No-partial-discharge type disc-shaped suspended composite insulator

A composite insulator and shape-suspension technology, which is applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve the problems of poor anti-pollution flashover performance of insulators, serious partial discharge, and high manufacturing costs, and achieve tensile mechanical strength dispersion Reduced size, simple production process, convenient installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

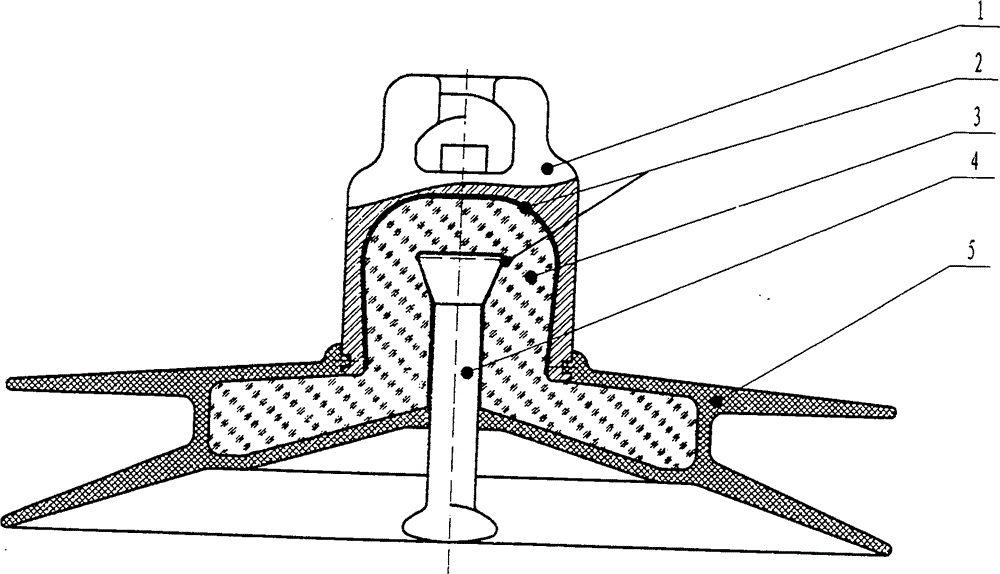

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The accompanying drawing is a schematic structural view of a double-layer silicone rubber shed according to an embodiment of the present invention, and the scope of protection of the present invention is not limited to this embodiment.

[0016] As shown in the figure, the structure of the present invention is that a metal steel foot 4 is provided in the inner cavity of the metal cap 1, and the upper half of the inner cavity surface of the metal steel cap 1 and the outer surface of the metal steel foot 4 are respectively preset. Metal wire mesh 2, pouring organic resin into the gap between the metal steel cap and the metal steel foot that is pre-laid with wire mesh 2, and heating and curing to form a resin insulator 3, the resin insulator 3 has an outer insulating umbrella Disk, the outer surface of the outer insulating umbrella disk of the resin insulator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com