Patents

Literature

44results about How to "Realize large-scale automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

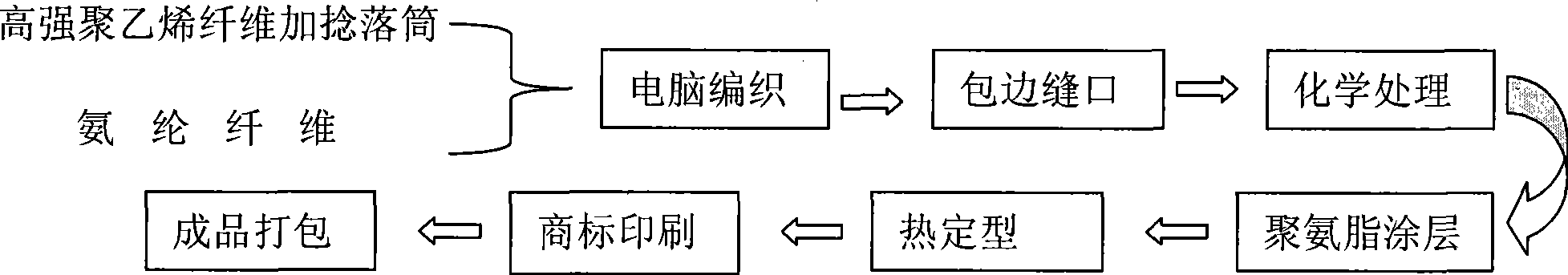

Method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves

ActiveCN104814549ASimple processImprove cut resistanceProtective garmentSpecial outerwear garmentsUltra-high-molecular-weight polyethyleneFilament yarn

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

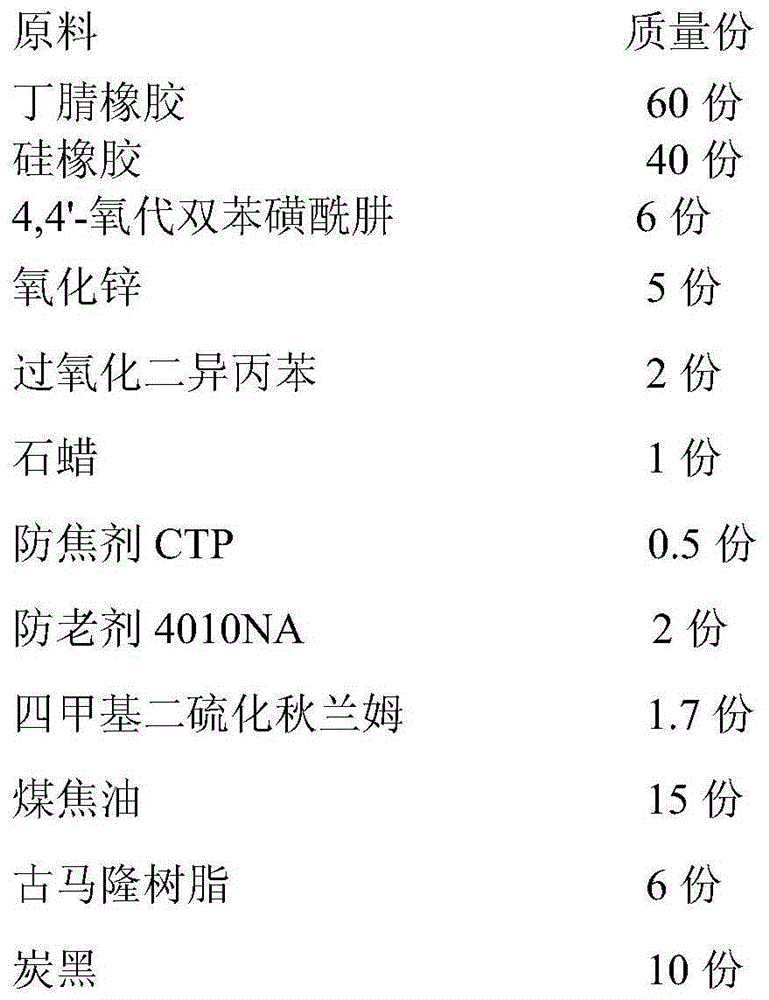

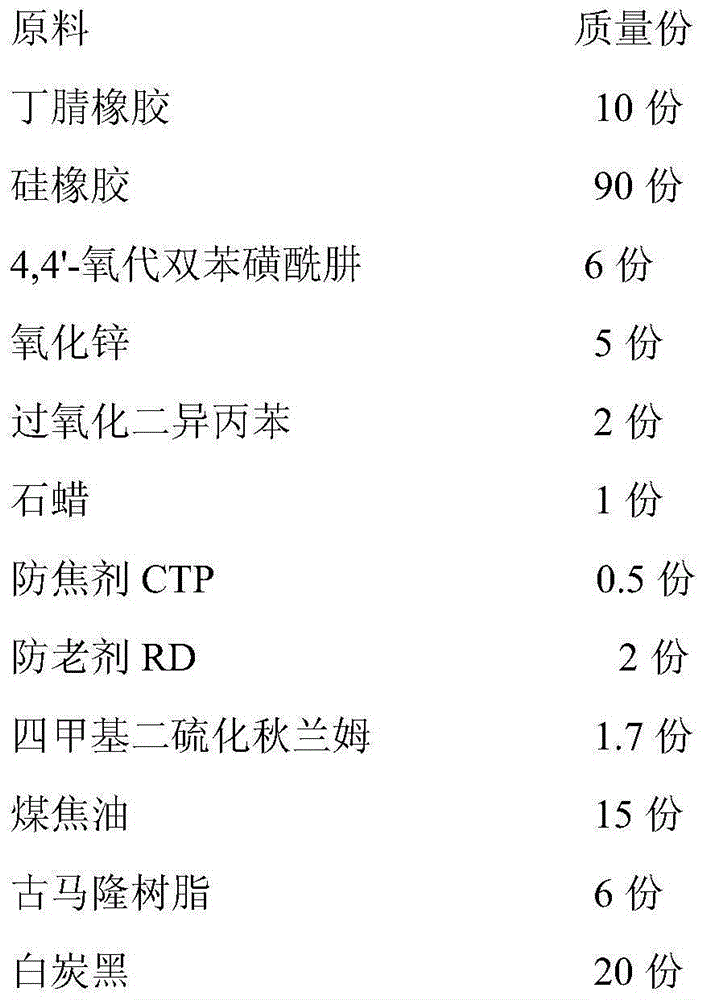

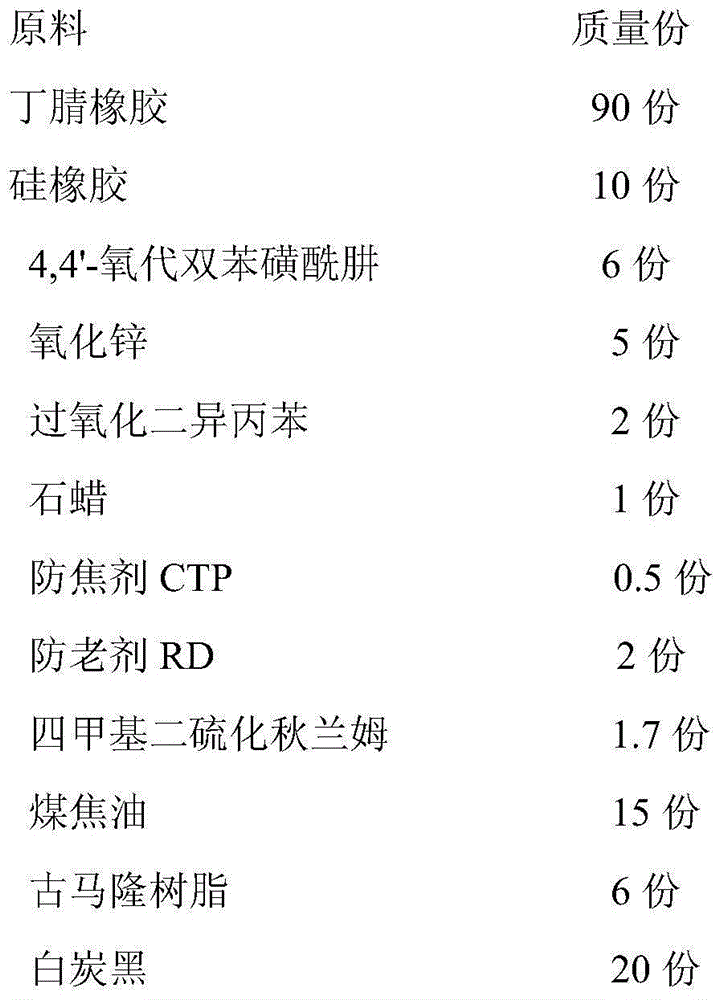

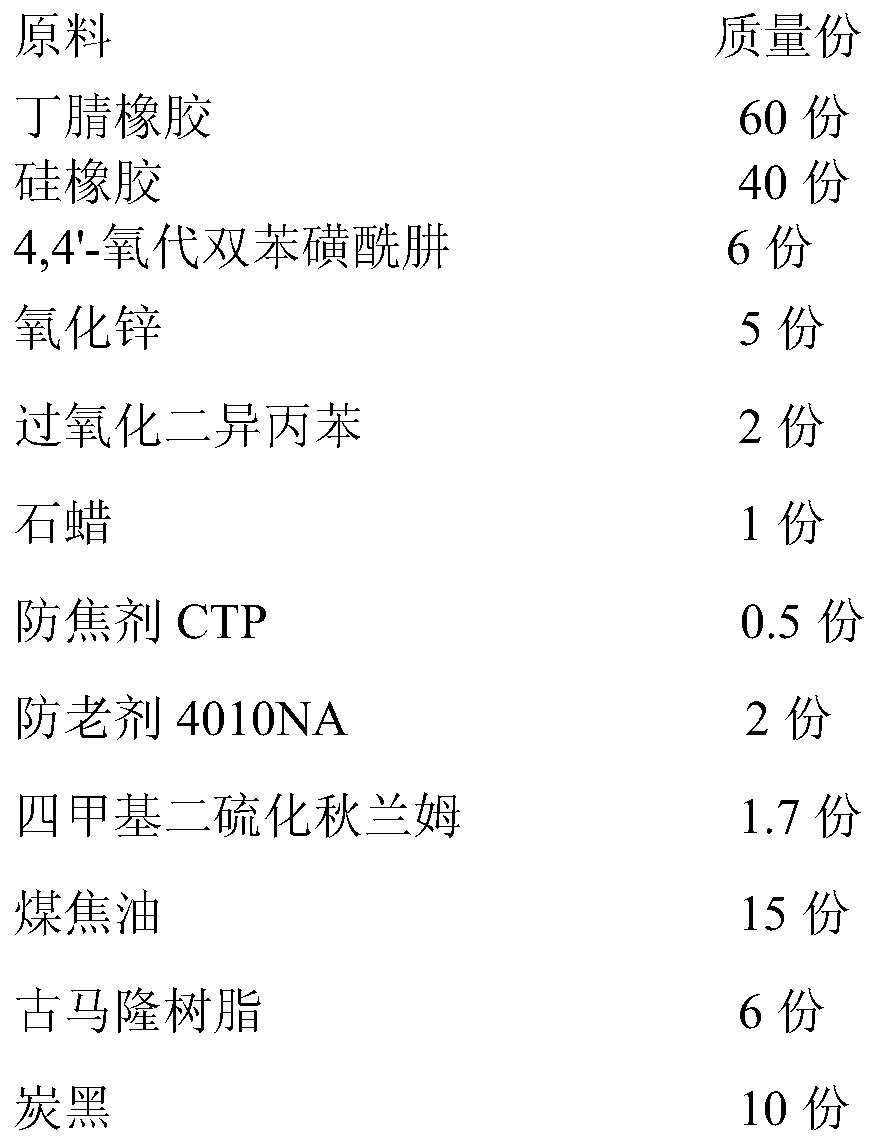

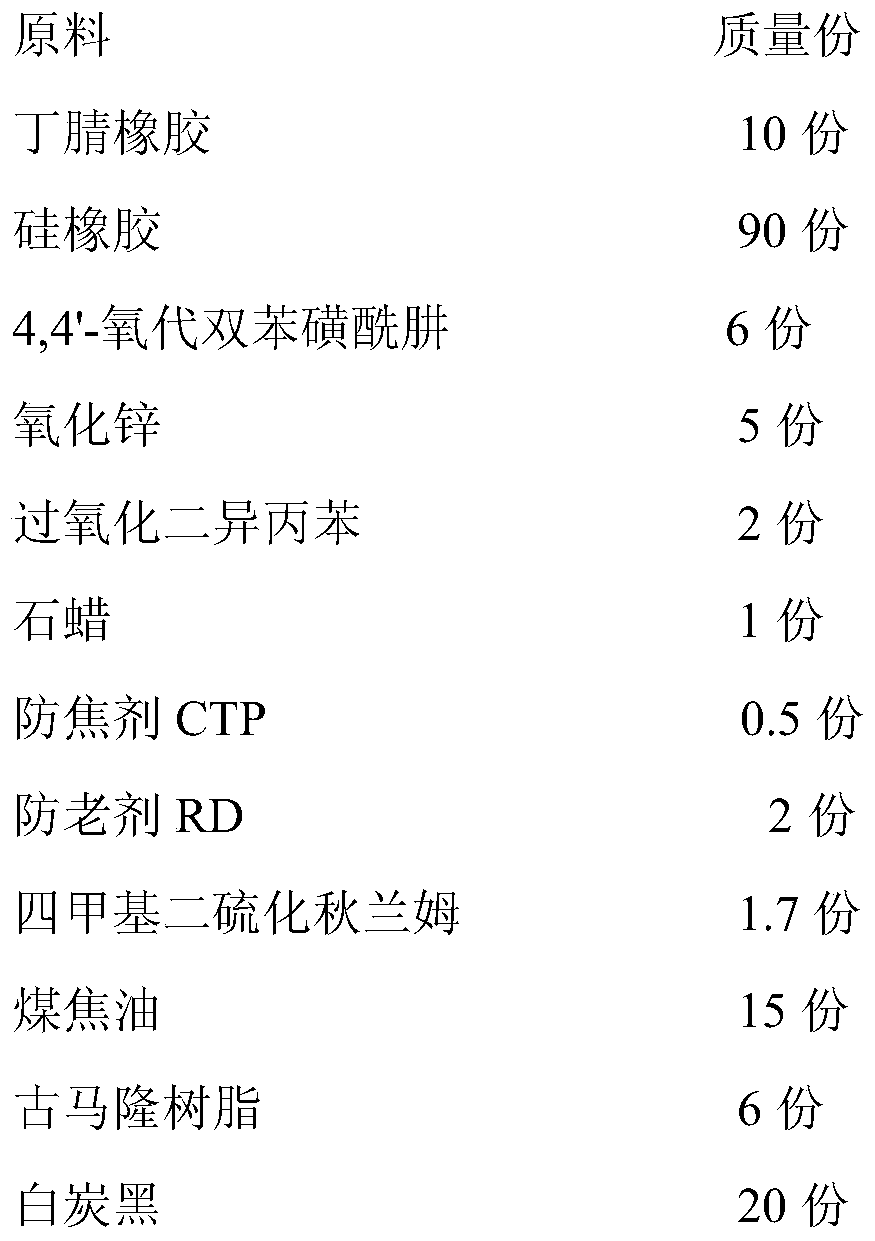

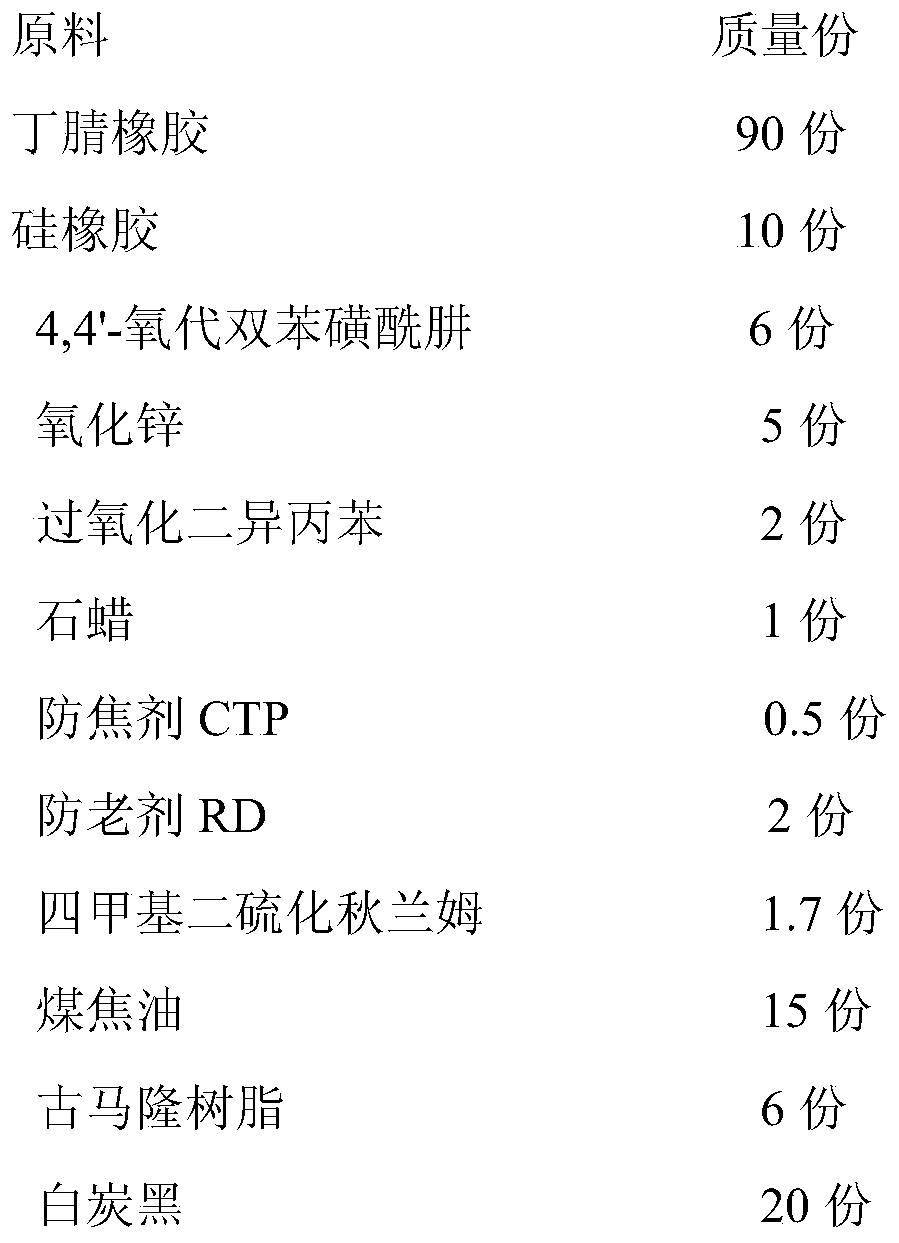

Compound damping foam rubber material and preparation method thereof

ActiveCN106543500AImprove sound absorption performanceOptimizing the Ratio of Raw RubberRubber materialSound energy

The invention provides a compound damping foam rubber material. The material is prepared from rubber, reinforcing filling and addition agents, wherein the addition agents comprise a vulcanizing agent, a dispersant, an anti-scorching agent, an anti-ageing agent, an accelerant, a secondary accelerant and a softening agent; the rubber is selected from at least two of silicone rubber, nitrile butadiene rubber, butadiene rubber, isoprene rubber and ethylene propylene rubber; and the addition agents also comprise a foaming agent. The compound damping foam rubber material provided by the invention has the advantages of light weight, cost reduction, good transformer oil resisting performance, good electric insulating performance and the like; a pore structure generated by foaming and the rubber material have a viscoelastic damping synergistic effect to enhance sound energy dissipation and improve noise-reduction performance of the compound damping foam rubber material; and the compound damping foam rubber material can be used as a sound-absorption and noise-reduction material to be applied to vibration absorption and noise reduction of a transformer body, and has remarkable economic and social benefits.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

