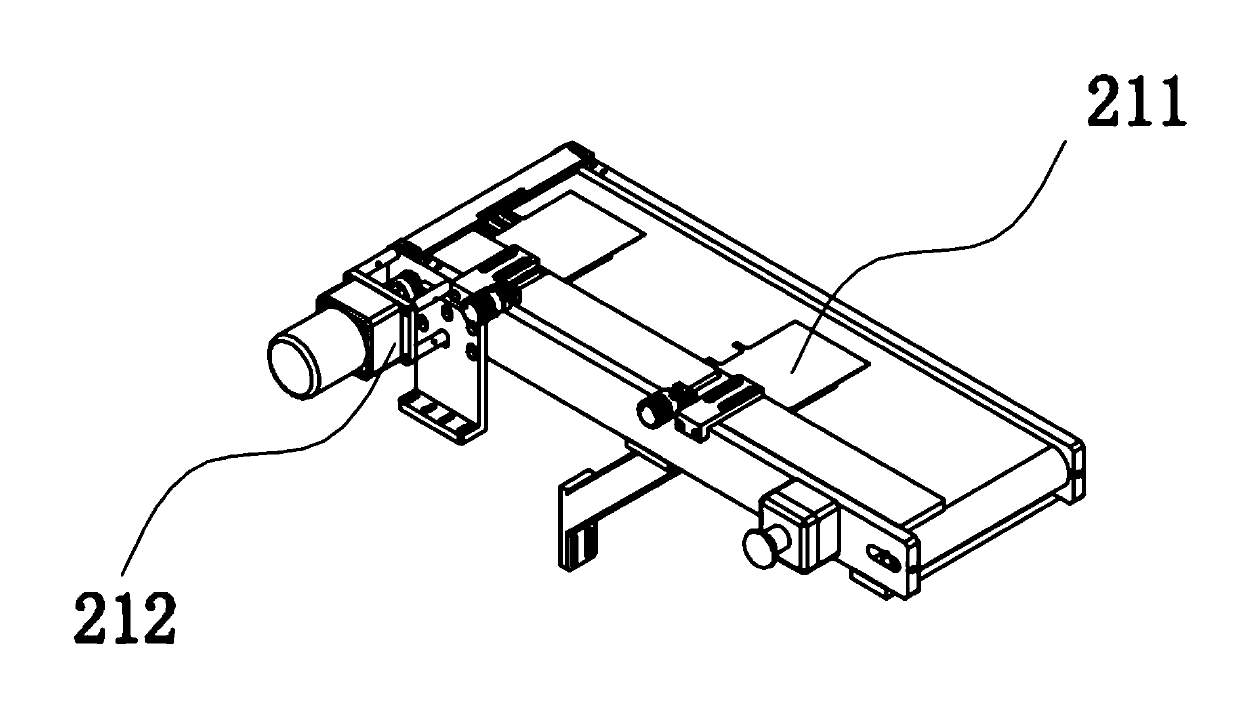

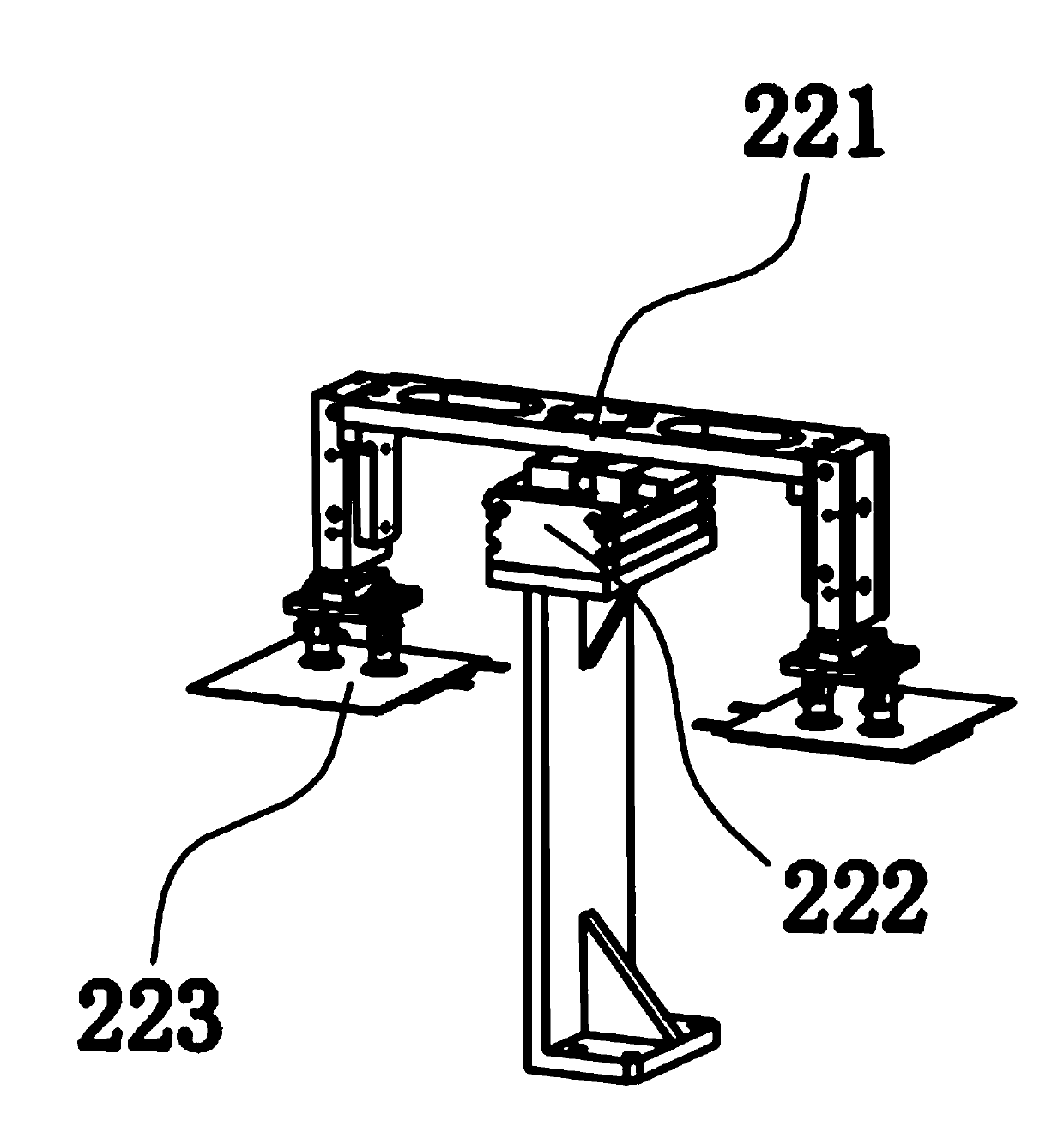

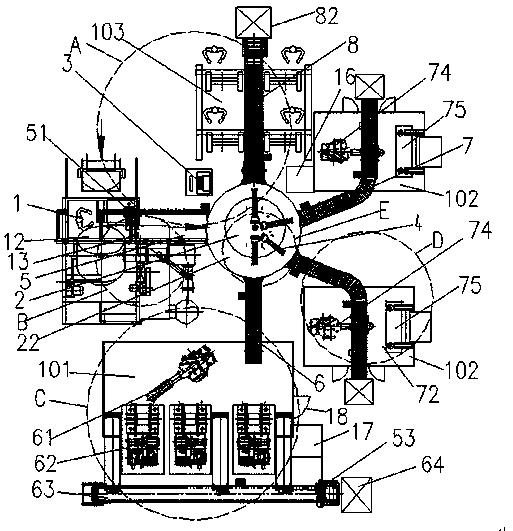

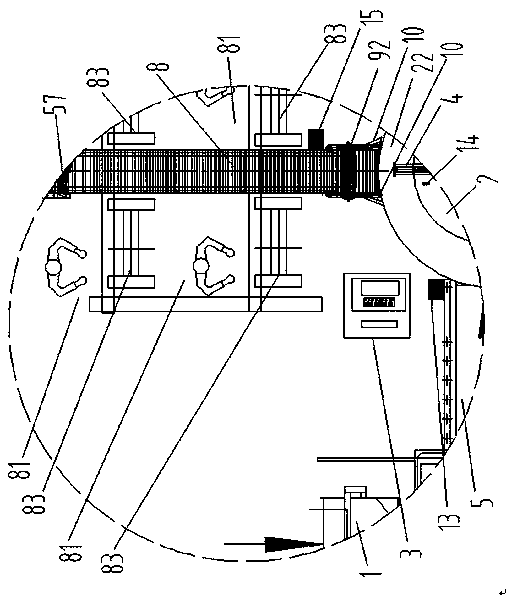

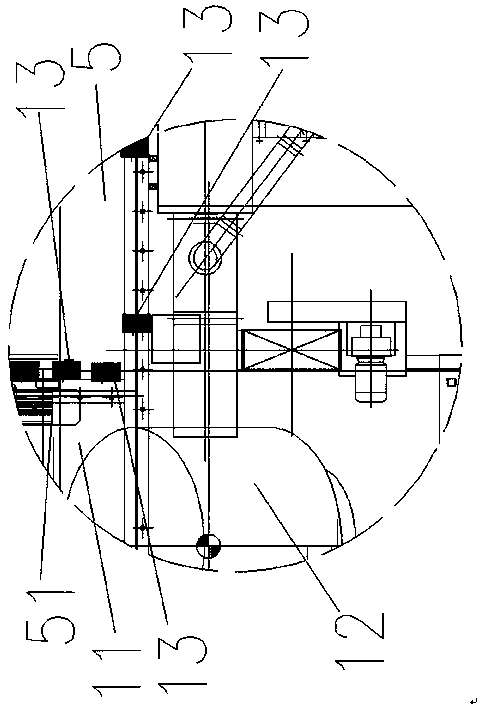

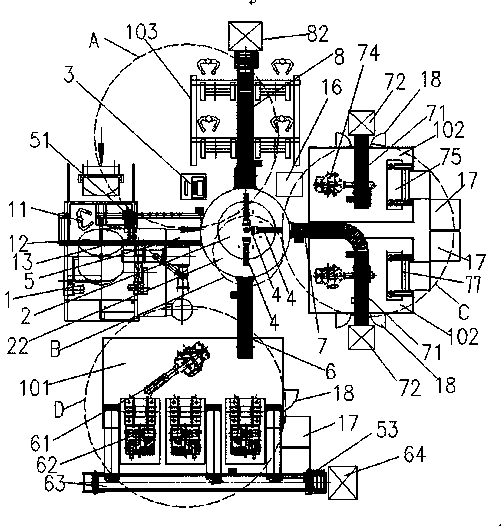

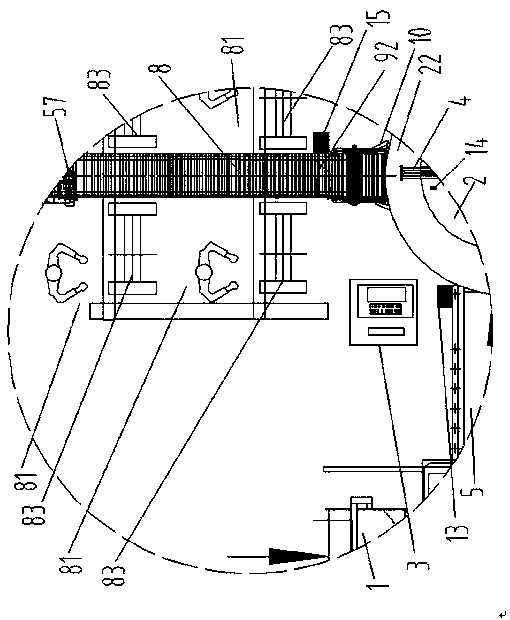

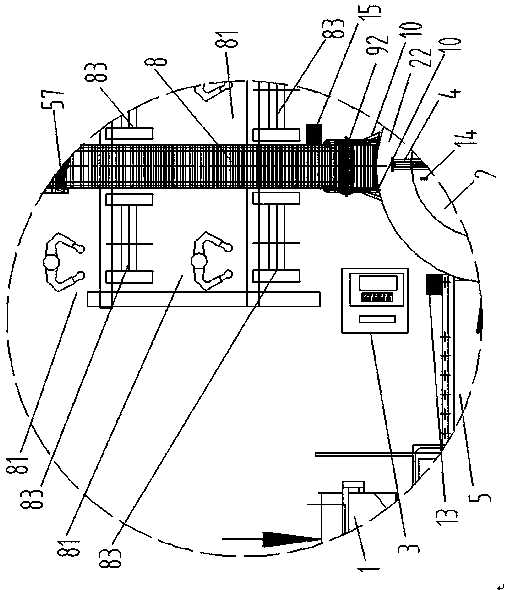

Finishing line after casting and finishing method using the line

ActiveCN107716914BRealization of online automatic finishingPrecise positioningCasting plantsCasting safety devicesControl systemAssembly line

The invention discloses a casting post-finishing assembly line and a finishing method adopting the same. The casting post-finishing assembly line comprises a feeding mechanism, a finishing mechanism,a conveying mechanism used for distributing a casting to the finishing mechanism, and a control mechanism. During finishing, the casting is fed into the conveying mechanism through the feeding mechanism and then distributed to one of a finishing module for thin and long castings, finishing modules for circular-ring-shaped castings and a finishing module for other castings of the finishing mechanism through the conveying mechanism. The casting post-finishing assembly line can finish the different types of castings, and thus the universality of the equipment is improved; and the whole system iscontrolled through the control mechanism, and accordingly on-line automatic finishing of the casting is achieved.

