Cold forging finishing punch for inner cavities of finish-forge pieces of outer spherical cages

A technology for finishing punches and outer ball cages, applied in forging/pressing/hammer devices, forging/pressing/hammering machines, manufacturing tools, etc., which can solve the problem of insufficient finishing precision of inner cavity cold forging and inability to form lead angles , low pass rate of finished products and other problems, to achieve the effect of high pass rate of finished products, improvement of product pass rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

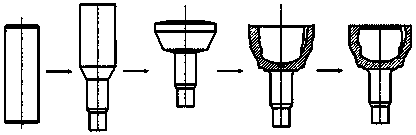

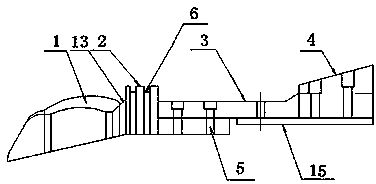

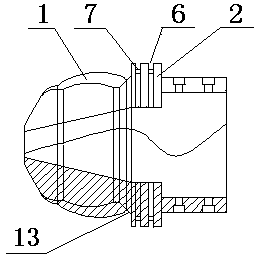

[0028] according to figure 2 -8, this embodiment provides a cold forging finishing punch for the inner cavity of the precision forging of the outer spherical cage, which is composed of at least three split punches and a middle mandrel 8, and the single split punch is from top to bottom Including punch extrusion part 1, punch base 2, punch rod part 3, punch guide block 4, the shape of the punch extrusion part 1 matches the shape of the ball channel cavity, and all split punches After the head is assembled, the shape of the punch base 2 is cylindrical, and the cylindrical punch base 2 is provided with at least one annular groove 6, and a rubber ring 7 is arranged in the described annular groove 6, and the described annular groove 6 is provided with a rubber ring 7. The lower part of the middle mandrel 8 is provided with a cylindrical pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com