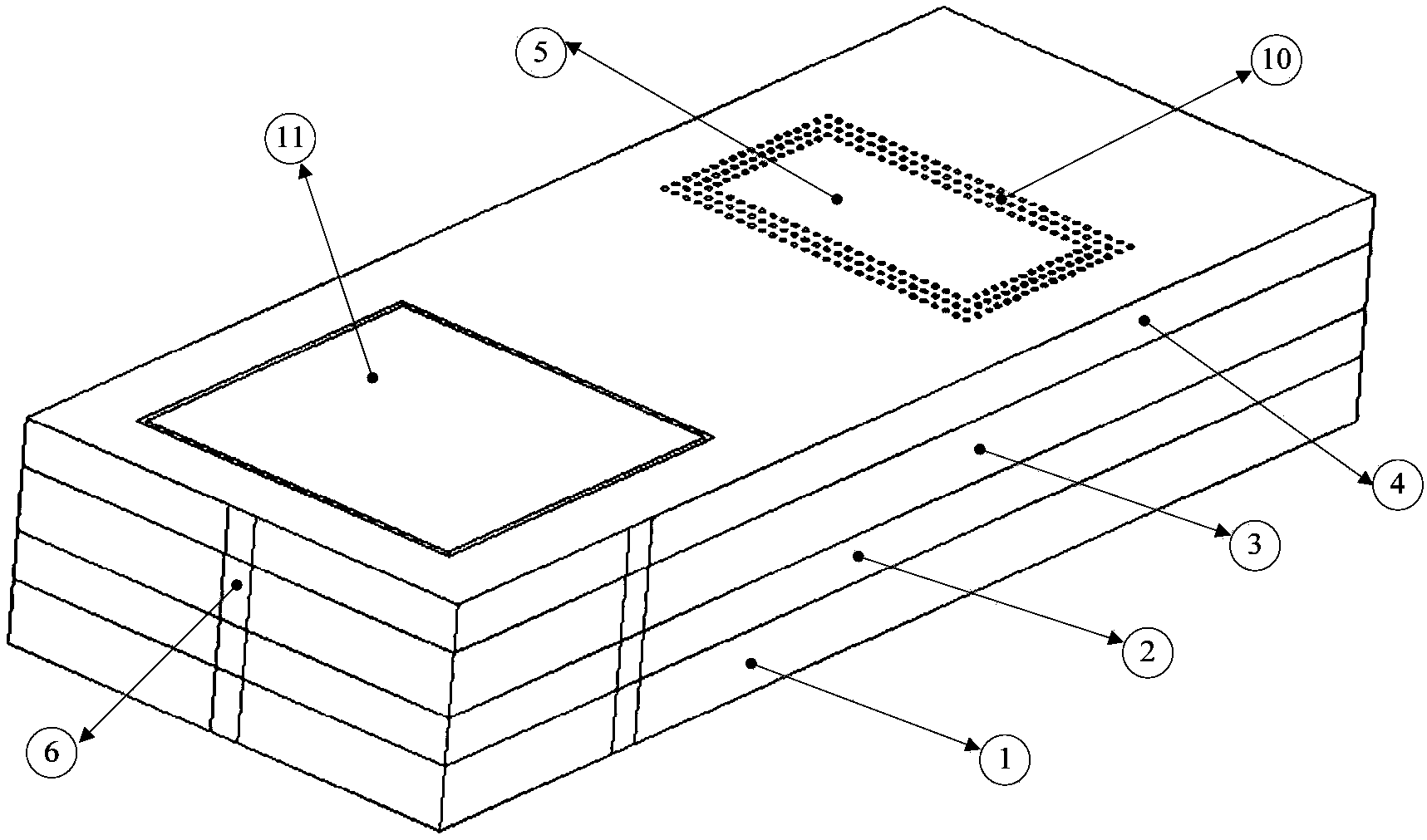

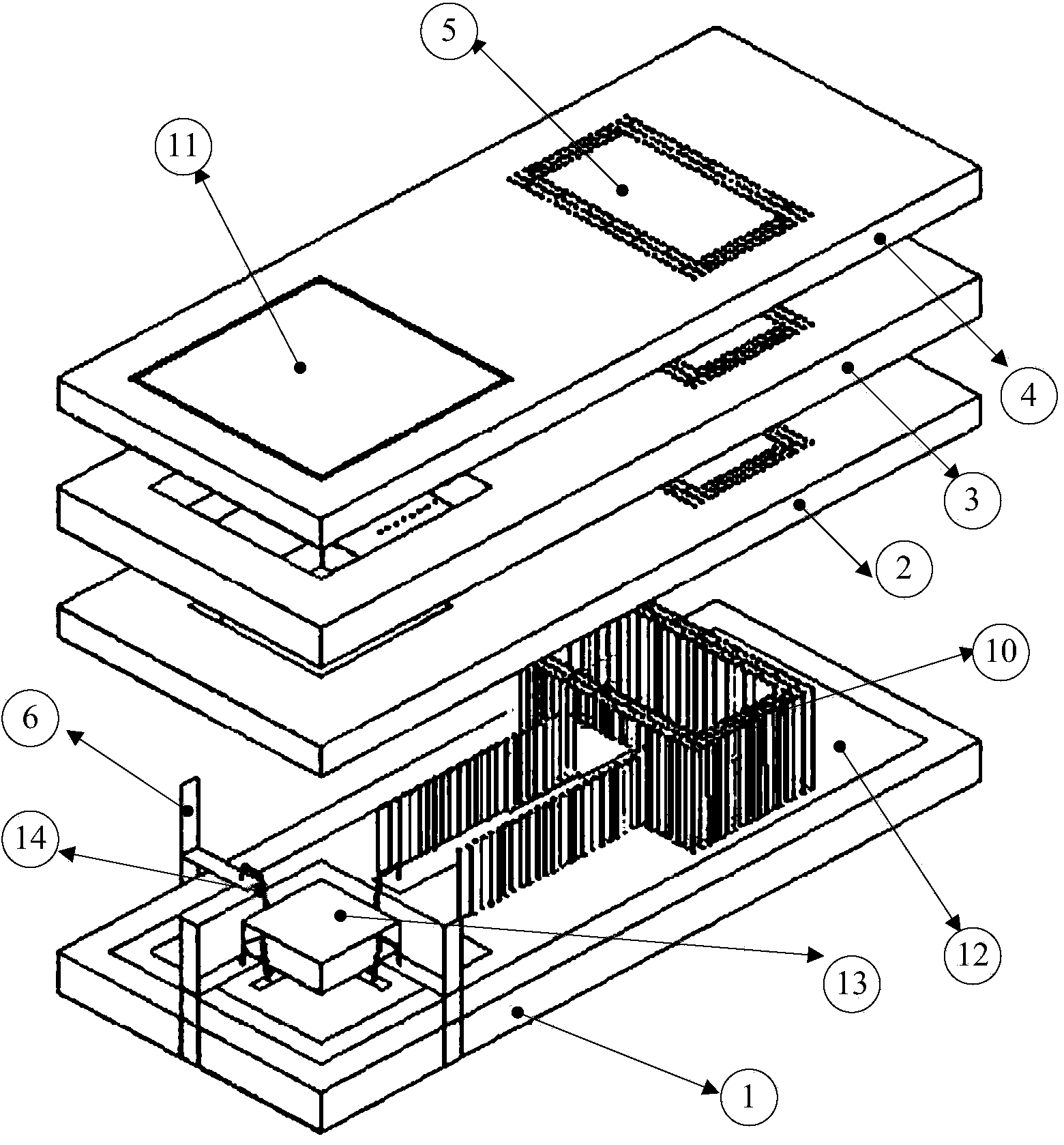

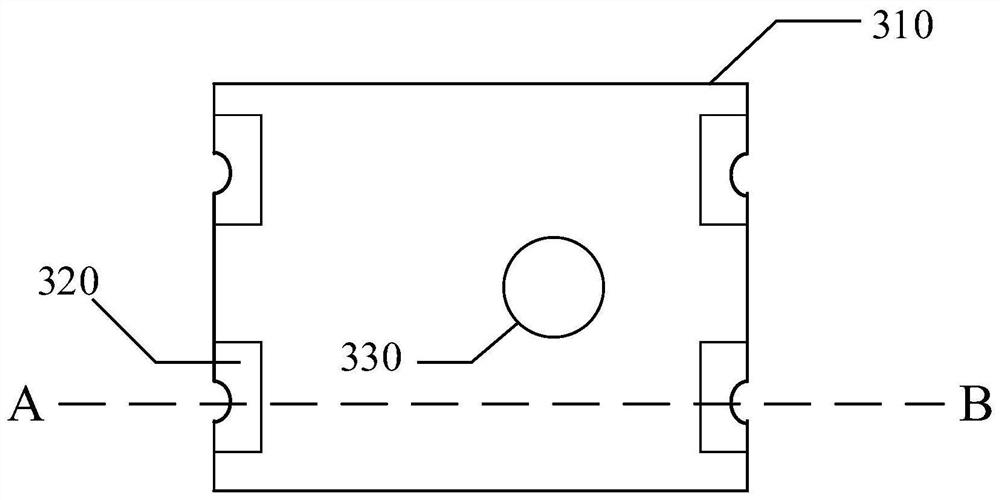

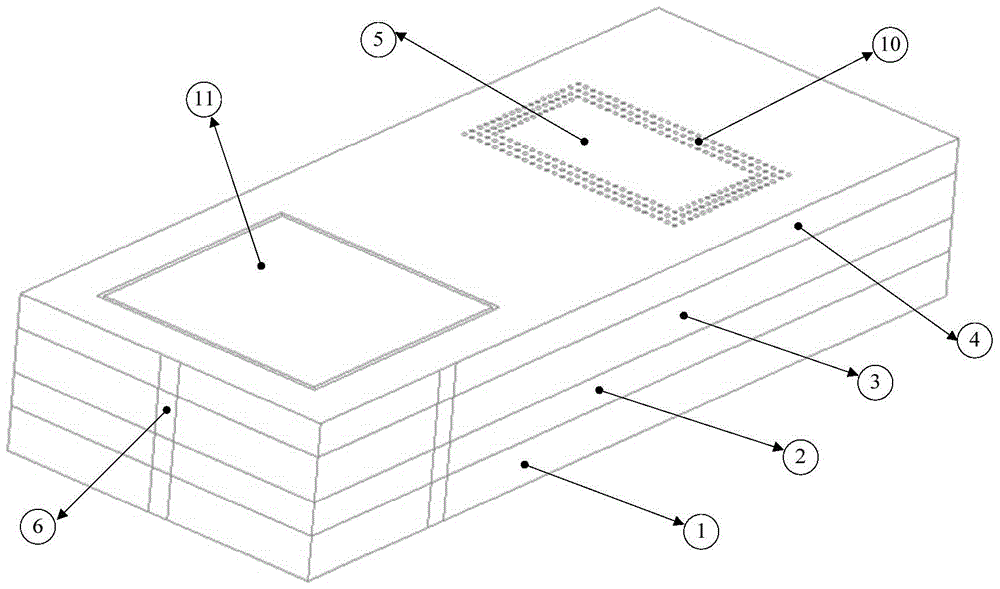

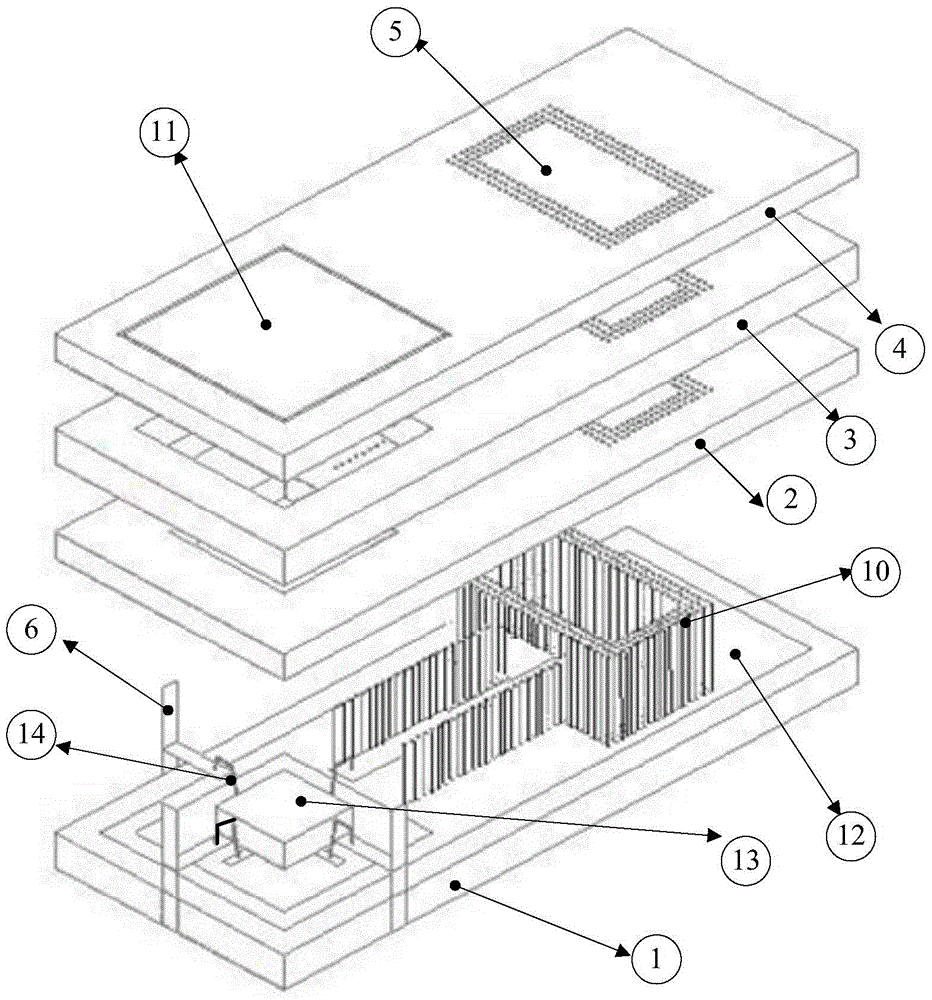

Packaging structure for integrating VCO and waveguide antenna

InactiveCN104051434ASmall sizeEasy to miniaturize designSemiconductor/solid-state device detailsSolid-state devicesPhysicsFrequency band

The invention discloses a packaging structure for integrating a VCO and a waveguide antenna. The packaging structure comprises an LTCC packaging body composed of a bottom dielectric substrate layer, a plurality of middle dielectric substrate layers and a top dielectric substrate layer. A VCO chip is packaged at one end of the LTCC packaging body, and a waveguide reflection cavity and a micro-strip coupling probe are packaged at the other end of the LTCC packaging body. Through the combination of the micro-strip waveguide conversion technology and the chip packaging technology, the E wave-band VCO and the micro-strip waveguide conversion antenna are integrated inside a standard LTCC packaging chip, the size for application and assembly of a microwave circuit is reduced, the miniaturization design of products is facilitated, and most importantly, the influence on the circuit by spurious and distribution parameters in the circuit connection process is effectively reduced. The performance of the packaging structure similar to that of a packaging mode through metal ceramic is obtained by the adoption of the LTCC packaging technology, the working frequency relative bandwidth is larger than 20 percent, and insertion losses caused by micro-strip waveguide conversion are smaller than 1.2 dB within the working band.

Owner:XIDIAN UNIV

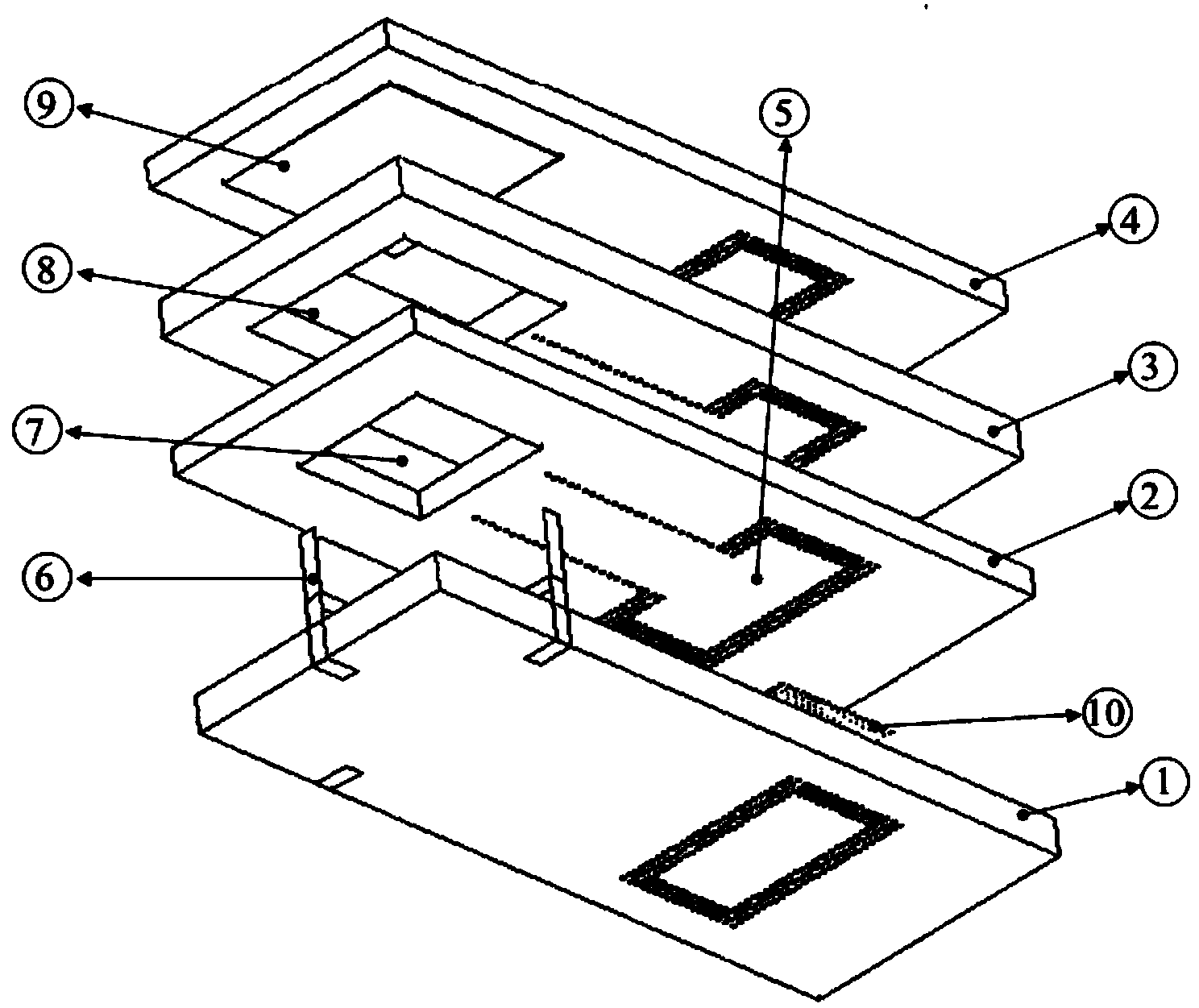

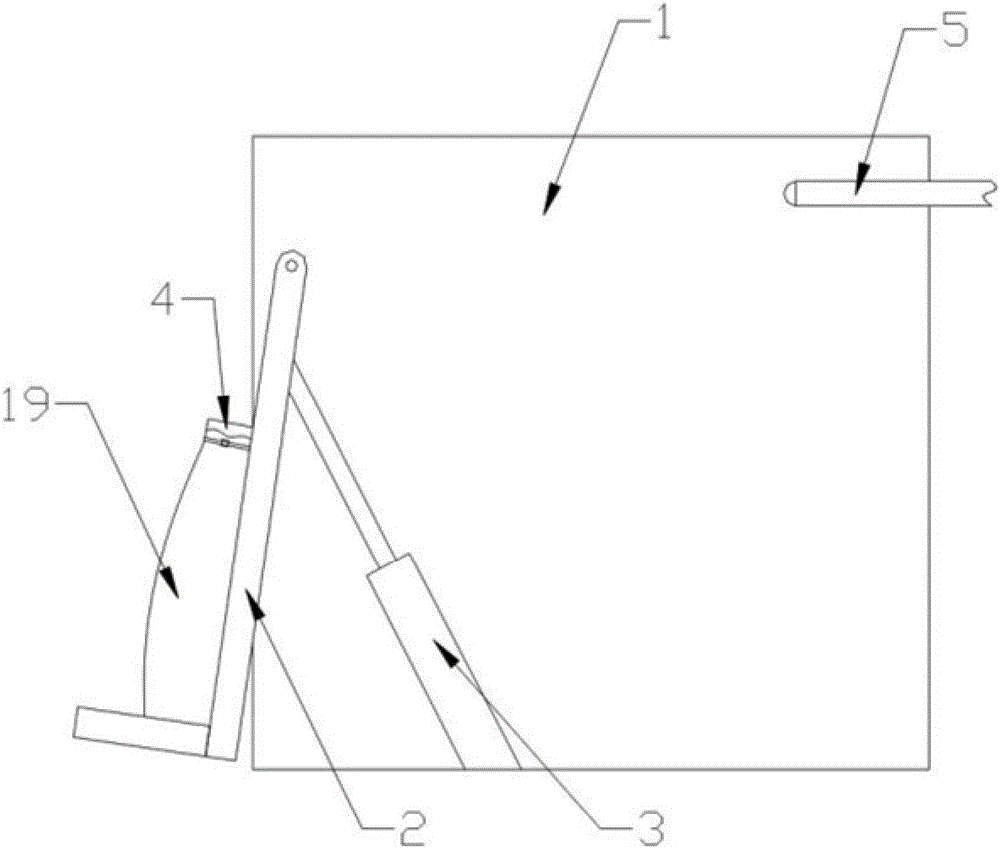

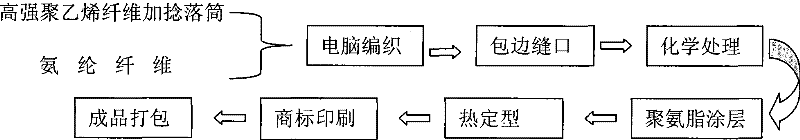

Technology for producing ultra-high strong fiber anti-cutting gloves

The invention relates to a technique for manufacturing a glove by taking ultra-strong polyethylene fibers as a base material; when weaving is carried out, the ultra-strong polyethylene fibers are adopted to weave all fingers and the first half part of the palm of the glove; the ultra-strong polyethylene fibers and urethane elastic fibers are adopted to weave the second half part of the palm in a blended way. Then surface chemical treatment is adopted to the glove to improve the wetting quality and the adhering property of the glove. Modified polyurethane resin coating and hot shaping are carried out to the fingers and the palm part of the glove. The technique of the invention has simple process, can realize large-scale automatic production and can effectively manufacture light and convenient and flexible soft anti-cut gloves that can prevent from cutting, stabbing, tearing and abrading.

