Lifting slope rail connecting device

A technology of track connection and ascending and descending slopes, which is applied in the direction of tracks, movable tracks, tunnels, etc., to achieve the effects of less replacement frequency, convenient installation and operation, and avoiding track jumping accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

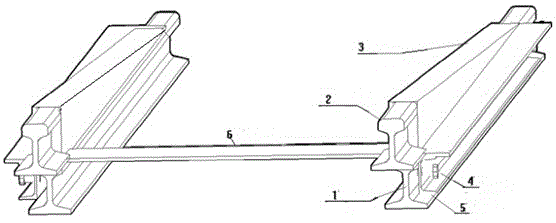

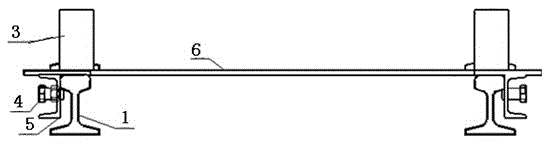

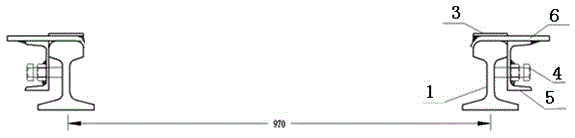

[0017] Such as Figure 1-3 As shown, the lifting slope track connection device of the present invention comprises wedge-shaped flat steel track 3, channel steel and 5 door-shaped steel plates 6, and the door-shaped steel plate is placed on the TBM supporting standard rail 1 on both sides, and two wedge-shaped flat steel tracks 3 are symmetrically arranged on On the door-shaped steel plate 6, two channel steels 5 are arranged on the outer side of the TBM single-line standard rail to be welded with the door-shaped steel plate, and four limit bolts 4 are fixed at the front and rear of the channel steel.

[0018] The wedge-shaped flat steel track is 70*50mm flat steel (16Mn), the door-shaped connecting steel plate is 10mmQ235 steel plate, the channel steel is [10, and the limit bolt is M22*60 high-strength bolt.

[0019] The processing of this track connection device: process steel materials such as wedge-shaped Mn16 flat steel, door-shaped connecting steel plate and [10 channel s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com