Corrugated spiral milling cutter for precise machining of aerospace material

A technology of helical milling cutters and aerospace materials, which is applied in the direction of cutting tools for milling machines, milling cutters, metal processing equipment, etc., can solve the problems of poor roughness and machining accuracy, achieve high machining accuracy, good surface roughness, avoid The effect of the vibration knife phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

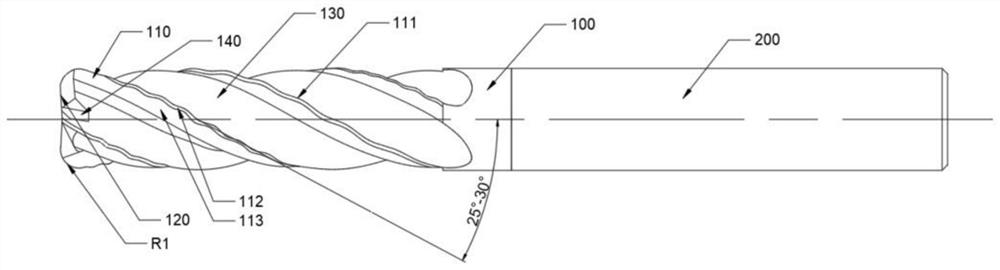

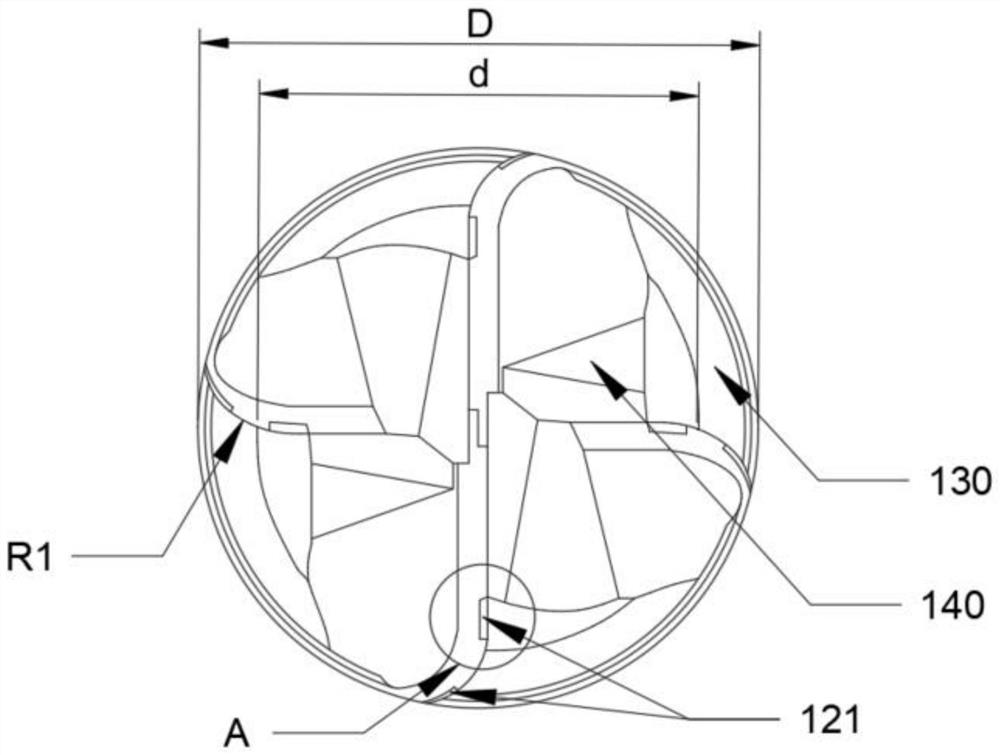

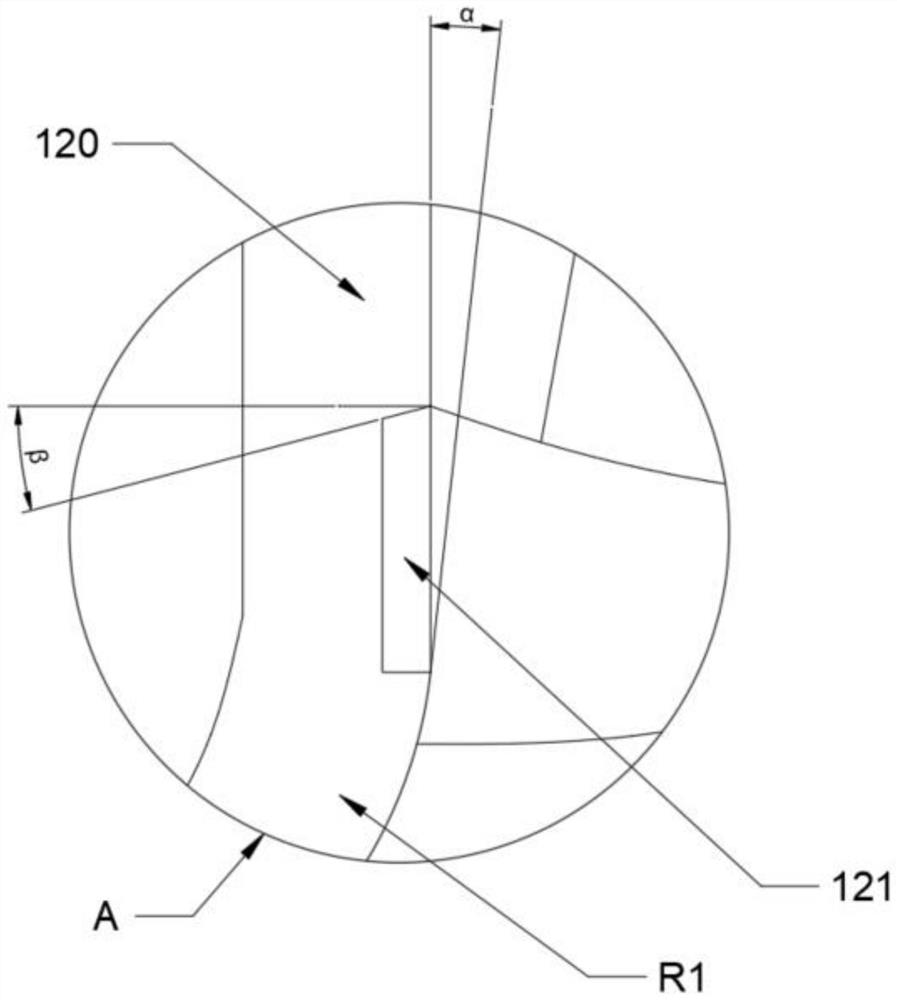

[0024] Such as figure 1 The shown corrugated spiral milling cutter for finishing aerospace materials includes a blade 100 for cutting and a handle 200 for clamping. Specifically, the blade 100 is made of polycrystalline diamond material, and the handle 200 is made of hard alloy, the blade 100 is connected to one end of the handle 200 by high-frequency induction welding to form an integral body, and the blade 100 is made of polycrystalline diamond, which has higher hardness, better wear resistance and durability than cemented carbide. High characteristics, when processing high-hardness materials such as carbon fiber materials, there will be no rapid wear of the tool due to the high hardness of the workpiece during the processing, and then problems such as delamination, tearing and burrs in the processing of the workpiece.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com