Owner:NINGBO DACHENG ADVANCED MATERIAL

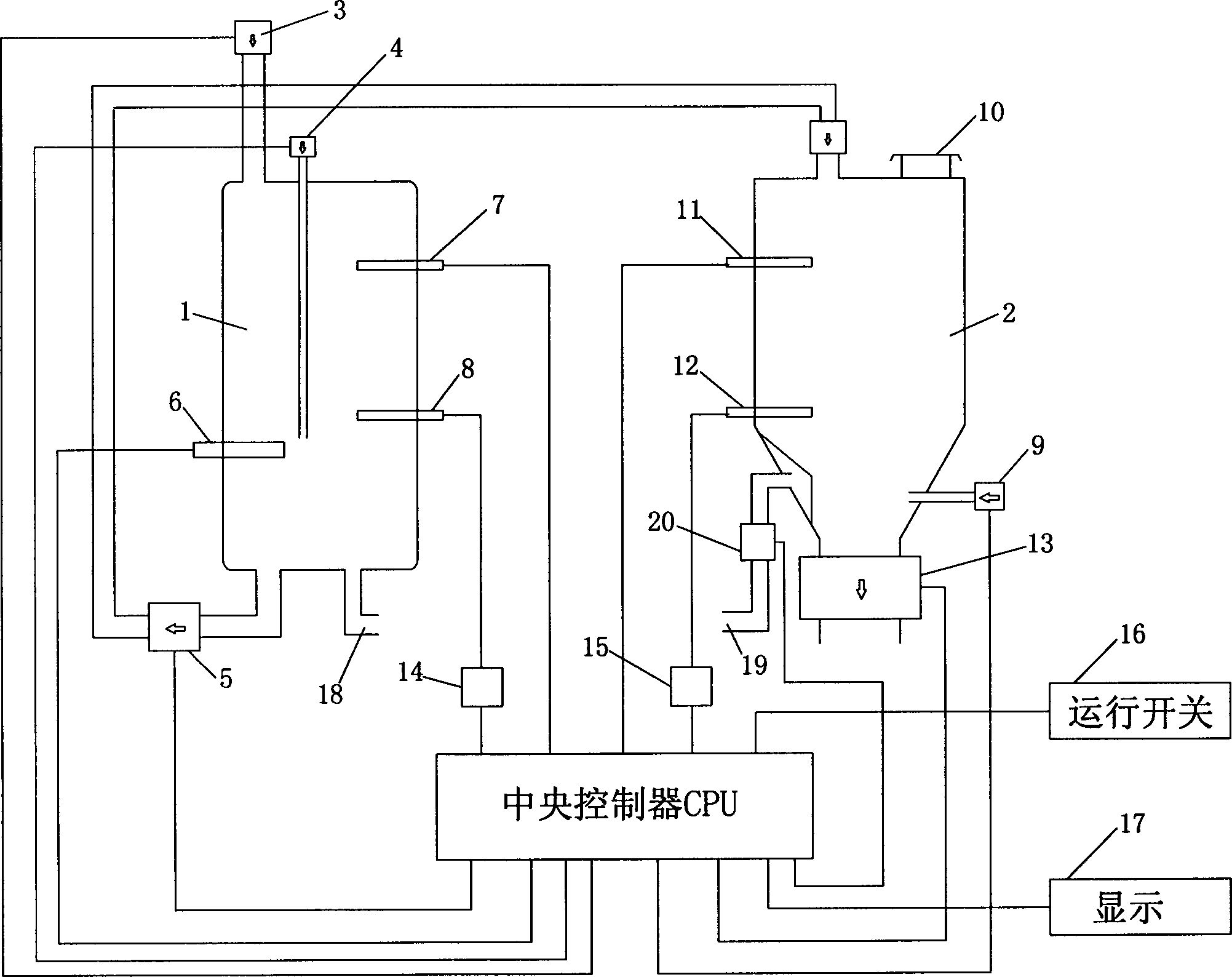

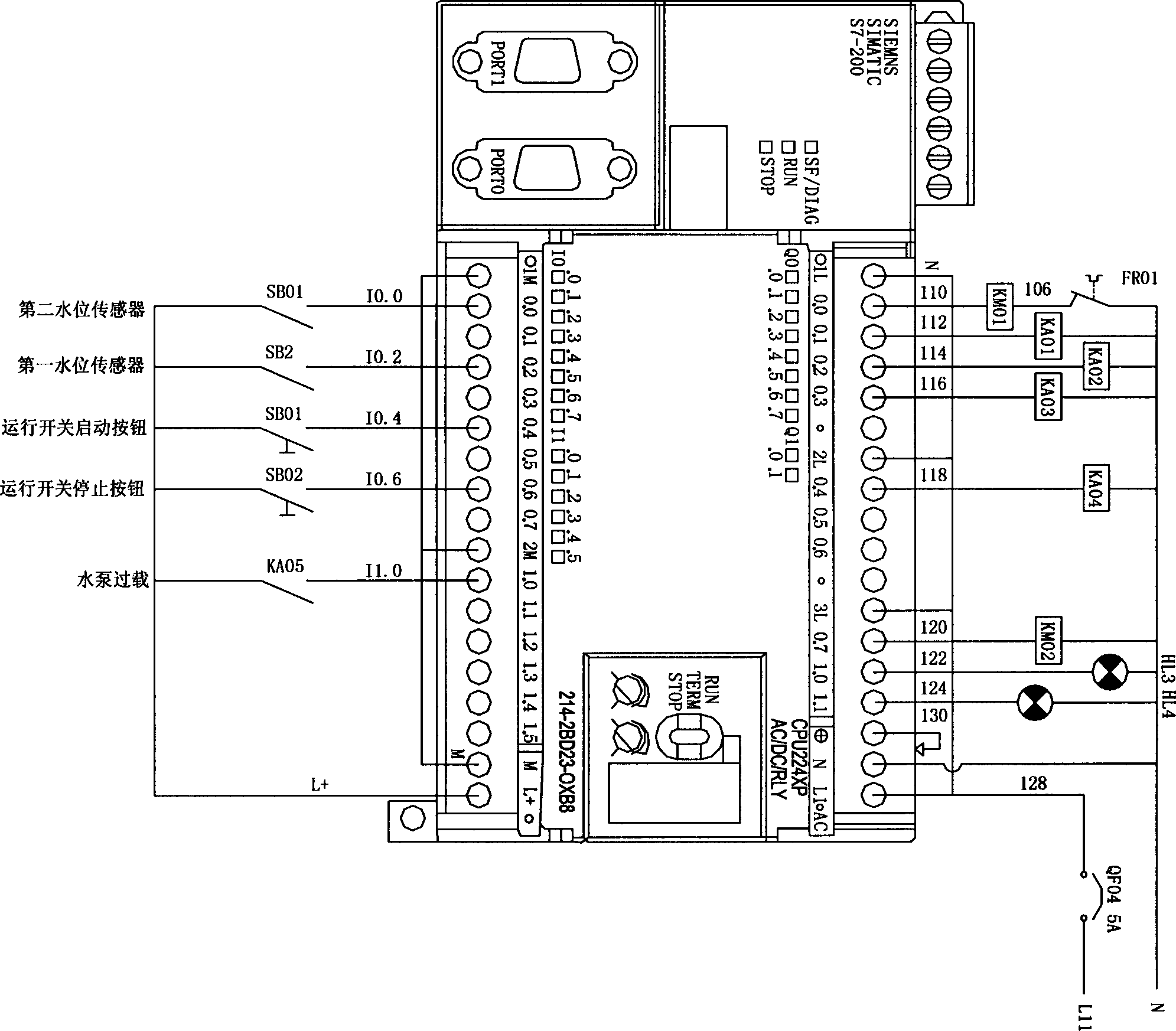

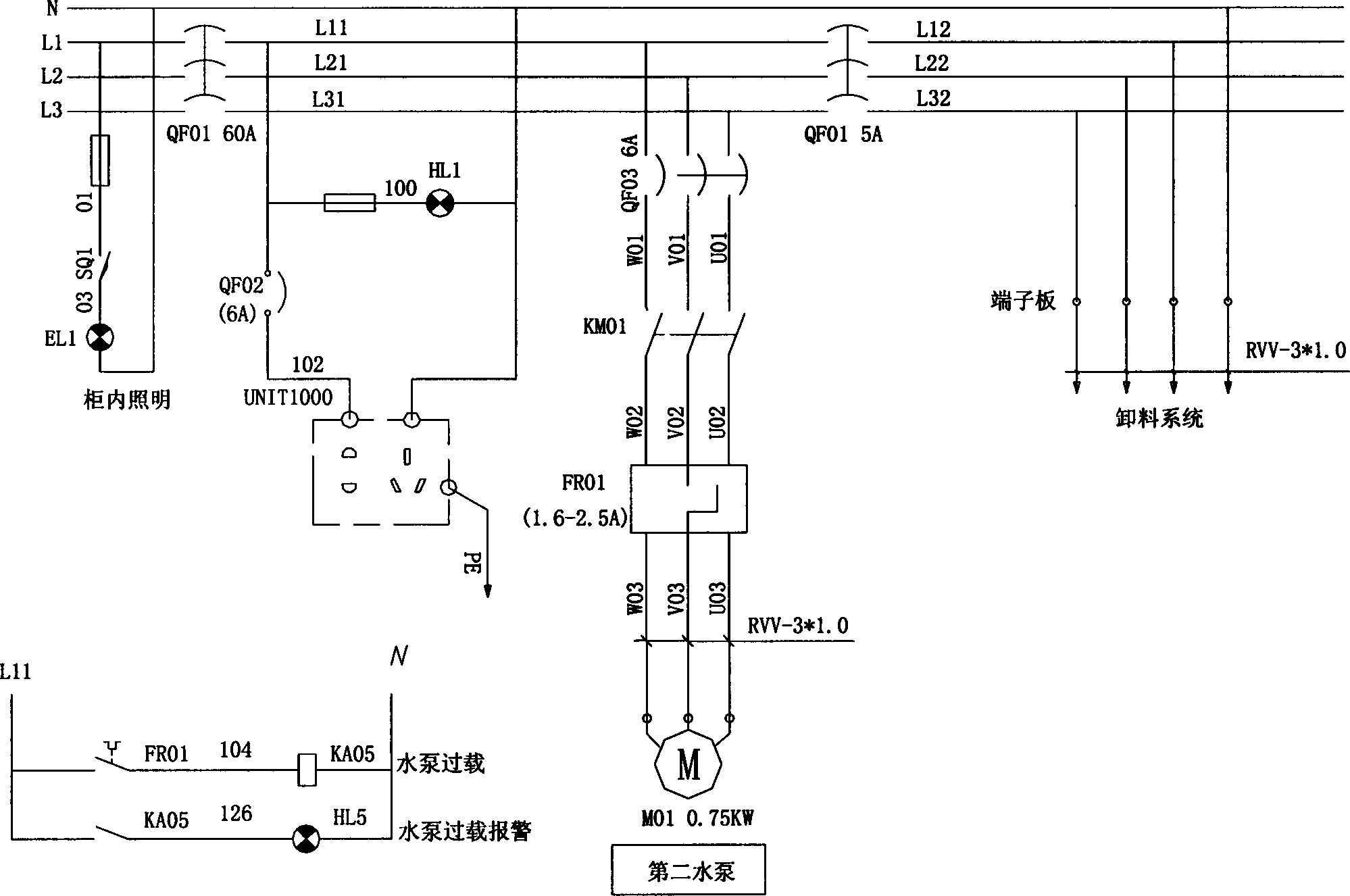

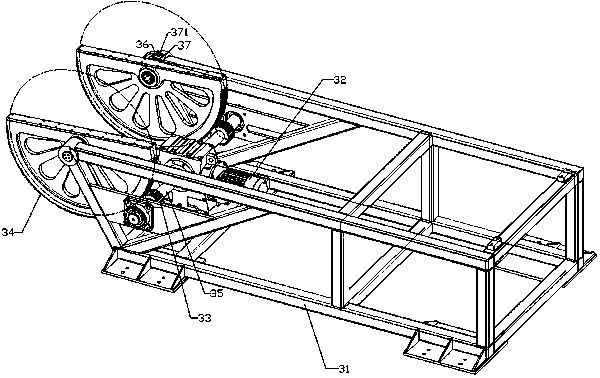

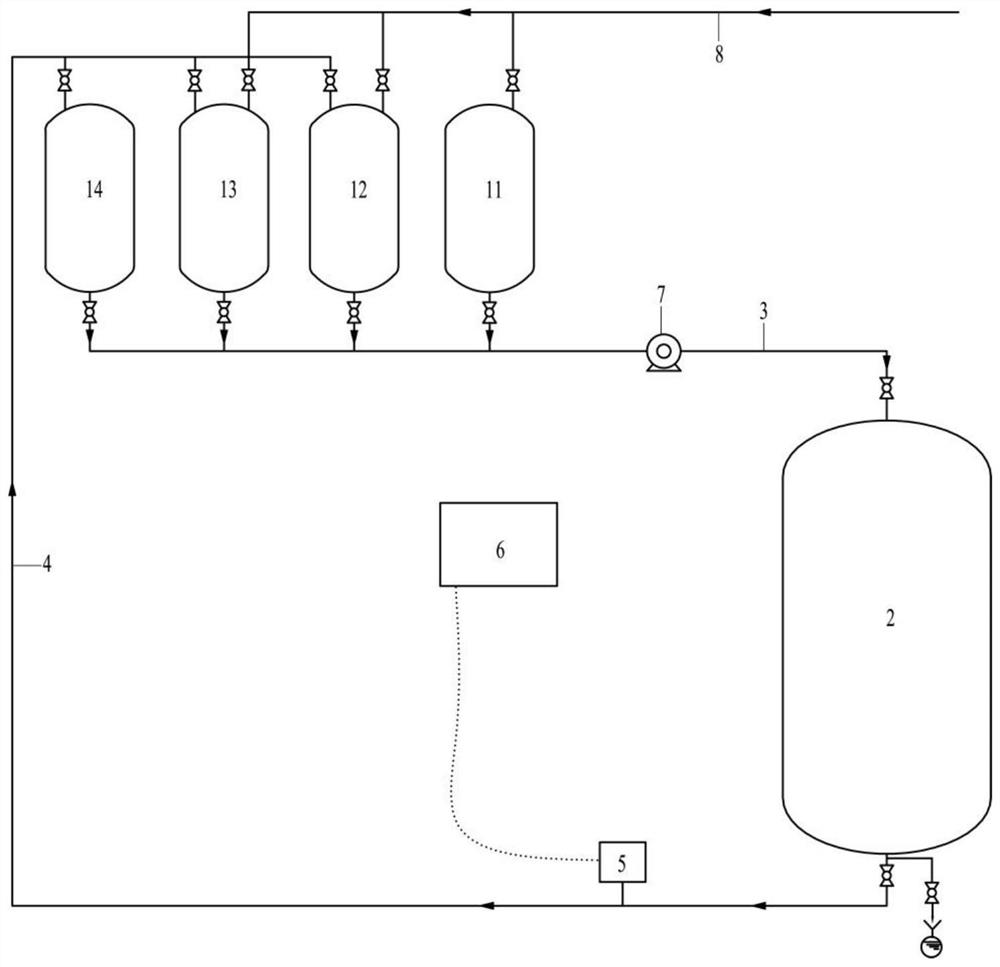

Device based on biological germination process technology and electrical control system

InactiveCN102669579ARealize large-scale automated productionExcellent man-machine communication interfaceAgriculture gas emission reductionCultivating equipmentsNutritive valuesWarm water

The invention discloses a device based on biological germination process technology and an electrical control system, wherein the device comprises a germination tank and a water tank matched with the germination tank, wherein a heating pipe, a first water level sensor and a first temperature sensor are arranged in the warm water tank; a second temperature sensor and a second water level sensor are arranged in the germination tank; parameters such as water exchange, sterilization, ventilation, material reversal, temperature and the like in the germination process of grains are controlled by a PLC (Programmable Logical Controller) control system, thereby guaranteeing the stress (adverse) environments of germination and guaranteeing great increase of functional nutritional ingredients and improvement of germination percentage and production efficiency after germination. Compared with the previous germination device, the device disclosed by the invention adopts an advanced programmable control system and an excellent human-machine interaction interface, and has a series of advantages of high automation degree, high production efficiency, labor-saving property, simplicity in operation, high yield and the like; and the device is capable of industrially producing germination foods with high nutritive value.

Owner:南京珵儒机械科技有限公司

Process for producing novel antibacterial thermal home textile yarns

InactiveCN108193336ASkin-friendly and comfortableImprove yarn strengthCarbon fibresBiochemical fibre treatmentCardingCarbon fibers

The invention discloses a method for spinning and weaving novel antibacterial thermal home textile yarns. The novel antibacterial thermal home textile yarns comprise, by weight, 35%-65% of coffee carbon fibers, 15%-25% of modal fibers and 15%-25% of PTT (polytrimethylene terephthalate) fibers. The coffee carbon fibers, the modal fibers and the PTT fibers are blended to form the novel antibacterialthermal home textile yarns. The method for processing the novel antibacterial thermal home textile yarns includes working procedures of blowing, cotton carding, drawing, roving, spinning and the like. The method has the advantages that the method includes simple processes, and the novel antibacterial thermal home textile yarns can be automatically produced by the aid of the method on a large scale; the novel antibacterial thermal home textile yarns are skin-friendly, comfortable, antibacterial and thermal, and are high in yarn strength, low in hairiness and excellent in moisture absorption and breathability, pilling can be prevented, requirements of consumers in family, hotels and the like can be met, home textile fabrics woven by the aid of the method are fluffy and thermal, and accordingly the method has an excellent application prospect.

