Method for preventing and detecting winding of buoyant cable

A technology of floating cables and cable reels, which is applied in the direction of using electric/magnetic devices to transmit sensing components, public buildings, gymnasiums, etc., and can solve problems such as long cleaning time of swimming pools, automatic charging, tangling and knotting of umbilical cord cables, etc. , to achieve the effect of convenient manual intervention, equipment environmental protection, avoiding winding and knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

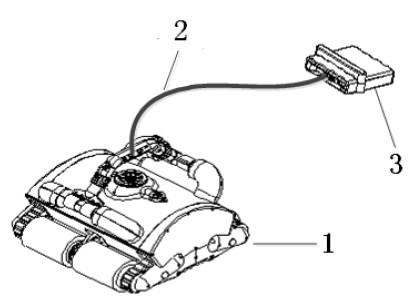

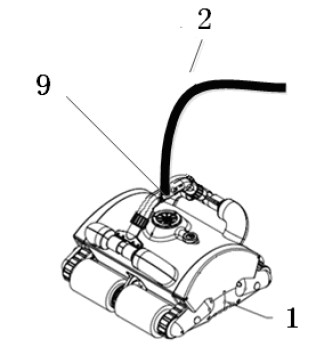

[0047] Such as figure 2 As shown, the device of the present invention includes an automatic cleaning machine 1, a floating cable 2, a power controller 3, and a cable reel device 4.

[0048] Automatic cleaning machine 1 is made up of two parts of arc-shaped main body structure and outlet handle.

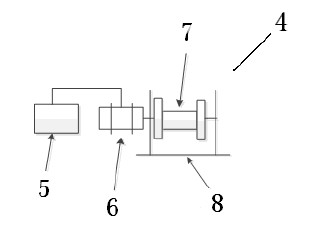

[0049] Wherein the cable reel device 4 is composed of a motor controller 5, a 24VDC DC motor 6, a reel 7, and a bracket 8. The DC motor 6 and the reel 7 are coaxially connected, and the motor controller 5 controls the DC motor 6 to drive the reel 7 forward. Or reverse rotation, the DC motor 6 controls the moment and direction of rotation of the floating cable 2 reel 7, when the automatic cleaning machine 1 is working, if the position away from the power box is getting farther and farther away, the reel slowly releases the floating cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com