Three-axis double door frame double drive five linkage combination production center

A composite machining center, dual-drive technology, used in manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of low precision retention of the mechanism, save loading and unloading auxiliary time, reduce design and manufacturing, and improve stiffness and bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

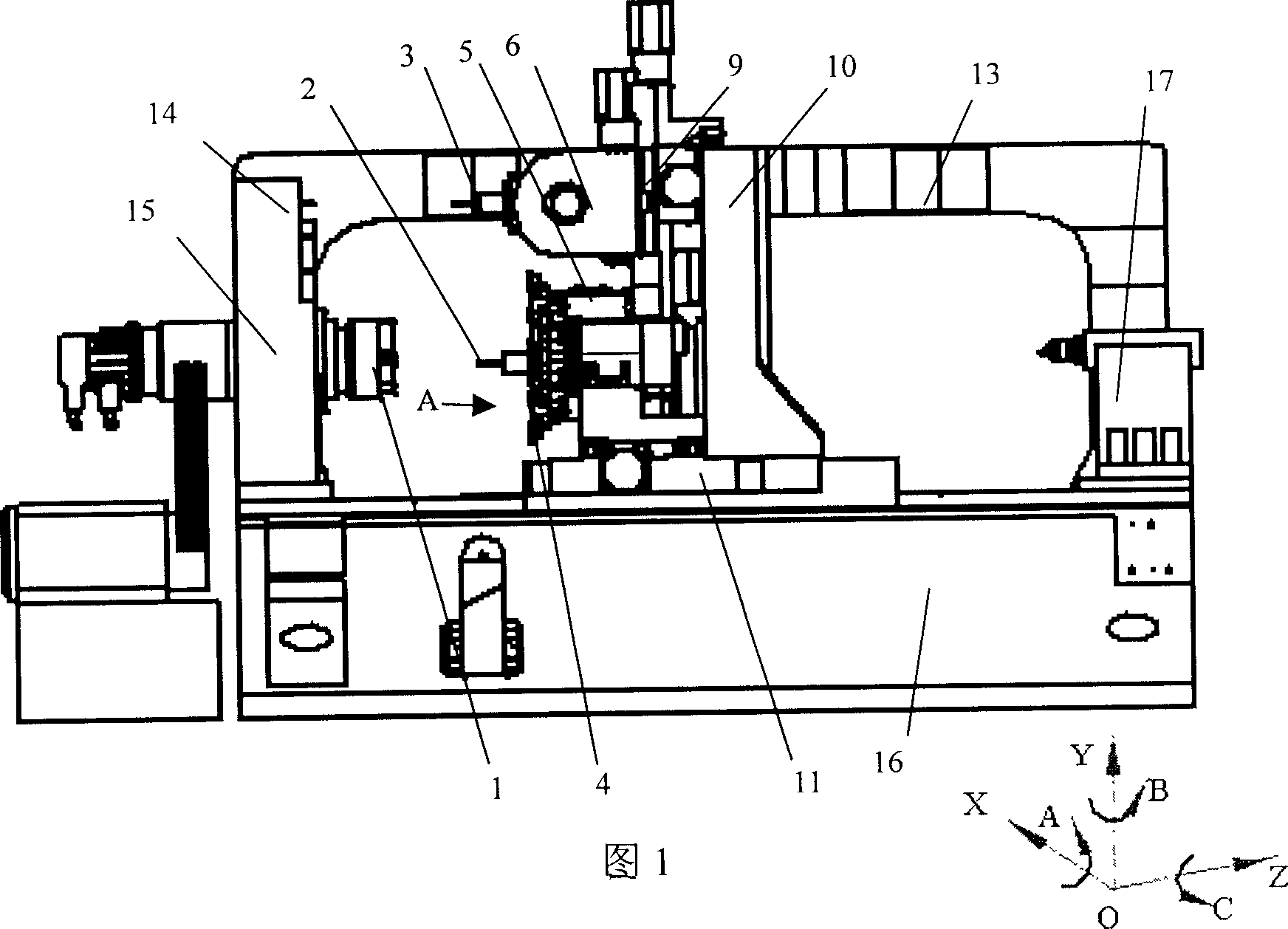

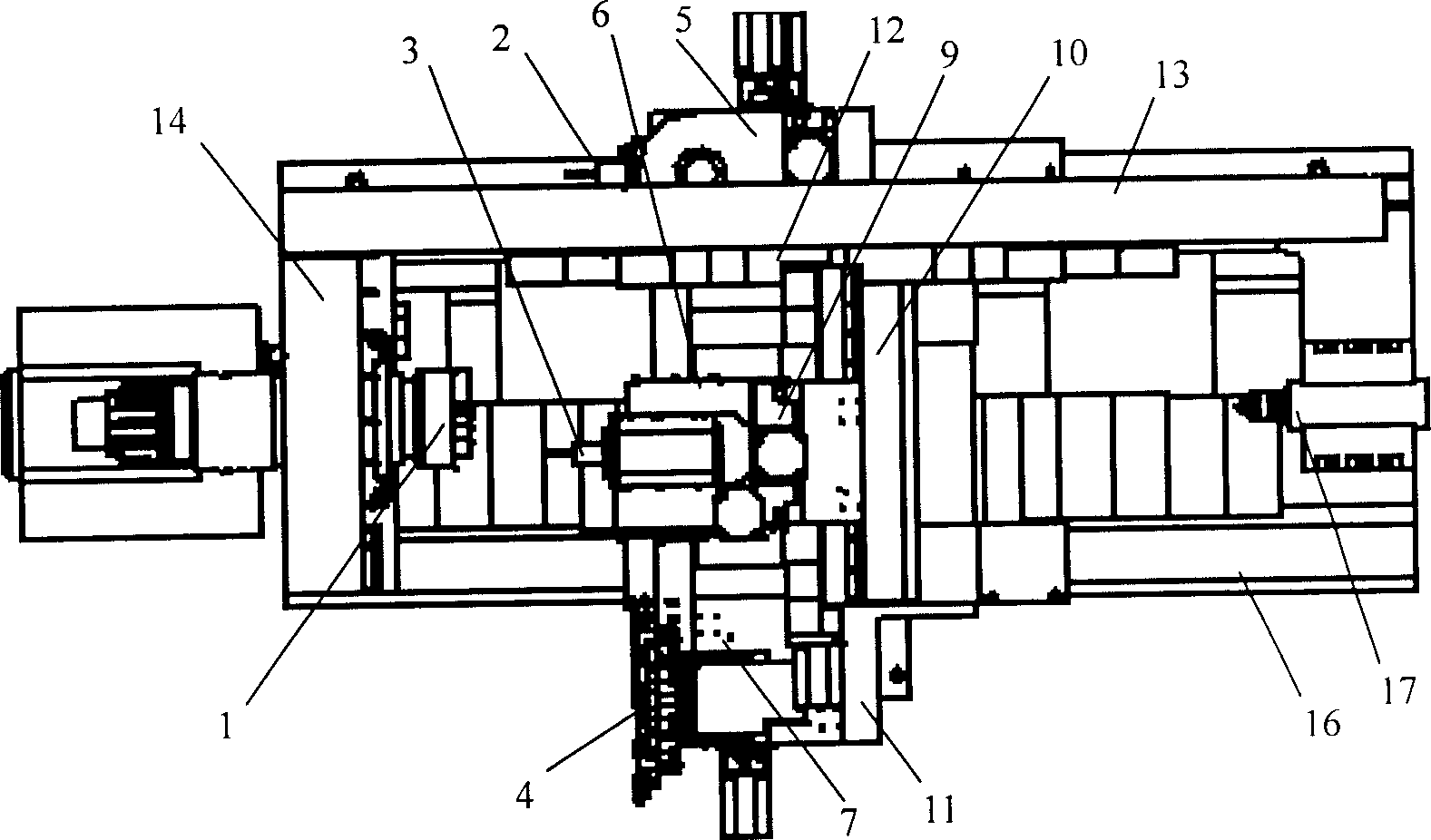

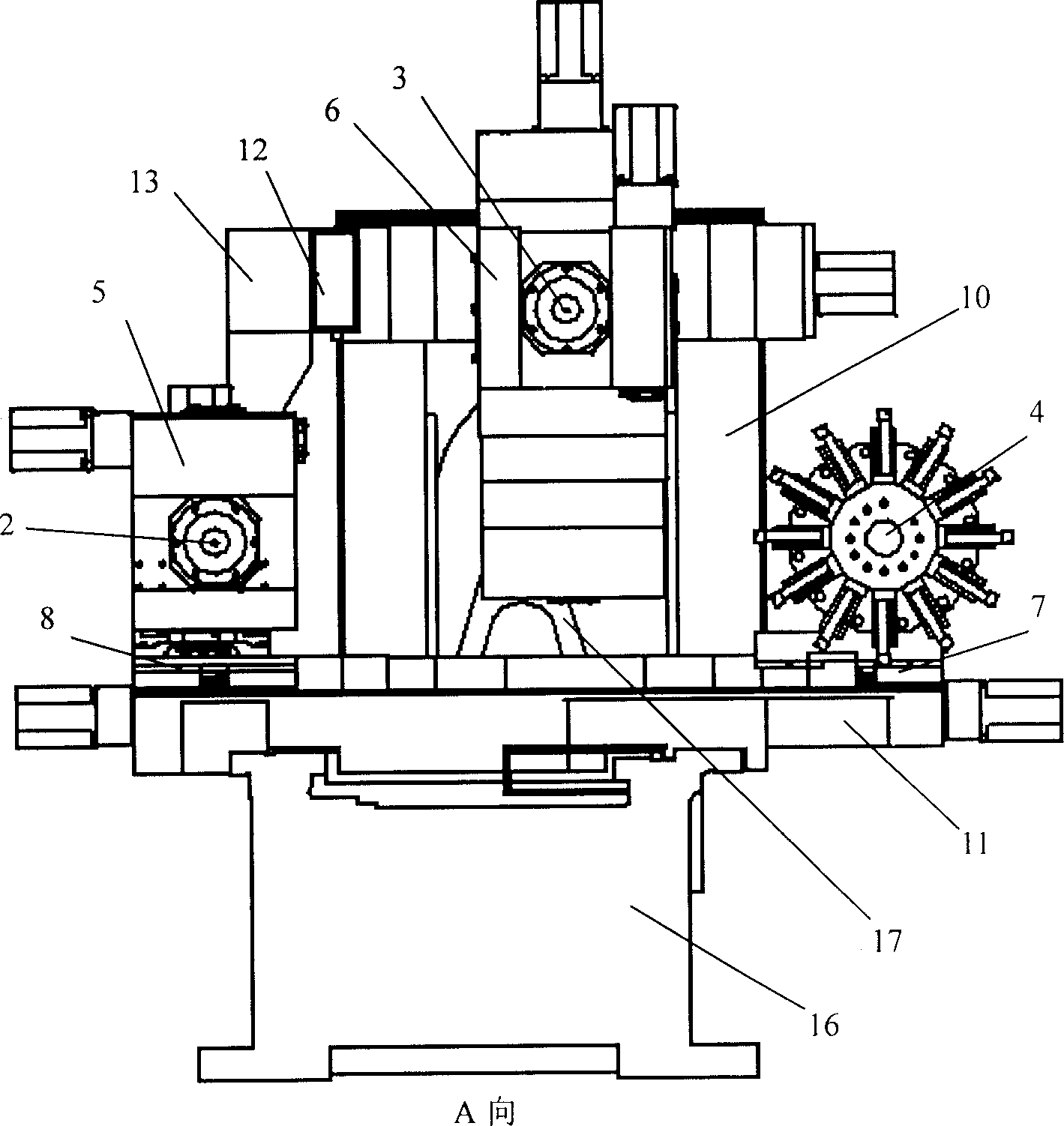

[0015] Referring to Fig. 1, in the embodiment, the spindle head 1 has a C-axis function, and the main shaft of the spindle head 2 is also a servo axis, which can be hobbed. The spindle head 3A is a high-speed spindle head capable of fine milling, fine turning milling or grinding; the tool holder 4 is a turret-type turning tool holder, and its components and the saddle combination have two servo axis functions of X and Z. The combination of tool post 5 and bed saddle has four servo axis functions of B, Y, X and Z; the combination of tool post 6 and small gantry has four servo axis functions of A, Y, X and Z, and there are 11 servo control axes in total. Up to 5 servo axes linkage can be realized. In addition to turning, milling, and gear cutting, the three-spindle, double-gantry, double-drive, and five-linkage compound machining center of this embodiment can also perform high-speed fine milling, fine turning and milling, or grinding. The rough and fine feed mechanism of the ma...

Embodiment 2

[0017] Referring to Fig. 1, the difference from Embodiment 1 is that the spindle head 3 adopts a grinding spindle head, so its finishing function is grinding. The machine has a total of 11 servo-controlled axes.

Embodiment 3

[0019] Referring to FIG. 1 , the difference from Embodiment 1 is that the spindle of the spindle head 3A also has the function of a servo axis, so that the machine tool has twelve servo-controlled axes in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com