Owner:IANGSU COLLEGE OF ENG & TECH

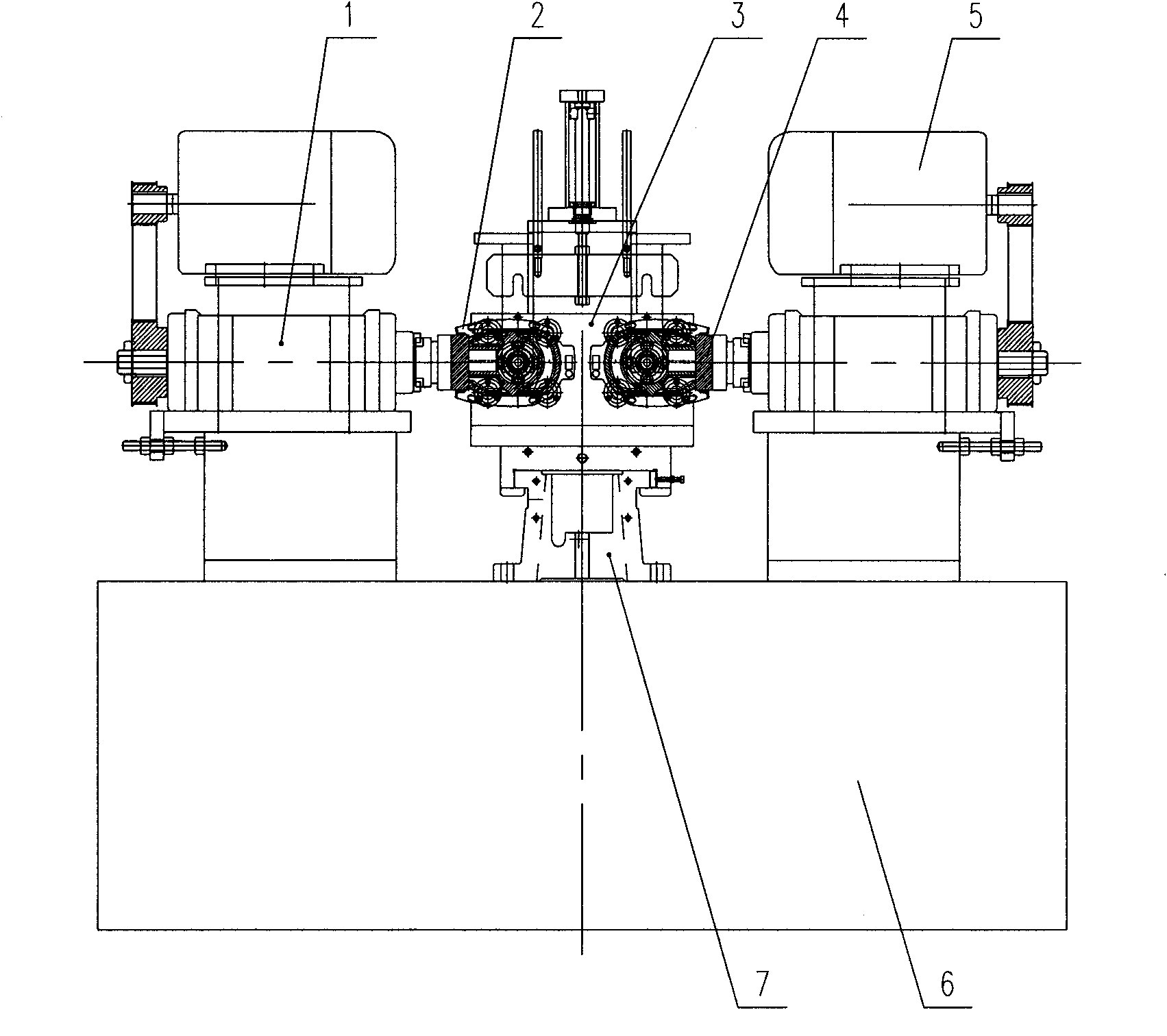

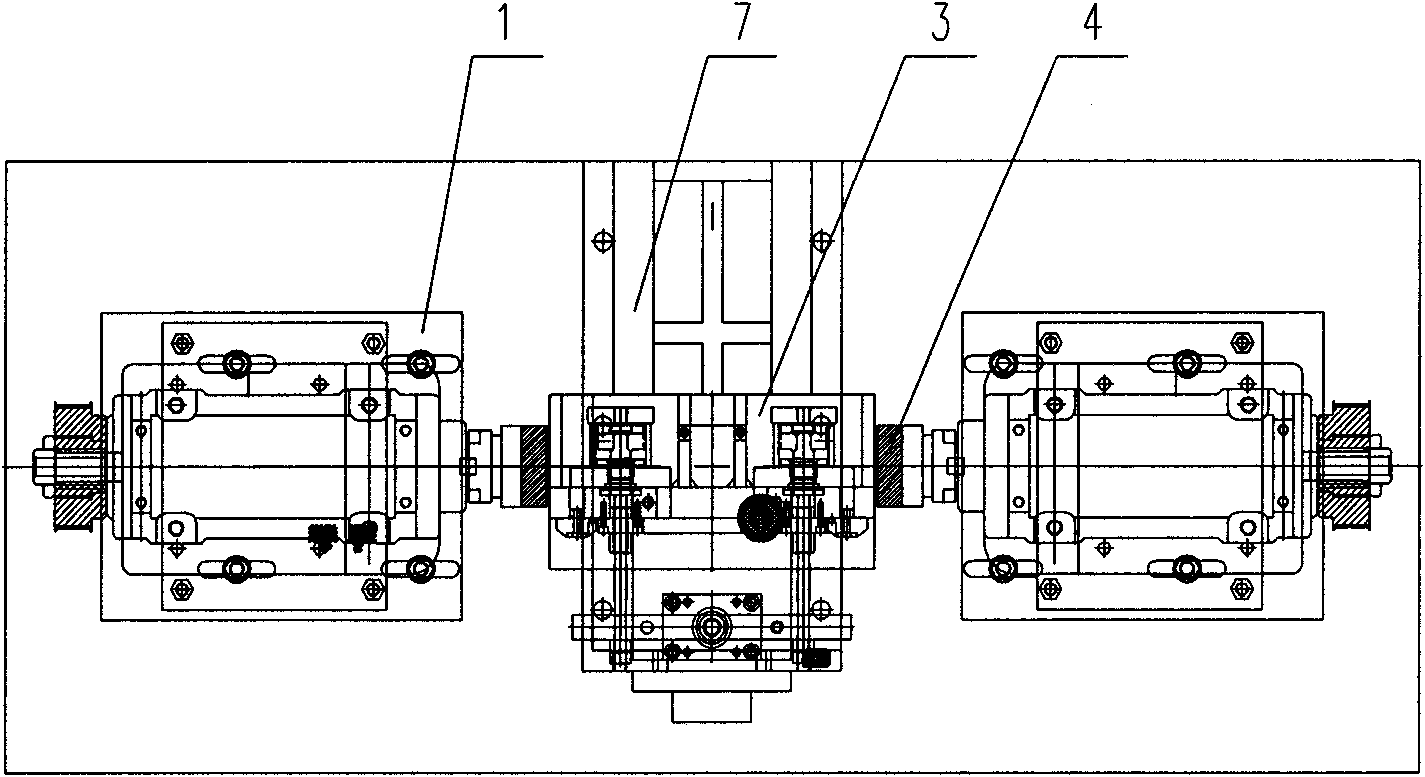

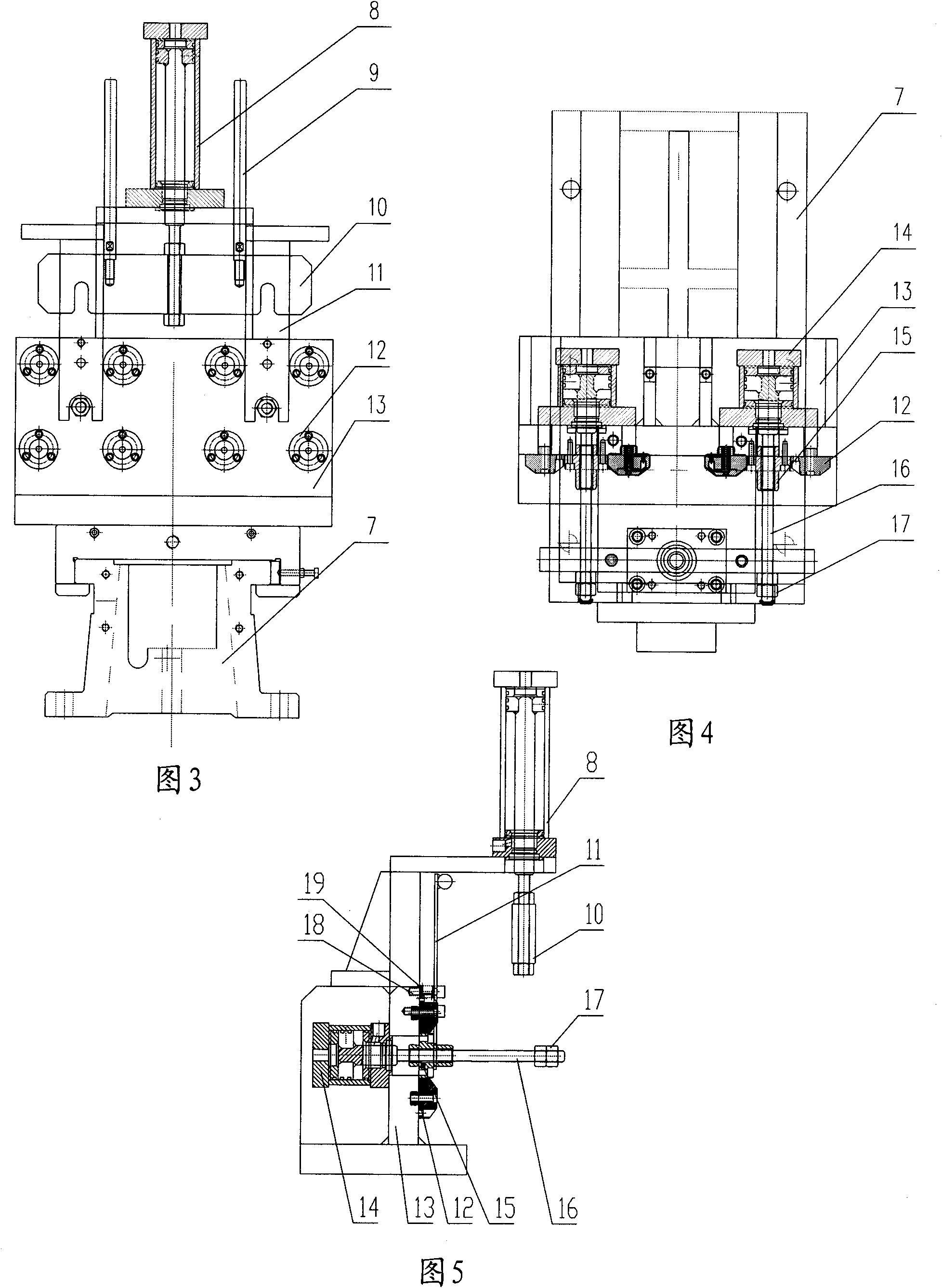

Special machine tool for rough milling cylinder head end surface

InactiveCN102059380AIncrease productivityEasy to useMilling machinesLarge fixed membersCylinder headEngineering

The invention relates to a special machine tool for a rough milling cylinder head end surface. The special machine tool comprises a machine tool body, wherein the upper end surface of the machine tool body is provided with two opposite power head components; the machine tool body between the two power head components is provided with a sliding table; and a fixture body capable of clamping two workpieces at the same time is mounted on the sliding table. The special machine tool for the rough milling cylinder head end surface of Danfoss cylinder has advantages of scientific and reasonable design and high practicability, and is simple and convenient to use; and moreover, by utilizing the special machine tool, the production efficiency is improved, the production time is shortened, the labor intensity of workers is reduced, manpower and material resources are remarkably saved, and large-scale automatic production is realized.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

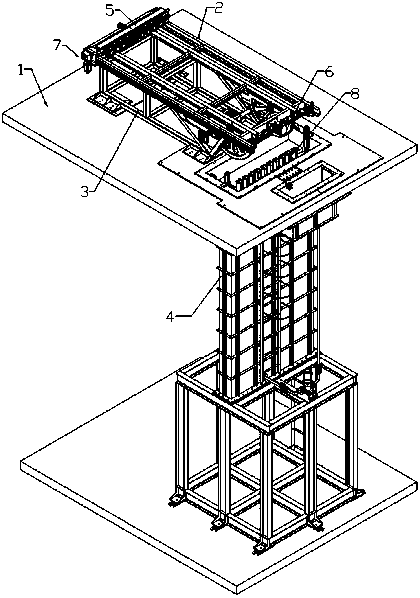

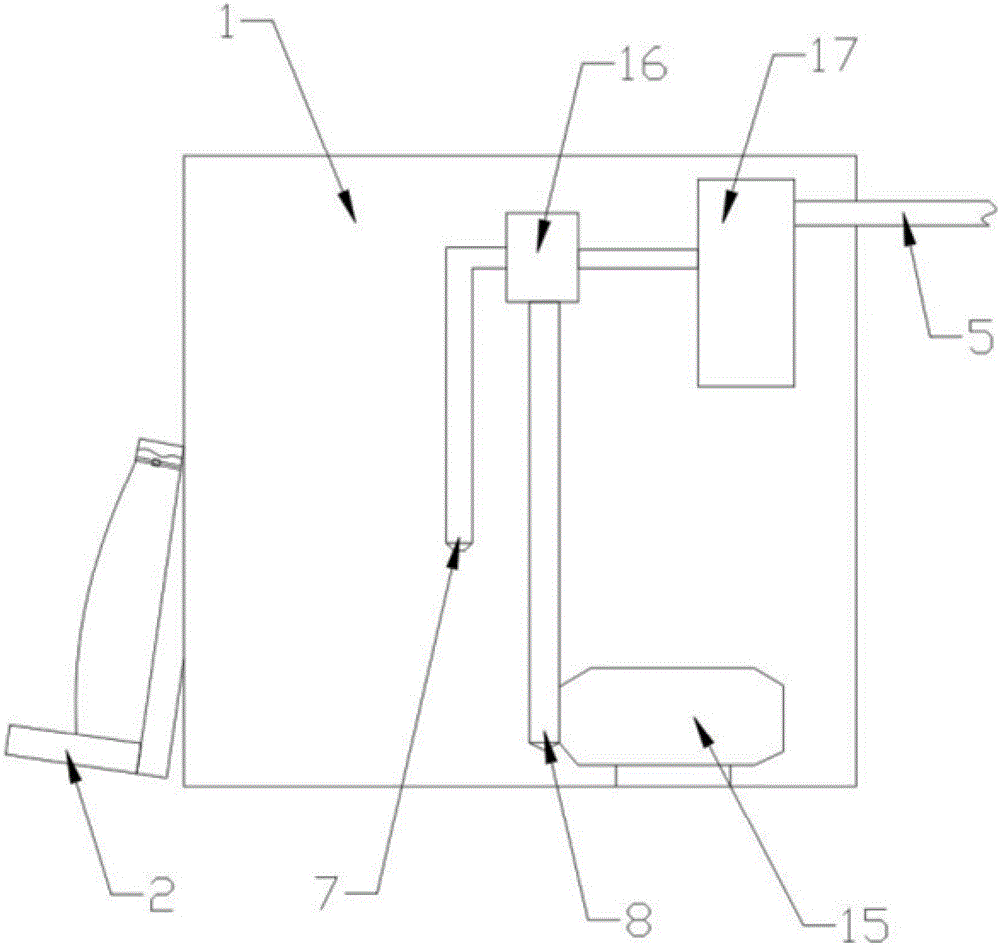

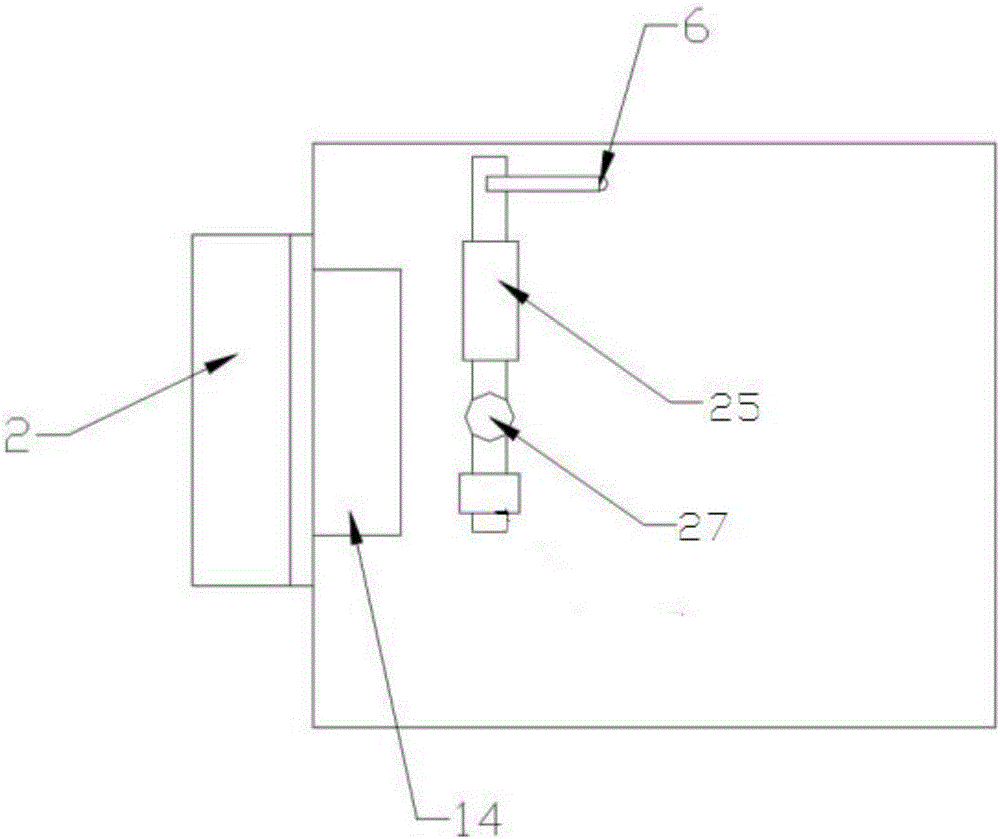

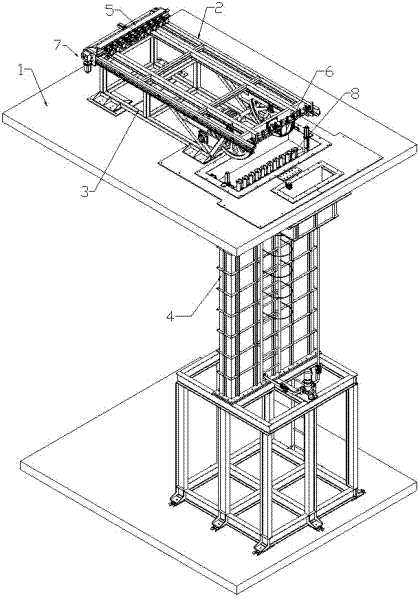

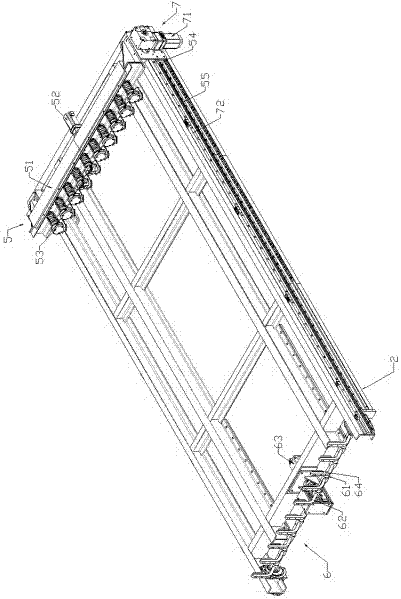

Glass tube coating device

ActiveCN104069980ARealize fully automatic workRealize large-scale automated productionLiquid surface applicatorsCoatingsAutomatic controlLocking mechanism

The invention relates to a glass tube coating device which comprises a rack, wherein a glass holding frame, a locking mechanism, a turnover mechanism and a lifting mechanism are arranged on the rack; the turnover mechanism comprises a support, a turnover motor, a driving gear and a driven gear; the driving gear is meshed with the driven gear, and the driven gear is a semicircular gear; the circle center of the semicircular gear is articulated with the support, and the right-angle side of the semicircular gear is fixed to the glass holding frame; the turnover motor is fixed on the support, drives the driving gear to rotate, further drives the driven gear to rotate, and further drives the glass holding frame to rotate. Through the transition between the horizontal state and the vertical state of a glass tube and match with the longitudinal movement, the glass tube coating device with a novel structure realizes fully-automatic operation of feeding, rotating, decreasing infiltration coating, lifting, rotating and discharging and completely automated control, can realize large-scale automated production, and greatly improves the production efficiency.

