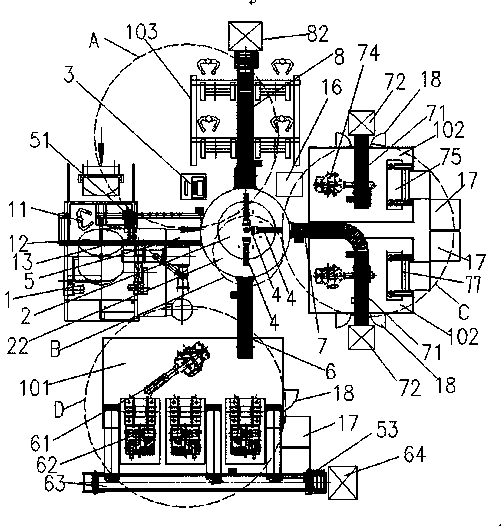

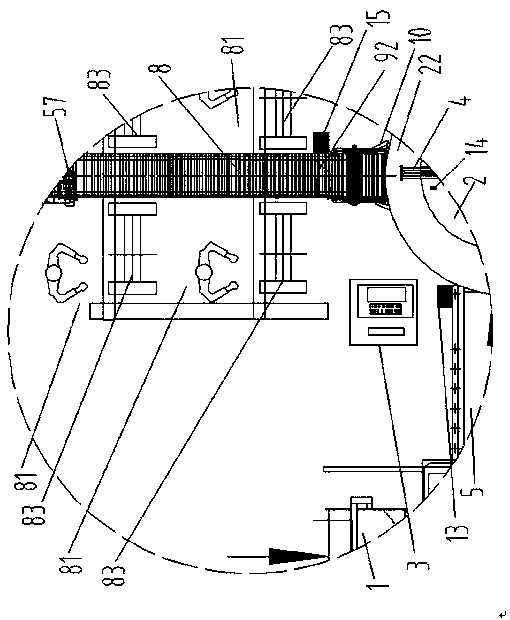

Post-casting finishing line and finishing method thereof

A technology of casting finishing and assembly line, which is applied to the parts of grinding machine tools, the control of workpiece feed movement, and the machine tools suitable for grinding the edge of workpieces, etc. to improve the quality of the working environment, realize online automatic finishing, and reduce the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

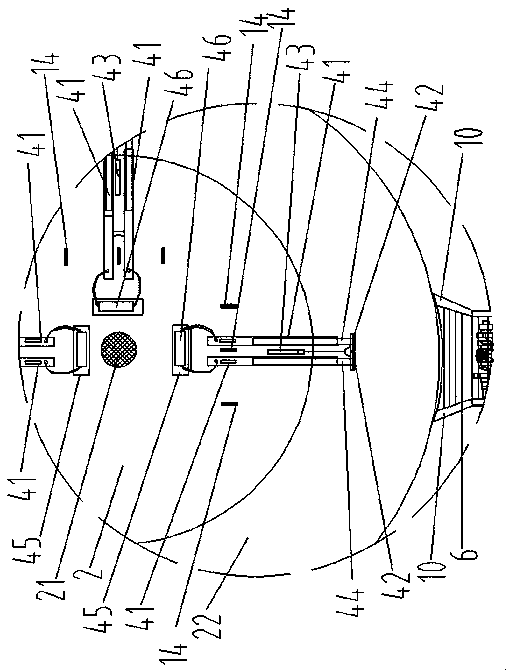

Embodiment 2

[0070] Example 2. The difference between this embodiment and Embodiment 1 lies in that other casting finishing modules 103 are provided with dust collectors 17 . The first annular casting multi-station grinding machine 75 and the second annular casting multi-station grinding machine 77 are respectively provided with three stations.

Embodiment 3

[0071] Example 3. The difference between this embodiment and Embodiment 1 is that the first multi-station grinding machine 75 for annular castings and the second multi-station grinding machine 77 for annular castings are each provided with four stations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com