Full-automatic deslagging, oil separation and lifting integrated device

A fully automatic and oil-separating technology, which is applied in liquid separation, chemical instruments and methods, grease/oily substance/suspton removal devices, etc. It can solve the problems of incomplete oil separation and secondary environmental pollution that cannot meet the requirements of industrial and commercial automatic production To improve the work of manual removal of debris, unique anti-blocking filter, simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

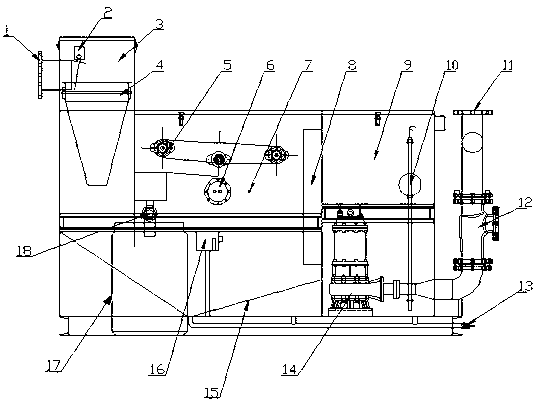

[0026] like figure 1 As shown, a fully automatic slag removal and oil separation lifting integrated equipment includes a solid-liquid separation box 3, an oil separation and mud discharge box 15 and a sewage lifting discharge box 9, and the oil separation and mud discharge box 15 is connected to the sewage through the drainage and ventilation pipeline The lifting discharge box 9 is connected, and the inside of the solid-liquid separation box 3 is located at the lower end of the water inlet 1 to be provided with a solid-liquid separation device 4, and the bottom of the solid-liquid separation box 3 communicates with the bottom of the oil separation and mud discharge box 15 in a funnel shape; The bottom of the oil separation and mud discharge box 15 is provided with a foaming device 16 and a sludge discharge pipe 13, and its upper part is provided with an oil scraping device 5, and the oil scraping device 5 is connected with a grease collection barrel 17 through a grease discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com