Owner:北京天瑞星光热技术有限公司

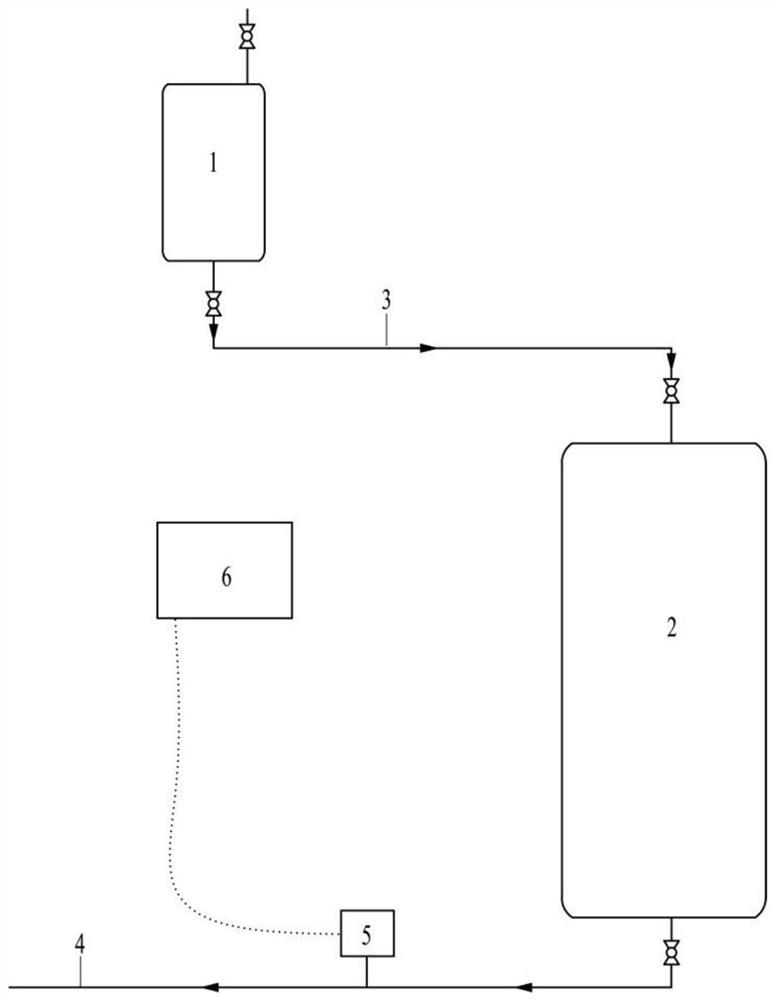

Automobile urea production device

PendingCN106492664ARealize large-scale automated productionIncrease productivityWater treatment parameter controlFlow mixersMechanical engineeringUltrapure water

The invention discloses an automobile urea production device. The automobile urea production device comprises a feeding system, a quantitative filling system, a circulating stirring system and a finished product solution output system, wherein the feeding system is used for pouring bagged urea; the quantitative filling system is used for filling ultrapure water; the circulating stirring system is used for mixing the pure water and the urea; the finished product solution output system is used for output the stirred solution; the quantitative filling system comprises a water filling system, a heating circulating system and a water supplementing system. The automobile urea production device with the above structure realizes large-scale automatic production, greatly improves the production efficiency and meets the production requirements.

Owner:CHENGDU GANWEI TECH

Preparation method of ultra-high molecular weight polyethylene cotton type cut-resistant gloves

ActiveCN104814549BImprove cut resistanceIncrease elasticityProtective garmentSpecial outerwear garmentsGlass fiberPolymer science

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

Technology for producing ultra-high strong fiber anti-cutting gloves

The invention relates to a technique for manufacturing a glove by taking ultra-strong polyethylene fibers as a base material; when weaving is carried out, the ultra-strong polyethylene fibers are adopted to weave all fingers and the first half part of the palm of the glove; the ultra-strong polyethylene fibers and urethane elastic fibers are adopted to weave the second half part of the palm in a blended way. Then surface chemical treatment is adopted to the glove to improve the wetting quality and the adhering property of the glove. Modified polyurethane resin coating and hot shaping are carried out to the fingers and the palm part of the glove. The technique of the invention has simple process, can realize large-scale automatic production and can effectively manufacture light and convenient and flexible soft anti-cut gloves that can prevent from cutting, stabbing, tearing and abrading.

Owner:NINGBO DACHENG ADVANCED MATERIAL

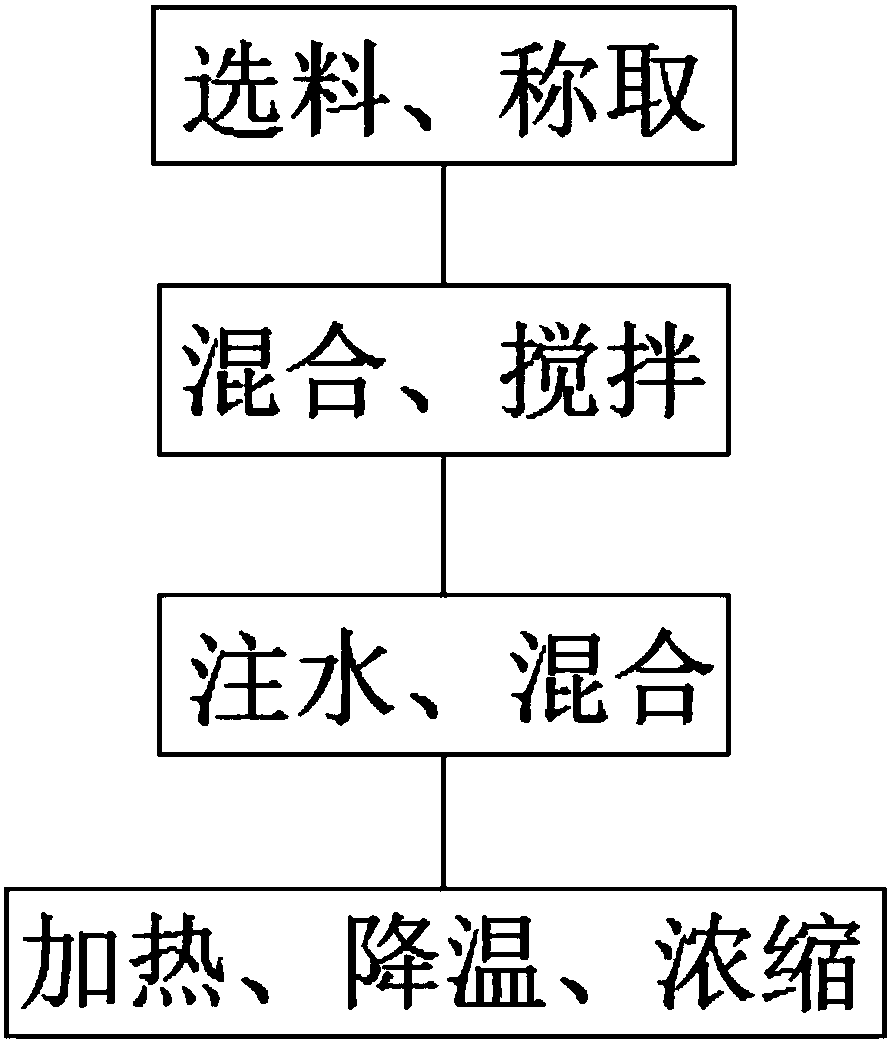

Production process of low-formaldehyde vehicle urea

InactiveCN109894005AIncrease productivityStirring speed is fastDispersed particle separationUreaProcess engineering

The invention discloses a production process of a low-formaldehyde vehicle urea. The production process comprises the following steps: a, first, the selection of urea raw materials is carried out, then the selected raw materials are classified, and then the classified raw materials are placed on an electronic scale for weighing one by one; b, after step a is finished, the weighed raw materials arepoured into a mixer, and then the mixed raw materials are stirred by using a stirrer; c, after step b is finished, pure water is injected into the mixer to mix with the mixed raw materials to form aurea solution; d, after step c is finished, the urea liquid is subjected to concentration including heating and cooling. The process can realize large-scale automatic production, greatly improve production efficiency, and meet the production requirements; operation is performed by using a stirring and heating integrated machine, the stirring speed of the urea raw materials can be effectively accelerated, the stirring time is reduced, the transfer of the urea raw materials is avoided, the probability of oxidation of the urea raw materials is reduced, and the stability of the urea in the production process is improved.

Owner:广州蓝禾素环保科技有限公司

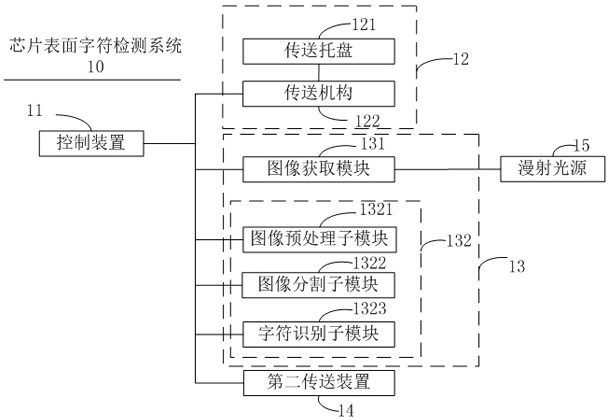

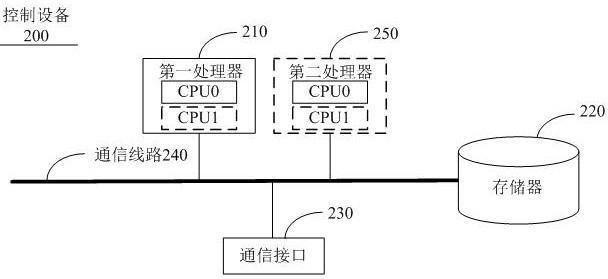

Chip surface character detection system

InactiveCN114187596ARealize automatic sortingImprove accuracySortingInstrumentsInformation controlControl character

The invention discloses a chip surface character detection system, relates to the technical field of chip production and testing, and aims to realize automatic sorting of chips and improve the production and testing efficiency of the chips. The system comprises a character recognition device, a first conveying device, a second conveying device and a control device. The control device is used for controlling the first conveying device to convey the chips to the recognition area of the character recognition device according to the preset conveying rate. The control device is further used for controlling the character recognition device to obtain a first image of the characters on the upper surface of the chip in the recognition area according to a preset recognition rate. Wherein the character recognition device is used for sequentially carrying out image binarization processing and image segmentation on the first image to obtain a plurality of character areas, and respectively matching the plurality of character areas with a preset character template to determine surface character detection information of the chip. And the control device is used for controlling the second conveying device to convey the chip to a target position according to the surface character detection information.

Owner:成都爱旗科技有限公司

Multi-component ultrahigh-entropy lightweight refractory composite material

ActiveCN112877559AGive full play to high temperature strengthHigh temperature strengthOxidation resistantSpaceflight

The invention provides a multi-component ultrahigh-entropy light-weight refractory composite material. Four light alloy elements including Mo, Ti, Al and Nb are used as a matrix, non-metallic elements including Si, C, N, B and O are introduced into the matrix, and the composite material contains multiphase ceramics including TiC, TiB2, SiC, Si3N4, BC, MoSi2, Nb2O5, SiO2 and the like, so that the high-temperature strength and oxidation resistance of the matrix are effectively improved, and the low-density, high-temperature, high-toughness and long-term oxidation resistance performance of alloy can be achieved. According to the multi-component ultrahigh-entropy light-weight refractory composite material, the composite material is prepared through powder mixing, forming, sintering and pre-oxidation, and the anti-oxidation time of the composite material in the air environment of 800-1500 DEG C is 100-300 h; the room-temperature tensile strength is 600-1000 MPa, and the ductility is greater than or equal to 10%; and the density is 4.5-5.5 g / cm<3>. The multi-component ultrahigh-entropy light-weight refractory composite material is suitable for the fields of aviation, spaceflight, weapons, nuclear energy, microelectronics and the like.

