Axial floating positioning mandrel clamp

A floating positioning and mandrel technology, applied in the direction of manufacturing tools, gear teeth, gear cutting machines, etc., can solve the problems of difficult control of the machining quality of workpiece bevel gears, clamping errors, and difficulty in forming and processing, and achieves easy production and positioning. Accurate and improved ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

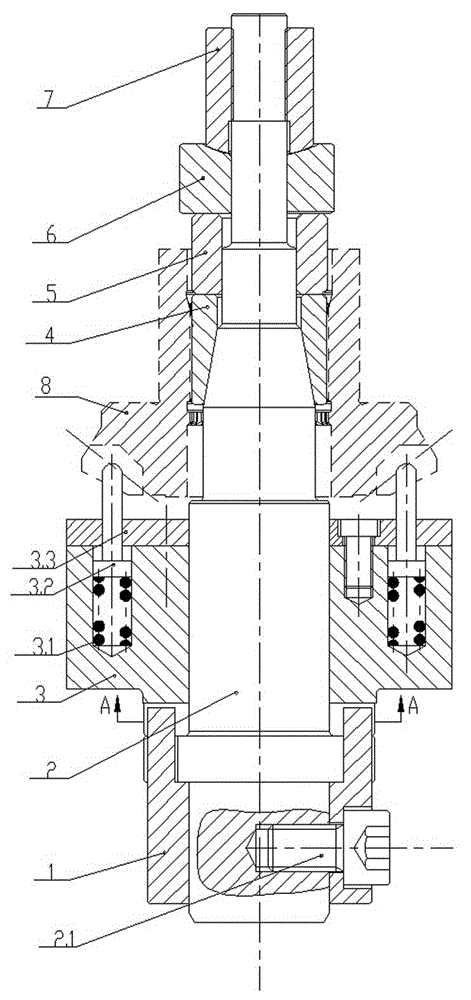

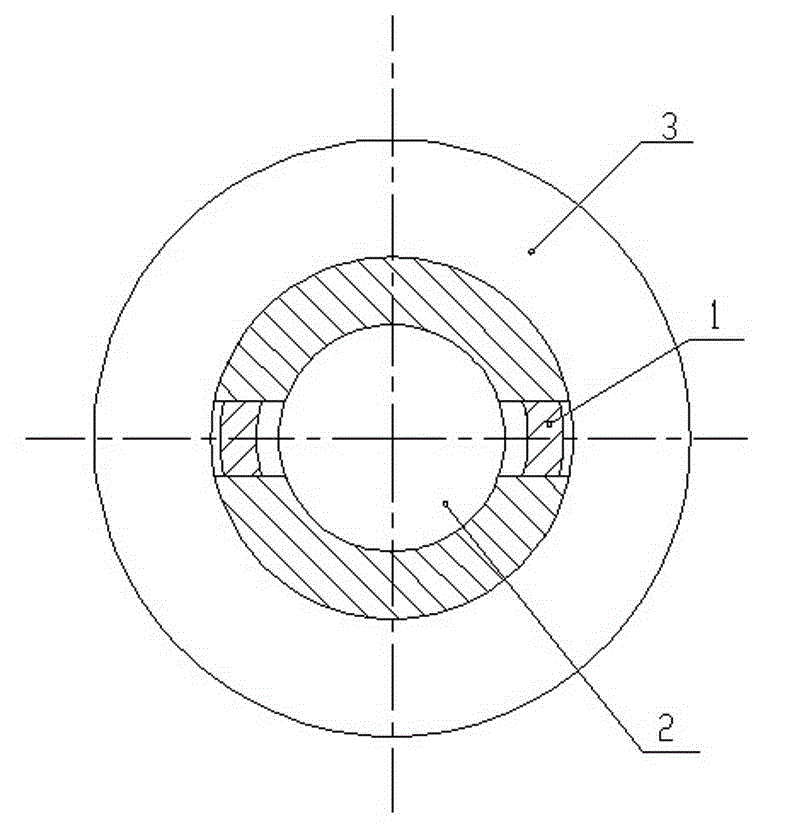

[0017] figure 1 The shown axial floating positioning mandrel fixture is composed of a circular sleeve 1, a mandrel 2, a base 3, an expansion sleeve 4, a snare 5, a washer 6 and a nut 7. The mandrel 2 is an elongated shaft each provided with multi-section shoulders, the large-diameter end is a cylindrical shaft, and the small-diameter end is provided with an external thread that cooperates with the nut 7 . The round sleeve 1 fitted on the large-diameter end of the mandrel 2 is radially locked by the bolt 2.1, and the base 3 is fitted next to the round sleeve 1 on the mandrel 2, and the base 3 and the mandrel 2 are in clearance fit. The middle section of mandrel 2 is provided with a section of taper shaft, and the thin-wall expansion sleeve 4 is set on the taper shaft. The outer wall of expansion sleeve 4 is a cylinder, and its outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com