High-strength, high-modulus and high-melting point PVA (Polyvinyl Acetate) fiber and manufacturing method thereof

A high-modulus, high-melting-point technology, applied in rayon manufacturing, fiber chemical characteristics, wet spinning, etc., can solve the problem of no large-scale industrialized equipment, and achieve the effect of increasing the draw ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

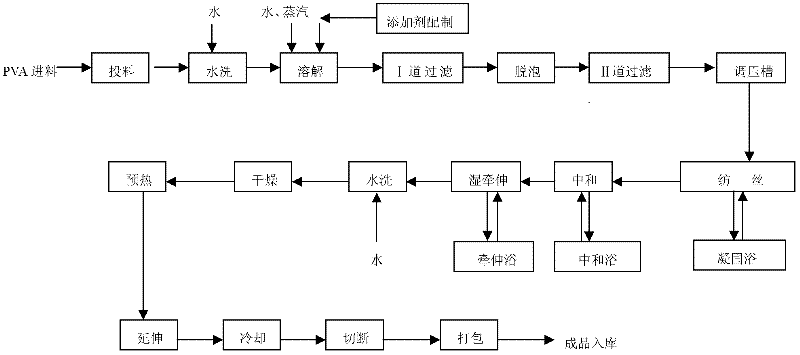

Method used

Image

Examples

Embodiment 1

[0029] Raw material PVA: polymerization degree 1720, residual acetate 0.21%, sodium acetate after washing 0.23%; additive preparation: H 3 BO 3 1.35%, CuSO 4 0.05%; dissolution: dissolution temperature 97°C, dissolution time 110 minutes, stock solution concentration 16.8%; defoaming: defoaming temperature 98°C, defoaming time 4 hours; spinning: spinning coagulation bath NaOH18g / l, NaOH 2 SO 4 310g / l, H 3 BO 3 5.5g / l, negative stretching in bath -20.8%, spinning air bath stretching 2.08 times; neutralization, wet drafting: neutralization, wet drafting coagulation bath Na 2 SO 4 310g / l, H 2 SO 4 12g / l, wet heat stretching 2.3 times, wet heat stretching 85°C; preheating, stretching: preheating temperature 225°C, stretching dry stretching 2.93 times, stretching oven temperature 212°C;

[0030] The main technical quality index of embodiment 1PVA fiber is as follows:

[0031] Indicator name

Embodiment 2

[0033] Raw material PVA: polymerization degree 1820, residual acetate 0.35%, sodium acetate 0.2% after washing; additive preparation: H 3 BO 3 1.52%, CuSO 4 0.05%; dissolution: dissolution temperature 98°C, dissolution time 120 minutes, stock solution concentration 16.0%; defoaming: defoaming temperature 98°C, defoaming time 4.5 hours; spinning: spinning coagulation bath NaOH35g / l, Na 2 SO 4 330g / l, H 3 BO 3 6.5g / l, negative stretching in bath -30.8%, spinning air bath stretching 2.08 times; neutralization, wet drafting: neutralization, wet drafting coagulation bath Na 2 SO 4 330g / l, H 2 SO 4 40g / l, wet heat stretching 2.0 times, wet heat stretching 88°C; preheating, stretching: preheating temperature 225°C, stretching dry stretching 3.44 times, stretching oven temperature 228°C;

[0034] The main technical quality index of embodiment 2PVA fiber is as follows:

[0035] Indicator name

Embodiment 3

[0037] Raw material PVA: polymerization degree 1950, residual acetate 0.28%, sodium acetate 0.40% after washing; additive configuration: H 3 BO 3 1.25%, CuSO 4 0.08%; dissolution: dissolution temperature 99°C, dissolution time 120 minutes, stock solution concentration 15.8%; defoaming: defoaming temperature 99°C, defoaming time 5 hours; spinning: spinning coagulation bath NaOH45g / L, Na 2 SO 4 330g / L, H 3 BO 3 6g / L, negative stretching in bath -29.9%, spinning air bath stretching 2.06 times; neutralization, wet drafting: neutralization, wet drafting coagulation bath Na 2 SO 4 340g / L, H 2 SO 4 50g / L, wet heat stretching 2.5 times, wet heat stretching 92°C; preheating, stretching: preheating temperature 230°C, stretching dry stretching 2.8 times, stretching oven temperature 220°C;

[0038] The main technical quality index of embodiment 3PVA fiber is as follows:

[0039] Indicator name

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com