Owner:长沙微纳坤宸新材料有限公司

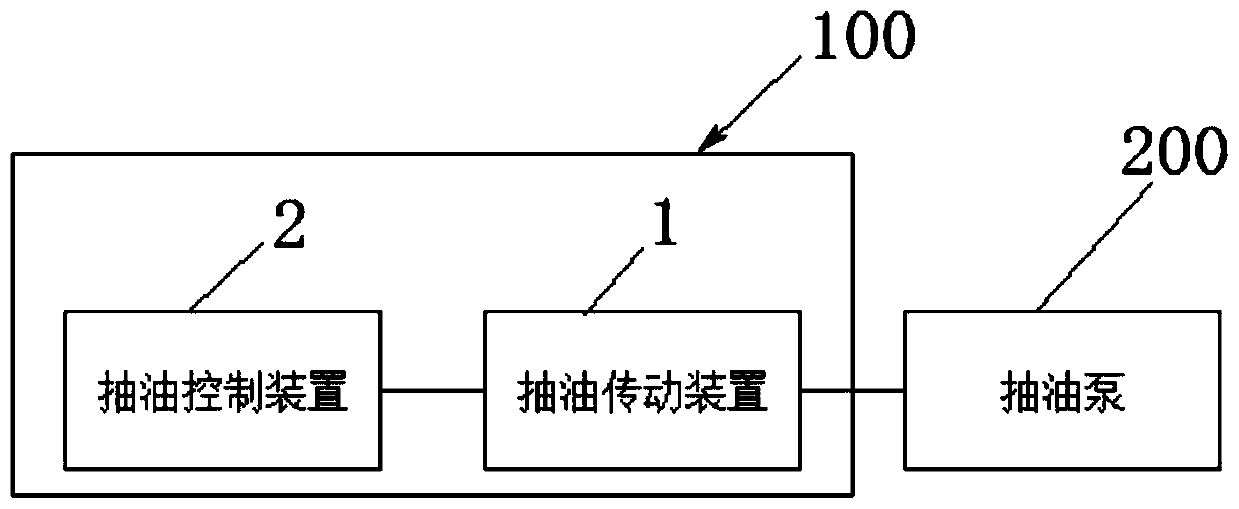

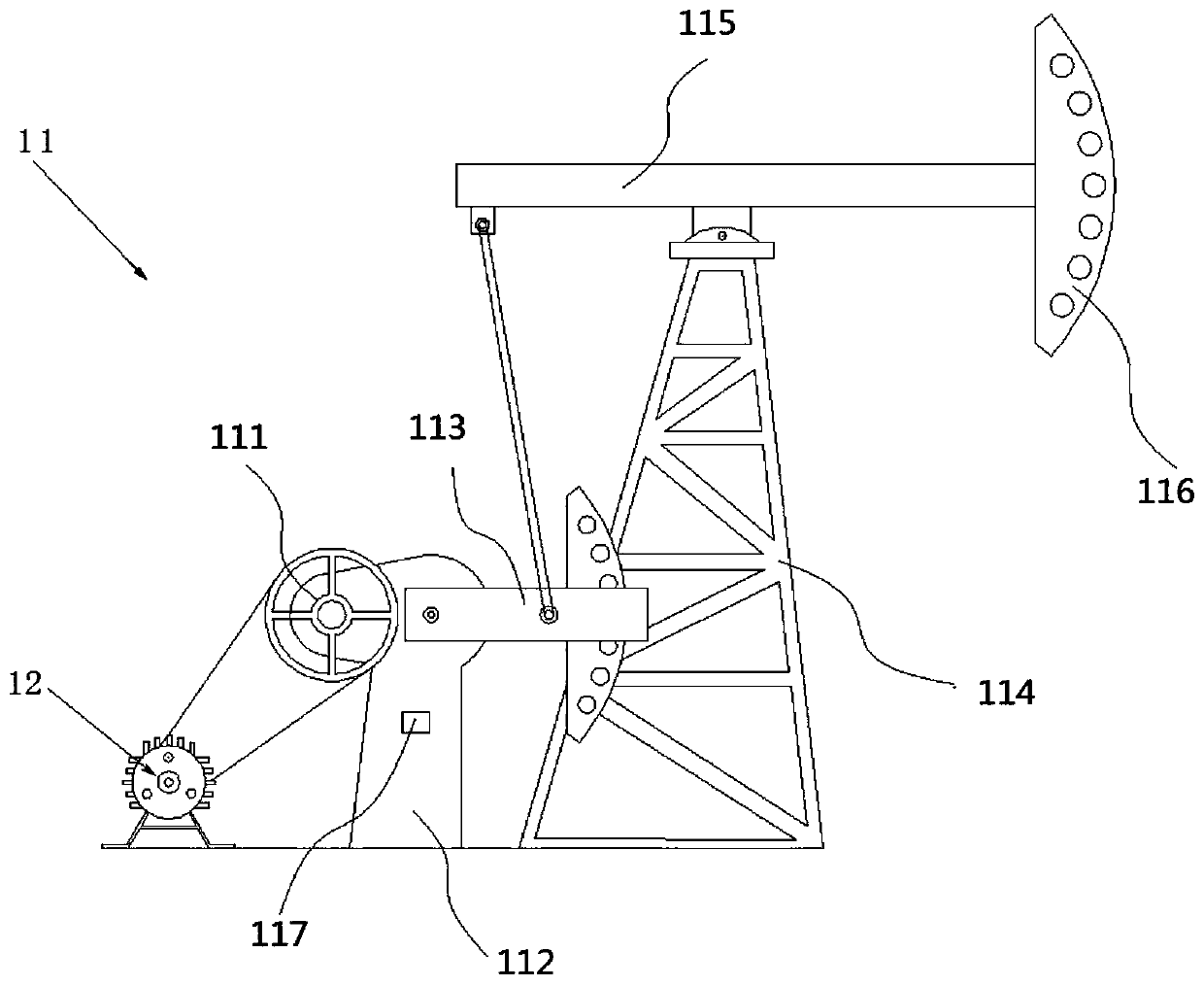

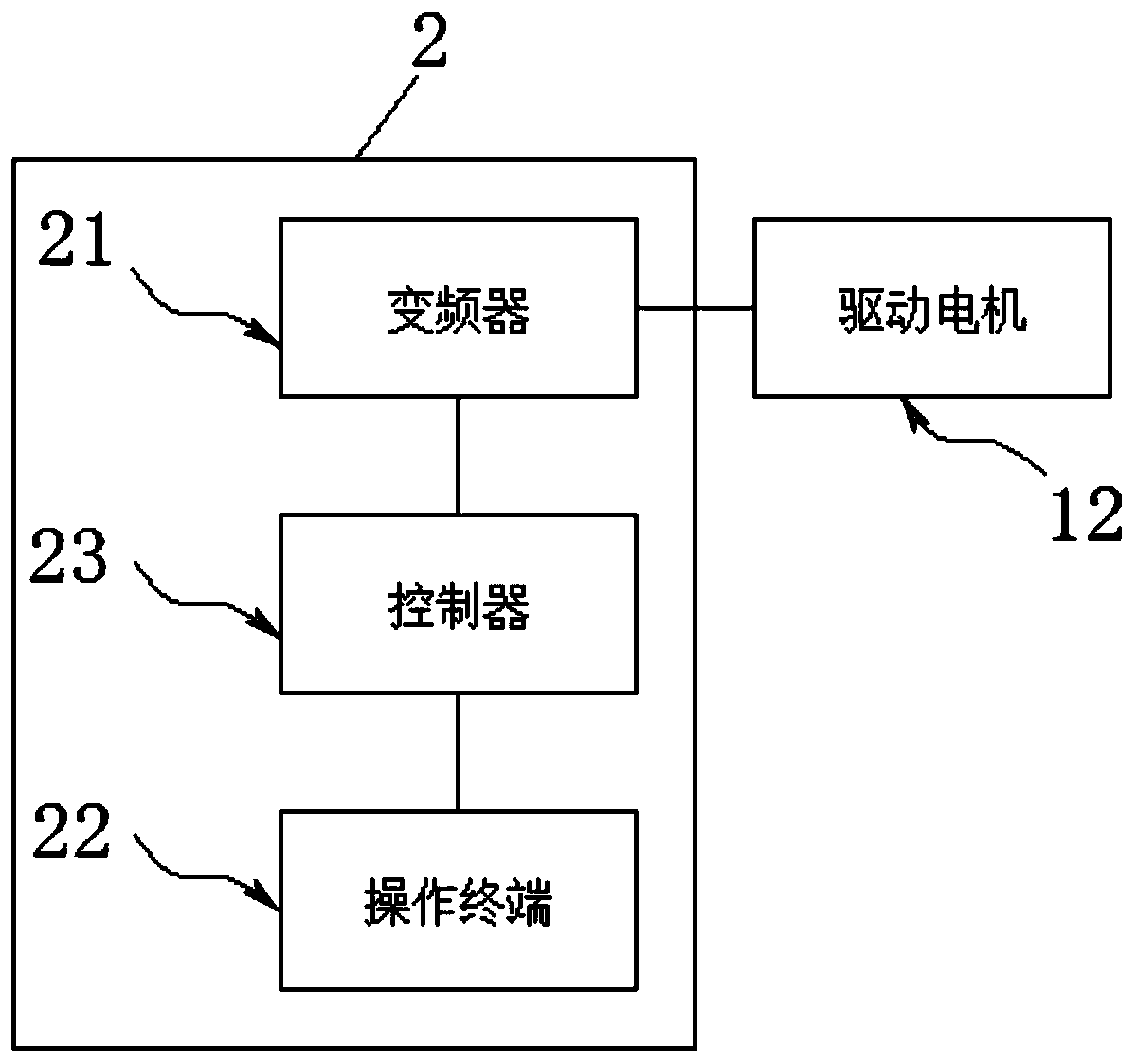

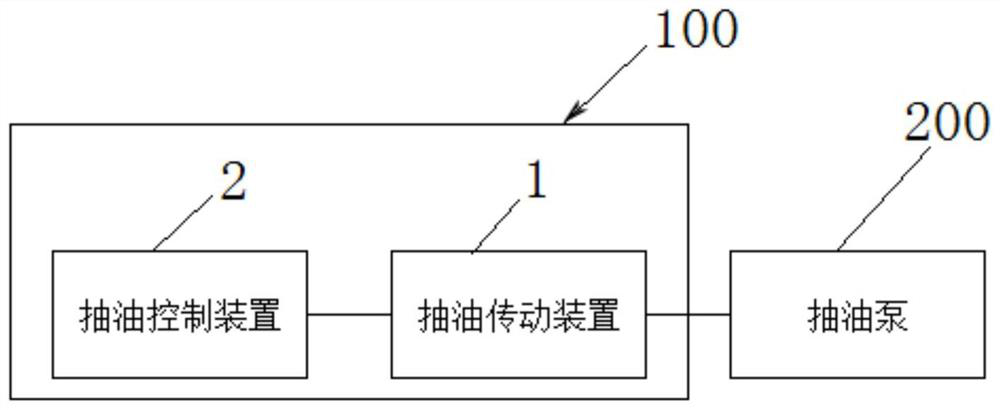

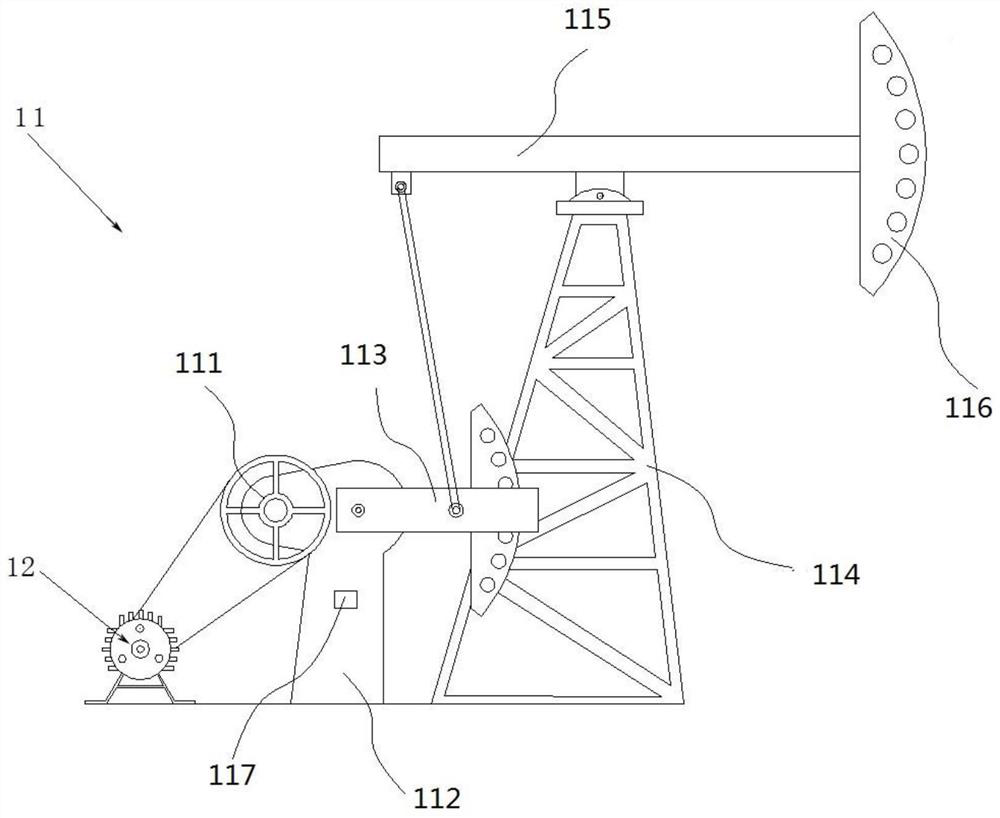

Pump efficiency adjusting intelligent oil pumping unit

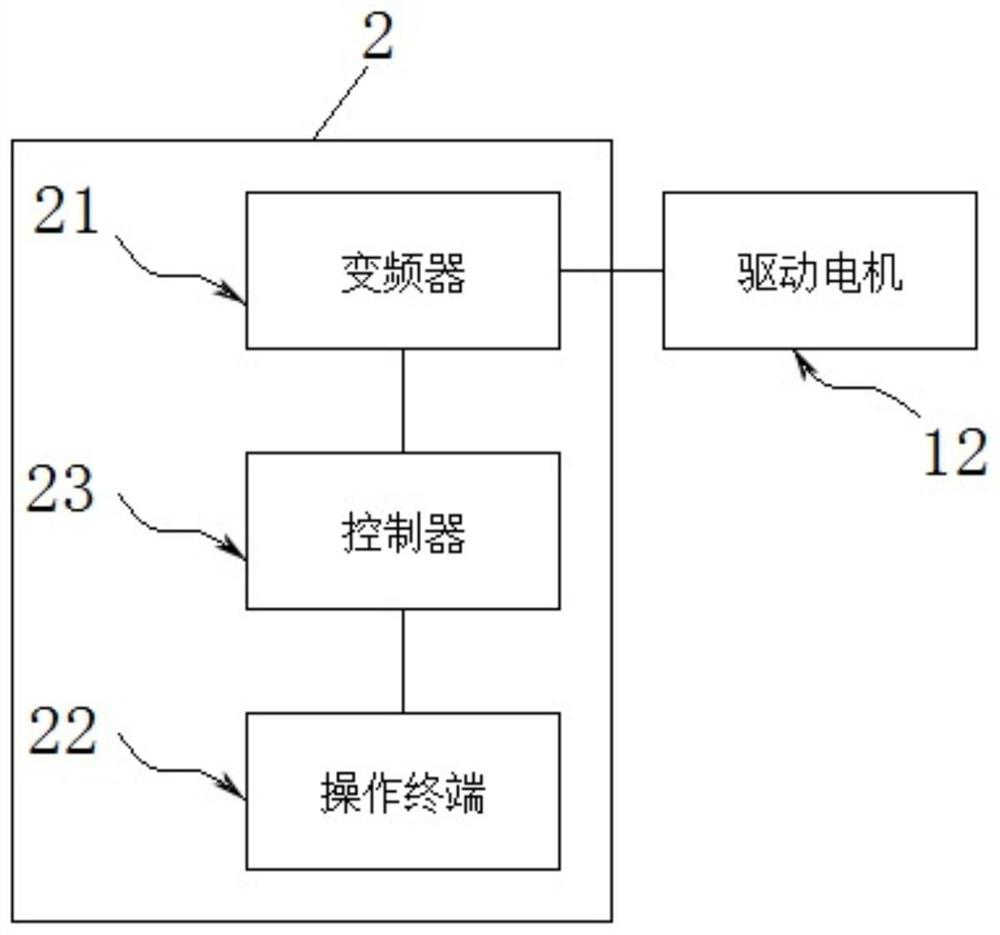

ActiveCN111472723AHigh precisionImprove management efficiencyAC motor controlConstructionsCurrent electricControl engineering

The invention provides a pump efficiency adjusting intelligent oil pumping unit. The pump efficiency adjusting intelligent oil pumping unit is arranged in an oil well and can pull an oil pump to pumpoil according to pump efficiency set by a worker; the pump efficiency adjusting intelligent oil pumping unit comprises an oil pumping action device and an oil pumping control device used for controlling the oil pumping action device to act. According to the pump efficiency input and set by the worker, a corresponding reference indicator diagram is generated; and the corresponding reference indicator diagram is compared with a current indicator diagram which is generated according to a current electric parameter, obtained by measurement, and a stored fixed electric parameter and a stored transmission parameter. According to offset between the current indicator diagram and the reference indicator diagram, a corresponding adjusting frequency is generated; and a current frequency of a drivingmotor is adjusted according to the adjusting frequency; and a current frequency of the driving motor is adjusted according to the adjusting frequency to control the oil pumping action mechanism to pull the oil pumping efficiency of the oil pump.

Owner:上海复泉工程技术有限公司

Glass tube coating device

ActiveCN104069980BRealize fully automatic workRealize large-scale automated productionLiquid surface applicatorsCoatingsGear driveMotor drive

A glass tube coating device, comprising a frame, the frame is provided with a glass placement frame, a locking mechanism, an overturning mechanism and a lifting mechanism, and the overturning mechanism includes a bracket, an overturning motor, a driving gear and a driven gear. The driving gear and the driven gear mesh with each other. The driven gear is a semicircular gear. The gear rotation further drives the driven gear to rotate, and further drives the glass placement rack to rotate. The glass tube coating mechanism with a new structure realizes the transformation from the horizontal state to the vertical state of the glass tube, and then cooperates with the vertical movement to realize the automatic feeding , Rotation, descent dipping coating, lifting, rotation, unloading fully automatic work, complete automatic control, can realize large-scale automatic production and greatly improve production efficiency.

Owner:北京天瑞星光热技术有限公司

Cutting-resistant glove processing technology

InactiveCN110644243ASimple processing technologyImprove cut resistanceWeft knittingGlovesPolyesterYarn

The invention provides a cutting-resistant glove processing technology, and relates to the field of labor protection gloves. The cutting-resistant glove processing technology includes the steps: glovecore preparation; glove core coating. Inner yarns and outer yarns are interwoven to form a glove core, polyethylene fibers with super-high relative molecule weight and bamboo-carbon modified polyester fibers wrap carbon fibers to form the outer yarns, and polyethylene fibers with super-high relative molecule weight and nylon fibers spirally wrap polyurethane filaments to form the inner yarns. A coating method of the glove core particularly includes the step: coating a composite material outside the woven glove core. The cutting-resistant glove processing technology is simple, large-scale automation production can be achieved, a processed cutting-resistant glove has excellent cutting resistance, comfortable and portable to wear and long in service life, hand flexibility is good, and replacing frequency is reduced.

Owner:徐州华通手套有限公司

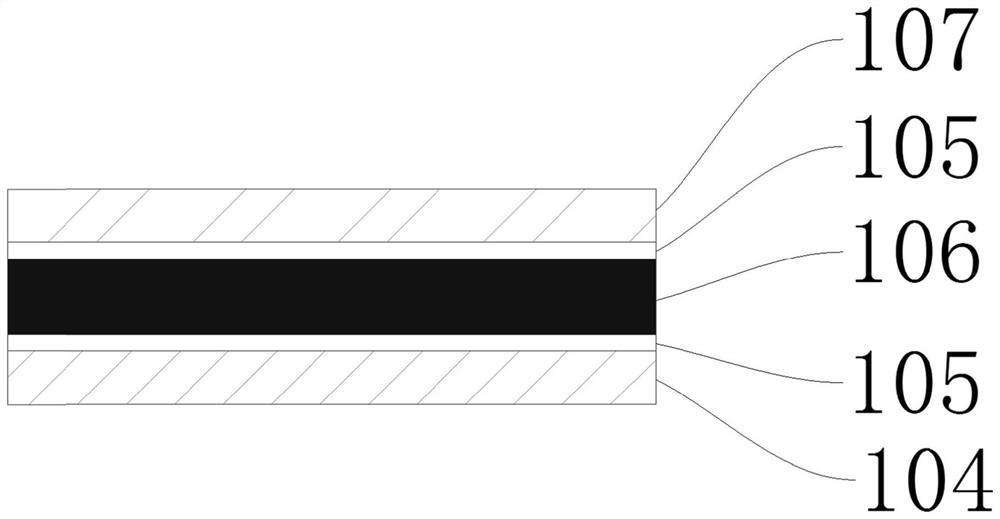

Anti-bacterial air filtering material containing graphene oxide material and applied to vehicles and preparation method of anti-bacterial air filtering material

InactiveCN108043112AImprove antibacterial propertiesSolve the antibacterial effect is not goodMembrane filtersFiltration separationEscherichia coliAir filter

The invention discloses an anti-bacterial air filtering material containing a graphene oxide material and applied to vehicles and a preparation method of the anti-bacterial air filtering material. Theanti-bacterial air filtering material comprises an oxidized coconut carbon fiber layer, a graphene oxide fiber layer and a basalt fiber layer, wherein the graphene oxide fiber layer is arranged belowthe oxidized coconut carbon fiber layer; the basalt fiber layer is arranged below the graphene oxide fiber layer; the graphene oxide fiber layer is located between the coconut carbon fiber layer andthe basalt fiber layer; after the three layer structures are composited in sequence, anti-bacterial treatment is performed in a roll baking manner, and the anti-bacterial 3D air filtering material forthe vehicles is prepared. The technology is simple, large-scale automated production can be realized, the anti-bacterial air filtering material is better in anti-bacterial effect, and anti-bacterialrate for escherichia coli, staphylococcus aureus and bacillus subtilis exceeds 99.9%; besides, a long-term effect test result indicates that the anti-bacterial effect of the anti-bacterial material cannot be reduced obviously with prolongation of use time.

