Device and method for removing interface dirt in post-processing extraction equipment

A technology of interface dirt and extraction equipment, which is applied in the direction of reactor fuel elements, nuclear power generation, climate sustainability, etc., can solve the problems of lack of interface dirt removal devices, etc., and achieve the effect of convenient operation, reliable actual operation, and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

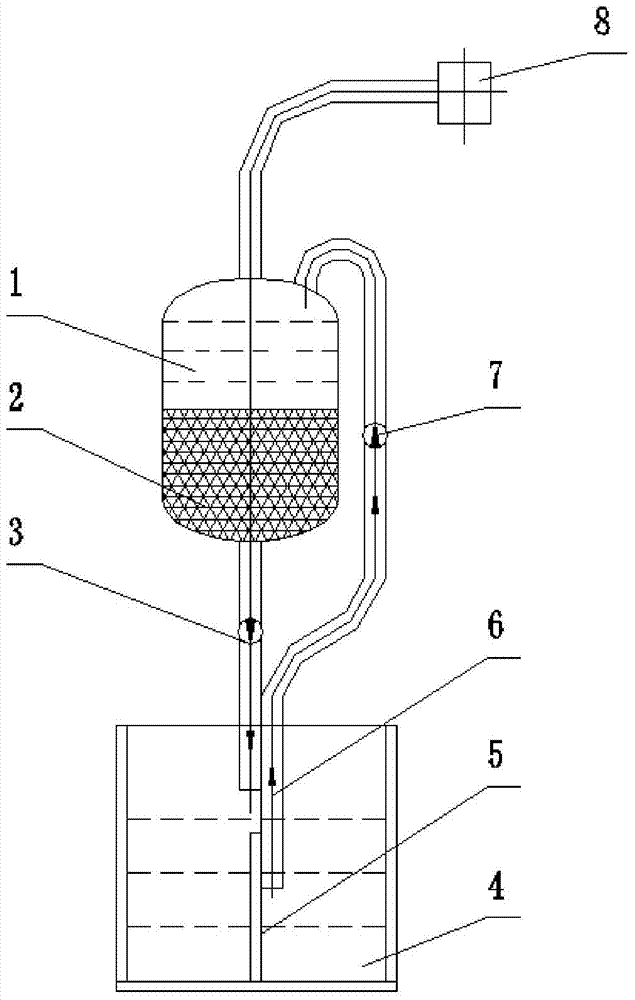

[0015] as attached figure 1 As shown, the removal device of the interface dirt in the post-processing extraction equipment of the present invention includes a liquid storage tank (glass material, volume 10ml), a suction pipe, a liquid discharge pipe, and a pulse generator. The filter material (sintered glass sand of G3) forms a liquid storage space above the interior of the liquid storage tank; one end of the suction pipe communicates with the top of the liquid storage tank, and the other end opens below the liquid storage tank; the drain pipe and the storage tank The bottom of the liquid pool is connected; the suction pipe and the liquid discharge pipe are provided with one-way valves; the top of the liquid storage pool is also connected with the pulse generator through a pipeline.

[0016] A liquid level control pillar can also be arranged at the mouth of the suction pipe; the liquid level control pillar is a pillar fixed together with the pipette and whose length exceeds th...

Embodiment 2

[0018] The interface dirt removal device in the post-processing extraction equipment of Example 1 is used to remove the interface dirt of a certain extraction material liquid, and the specific operations are as follows:

[0019] First, place the nozzle of the suction pipe at the interface dirt in the extraction equipment, and under the drive of the pulse generator, the feed liquid with the interface dirt is sucked into the liquid storage pool through the suction tube, and passes through the filter material in the liquid storage pool. After filtering out the interface dirt, the feed liquid is returned to the extraction equipment through the discharge pipe to realize the removal of the interface dirt. After about 10 minutes of operation, the feed liquid in the extraction equipment gradually clarifies, which proves that the operation effect of the device is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com