Method for detecting precision of numerical control machine tool by special tool

A technology of CNC machine tools and tooling, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of consuming a lot of manpower, material and financial resources, wasting resources, and reducing precision, so as to achieve widespread application value and increase processing The effect of yield rate and convenient precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

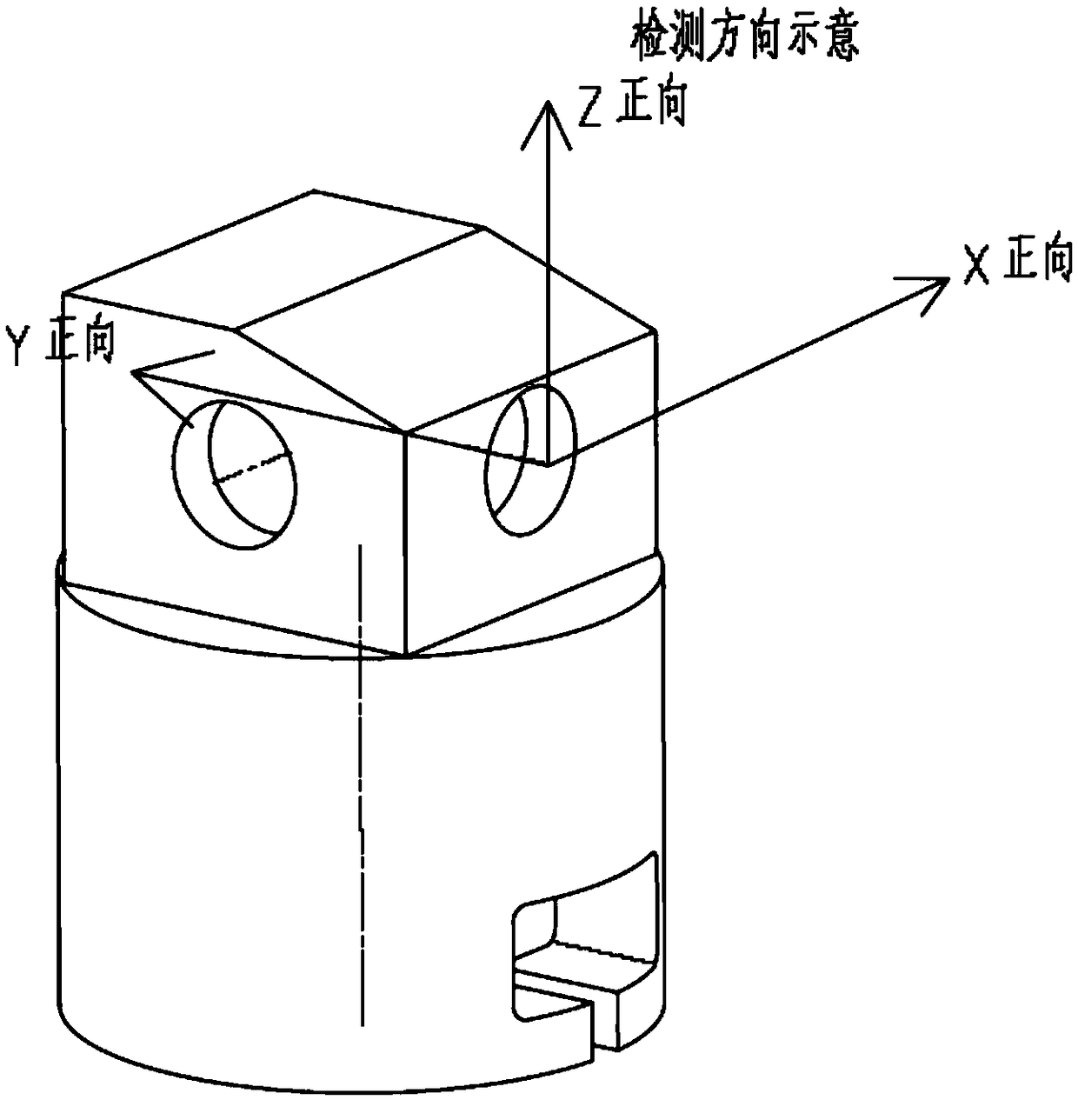

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0023] The present invention aims at the condition that the accuracy of the numerical control machine tool is reduced after long-term operation, and uses the special tooling to complete the detection of the precision error of the numerical control machine tool for boring, angle processing, and linear processing, complete the conversion of the error linear ratio, and reverse compensation into the numerical control program. In the theoretical size, the processing of high-precision parts is completed.