Owner:IANGSU COLLEGE OF ENG & TECH

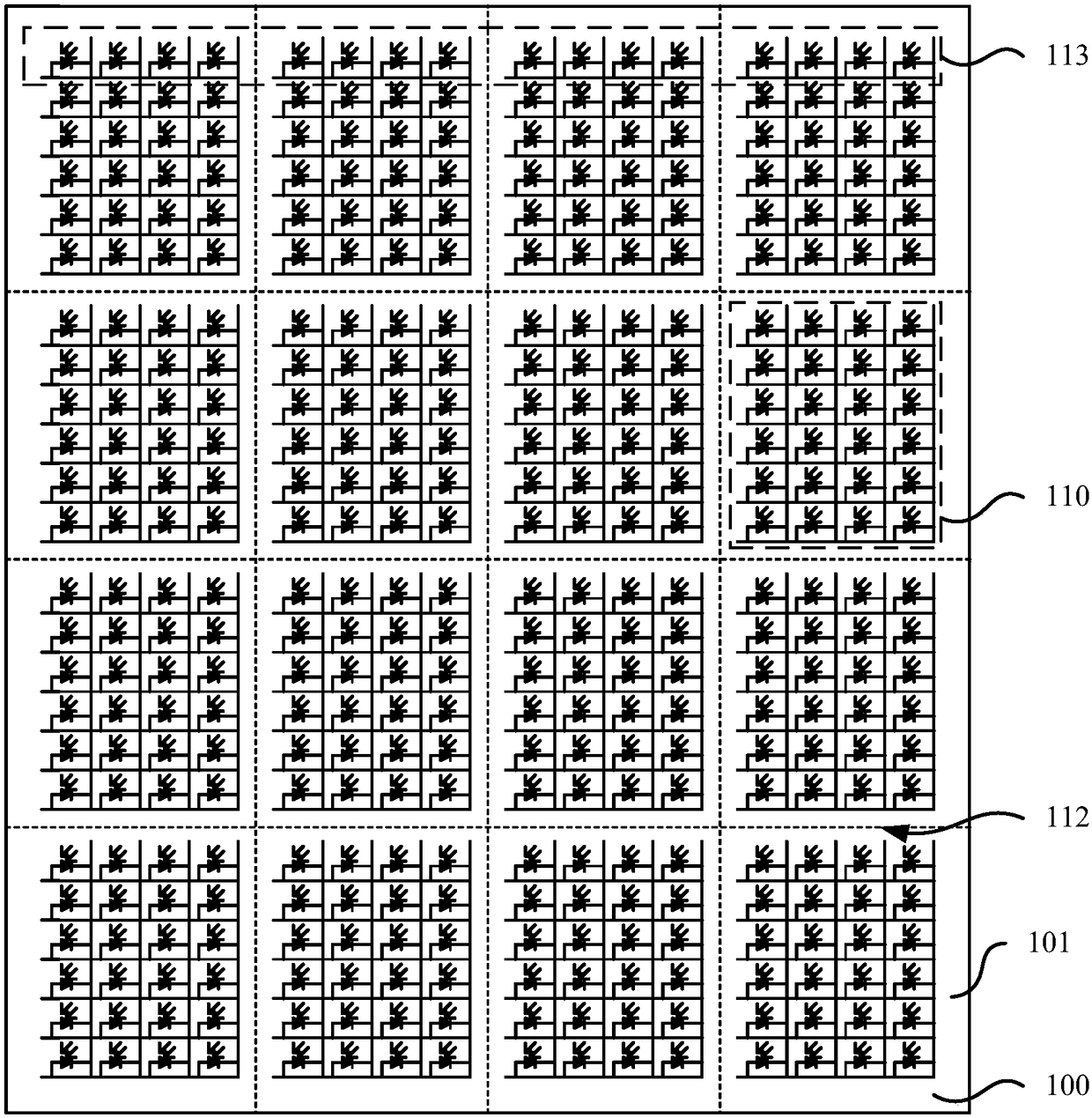

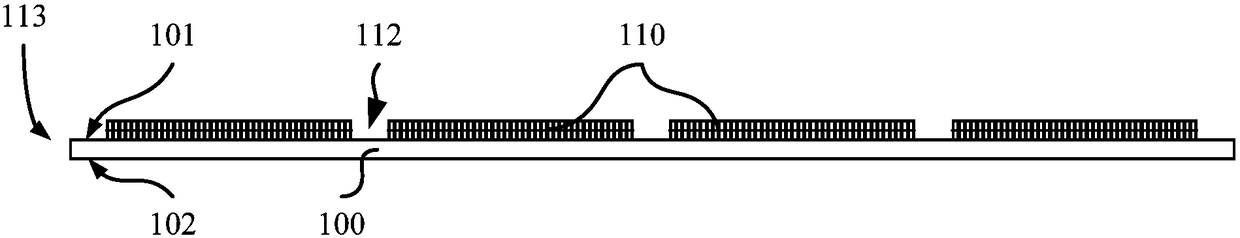

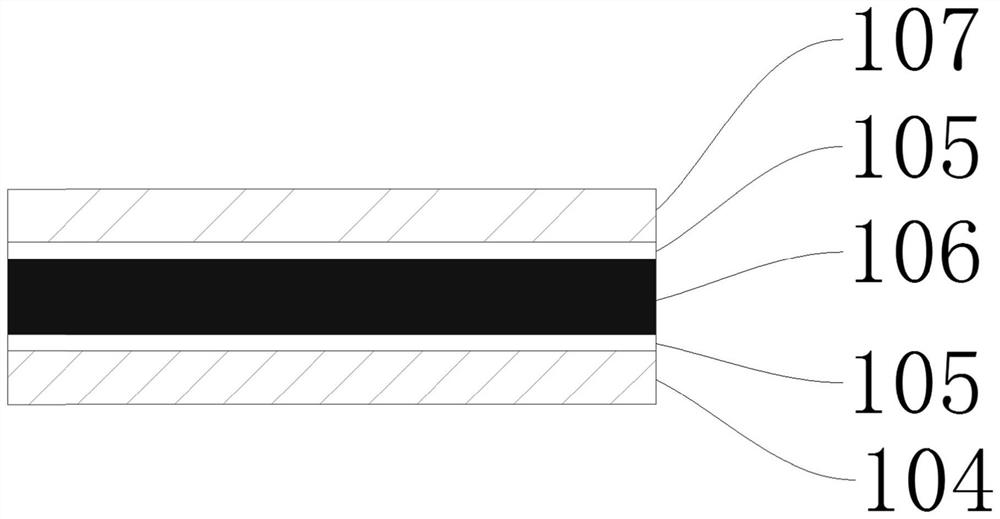

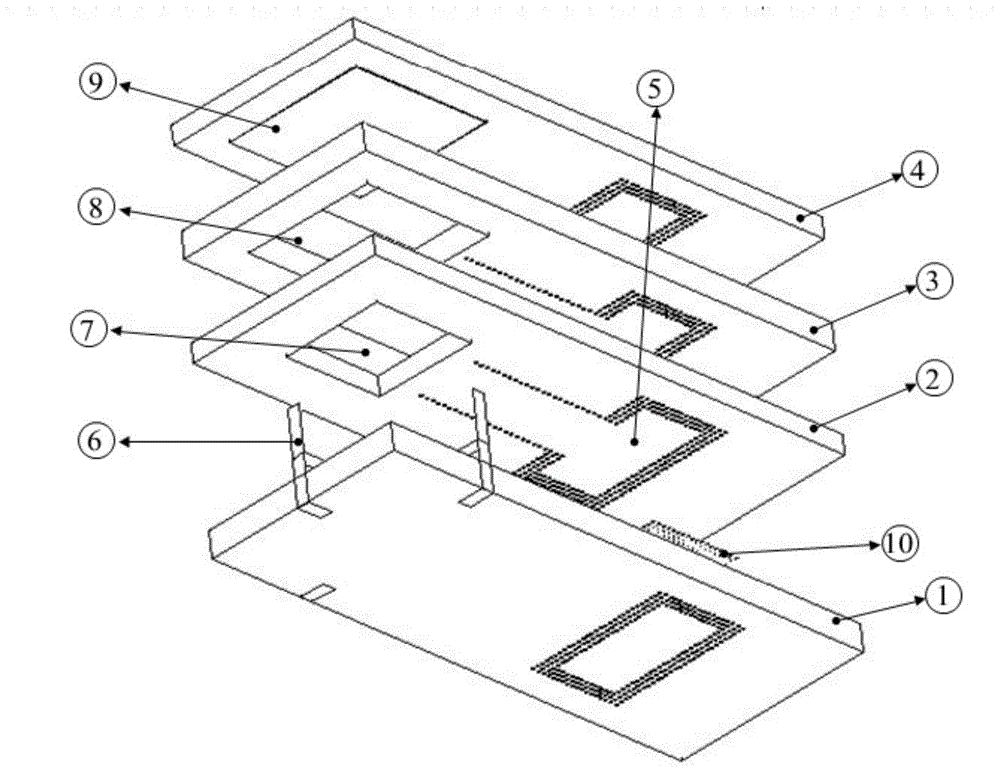

Fingerprint imaging module and formation method thereof, fingerprint imaging module motherboard, and electronic equipment

InactiveCN108630675AReduce module thicknessReduce adoptionSolid-state devicesSemiconductor/solid-state device manufacturingElectronPixel array

The invention provides a fingerprint imaging module and a formation method thereof, a fingerprint imaging module motherboard, and electronic equipment. The fingerprint imaging module comprises a substrate comprising a first surface and a second surface arranged in an opposite manner, a light-emitting stacking layer located on the second surface of the substrate and used for generating an incidentlight, a sensing surface on which a reflected light carrying fingerprint information is formed by the incident light, and a pixel array located on the first surface of the substrate and used for acquiring the reflected light to obtain fingerprint information. According to the technical scheme, the integration of a light source and an image sensor can be realized, the thickness of the fingerprint imaging module can be effectively reduced, and the integrated level of the equipment can be improved; besides, the thickness of the fingerprint imaging module is reduced, and the adoption of a module thinning process can be reduced so that the loss of the yield during formation of the fingerprint imaging module in the thinning process can be reduced, the manufacturing yield can be increased, and the cost can be lowered.

Owner:SHANGHAI OXI TECH

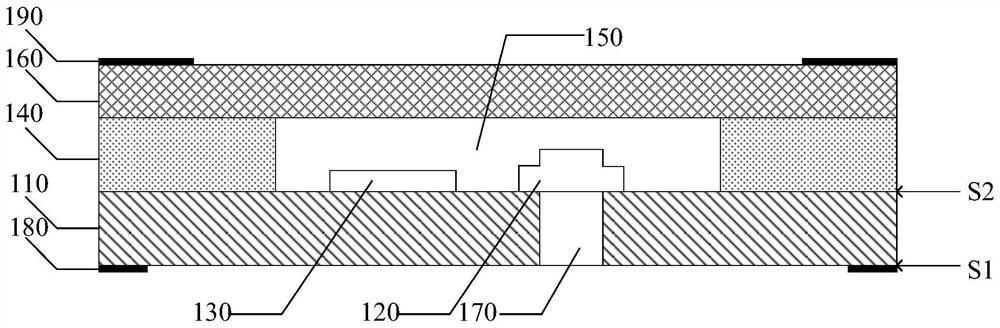

Pressure module and manufacturing method thereof

PendingCN112225169AGet goodAvoid damageTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringPressure sensing

The embodiment of the invention discloses a pressure module and a manufacturing method thereof. The pressure module comprises a circuit substrate, an MEMS chip, an ASIC chip, a first packaging circuitboard, a pouring sealant and a second packaging circuit board. According to the technical scheme provided by the invention, the MEMS chip and the ASIC chip are fused together and arranged in the cavity formed by the circuit substrate, the first packaging circuit board and the second packaging circuit board, and are filled with the pouring sealant, so that the purpose that the chip is sealed without leakage is achieved, the MEMS chip and the ASIC chip can be ensured not to be damaged and not to fall off at a bonding part under high pressure, and the overall structural compactness is improved;in addition, the MEMS chip and the ASIC chip are only used as pressure sensing elements, so that the reliability and the stability of a product are improved, the cost and the manufacturability and assembly cost of the pressure module are reduced, and large-scale automatic production is realized.

Owner:华景传感科技(无锡)有限公司

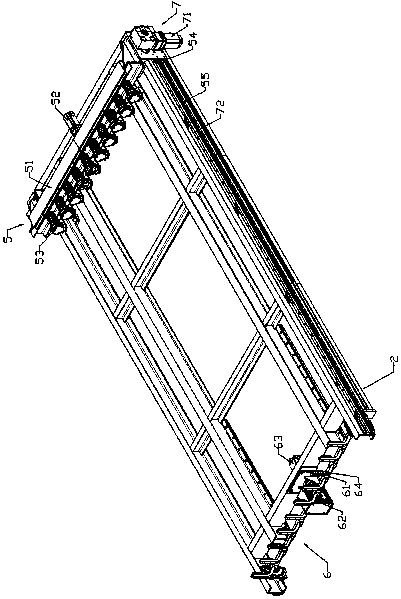

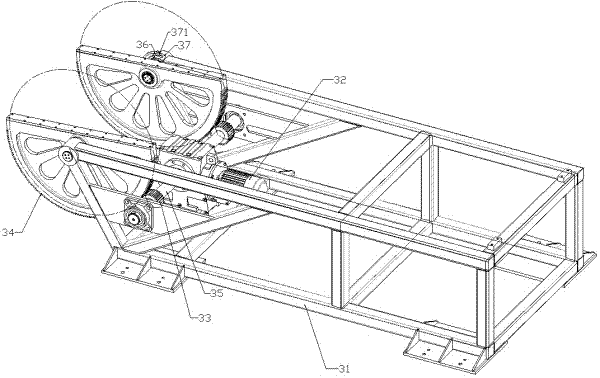

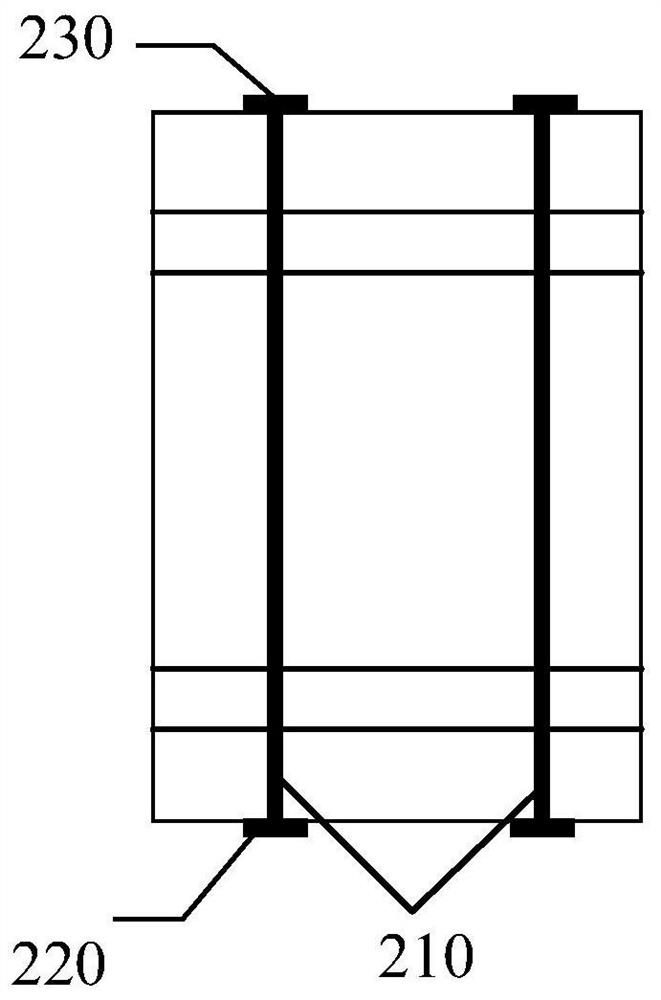

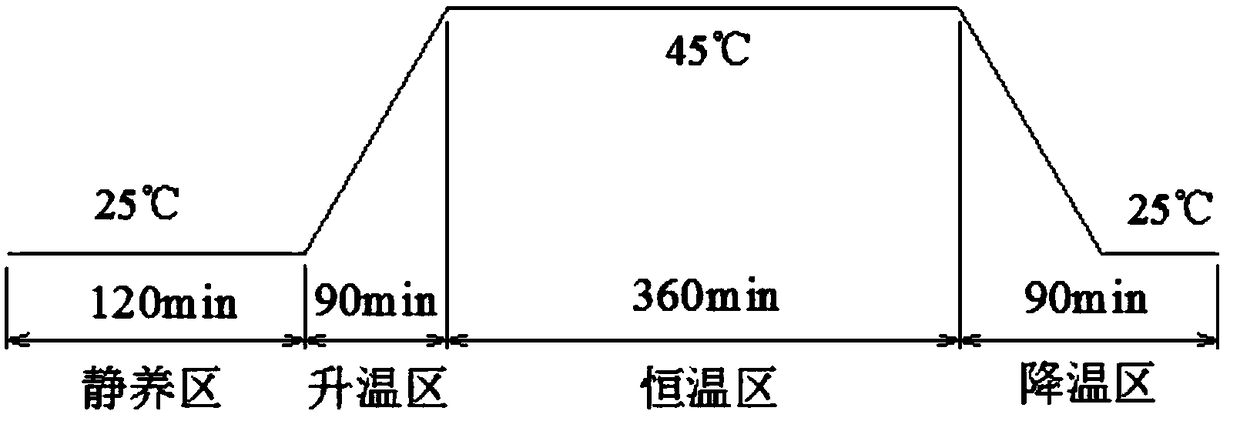

Maintenance device for rail plate production adopting unit assembly-line method, and assembly-line unit

PendingCN109366708ASimplify the transfer processSimple structureCeramic shaping plantsPulp and paper industryAssembly line

The invention discloses a maintenance device for rail plate production adopting a unit assembly-line method, and an assembly-line unit. The maintenance device comprises a maintenance channel, whereingates are formed in the two ends of the maintenance channel; a steam pipeline and a temperature sensor are arranged in the maintenance channel; a cooling component is arranged in the maintenance channel; an outlet is formed in the steam pipeline; the steam pipeline communicates with a steam generator; the steam generator is connected with a control component; and the control component is connectedwith the temperature sensor and the cooling component. By applying the maintenance device, the cooperative working of the steam generator and the temperature sensor is controlled through the controlcomponent, so that standing, heating, and constant-temperature and cooling maintenance for rail plates located in the independent maintenance channel are realized in one process; moving in each phaseis not needed, so that simultaneous maintenance for one batch of the rail plates is realized; the next batch of rail plates is placed after the maintenance is completed, so that the circulation flow of the rail plates is simplified, and the maintenance efficiency is increased; the maintenance device is applied to the efficient working of factory assembly-line production for the rail plates; and the maintenance device is simple in structure, convenient to use, and good in effect.