Owner:山东时风(集团)有限责任公司

Post-casting finishing line and finishing method thereof

ActiveCN107662156BPrecise positioningAccurate grippingEdge grinding machinesGrinding carriagesControl systemAssembly line

The invention discloses a casting after-finishing assembly line and a finishing method thereof. The casting after-finishing assembly line comprises a feeding mechanism, a finishing mechanism, a conveying mechanism for distributing castings to the finishing mechanism, and a control mechanism. The finishing mechanism comprises a thin casting finishing module, a circular casting finishing module anda finishing module for other castings. During finishing, the castings are conveyed into the conveying mechanism through the feeding mechanism, the castings are distributed to one of the thin casting finishing module, the circular casting finishing module and the finishing module for other castings through the conveying mechanism for finishing. According to the casting after-finishing assembly line, the castings of different types can be subjected to finishing, and the universality of the equipment is improved; the whole system is controlled through a control system, and therefore online automatic finishing of the castings is achieved.

Owner:山东时风(集团)有限责任公司

Casting post-finishing assembly line and finishing method adopting same

ActiveCN107716914ARealization of online automatic finishingPrecise positioningCasting plantsCasting safety devicesControl systemAssembly line

The invention discloses a casting post-finishing assembly line and a finishing method adopting the same. The casting post-finishing assembly line comprises a feeding mechanism, a finishing mechanism,a conveying mechanism used for distributing a casting to the finishing mechanism, and a control mechanism. During finishing, the casting is fed into the conveying mechanism through the feeding mechanism and then distributed to one of a finishing module for thin and long castings, finishing modules for circular-ring-shaped castings and a finishing module for other castings of the finishing mechanism through the conveying mechanism. The casting post-finishing assembly line can finish the different types of castings, and thus the universality of the equipment is improved; and the whole system iscontrolled through the control mechanism, and accordingly on-line automatic finishing of the casting is achieved.

Owner:山东时风(集团)有限责任公司

Workpiece clamp for inner-meshing forced movement chain roller mill

PendingCN109604742AImprove finishing accuracyImprove machining accuracyGear-cutting machinesGear teethEngineeringMechanical engineering

The invention discloses a workpiece clamp for an inner-meshing forced movement chain roller mill. The workpiece clamp is used for installing a machined inner gear ring and carrying out transmission onthe machined inner gear ring; the inner meshing forced movement chain roller mill comprises a main shaft, a pull rod, a clamp base and an elastic sleeve, the main shaft is used for receiving and transmitting torque, the pull rod is arranged in a central through hole of the main shaft and is used for installing the pull rod of the machined inner gear ring, the clamp base is arranged on the main shaft and is used for axially positioning the pull rod and is provided with the machined inner gear ring, and the elastic sleeve sleeves the main shaft and is used for radially tensioning the machined inner gear ring. According to the workpiece clamp for the inner-meshing forced movement chain roller mill, the machining precision of the tooth-shaped tooth surface of the machined gear after quenchingis high, machining of various inner gear rings can be adapted, and universality is high.

Owner:YIYANG KANGYI MACHINERY DEV

Three-axis double door frame double drive five linkage combination production center

InactiveCN1298500CImprove accuracy retentionIncrease stiffnessOther manufacturing equipments/toolsDigital controlMachine tool

The invention discloses a kind of digital control compound processing centre which has three primary axis heads and three blade brackets to provide double drives, it is made up of turning primary axis head, milling axis head, fine machining primary head, turning blade bracket, milling blade bracket components, straight lade bracket component, saddle, transverse sliding boards, small door bracket component, a bed, the side door bracket component, tail bracket component and blade bank. The fine machining primary head can be changed, it can assemble high speed milling head, grinding head; the primary axis has servo axis function, the other two primary axes is servo axis. The bathe has at least nine servo axes, it can have twenty servo axes at most, it can realize five-axes linked control; the piece can realize turning, milling, boring, drilling and screwing, and high speed milling and so on. The raw and fine process can be separated, in order to upgrades the precise maintaining of bathe.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com