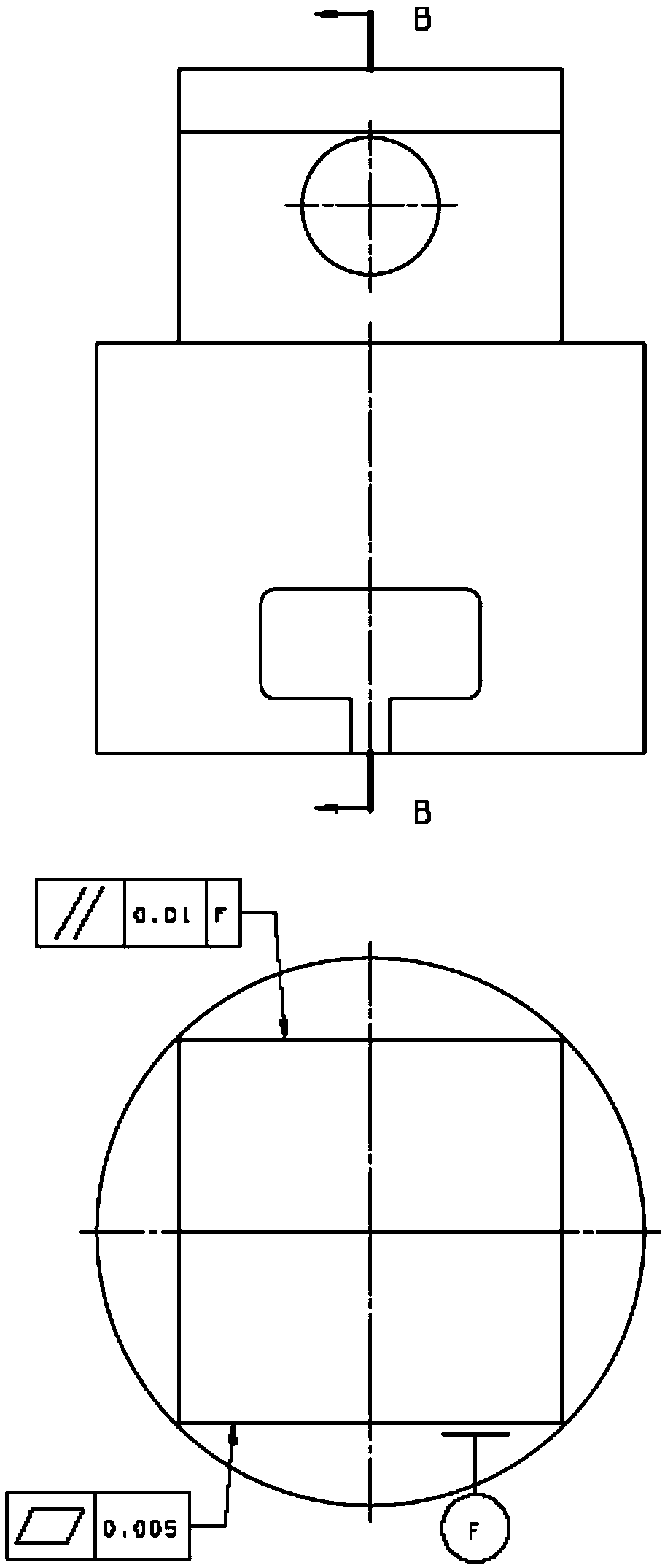

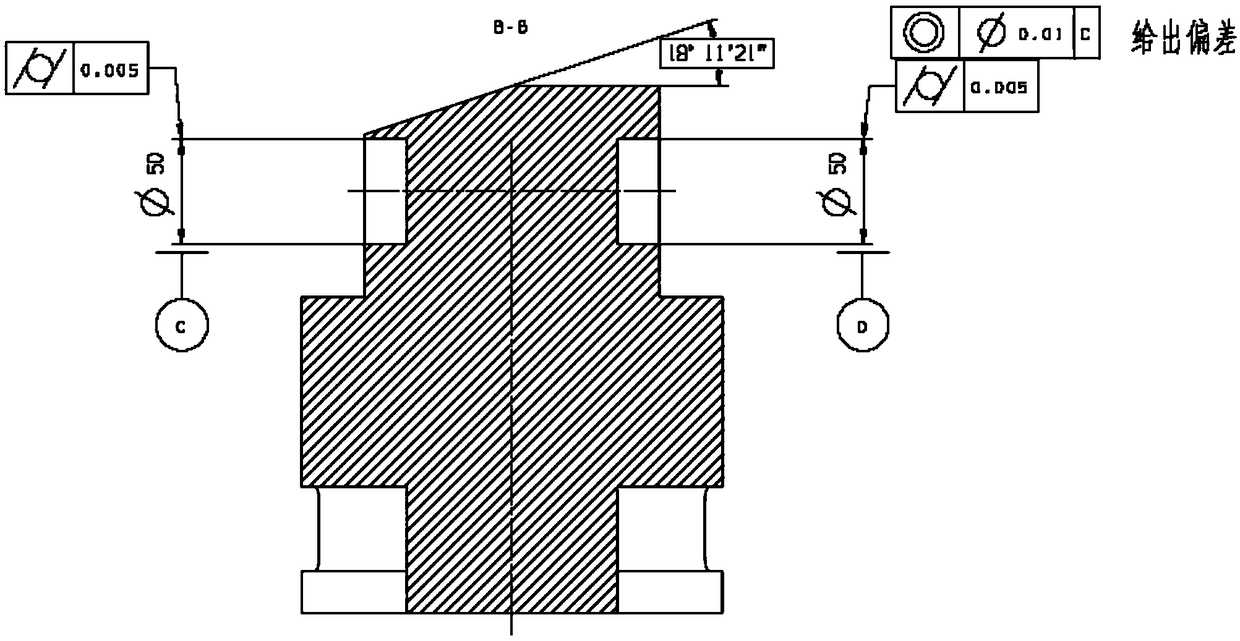

[0024] At first according to the use requirement of the present invention, design and make the special-purpose tooling 1 that is suitable for detecting the precision of numerical control machine tool, special-purpose tooling 1 is made up of the cylinder of height 100mm, diameter 100mm and the cube that height is 50mm, side length 70mm; The upper and lower end faces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com