Owner:四川升腾元创机电技术研究有限公司 +1

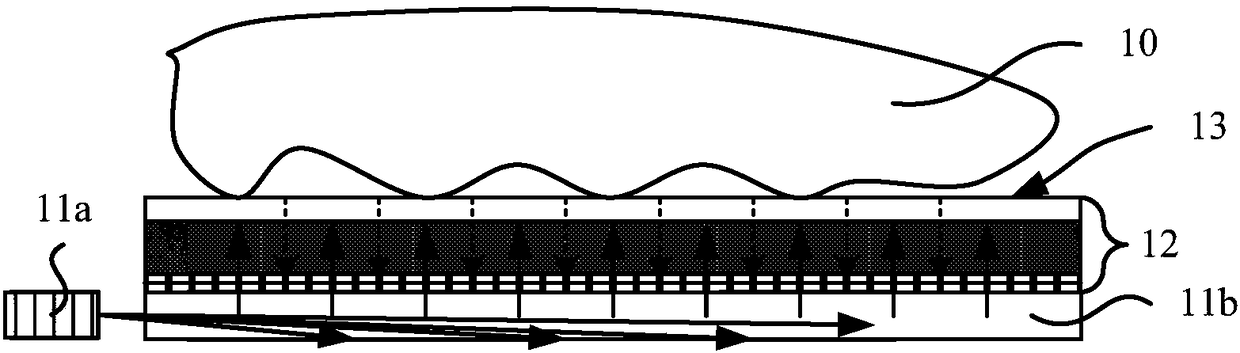

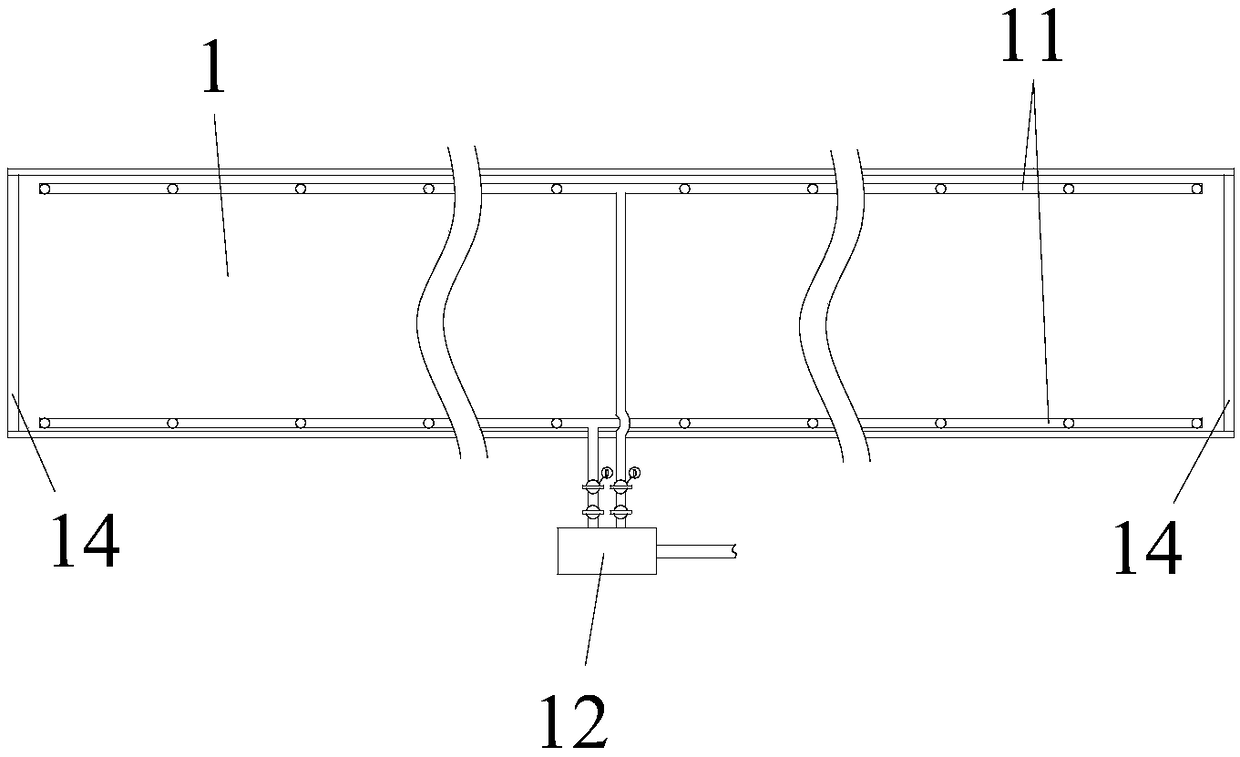

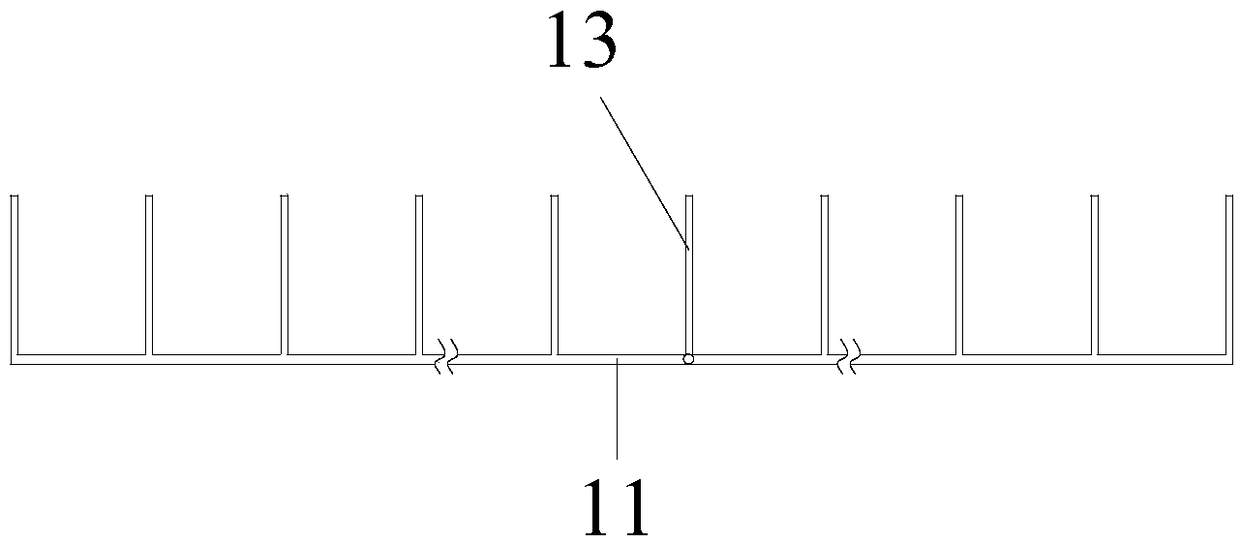

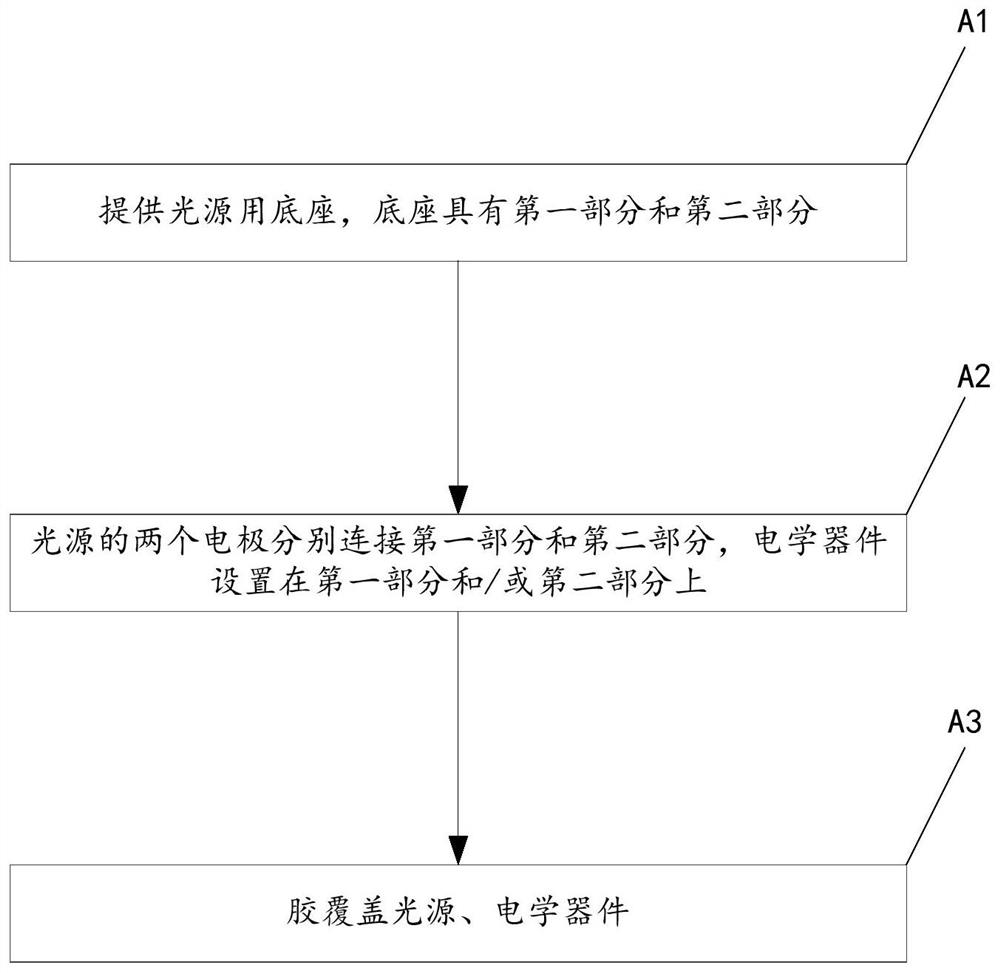

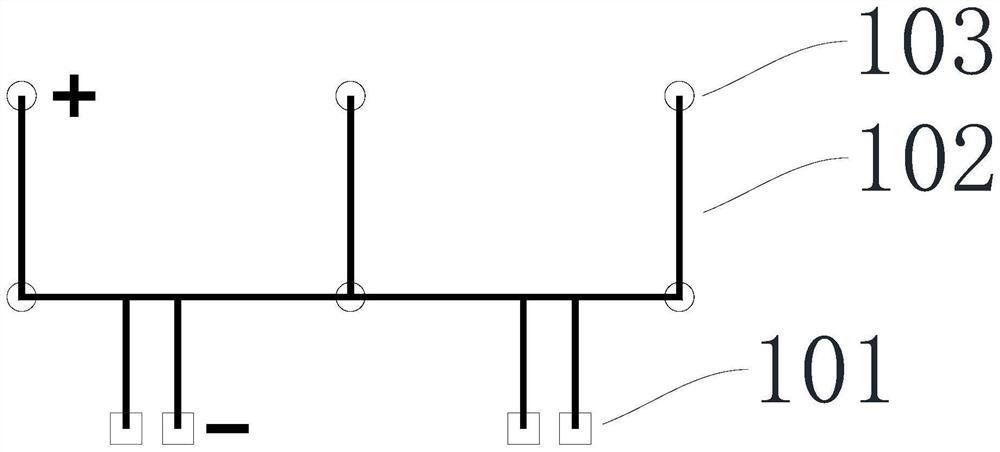

Manufacturing method of light emitting device

ActiveCN109630913BRealize large-scale automated productionRealize full automationLighting support devicesSemiconductor devices for light sourcesLight emitting deviceMaterials science

The invention provides a method for manufacturing a light-emitting device. The method for manufacturing the light-emitting device comprises the steps of: (A1) obtaining a base for a light source, wherein the base is provided with a first portion and a second portion that are isolated from each other, the first portion and the second portion are connected by an insulating plastic; (A2) electricallyconnecting a first electrode of the light source to the exposed first portion, electrically connecting a second electrode to the second portion, wherein an electrical device is disposed on the firstportion and / or the second portion, and electrically connecting an external power source connected through the first part or the second part to the light source after being rectified and controlled bythe electrical device; (A3) coating the light source, the electrical device, the first part and the second part with glue. The method has the advantages of simple structure, automation and the like.

Owner:ZHONGYANG OPTOELECTRONICS CO LTD

Production process of adblue

PendingCN114524754AReduce the generation of waste liquidRealize large-scale automated productionUrea derivatives preparationInternal combustion piston enginesChemistryUrea

The invention relates to the technical field of adblue production, in particular to an adblue production process which comprises the following steps: step 1, selecting urea raw materials, classifying the urea raw materials, and weighing the urea raw materials; 2, pretreating the raw material urea; step 3, preparing pure water; 4, urea raw materials are added into the mixer, and pure water is injected to be mixed with the urea raw materials to form a urea solution; 5, filtering and concentrating the urea solution; step 6, detecting the urea solution, and storing the urea solution for later use if the urea solution is detected to be qualified; if the detection result is unqualified, the process flows to the step 5, purification and concentration are carried out through a filtering device, and after concentration is qualified, storage and standby application are carried out. The device is energy-saving and environment-friendly, waste liquid is reduced, unqualified products can flow back to be purified and concentrated again, continuous production of the adblue is guaranteed, large-scale automatic production can be achieved, the production efficiency is greatly improved, and the production cost is reduced.

Owner:亿路洁(广州)环保股份有限公司

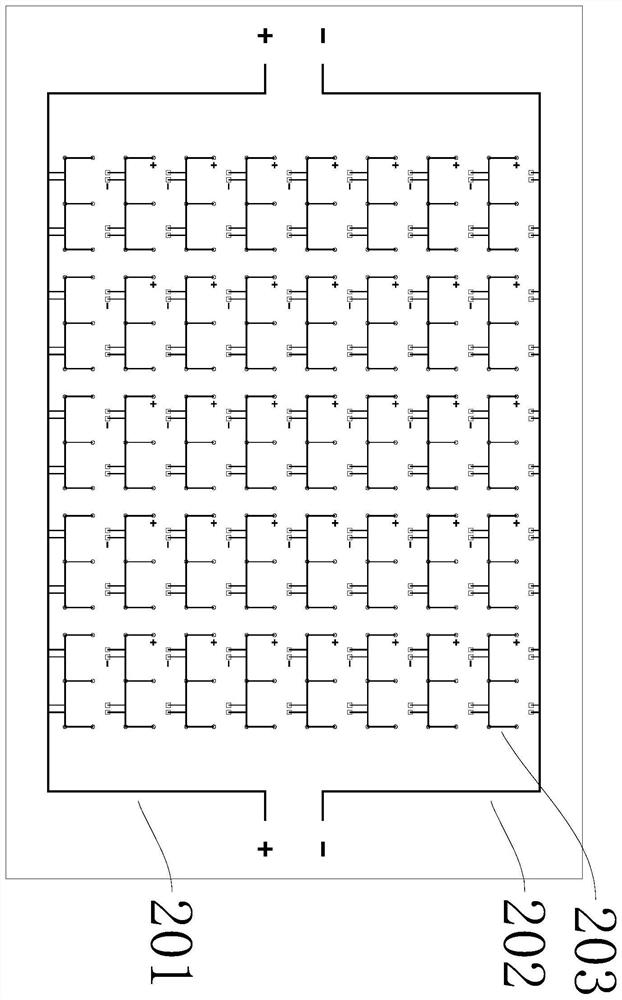

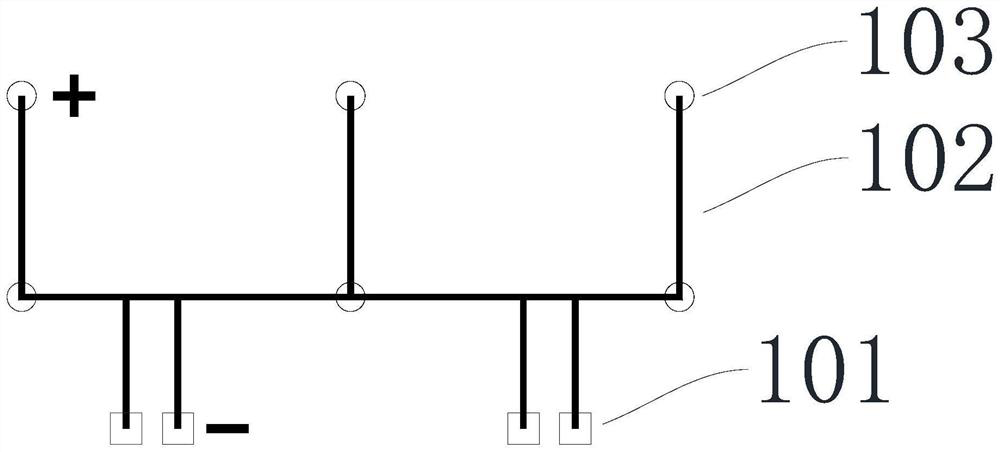

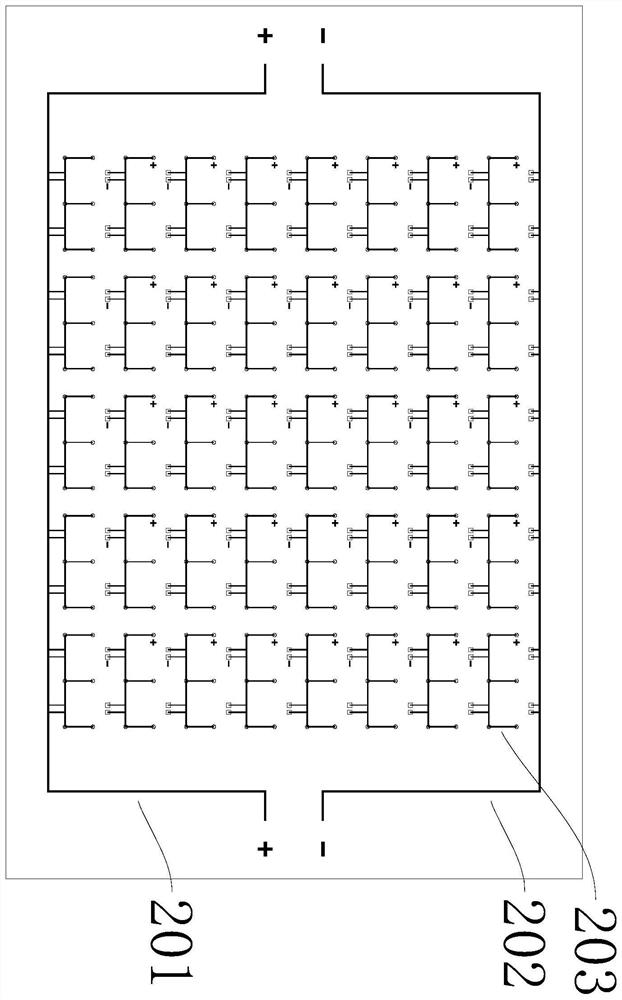

A solar array and its preparation method and application

ActiveCN114373816BRealize full flexibilitySmall size when foldedFlexible printed circuitsPhotovoltaic energy generationElectrical batteryHemt circuits

The invention discloses a solar array and a preparation method and application thereof. The solar array comprises an FPC and a plurality of flexible CIC cells arranged in sequence; the FPC comprises a bottom layer, a printed circuit layer and a top layer arranged in sequence; Several sub-circuits are arranged in the circuit-making layer; several positive pads and several negative pads are arranged on the sub-circuits; the positive pads of the sub-circuits are connected by wires and the current is led to the negative pads ; The sub-circuit and the flexible CIC battery are correspondingly arranged. The invention realizes the full flexibility of the solar cell array, so that the solar cell array has a smaller folded volume and lighter weight, the folded volume is reduced by about 80% compared with the rigid solar array, and the weight is reduced to 30%. The satellites of the same size and weight have higher power, carry more payloads, and save satellite costs and launch costs.

Owner:北京博瑞原子空间能源科技有限公司

Pump Efficiency Adjustment Intelligent Pumping Unit

ActiveCN111472723BHigh precisionImprove management efficiencyAC motor controlConstructionsElectric machineControl engineering

The invention provides an intelligent oil pumping unit with pump efficiency adjustment, which can be set at the oil well to draw the oil pump according to the pump efficiency set by the worker, and is characterized in that it includes: an oil pumping action device; and controls the action of the oil pumping action device oil pumping control device. Generate the corresponding benchmark dynamometer diagram according to the pump efficiency set by the workers, and compare it with the current dynamometer diagram generated based on the current electrical parameters obtained from the measurement and the stored fixed electrical parameters and transmission parameters. A corresponding adjustment frequency is generated according to the offset of the current dynamometer relative to the reference dynamometer, and the current frequency of the driving motor is adjusted according to the adjustment frequency to control the oil pumping efficiency of the oil pumping action mechanism for pulling the oil well pump.

Owner:上海复泉工程技术有限公司

Solar array and preparation method and application thereof

ActiveCN114373816ARealize full flexibilitySmall size when foldedFlexible printed circuitsPhotovoltaic energy generationElectrical batteryHemt circuits

The invention discloses a solar array and a preparation method and application thereof. The solar array comprises an FPC and a plurality of flexible CIC batteries which are arranged in sequence. The FPC comprises a bottom layer, a printed circuit layer and a top layer which are arranged in sequence. A plurality of sub-circuits are arranged in the printed circuit layer; a plurality of positive electrode bonding pads and a plurality of negative electrode bonding pads are arranged on the sub-circuit; the positive electrode pads of the sub-circuits are connected through a wire and then current is led out to the negative electrode pad. And the sub-circuit and the flexible CIC battery are correspondingly arranged. According to the invention, the full flexibility of the solar cell array is realized, so that the solar cell array has smaller folding volume and lighter weight, and the folding volume is reduced by about 80% compared with a rigid solar array; and the weight is reduced to 30%. And the satellites with the same volume and weight have higher power and carry more effective loads, so that the cost of the satellites and the launching cost are saved.

Owner:北京博瑞原子空间能源科技有限公司

A packaging structure integrating vco and waveguide antenna

InactiveCN104051434BSmall sizeSimplify and reduce difficultySemiconductor/solid-state device detailsSolid-state devicesMicrowaveCoupling

The invention discloses a packaging structure for integrating a VCO and a waveguide antenna. The packaging structure comprises an LTCC packaging body composed of a bottom dielectric substrate layer, a plurality of middle dielectric substrate layers and a top dielectric substrate layer. A VCO chip is packaged at one end of the LTCC packaging body, and a waveguide reflection cavity and a micro-strip coupling probe are packaged at the other end of the LTCC packaging body. Through the combination of the micro-strip waveguide conversion technology and the chip packaging technology, the E wave-band VCO and the micro-strip waveguide conversion antenna are integrated inside a standard LTCC packaging chip, the size for application and assembly of a microwave circuit is reduced, the miniaturization design of products is facilitated, and most importantly, the influence on the circuit by spurious and distribution parameters in the circuit connection process is effectively reduced. The performance of the packaging structure similar to that of a packaging mode through metal ceramic is obtained by the adoption of the LTCC packaging technology, the working frequency relative bandwidth is larger than 20 percent, and insertion losses caused by micro-strip waveguide conversion are smaller than 1.2 dB within the working band.

Owner:XIDIAN UNIV

A system for automatic control of lithium washing process using conductivity meter

ActiveCN108983728BHigh degree of automationReduce lossesProgramme total factory controlThermodynamicsAutomatic control

The invention provides a system for realizing the automatic control of the lithium washing process by using a conductivity meter, including a conductivity meter, the conductivity meter is installed on the outlet pipeline of the lithium ion adsorption tower, and is used to detect the lithium ion adsorption tower The conductivity of the lithium eluate in the medium. The invention adopts the automatic detection of the conductivity meter, improves the accuracy of detection and production efficiency, overcomes the trouble of each step of assay analysis and waste of time, and reduces the loss of lithium ions; adopts the decentralized control system DCS, according to the conductivity meter The displayed data remotely controls the opening / closing of the valve during the lithium washing process, improves the automation of the lithium washing process, and realizes large-scale automated production; the system can run stably for a long time, has a high level of automation, simple operation, strong safety, and economic benefits.

Owner:QINGHAI SALT LAKE IND +1

Printing and dyeing sewage filter material containing mesoporous material and preparation method of printing and dyeing sewage filter material

InactiveCN108609685ASimple processLow cost of preparationWater/sewage treatment by irradiationWater contaminantsIonMolecular sieve

The invention discloses a printing and dyeing sewage filter material containing a mesoporous material and a preparation method of the printing and dyeing sewage filter material. The filter material ischaracterized by comprising binchotan fibers, bamboo carbon fibers and a basalt base material part, and through loading the three filter components with a mesoporous molecular sieve, the specific surface area of a filter tip and a micro pore channel are increased. The filter material prepared by the preparation method disclosed by the invention is used for wastewater treatment of a textile printing and dyeing enterprise and has the advantages of being high in decolorizing rate, high in dye and metal ion adsorbability, free from environmental secondary pollution, green, environmentally-friendly and the like; and the preparation method is simple in process and has a good application prospect.

Owner:IANGSU COLLEGE OF ENG & TECH

A kind of composite damping foam rubber material and preparation method thereof

ActiveCN106543500BImprove sound absorption performanceOptimizing the Ratio of Raw RubberRubber materialPolymer science

The invention provides a compound damping foam rubber material. The material is prepared from rubber, reinforcing filling and addition agents, wherein the addition agents comprise a vulcanizing agent, a dispersant, an anti-scorching agent, an anti-ageing agent, an accelerant, a secondary accelerant and a softening agent; the rubber is selected from at least two of silicone rubber, nitrile butadiene rubber, butadiene rubber, isoprene rubber and ethylene propylene rubber; and the addition agents also comprise a foaming agent. The compound damping foam rubber material provided by the invention has the advantages of light weight, cost reduction, good transformer oil resisting performance, good electric insulating performance and the like; a pore structure generated by foaming and the rubber material have a viscoelastic damping synergistic effect to enhance sound energy dissipation and improve noise-reduction performance of the compound damping foam rubber material; and the compound damping foam rubber material can be used as a sound-absorption and noise-reduction material to be applied to vibration absorption and noise reduction of a transformer body, and has remarkable economic and social benefits.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com